Press release

Guide to the Best Vehicle Inspection System For Hail Damage Detection from Elscope Vision

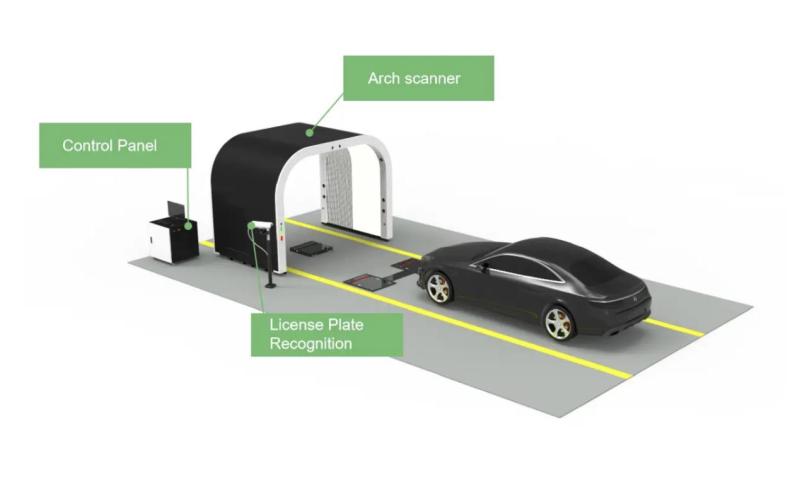

Have you ever walked out to your driveway after a severe summer storm and felt that sinking sensation while looking at your car's hood? Those tiny, almost invisible dimples caused by hailstones might seem like minor cosmetic issues, but for automotive professionals, they represent a complex logistical challenge.As extreme weather events become more frequent globally, the automotive industry is seeking the Best Vehicle Inspection System For Hail Damage Detection(https://www.elscopevision.com/the-ai-powered-arch-scanner-dragate-hail-pdr/) to replace slow, subjective manual checks. A modern vehicle inspection system for hail damage detection utilizes high-resolution cameras and artificial intelligence to identify thousands of tiny dents in seconds, providing a level of precision that the human eye simply cannot sustain over a long workday.

The Growing Necessity of Automated Damage Assessment

The automotive landscape is currently undergoing a massive transformation, where data is becoming as valuable as the hardware itself. For car dealerships, fleet operators, and insurance adjusters, the traditional method of "shadow-board" manual inspection is no longer sustainable. When hail hits a logistics hub containing thousands of new vehicles, manual appraisal can take weeks, leading to massive bottlenecks and depreciating asset values. The global reliance on rapid logistics means that any delay in identifying a vehicle damage inspection system flaw can result in significant financial loss.

The Financial Risk of Undetected External Defects

The hidden dangers of undetected hail damage are profound. Beyond the obvious aesthetic impact, unrecorded micro-dents can lead to long-term paint degradation and rust. For the secondary market, a vehicle with undisclosed hail damage significantly loses its resale value. If a rental company or a leasing operator fails to detect these imperfections during a "turn-in" inspection, they absorb the repair costs that should have been covered by insurance or the previous user. This is where a professional car body damage scanner becomes an essential gatekeeper for financial integrity.

Comparative Analysis: Manual Inspection vs. Digital Scanning

When comparing traditional inspection methods to advanced digital solutions, the gap in performance is stark. Manual inspections are prone to "inspector fatigue," where the accuracy of detection drops significantly after the first hour of work. In contrast, high-tech vehicle scanning provides 100% consistency. Unlike human appraisers who might miss dents under poor lighting or on specific paint colors, a dedicated vehicle damage inspection solution uses controlled lighting environments and AI algorithms to ensure no defect goes unnoticed.

Technological Leadership in Machine Vision

The technical prowess behind these advancements is spearheaded by innovators like New Tech Automotive Technology (Shanghai) Co., Ltd., better known through its professional brand, Elscope Vision. As a national high-tech enterprise in China, the company has mastered the full-stack R&D required for the next generation of automated diagnostics. Their expertise spans hardware engineering, AI algorithms, and cloud architecture. This integrated approach allows for the development of the hail damage scanner, a system that doesn't just take pictures but understands the geometry of the vehicle's surface.

Industrial Strength and Supply Chain Excellence

At the heart of their service advantage is a robust supply chain and a deep understanding of machine vision patents. By controlling the manufacturing and software development processes, Elscope Vision(https://www.elscopevision.com/contact-us/) ensures that their vehicle inspection system remains adaptable to various vehicle types-from passenger cars to heavy commercial vehicles and buses. This versatility is crucial for PDR (Paintless Dent Repair) shops and OEM manufacturers who deal with diverse fleets. Their vehicle damage inspection system is designed to integrate seamlessly into existing workflows, whether at a busy auction site or a factory exit point.

A Data-Driven Service Ecosystem

The service model offered by such a leading provider in China goes beyond mere hardware delivery. It includes comprehensive data-driven reporting that allows businesses to track damage trends over time. Their high-tech vehicle scanning systems, such as the AI-powered arch scanners, provide a "digital twin" of the vehicle's condition, which can be stored in the cloud for insurance verification and remarketing transparency. This level of technological depth ensures that every stakeholder in the automotive lifecycle has access to a single source of truth regarding a vehicle's exterior health.

Strategic Criteria for Selecting a Scanning Solution

Choosing the right vehicle damage inspection solution requires a strategic approach. Not all scanners are created equal, and businesses must evaluate several critical factors before investing:

Detection Accuracy and Speed The system should be able to identify dents as small as millimeter level while processing the vehicle in under seconds to maintain high throughput.

AI Maturity and Data Processing Look for a car body damage scanner backed by a large dataset. The AI must be able to differentiate between actual damage and surface debris like dust or water droplets.

Integration Capabilities A superior vehicle inspection system must offer API connectivity to existing dealer management or warehouse systems for automated record-keeping.

Environmental Adaptability Since hail often occurs in unpredictable climates, the hardware should be durable enough to operate in various lighting and temperature conditions.

Comprehensive Support Ensure the provider has a proven track record in China and internationally, offering both software updates and hardware maintenance to keep the system at peak performance.

The Future of PDR (Paintless Dent Repair) hail damage inspection and Quality Control

As the industry moves toward total automation, the role of a hail damage scanner will only grow. It is no longer just a tool for repair shops but a critical component of the global automotive supply chain. By adopting a vehicle damage inspection solution that combines AI precision with industrial-grade hardware, companies can safeguard their margins, enhance customer trust, and ensure that every vehicle-regardless of the weather it has endured-is accurately valued and expertly maintained.

For more information on advanced automotive inspection technology, visit: https://www.elscopevision.com/.

New Tech Automotive Technology(Shanghai)Co., Ltd.

No.1999, East Jinxiu Road, Pudong, Shanghai, China

mktdept@ntatchina.com

New Tech Automotive Technology (Shanghai) Co., Ltd. (NTA) is a leading provider of intelligent vehicle inspection solutions in China. The company is recognized as a national high-tech enterprise and holds numerous patents in machine vision and automotive inspection technologies. Backed by strong capabilities in hardware engineering, automation, AI algorithms, software development, and cloud architecture, NTA masters full-stack R&D and delivers advanced scanning systems that enable fast, accurate, and fully automated vehicle diagnostics.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Guide to the Best Vehicle Inspection System For Hail Damage Detection from Elscope Vision here

News-ID: 4381217 • Views: …

More Releases from New Tech Automotive Technology(Shanghai) Co., Ltd.

From China to the Global Market: The Rise of Elscope Vision Among the World's To …

As a vehicle smoothly approaches the service bay of a contemporary maintenance facility, it rolls over a low-profile scanning strip integrated seamlessly into the floor. Within seconds, high-definition imagery of the vehicle's chassis appears on a technician's tablet, highlighting wear and tear that the naked eye might miss. This seamless integration of hardware and software marks the transition from manual labor to automated precision. As the global automotive industry undergoes…

What Makes Elscope Vision a Leading Advanced AI Vehicle Inspection Solution Manu …

In a busy logistics hub on the outskirts of Shanghai, a fleet of commercial trucks returns from a long-haul journey. Traditionally, these vehicles would face a time-consuming manual inspection-technicians crawling underneath chassis and circling exteriors with flashlights to spot minor dents, tire wear, or fluid leaks. This process is often prone to human error and subjective judgment. Today, however, these trucks simply drive through a sleek, high-tech archway. Within seconds,…

Top AI-powered Vehicle Inspection Alternative to Uveye: How Elscope Vision Advan …

A luxury sedan pulls into a busy service center, the driver concerned about a faint rattling sound and a possible scratch from a tight parking garage. In the past, a service advisor would walk around the vehicle with a clipboard, squinting at body panels under flickering fluorescent lights and perhaps missing a small underbody scrape that could lead to future corrosion. Today, that same vehicle glides through a sleek, sensor-equipped…

How China Tire Tread Scanner Industry Leader NTA Redefines Maintenance Standards …

The exhibition hall of the Auto Maintenance & Repair Expo (AMR) in Beijing hums with the steady sound of industrial machinery and professional discourse. At the center of the bustling floor, rows of diagnostic equipment represent the latest advancements in automotive care. As vehicles move across the exhibition space, a streamlined, low-profile device integrated into the floor captures attention. A car passes over it without stopping, and instantly, a high-resolution…

More Releases for Inspection

Inspection Drones Market 2032: Advancements, Trends, and AI-Enabled Industrial I …

The Inspection Drones Market size was valued at USD 8.90 Billion in 2024 and the total Inspection Drones revenue is expected to grow at a CAGR of 12.9% from 2025 to 2032, reaching nearly USD 23.50 Billion.

Inspection Drones Market Overview:

The Inspection Drones Market has garnered strong attention from industries that require rapid and accurate evaluation of assets such as power lines, wind turbines, pipelines, bridges, and industrial installations. These drones…

Railway Inspection Services Market Outlook : Solutions, Inspection Vehicles & Sy …

Railway inspection is the practice of examining rail tracks for flaws that lead to catastrophic failures causing accidents. According to the U.S. Federal Railroad Administration Office of Safety Analysis, track defects are the second cause of railway accidents in U.S. Some of the reasons causing track defects are shear stresses, wheel/rail contact stresses, thermal stresses, residual stresses, and dynamic effects. Moreover, due to contact stresses defects such as tongue lipping,…

Surface Inspection Market: Surface Inspection Market to Grow to USD 10.29B by 20 …

Surface Inspection Market Scope:

Key Insights : Surface Inspection Market size was valued at USD 5.02 billion in 2022 and is poised to grow from USD 5.44 billion in 2023 to USD 10.29 billion by 2031, growing at a CAGR of 8.3% in the forecast period (2024-2031).

Discover Your Competitive Edge with a Free Sample Report :https://www.skyquestt.com/sample-request/surface-inspection-market

Access the full 2024 Market report for a comprehensive understanding @https://www.skyquestt.com/report/surface-inspection-market

In-Depth Exploration of the global…

Thermal Drone Inspection Market Soars as Industries Embrace Efficient and Safe I …

The global thermal drone inspection market is estimated to exceed US$ 282.4 million by the end of 2023, by growing at an impressive CAGR of 13.4% over the assessment period of 2023-2033.

The deployment of thermal cameras with infrared sensors and high quality image processors has significantly expanded the applications of the thermal drones. They can be utilized in various industries, for instance, firefighting, search & rescue, ariel utility and advanced…

beXel launched different inspection modules to improve inspection quality

beXel launched a Variety of modules to facilitate the inspection process and provide smart solutions for the customers such as

(Drops Inspection, Job order management, Lifting Inspection, NDT inspection, Tubular Inspection, Desktop Offline App).

A quality inspection involves measuring, examining, testing, or gauging various characteristics of a product and comparing those results with specified requirements to determine whether there is conformity.

Quality Control (QC) is critical to build and deliver products that meet…

Carlsbad, CA Mold Inspection and Asbestos Testing Services Offered by Murrieta M …

Carlsbad, CA, December 16, 2019 – EZ Mold Inspections continues expanding its service area in San Diego County and now provides asbestos testing and mold inspections in Carlsbad, California. The inspection company is based in the Murrieta-Temecula area. The company now serves nine areas in Riverside County and two cities in San Diego County including Oceanside, CA and Carlsbad, CA.

With more than two decades of experience in real estate and…