Press release

Vermicompost Manufacturing Plant Cost, DPR 2026: Demand Analysis, CapEx/OpEx & ROI Insights

The global vermicompost industry is witnessing robust growth driven by increasing adoption in organic farming, rising demand for sustainable soil amendments, and expanding use in horticulture and landscaping applications. At the heart of this expansion lies a critical agricultural input-vermicompost. As industries transition toward organic and regenerative agricultural practices, establishing a vermicompost manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and agri-business investors seeking to capitalize on this growing and essential market.IMARC Group's report, "Vermicompost Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The vermicompost manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for Sample Report: https://www.imarcgroup.com/vermicompost-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global vermicompost market demonstrates strong growth trajectory, valued at USD 95.72 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 263.31 Billion by 2034, exhibiting a robust CAGR of 11.9% from 2026-2034. This sustained expansion is driven by increasing consumption in pulp and paper bleaching, rising demand for eco-friendly oxidation agents in chemical processing, expanding healthcare and sanitation applications, and growing adoption of chlorine-free bleaching technologies across developing economies.

Vermicompost is an organic fertilizer produced through the decomposition of organic matter by earthworms, particularly species such as Eisenia fetida. It is a nutrient-rich, natural soil amendment that improves soil structure, water retention, and microbial activity. The vermicomposting process converts organic waste-such as cattle dung, agricultural residues, and food waste-into a high-value soil conditioner. Vermicompost is regarded as an environmentally friendly alternative to chemical fertilizers, promoting plant growth and soil health. It is available in various forms including loose compost, pelletized compost, and liquid extract (vermicompost tea), catering to diverse agricultural, horticultural, and landscaping applications.

The vermicompost market is primarily influenced by the rising demand for organic food production and the global shift toward sustainable agriculture. The organic farming sector continues to be the largest consumer of vermicompost as farmers move away from synthetic fertilizers. Horticulture and landscaping are also contributing significantly to this growth, as vermicompost is widely used to enhance soil quality and plant vitality. Additionally, growing awareness of food safety, soil degradation, and environmental pollution is driving adoption across emerging markets. Government initiatives supporting organic farming and organic certification programs are further accelerating market expansion globally.

Plant Capacity and Production Scale

The proposed vermicompost manufacturing facility is designed with an annual production capacity of 2,000 Metric Tons per year, enabling economies of scale while maintaining operational flexibility.

Financial Viability and Profitability Analysis

The vermicompost manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 50-65%

• Net Profit Margins: 25-40%

These margins are supported by stable demand across agricultural sectors, value-added organic product positioning, and the critical nature of vermicompost in soil health and organic farming applications. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established agri-business operators looking to diversify their product portfolio in the organic inputs sector.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a vermicompost manufacturing plant is primarily driven by:

• Raw Materials: 20-30% of total OpEx

• Utilities: 5% of OpEx

Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute a significant portion of operating costs, with cattle dung being the primary input material along with agricultural waste, food scraps, and bedding materials for earthworms. Establishing long-term contracts with reliable waste suppliers and livestock farms helps mitigate supply variability and ensures consistent raw material availability, which is critical given that organic waste feedstock availability represents the most significant input factor in vermicompost production.

Capital Investment Requirements

Setting up a vermicompost manufacturing plant requires capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to hydrogen, oxygen, and chemical suppliers. Proximity to target markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized production equipment essential for manufacturing. Key machinery includes:

• Specialized reactors for chemical synthesis under controlled conditions

• Hydrogenation units for hydrogen processing and reaction

• Oxidation columns for conversion processes

• Extractors for product separation and purification

• Distillation systems for concentration and refining

• Storage tanks for raw materials and finished product

• Safety control systems for monitoring and emergency response

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the production process. The layout should be optimized with separate areas for raw material storage, reaction zone, extraction unit, distillation section, quality control laboratory, finished goods warehouse, utility block, and administrative block.

Other Capital Costs: Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Buy Now: https://www.imarcgroup.com/checkout?id=22795&method=2175

Major Applications and Market Segments

Hydrogen peroxide products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Pulp and Paper: Used as a chlorine-free bleaching agent that can improve the quality and brightness of the fibers while having a lesser impact on the environment.

Chemical Processing: Serves as a non-polluting oxidizing agent in the manufacture of organic and inorganic chemicals, specialty chemicals, and their precursors.

Healthcare and Sanitation: Used for cleaning wounds, disinfecting surfaces, and sterilization due to its antimicrobial effects and decomposition that leaves no residue.

Textiles: Used in the bleaching and finishing of fabrics to obtain a perfect white color without harming the fibers.

End-use industries include pulp and paper, chemical manufacturing, healthcare, textiles, and environmental applications, all of which contribute to sustained market demand.

Why Invest in Vermicompost Manufacturing?

Several compelling factors make vermicompost manufacturing an attractive investment opportunity:

Essential Industrial Chemical: Hydrogen peroxide is the necessary component for the processes of bleaching, oxidation, and disinfection in the pulp and paper industry, chemical processing, and healthcare. That is why it has become a regularly used commodity chemical with a constant demand for it.

Environmentally Preferred Product: As a natural organic input, vermicompost replaces synthetic chemical fertilizers, supporting sustainable agriculture in accordance with global environmental and regulatory trends.

Steady Demand from Core Industries: The growth of key sectors like organic farming, horticulture, landscaping, and urban agriculture is providing steady and long-term consumption for vermicompost manufacturers.

Policy and Sustainability Support: The strict environmental regulations regarding chemical fertilizer use and soil pollution are facilitating the transition of many agricultural producers to vermicompost-based solutions.

Regional Manufacturing Advantage: Establishing production facilities in the area minimizes the dangers linked to the transportation of hazardous materials and also guarantees the nearby located industrial clusters a constant supply of the product.

Diverse Application Portfolio: The versatility of vermicompost across multiple sectors-from organic crop production to floriculture and soil remediation-provides manufacturers with diversified revenue streams and reduced market concentration risk.

Manufacturing Process Excellence

The vermicompost production process involves several carefully managed stages using earthworm-based bioconversion:

Hydrogenation: Anthraquinone is hydrogenated in the presence of catalysts to form anthrahydroquinone

Extraction: Hydrogen peroxide is extracted from the organic solution using water

Concentration: The aqueous solution is concentrated through distillation to achieve desired product specifications

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=22795&flag=C

Industry Leadership

The global vermicompost industry is led by established organic fertilizer producers and agri-input companies with extensive production capabilities and diverse application portfolios. Key industry players include:

• Airedale Group

• Arkema S.A.

• Evonik Industries AG

• Mitsubishi Gas Chemical Company Inc.

• National Peroxide Limited

• Nouryon

• OCI COMPANY Ltd

• Solvay S.A.

• Taekwang Industrial Co., Ltd.

These companies serve diverse end-use sectors including organic farming, horticulture, urban gardening, soil remediation, and landscaping, demonstrating the broad market applicability of vermicompost products.

Conclusion

The vermicompost manufacturing sector presents a strategically positioned investment opportunity at the intersection of organic agriculture, environmental sustainability, and diverse market applications. With favorable profit margins ranging from 25-35% gross profit and 10-15% net profit, strong market drivers including rising adoption of organic farming practices, growing demand for natural soil amendments, expanding horticulture and urban agriculture applications, and supportive government policies promoting sustainable agricultural inputs, establishing a vermicompost manufacturing plant offers significant potential for long-term business success and sustainable returns.

The combination of essential agricultural input status, environmentally preferred positioning, steady demand from core industries, and diverse application portfolio creates an attractive value proposition for serious chemical investors committed to quality manufacturing and operational excellence.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: +1-201-971-6302

About IMARC Group:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its clients' business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Vermicompost Manufacturing Plant Cost, DPR 2026: Demand Analysis, CapEx/OpEx & ROI Insights here

News-ID: 4393708 • Views: …

More Releases from IMARC Group

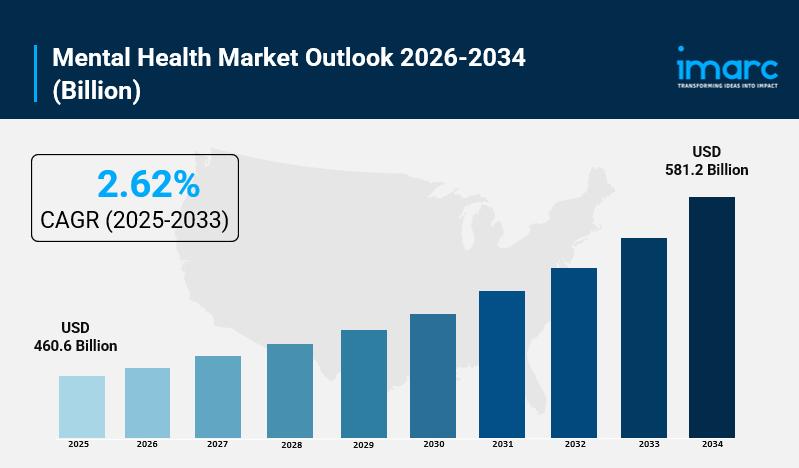

Mental Health Market Size, Share, Industry Trends, Growth Factors and Forecast 2 …

IMARC Group, a leading market research company, has recently released a report titled "Mental Health Market Size, Share, Trends, and Forecast by Disorder, Service, Age Group, and Region 2026-2034." The study provides a detailed analysis of the industry, including the global mental health market size, trends, share and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Mental Health Market Highlights:

• Mental Health…

Polylactic Acid Production Plant DPR & Unit Setup Cost 2026: Machinery Requireme …

Polylactic acid (PLA) is a biodegradable thermoplastic polymer derived from renewable agricultural resources including corn starch, sugarcane, and cassava. The production process begins with sugar fermentation, which converts the sugar into lactic acid, followed by polymerization to produce PLA resin. The material demonstrates outstanding clarity, rigidity, and processing capabilities, and can be composted in industrial composting facilities.

PLA exhibits lower toxicity levels combined with superior tensile strength and beneficial thermal…

Alcoholic Beverage Manufacturing Plant Cost 2026: CapEx/OpEx Analysis with Profi …

The global alcoholic beverage manufacturing industry represents a sophisticated and highly regulated sector producing diverse liquid consumables through controlled fermentation and distillation processes. Alcoholic beverages are consumable liquids that result from the fermentation and distillation of agricultural products including grains, fruits, sugarcane, and molasses. These beverages contain ethanol as their main alcoholic substance and are divided into four categories: beer, wine, spirits, and flavored or ready-to-drink alcoholic products. The manufacturing…

API Manufacturing Plant Cost DPR 2026: Capex, Opex & Compliance Requirements

Active Pharmaceutical Ingredients (APIs) are bioactive molecules that serve as the active constituent of any pharmaceutical formulation, producing the desired therapeutic effect upon administration. APIs are prepared through complex processes of chemical synthesis, fermentation, and biotechnology under highly stringent regulatory and quality guidelines. They must comply with specific attributes pertaining to quality, strength, stability, and safety as per pharmacopoeia standards such as USP, EP, and IP. APIs represent the active…

More Releases for Vermicompost

Vermicompost Market Study Reveals New Development Opportunities till 2031

HTF MI recently introduced Global Vermicompost Market study with 143+ pages in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status (2025-2032). The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence. Some key players from the complete study Earthworms, Red Wigglers, The Worm Farm, Uncle Jim's Worm Farm, Vermicomposters, BioWorks, The Worm Digger,…

Vermicompost Market Size and Forecast

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- The global Vermicompost Market is expected to record a CAGR of XX.X% from 2024 to 2031 In 2024, the market size is projected to reach a valuation of USD XX.X Billion. By 2031 the valuation is anticipated to reach USD XX.X Billion.

The Vermicompost market is expanding significantly due to the rising demand for organic farming and sustainable agricultural practices. Vermicompost, produced through the decomposition of organic waste…

Vermicompost Market: Nourishing Agriculture with Nature's Gold

Introduction

The global vermicompost market is experiencing remarkable growth as farmers and agricultural enthusiasts recognize the immense benefits of this organic fertilizer. Vermicompost, also known as worm castings, is a nutrient-rich and environmentally friendly product derived from the natural decomposition of organic waste through the action of earthworms. As the demand for sustainable agricultural practices rises, vermicompost has emerged as a key player in nourishing the soil and promoting eco-friendly farming.…

Vermicompost Market: Nourishing Agriculture Sustainably

Introduction

The global vermicompost market has witnessed substantial growth as the agriculture industry increasingly embraces sustainable and organic farming practices. Vermicompost, also known as worm castings, is a nutrient-rich organic fertilizer produced through the natural process of composting with the help of earthworms. This highly valuable humus enhances soil health, enriches nutrient content, and promotes strong plant growth. As the world faces challenges related to soil degradation and environmental concerns, vermicompost…

Organic Vermicompost Market Key Regions, Company Profile, Opportunity and Challe …

Global Organic Vermicompost Sales Market Report 2021

The Organic Vermicompost Market Report 2021-2027 provides global market size, regional and national level market size, market segment growth, market share, competitive landscape, sales analysis, influence of domestic and global market participants, and value chain Detailed analysis of optimization, trade regulations, latest developments, opportunity analysis, strategic market growth analysis, product launches, regional market expansion and technological innovation.

Organic Vermicompost Market refers to the protection of…

Global Organic Vermicompost Market Growth 2019-2024

LP INFORMATION offers a latest published report on Organic Vermicompost Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the Organic Vermicompost market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019. In particular,…