Press release

Steel Rebar Manufacturing Plant DPR - 2026, Machinery Cost, CapEx/OpEx and Profit Analysis

The global construction industry stands at the foundation of economic development and infrastructure modernization worldwide, requiring essential building materials that provide structural integrity and long-term durability. Steel rebar, consisting of hot-rolled or mechanically processed steel bars manufactured to reinforce concrete and masonry structures, represents a critical component for improving tensile strength and ensuring structural safety across diverse construction applications. As rapid urbanization accelerates, infrastructure development intensifies, residential and commercial construction activities expand, and government investments in transportation, energy, and public works projects increase, establishing a steel rebar manufacturing plant presents a strategically compelling investment opportunity for entrepreneurs and industrial investors seeking to capitalize on this fundamental market serving construction and real estate, infrastructure and transportation, industrial facilities, energy projects, and public utilities sectors.Browse Full Related Report: https://www.imarcgroup.com/steel-rebar-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global steel rebar market demonstrates robust growth momentum, valued at USD 272.73 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 434.09 Billion by 2034, exhibiting a solid CAGR of 5.3% from 2026 to 2034. This sustained expansion reflects the fundamental importance of steel rebar in modern construction and the growing global demand for reinforced concrete structures.

Steel rebar is manufactured in standardized diameters and grades to ensure uniform load-bearing performance, durability, and compatibility with construction design requirements. These bars offer consistent mechanical properties that reduce structural failure risks while enabling faster and more reliable construction execution. Various variants available in the market include plain mild steel bars, deformed bars, thermo-mechanically treated TMT rebars, epoxy-coated rebars, and corrosion-resistant rebars. These products exhibit high strength, weldability, and resistance to stress and environmental conditions. Their standardized composition supports large-scale infrastructure projects as well as small and mid-sized construction applications, ensuring consistent quality across diverse end uses and providing essential reinforcement for concrete structures worldwide.

Plant Capacity and Production Scale

The proposed steel rebar manufacturing facility is designed with an annual production capacity of 500,000 Metric Tons, enabling substantial economies of scale while maintaining operational flexibility to respond to market dynamics. This capacity positions manufacturers to serve multiple construction segments from residential housing projects and commercial buildings to infrastructure projects and industrial facilities, ensuring diversified revenue streams and strategic market positioning across the construction value chain.

Financial Viability and Profitability Analysis

The steel rebar manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

Gross Profit Margins: 10-20%

Net Profit Margins: 4-10%

These margin profiles are supported by stable demand across construction and real estate, infrastructure and transportation, industrial and manufacturing facilities, energy and power projects, and public utilities development sectors. The financial projections have been developed based on realistic assumptions related to capital investment, operating costs, production capacity utilization, pricing trends, and demand outlook, providing a comprehensive view of project financial viability, return on investment potential, profitability trajectory, and long-term sustainability in this essential construction materials sector.

Operating Cost Structure

Understanding the operating expenditure structure is crucial for effective financial planning and cost management. The cost structure is characterized by:

Raw Materials: 80-85% of total OpEx

Utilities: 10-15% of OpEx

Raw material consumption represents the dominant cost component, with steel or direct reduced iron accounting for approximately 80-85% of total operating expenses. Additional materials include ferroalloys that enhance specific mechanical properties. The utility costs reflect the energy-intensive nature of steel melting, rolling, and heat treatment processes. By the fifth year, total operational costs are expected to increase substantially due to factors including inflation, market fluctuations, potential rises in key material costs, supply chain disruptions, rising consumer demand, and shifts in the global economic environment.

Buy Now: https://www.imarcgroup.com/checkout?id=23105&method=2175

Capital Investment Requirements

Establishing and operating a steel rebar manufacturing plant involves various cost components. The total capital investment depends on plant capacity, technology, and location, covering land acquisition, site preparation, and necessary infrastructure.

Land and Site Development: The location must offer convenient access to key raw materials including steel, direct reduced iron, and ferroalloys. Proximity to target markets minimizes distribution costs. The site must provide robust infrastructure including reliable transportation, utilities, and waste management systems, with compliance with local zoning laws and environmental regulations.

Machinery and Equipment: Machinery costs account for the largest portion of total capital expenditure. Essential equipment includes:

• Induction or electric arc furnaces

• Billet casting machines

• Reheating furnaces

• Hot rolling mills

• Quenching and tempering units

• Straightening and cutting machines

• Inspection systems

• Bundling and packaging equipment

Civil Works: The layout should be optimized to enhance workflow efficiency, ensure workplace safety, and minimize material handling. Separate areas must be designated for raw material storage, production operations, quality control, and finished goods storage.

Major Applications and Market Segments

Industrial Facilities: Factories, warehouses, and processing plants use steel rebar for reinforced flooring, heavy machinery bases, and structural frames.

Public Utilities: Water treatment plants, power stations, and transport terminals rely on steel rebar for durable and compliant construction.

Residential Construction Sector: Steel rebar is used in foundations, columns, slabs, and beams to enhance strength and safety of houses and apartment complexes.

Commercial Buildings: Offices, malls, and commercial complexes depend on steel rebar to support heavy loads and ensure long-term structural stability.

Infrastructure Projects: Bridges, flyovers, metros, and highways utilize steel rebar to withstand high stress, vibration, and dynamic loads.

Why Invest in Steel Rebar Manufacturing?

Growth in Residential and Commercial Construction: Increasing population and real estate development are creating sustained demand for reinforced concrete solutions across residential and commercial building projects.

Structural Strength and Safety: High tensile strength and ductility make steel rebar essential for improving load resistance and seismic performance of structures, ensuring building safety and longevity.

Rising Demand for Infrastructure Development: Expanding urban centers and government-led infrastructure programs are significantly increasing demand for steel rebar worldwide. As of May 2025, 7,555 smart city projects representing 94% of the total 8,067 projects have been completed in India, demonstrating the scale of infrastructure investment driving steel rebar demand.

Standardization and Design Flexibility: Steel rebar is available in multiple grades, diameters, and surface treatments to meet diverse structural and engineering requirements, providing flexibility for various construction applications.

Scalability and Cost Efficiency in Production: Steel rebar manufacturing can be scaled through continuous rolling mills and automated processes with competitive capital investment, enabling efficient production expansion as market demand grows.

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=23105&flag=C

Industry Leadership

Leading manufacturers in the global steel rebar industry include several multinational companies with extensive production capacities and diverse application portfolios. Key players include:

• ArcelorMittal

• NIPPON STEEL CORPORATION

• NLMK

• Nucor

• Tata Steel

These industry leaders serve diverse end-use sectors including construction and real estate, infrastructure and transportation, industrial and manufacturing facilities, energy and power projects, and public utilities development, demonstrating the broad market applicability of steel rebar products.

Recent Industry Developments

June 2025: Hybar LLC produced its first steel rebar at its new mini mill in Osceola, Arkansas, marking a major expansion of steel rebar production capacity. The company advanced commissioning of its electric arc furnace, rolling mill, and integrated solar and battery storage systems to scale sustainable steel rebar manufacturing.

March 2025: GTB Steel opened a USD 31 million steel rebar manufacturing plant in Ararat, Armenia, after relocating the project from Yerakh due to security concerns. The facility operates with an annual capacity of 112.8 thousand tons, uses induction furnaces and rolling mills to produce steel rebar and related products, and supports workforce expansion as part of its steel rebar capacity expansion strategy.

Conclusion

The steel rebar manufacturing sector presents a strategically positioned investment opportunity supported by robust market fundamentals including market growth from USD 272.73 Billion in 2025 to USD 434.09 Billion by 2034 at a 5.3% CAGR, plant capacity of 500,000 metric tons annually, and profit margins of 10-20% gross and 4-10% net. With 7,555 smart city projects completed in India representing 94% of total planned projects, growing residential and commercial construction driven by increasing population, rising infrastructure development through government-led programs, structural strength requirements for seismic performance, and standardized products available in multiple grades and surface treatments, establishing a steel rebar manufacturing plant offers significant potential for long-term business success. The convergence of sustained construction demand, essential role in reinforced concrete structures, scalable production through continuous rolling mills, recent industry investments including Hybar's new Arkansas facility and GTB Steel's USD 31 million Armenian plant, and established industry leadership from ArcelorMittal, Nippon Steel, NLMK, Nucor, and Tata Steel creates an attractive value proposition for industrial investors committed to participating in this fundamental construction materials sector.

About IMARC Group

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its clients' business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Steel Rebar Manufacturing Plant DPR - 2026, Machinery Cost, CapEx/OpEx and Profit Analysis here

News-ID: 4378687 • Views: …

More Releases from IMARC Group

Bio-CNG Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Project …

The global energy landscape is undergoing a fundamental transformation as nations and industries worldwide seek cleaner, more sustainable alternatives to conventional fossil fuels. Bio-CNG (compressed natural gas), a renewable fuel derived from organic waste through advanced anaerobic digestion and biogas upgrading processes, represents a critical solution in this energy transition. This comprehensive investment guide examines the compelling opportunity of establishing a bio-CNG manufacturing facility, drawing on market intelligence, financial projections,…

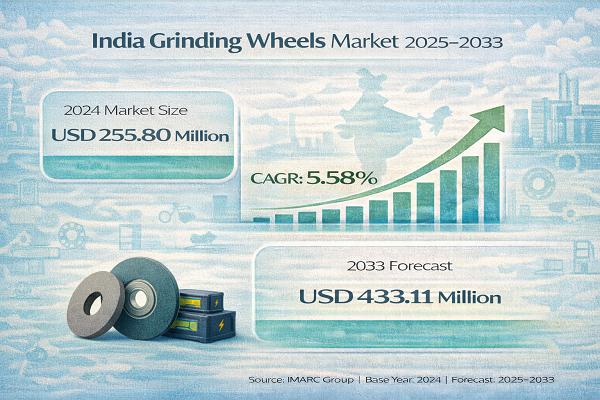

India Grinding Wheels Market Set for Steady Expansion, Forecast to Hit USD 433.1 …

India Grinding Wheels Market - Report Introduction

According to IMARC Group's report titled "India Grinding Wheels Market Size, Share, Trends, and Forecast by Type, Material, and Region, 2025-2033" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Note : We are in the process of updating our reports to cover the 2026-2034 forecast period. For the most recent data, insights, and industry updates, please…

Disposable Syringe Manufacturing Plant Cost 2026: Feasibility Study and Profitab …

The global disposable syringe market represents a compelling investment opportunity driven by surging demand for safe and hygienic delivery of drugs, expansion in healthcare infrastructure, and growing demand for standardized, single-use medical devices. Disposable syringes are single-use medical injection devices that are presterilized, manufactured from medical plastic components comprising a graduated barrel, plunger, and needle. They are designed for the safe and controlled administration of precise fluid, vaccine, or medication…

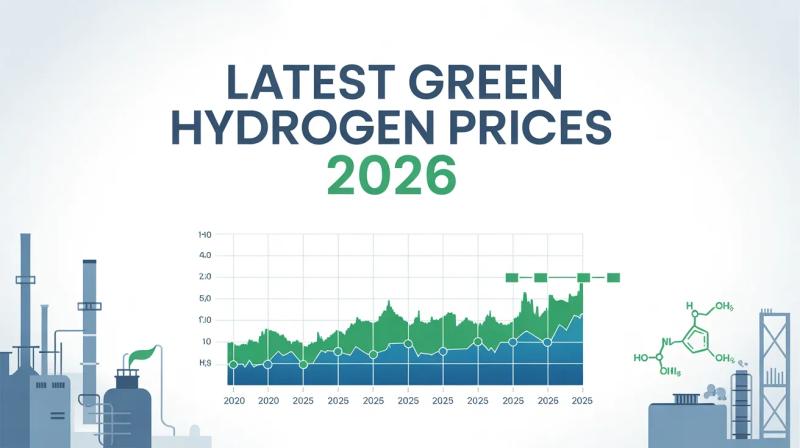

Green Hydrogen Prices 2026: Trend Analysis, Fluctuations & Forecast

Global Green Hydrogen Prices have been closely monitored as the sector grows rapidly with the energy transition. The Green Hydrogen Price Index reflects evolving costs influenced by renewable energy availability, electrolyzer efficiency, and regional market demand. Rising adoption in industrial, transportation, and clean energy applications has intensified interest in price trends, historical data, and future forecasts, making reliable pricing intelligence essential for investors, producers, and buyers worldwide.

Green Hydrogen Current Price…

More Releases for Steel

Steel Beams Market is Booming Worldwide with Steel Dynamics, JSW Steel, JFE Stee …

HTF MI just released the Global Steel Beams Market Study, a comprehensive analysis of the market that spans more than 143+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

Major Giants in Steel Beams Market are:

ArcelorMittal (Luxembourg), Nippon Steel (Japan),…

Special Ball Bearing Steel Market : Eminent Players - Nippon Steel, Suzhou Steel …

Market Description -

Los Angeles, (United States) - The information made available in the Special Ball Bearing Steel report will definitely facilitate to increase the knowledge and decision-making skills of the business, thus providing an immense opportunity for growth. This will at last increase the return rate and drive the competitive edge within. Being a custom market report, it provides services tailored to the exact challenge. Whether it is survey work,…

Miscellaneous Steel Detailing | Steel Detailer | Steel Detailing Services

We provide the highest quality of finished projects in the industry. Boasting unmatched turnaround times, and superb accuracy. WorldSteel Detailings has onboard team of experienced steel detailers and engineers with a wide range of experience from industrial and commercial projects to high rise buildings. By using innovative technologies and latest softwares, our structural steel detailing team provides accurate services as per your requirements based on country standards.Our steel detailing professionals…

What's driving the Structural Steel Market trends? ArcelorMittal, Tata Steel, Ni …

A detailed study on ‘Structural Steel market’ formulated by Market Study Report, LLC, puts together a concise analysis of the growth factors impacting the current business scenario across assorted regions. Significant information pertaining to the industry’s size, share, application, and statistics are also summed in the report in order to present an ensemble prediction. In addition, this report undertakes an accurate competitive analysis illustrating the status of market majors in…

What's driving the Structural Steel Market trends? ArcelorMittal, Tata Steel, Ni …

A detailed study on ‘Structural Steel market’ formulated by Market Study Report, LLC, puts together a concise analysis of the growth factors impacting the current business scenario across assorted regions. Significant information pertaining to the industry’s size, share, application, and statistics are also summed in the report in order to present an ensemble prediction. In addition, this report undertakes an accurate competitive analysis illustrating the status of market majors in…

What's driving the Structural Steel Market trends? ArcelorMittal, Tata Steel, Ni …

A detailed study on ‘Structural Steel market’ formulated by Market Study Report, LLC, puts together a concise analysis of the growth factors impacting the current business scenario across assorted regions. Significant information pertaining to the industry’s size, share, application, and statistics are also summed in the report in order to present an ensemble prediction. In addition, this report undertakes an accurate competitive analysis illustrating the status of market majors in…