Press release

Polylactic Acid Production Plant DPR & Unit Setup Cost 2026: Machinery Requirement, CapEx/OpEx & Raw Materials

Polylactic acid (PLA) is a biodegradable thermoplastic polymer derived from renewable agricultural resources including corn starch, sugarcane, and cassava. The production process begins with sugar fermentation, which converts the sugar into lactic acid, followed by polymerization to produce PLA resin. The material demonstrates outstanding clarity, rigidity, and processing capabilities, and can be composted in industrial composting facilities.PLA exhibits lower toxicity levels combined with superior tensile strength and beneficial thermal characteristics when compared to most conventional plastics. The renewable nature of PLA, together with its lower carbon emissions, makes it a sustainable alternative for packaging, disposable consumer products, fibers, films, and biomedical applications-replacing petroleum-based polymers. With the growing demand for bio-based and compostable polymers in sustainable packaging, increasing substitution of conventional plastics, and rising adoption of eco-friendly materials across food service and medical applications, PLA production represents one of the most compelling investment opportunities in the green materials sector.

IMARC Group's report, "Polylactic Acid Production Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a plant. The polylactic acid production plant setup report offers insights into the process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Market Overview and Growth Potential

The global polylactic acid market has demonstrated exceptional growth and continues to offer outstanding expansion potential. According to IMARC Group, the global PLA market was valued at USD 1,298.00 Million in 2025 and is projected to reach USD 4,201.09 Million by 2034, exhibiting a compound annual growth rate (CAGR) of 13.9% during 2026-2034-making it one of the fastest-growing segments in the global bioplastics industry.

Key market drivers include escalating environmental concerns and the accelerating shift toward bio-based and compostable materials. Increasing regulatory pressure on single-use plastics and rising consumer preference for sustainable alternatives are significantly strengthening PLA demand, particularly in packaging and food service applications. Technological advancements in fermentation efficiency, catalyst systems, and polymer processing have improved PLA performance, enabling its use in a broader range of applications including durable consumer goods and medical devices. Strategic collaborations and capacity expansions are further accelerating adoption. For example, in May 2025, Belgium-based Futerro S.A. partnered with its sister company Galactic S.A. to develop a new production facility in Port-Jérôme-sur-Seine, France, to convert lactic acid into polylactic acid derivatives and other bio-based molecules for agri-food and green chemistry markets.

Grab a sample PDF of this report: https://www.imarcgroup.com/polylactic-acid-manufacturing-plant-project-report/requestsample

Plant Capacity and Production Scale

The proposed polylactic acid production facility is designed with an annual production capacity ranging between 50,000-200,000 MT, enabling economies of scale while maintaining operational flexibility. This scalable design allows manufacturers to serve diverse market segments-including packaging, consumer goods, textiles, and medical and biomedical applications-while adjusting production volumes in response to evolving market demand and regional sustainability mandates. The typical timeline for plant establishment ranges from 18 to 24 months, depending on project size, location readiness, equipment procurement, and permit approvals.

Financial Viability and Profitability Analysis

The polylactic acid production project demonstrates healthy profitability potential under normal operating conditions. The plant's financial performance is supported by stable demand for sustainable materials and diversified value-added applications:

• Gross Profit Margins: 30-40%, supported by growing sustainability-driven demand and premium pricing for bio-based polymers

• Net Profit Margins: 15-25%, reflecting efficient process management and strong market positioning in the green materials sector

Profit margins typically improve with capacity expansion and increased utilization rates. The break-even period for a PLA production plant typically ranges from 3 to 5 years, depending on capital expenditure, operating costs, production scale, and market demand. Efficient operations and long-term supply contracts can further accelerate profitability.

Operating Cost Structure

The operating cost structure of a polylactic acid production plant is primarily driven by raw material consumption. Key cost components include:

• Raw Materials (lactic acid, catalysts, and purification solvents): 60-70% of total OpEx

• Utilities (electricity, water, steam): 20-25% of total OpEx

The primary raw material is lactic acid, derived from renewable resources like corn starch or sugarcane, along with catalysts for polymerization and solvents depending on the specific production process. Effective cost management strategies include securing long-term contracts with reliable suppliers to stabilize pricing, conducting sustainability and supply chain risk assessments, and minimizing transportation costs through strategic supplier proximity. The relatively significant utility cost component reflects the energy-intensive nature of fermentation, purification, polymerization, and drying processes.

Speak to an Analyst: https://www.imarcgroup.com/request?type=report&id=8631&flag=C

Capital Investment Requirements

Establishing a polylactic acid production plant involves significant capital expenditure components. Machinery costs account for the largest portion of total CapEx, followed by land and site development, civil works, and other capital costs. The key equipment requirements include:

• Fermenters for lactic acid production from renewable feedstocks

• Separation and purification units for lactic acid concentration and refinement

• Polymerization reactors for converting lactic acid into PLA polymer

• Extruders for shaping PLA into pellets, films, or fibers

• Pelletizers for producing uniform PLA resin granules

• Drying systems for moisture removal and product stabilization

• Saccharification equipment for raw material preprocessing

• Quality control instruments for monitoring polymer properties and consistency

Additional capital investments cover land acquisition, site preparation, infrastructure development, advanced environmental monitoring and effluent treatment systems, and utility infrastructure including electricity, water supply, and steam generation. The capital-intensive and technology-focused nature of PLA production serves as a meaningful barrier to entry, protecting established manufacturers with proven product quality and polymer purity standards.

Major Applications and Market Segments

Polylactic acid serves diverse end-use industries with high-value sustainable applications:

• Packaging: Food containers, cups, trays, films, and compostable packaging solutions

• Consumer Goods: Disposable cutlery, household items, stationery, and personal care packaging

• Textiles: Nonwoven fabrics, fibers, and eco-friendly apparel components

• Medical and Biomedical: Sutures, implants, drug delivery systems, and tissue engineering scaffolds

• Specialty Applications: 3D printing filaments, agricultural films, and industrial composites

Why Invest in Polylactic Acid Production?

Polylactic acid production presents multiple strategic advantages for investors and sustainability-focused entrepreneurs:

• Strong Sustainability Advantage: PLA is the preferred material amid plastic bags and increasing environmental regulations, producing lower greenhouse gas emissions and decreasing fossil fuel dependence while supporting global sustainability objectives.

• Rising Entry Barriers with Technology Focus: The fermentation-based polymer production process requires significant capital and specialized knowledge, while established standards of product quality, polymer purity, and downstream processing capabilities provide strong market protection.

• Megatrend Alignment: Sustainable packaging, biodegradable plastics, circular economy initiatives, and growing consumer interest in eco-friendly products are driving increased PLA demand across international markets.

• Policy and Regulatory Support: Government programs promoting bio-based materials, compostable plastics, single-use plastic alternatives, and green manufacturing incentives have created strong global demand for PLA materials.

• Supply Chain Localization Opportunity: Brand owners and packaging companies increasingly prefer localized PLA sourcing to ensure supply security, reduce logistics emissions, and manage cost volatility in bio-feedstocks.

Industry Leadership

The global polylactic acid industry features several leading producers with extensive production capacities and diverse application portfolios.

• NatureWorks LLC

• TotalEnergies Corbion bv

• JIANGSU SUPLA BIOPLASTICS CO., LTD.

• COFCO

• Futerro

• Jiangxi Keyuan Biopharm Co.,Ltd.

These companies serve end-use sectors spanning packaging, medical and healthcare, consumer goods, textiles, and specialty applications across global markets.

Buy Now: https://www.imarcgroup.com/checkout?id=8631&method=2175

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polylactic Acid Production Plant DPR & Unit Setup Cost 2026: Machinery Requirement, CapEx/OpEx & Raw Materials here

News-ID: 4393712 • Views: …

More Releases from IMARC Group

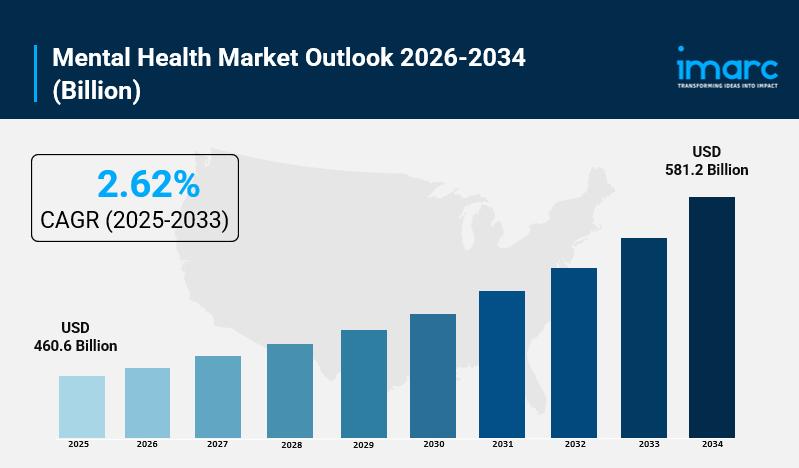

Mental Health Market Size, Share, Industry Trends, Growth Factors and Forecast 2 …

IMARC Group, a leading market research company, has recently released a report titled "Mental Health Market Size, Share, Trends, and Forecast by Disorder, Service, Age Group, and Region 2026-2034." The study provides a detailed analysis of the industry, including the global mental health market size, trends, share and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Mental Health Market Highlights:

• Mental Health…

Vermicompost Manufacturing Plant Cost, DPR 2026: Demand Analysis, CapEx/OpEx & R …

The global vermicompost industry is witnessing robust growth driven by increasing adoption in organic farming, rising demand for sustainable soil amendments, and expanding use in horticulture and landscaping applications. At the heart of this expansion lies a critical agricultural input-vermicompost. As industries transition toward organic and regenerative agricultural practices, establishing a vermicompost manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and agri-business investors seeking to capitalize on this…

Alcoholic Beverage Manufacturing Plant Cost 2026: CapEx/OpEx Analysis with Profi …

The global alcoholic beverage manufacturing industry represents a sophisticated and highly regulated sector producing diverse liquid consumables through controlled fermentation and distillation processes. Alcoholic beverages are consumable liquids that result from the fermentation and distillation of agricultural products including grains, fruits, sugarcane, and molasses. These beverages contain ethanol as their main alcoholic substance and are divided into four categories: beer, wine, spirits, and flavored or ready-to-drink alcoholic products. The manufacturing…

API Manufacturing Plant Cost DPR 2026: Capex, Opex & Compliance Requirements

Active Pharmaceutical Ingredients (APIs) are bioactive molecules that serve as the active constituent of any pharmaceutical formulation, producing the desired therapeutic effect upon administration. APIs are prepared through complex processes of chemical synthesis, fermentation, and biotechnology under highly stringent regulatory and quality guidelines. They must comply with specific attributes pertaining to quality, strength, stability, and safety as per pharmacopoeia standards such as USP, EP, and IP. APIs represent the active…

More Releases for PLA

How Compostable PLA Straws Help the Environment

Compostable PLA straw [https://www.naturecutlery.com/qh-st-5-5-x-200-mm-biodegradable-pla-drinking-straw-in-bulk-package-2-product/]s are emerging as one of the key solutions to the global plastic crisis. Made from renewable materials like corn starch, these straws are an eco-friendly alternative to traditional plastic straws. Here's a closer look at how compostable PLA straws can have a positive impact on the environment and why they're a smart choice for businesses focused on sustainability.

1. Reduce Plastic Waste Accumulation

Traditional plastic straws are single-use…

Polylactic Acid (PLA) Market Growth Opportunities and Competitive Landscape Repo …

Polylactic acid (PLA) is a biodegradable thermoplastic polymer made from renewable resources such as corn starch or sugar cane. Unlike other thermoplastics, PLA can be degraded by microorganisms over time, making it an attractive material for sustainable and biodegradable products.

Key Trends

One of the major trends in PLA technology is the development of new and improved methods for PLA production. For example, catalysis of the conversion of lactic acid to PLA…

Polylactic Acid (PLA) Market Insights by 2031 & Covid-19 Analysis | Total Corbio …

Global Polylactic Acid (PLA) Market report from Global Insight Services is the single authoritative source of intelligence on Polylactic Acid (PLA) Market. The report will provide you with analysis of impact of latest market disruptions such as Russia-Ukraine war and Covid-19 on the market. Report provides qualitative analysis of the market using various frameworks such as Porters' and PESTLE analysis. Report includes in-depth segmentation and market size data by categories,…

Bio-polylactic Acid (PLA) Films Market Size, Status and Global Outlook During 20 …

MarketInsightsReports has published a report titled global Bio-polylactic Acid (PLA) Films Market research report 2020 that is a detailed observation of several aspects, including the rate of growth, technological advances, and different methodologies implemented by the primary current market players. The report is based on a collective analysis of data, which is obtained through primary and secondary research. It provides a systematic approach to the current and prospective scenario of…

Polylactic Acid (PLA) Market May See Exponential Growth in Future | BASF SE; Dan …

This Polylactic Acid (PLA) Market research report involves six major parameters namely market analysis, market definition, market segmentation, key developments in the market, competitive analysis, and research methodology. Competitive analysis is the major aspect of any market research report and by understanding this many points are covered in the report including strategic profiling of key players in the market, analyse their core competencies, and draw a competitive landscape for the…

Growth of Bio-polylactic Acid (PLA) Films Market | Top Vendors- NatureWorks, Fut …

Global Bio-PLA Films Market was valued at $354 million in 2016, and is anticipated to reach $910 million by 2023, growing at a CAGR of 14.5% from 2017 to 2023.

The key players profiled in the report are NatureWorks LLC, Futerro, Tale & Lyle, Total Corbion PLA, Hiusan Biosciences, Toray Industries, Inc., Taghleef Industries, Amcor Ltd. Toyobo, and Avery Dennison Corporation.

The other major players (not profiled in report) in the…