Press release

Plastic Granules Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, Raw Materials & ROI

The global plastic granules manufacturing industry is witnessing robust growth driven by its increasing consumption in packaging, automotive, construction, and consumer goods sectors, rising demand for recycled and sustainable plastic materials, and expanding use in high-performance polymer applications. At the heart of this expansion lies a critical material input-plastic granules. As industries transition toward lightweight materials and sustainable manufacturing practices, establishing a plastic granules manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and polymer investors seeking to capitalize on this growing and essential market.IMARC Group's report, "Plastic Granules Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The plastic granules manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for Sample Report: https://www.imarcgroup.com/plastic-granules-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

Plastic granules are small, uniform pellets of thermoplastic or thermosetting polymers that serve as the primary raw material for plastic product manufacturing. They are produced through extrusion and pelletizing processes that transform polymer resins or recycled plastics into standardized granules suitable for injection molding, blow molding, and extrusion processes. Plastic granules are available in various polymer types including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and engineering plastics. They are categorized into virgin granules, recycled granules, and compounded granules based on their origin and processing requirements, and are graded by melt flow index, density, and color specifications for various industrial applications.

The plastic granules market is mainly influenced by the rise in demand for lightweight and durable materials and the adoption of circular economy practices including plastic recycling. The packaging industry continues to be the largest plastic granules consumer as manufacturers are gradually incorporating more recycled and bio-based polymer options.

Automotive and construction sectors are also contributing to this growth, as plastic granules are increasingly used for lightweight components and structural elements. Besides, the growing adoption of high-performance engineering plastics in electronics and medical devices, especially in emerging markets, is driving demand from these sectors. Furthermore, the restructuring of supply chains by major polymer producers reflects that the industry is trying to adapt to sustainability mandates and changing regulatory priorities.

Plant Capacity and Production Scale

The proposed plastic granules manufacturing facility is designed with an annual production capacity ranging between 10,000-20,000 MT per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments-from packaging and automotive to construction, consumer goods, and electronics-ensuring steady demand and consistent revenue streams across multiple industry verticals.

Financial Viability and Profitability Analysis

The plastic granules manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 25-35%

• Net Profit Margins: 10-15%

These margins are supported by stable demand across industrial sectors, value-added specialty polymer positioning, and the critical nature of plastic granules in packaging and manufacturing applications. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established polymer manufacturers looking to diversify their product portfolio in the plastics sector.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a plastic granules manufacturing plant is primarily driven by:

• Raw Materials: 60-70% of total OpEx

• Utilities: 15-20% of OpEx

Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with polymer resins and recycled plastics being the primary input materials along with additives, colorants, stabilizers, and processing aids. Establishing long-term contracts with reliable resin suppliers and recycling partners helps mitigate price volatility and ensures consistent raw material supply, which is critical given that resin price fluctuations represent the most significant cost factor in plastic granules manufacturing.

Capital Investment Requirements

Setting up a plastic granules manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to polymer resin suppliers, recycling facilities, and plastic compound manufacturers. Proximity to target markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized production equipment essential for manufacturing. Key machinery includes:

• Extrusion lines for melting and homogenizing polymer resins

• Pelletizing systems for cutting and shaping molten polymer into granules

• Mixing and compounding units for additive blending and color masterbatch

• Screening and sorting equipment for size classification and quality grading

• Dryers and cooling systems for moisture removal and granule conditioning

• Storage tanks for raw materials and finished product

• Safety control systems for monitoring and emergency response

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the production process. The layout should be optimized with separate areas for raw material storage, extrusion zone, pelletizing section, compounding unit, quality control laboratory, finished goods warehouse, utility block, and administrative block.

Other Capital Costs: Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Buy Now: https://www.imarcgroup.com/checkout?id=9097&method=2175

Major Applications and Market Segments

Plastic granules find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Packaging: Used extensively in rigid and flexible packaging for food, beverages, pharmaceuticals, and consumer goods due to lightweight properties, moisture resistance, and cost efficiency.

Automotive and Transportation: Utilized for lightweight interior components, bumpers, under-the-hood parts, and fuel systems, supporting vehicle weight reduction and fuel efficiency goals.

Construction and Building Materials: Used in pipes, fittings, window profiles, flooring, and insulation materials for their durability, chemical resistance, and low maintenance requirements.

Electronics and Consumer Goods: Applied in housings, connectors, appliances, and devices where dimensional stability, flame retardancy, and electrical insulation properties are essential.

End-use industries include packaging, automotive, construction, electronics, agriculture, and medical devices, all of which contribute to sustained market demand.

Why Invest in Plastic Granules Manufacturing?

Several compelling factors make plastic granules manufacturing an attractive investment opportunity:

Essential Industrial Material: Plastic granules are the fundamental raw material for virtually all plastic product manufacturing. From packaging films to automotive parts, they are a regularly consumed commodity with constant and growing demand across global industries.

Circular Economy Alignment: The growing emphasis on plastic recycling and the circular economy creates additional demand for recycled granules and compounded materials, aligning the business with global sustainability trends and regulatory requirements.

Steady Demand from Core Industries: The growth of key sectors like packaging, automotive, construction, and electronics is providing a steady and long-term consumption base for plastic granules manufacturers.

Policy and Sustainability Support: Stricter regulations on single-use plastics and mandates for recycled content are driving investment in advanced plastic granules manufacturing, particularly recycled and bio-based polymer granules, creating long-term policy tailwinds for producers.

Regional Manufacturing Advantage: Establishing local production facilities reduces import dependence, minimizes logistics costs, and provides nearby plastic product manufacturers with a reliable, responsive supply of quality granules to meet just-in-time production requirements.

Diverse Application Portfolio: The versatility of plastic granules across multiple industries-from packaging to automotive, construction, and electronics-provides manufacturers with diversified revenue streams and reduced market concentration risk.

Manufacturing Process Excellence

The plastic granules manufacturing process involves several precision-controlled stages using the extrusion and pelletizing method:

Material Preparation: Raw polymer resins or recycled plastics are sorted, cleaned, and pre-dried to remove moisture and contaminants before processing

Extrusion: The polymer material is fed into an extruder where it is melted, homogenized, and compounded with additives, colorants, or fillers under controlled temperature and pressure

Pelletizing: The molten polymer strand is extruded through a die plate and cut into uniform granules using an underwater pelletizer or strand pelletizer system

Cooling, Drying, and Classification: The granules are cooled in a water bath or air stream, dried to meet moisture specifications, and screened to classify by size before quality testing and packaging

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=9097&flag=C

Industry Leadership

The global plastic granules industry is led by established polymer manufacturers with extensive production capabilities and diverse application portfolios. Key industry players include:

• BASF SE

• LyondellBasell Industries N.V.

• SABIC (Saudi Basic Industries Corporation)

• Dow Inc.

• ExxonMobil Chemical Company

• Reliance Industries Limited

• Braskem S.A.

• INEOS Group Holdings S.A.

• Borealis AG

These companies serve diverse end-use sectors including packaging, automotive, construction, electronics, agriculture, and consumer goods, demonstrating the broad market applicability of plastic granules products.

Conclusion

The plastic granules manufacturing sector presents a strategically positioned investment opportunity at the intersection of polymer materials, circular economy sustainability, and diverse market applications. With favorable profit margins ranging from 25-35% gross profit and 10-15% net profit, strong market drivers including rising demand for lightweight packaging and automotive components, growing adoption of recycled plastics, expanding construction and electronics applications, and supportive sustainability policies promoting circular economy practices, establishing a plastic granules manufacturing plant offers significant potential for long-term business success and sustainable returns.

The combination of essential industrial material status, circular economy alignment, steady demand from core industries, and diverse application portfolio creates an attractive value proposition for serious polymer investors committed to quality manufacturing and operational excellence.

About Us:

IMARC is a global market research and consulting company providing end-to-end support across market entry, feasibility studies, factory setup, regulatory navigation, and financial modeling. With expertise in CAPEX and OPEX assessment, plant layout optimization, and industry benchmarking, IMARC helps businesses reduce risk, optimize costs, and achieve long-term growth across manufacturing sectors.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Plastic Granules Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, Raw Materials & ROI here

News-ID: 4393348 • Views: …

More Releases from IMARC Group

Animal Feed Manufacturing Plant Cost 2026: Industry Overview and Profitability A …

The global animal feed manufacturing industry stands as a critical pillar of the agricultural value chain, serving as the foundational nutritional solution that sustains livestock, poultry, aquaculture species, and companion animals worldwide. Animal feed functions as a comprehensive nutritional solution providing essential dietary needs through specific blending of cereals, oilseed meals, vitamins, minerals, amino acids and feed additives mixed in exact proportions to enhance animal growth, reproductive capabilities, immune system…

Edible Vegetable Oil Manufacturing Plant DPR - 2026, Market Trends, Machinery Co …

The global food industry continues to depend fundamentally on edible vegetable oils as one of the most widely consumed and commercially significant food commodities, serving households, restaurants, and food processing facilities across every region of the world. Edible vegetable oil is a refined, purified oil extracted from plant sources such as soybean, sunflower, palm, canola, and groundnut, serving multiple purposes including cooking, frying, baking, and as a component of processed…

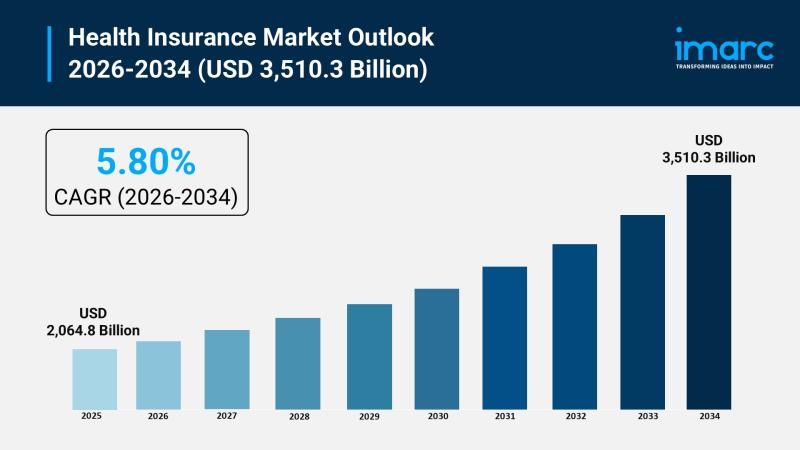

Health Insurance Market Size to Hit USD 3,510.3 Billion in 2034 | Grow CAGR by 5 …

Market Overview:

The health insurance market is experiencing rapid growth, driven by integration of artificial intelligence and advanced analytics, expanding government initiatives and universal coverage mandates, and rising healthcare costs and medical inflation. According to IMARC Group's latest research publication, "Health Insurance Market Size, Share, Trends and Forecast by Provider, Type, Plan Type, Demographics, Provider Type, and Region, 2026-2034, the global health insurance market size was valued at USD 2,064.8 Billion…

India FemTech Market Expected to Reach USD 5,518.58 Million by 2034, Industry Gr …

IMARC Group's latest research publication "India FemTech Market Size, Share, Trends and Forecast by Type, Application, End Use, and Region, 2026-2034" the India FemTech market size reached USD 1,485.81 Million in 2025. The market is expected to reach USD 5,518.58 Million by 2034, exhibiting a growth rate (CAGR) of 15.70% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-femtech-market/requestsample

What is FemTech?

FemTech, short for Female Technology, refers to a broad category of software, devices,…

More Releases for Plastic

Plastic bottles at events - Better party with plastic

Partying, dancing, camping - festivals attract hundreds of thousands of visitors every year in Germany alone. One challenge: supply and safety. For this reason, drinks in glass bottles are banned at most events due to the risk of injury. Lightweight and unbreakable plastic bottles, on the other hand, are considered a safe and practical alternative. Not only that: they can even be used to make a musical instrument.

Festivals or pageants…

Plastic Pallet With Plastic Crate Use: Efficient Material Handling

When it comes to efficient moving and storage of goods, a combination of plastic pallets [https://www.agriculture-solution.com/plastic-pallet/]and plastic crates is a popular choice. They are widely used in various industries such as manufacturing, retail, agriculture, etc. for storage and transportation of goods. Plastic pallets are designed to provide a stable base for stacking and shipping goods, while plastic crates provide safe and protective containers for stored or transported items. Plastic pallets…

Plastic Granules Market to Witness Massive Growth by Balaji Plastic, Navkar Indu …

The Worldwide Plastic Granules Market has witnessed continuous growth in the past few years and is projected to grow at a good pace during the forecast period of 2023-2029. The exploration provides a 360° view and insights, highlighting major outcomes of Worldwide Plastic Granules industry. These insights help the business decision-makers to formulate better business plans and make informed decisions to improve profitability. Additionally, the study helps venture or emerging…

Insights on the Growth of Plastic Granules Market 2018 to 2025 | Profiling Key C …

UpMarketResearch offers a Latest report on “Plastic Granules Market Analysis & Forecast 2018-2025” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 114 pages which highly exhibits on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Request Sample Copy of This Report@ https://www.upmarketresearch.com/home/requested_sample/49052

Plastic Granules research report delivers a close watch on leading competitors with strategic…

Agriculture Film Market SWOT Analysis of Leading Key Players Shandong Tianhe Pla …

HTF MI recently introduced Global Agriculture Film Market study with in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status to 2023. The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence and some of the key players from the complete study are British Polythene Industries (BPI), Trioplast, Berry Plastics, Armando Alvarez, Polypak, Barbier…

Building Materials Market 218 : Hepworth, National Plastic Industry, Hira Indust …

Building materials in this report covered the PVC pipes and fittings, PPR pipes and fittings, PE pipes and fittings, fabrication, ducts systems for infrastructure, valves and pumps and electrical conduits PVC systems.

At present, Hepworth, National Plastic Industry, Hira Industries, Florance Plastic Industries, Polyfab Plastic Industry, MPI, Union Pipes Industry, ANABEEB, Borouge and ACO Group are the UAE leading suppliers of the building materials, and top ten of them shared about…