Press release

Global Polymer Blends & Alloys Market Deep-Dive 2026-2036: Strategic Forecasts, Market Entry Insights & Emerging Opportunities

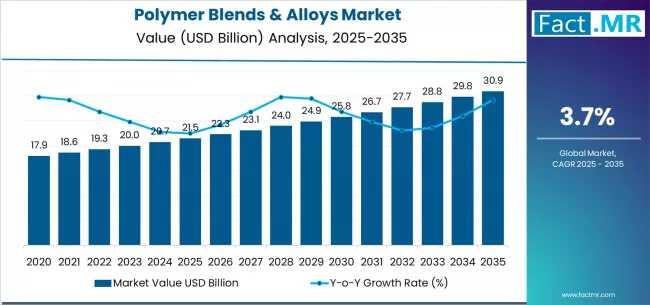

Global Polymer Blends and Alloys Market Poised for Significant Growth, Projected to Reach $9.79 Billion by 2036The global Polymer Blends and Alloys Market is entering a decade of transformative expansion, driven by the intensifying demand for lightweight, high-performance materials in the automotive and electronics sectors. According to recent industry analysis, the market is projected to grow from a valuation of $5.41 billion in 2026 to approximately $9.79 billion by 2035, exhibiting a robust compound annual growth rate (CAGR) of 6.7%.

This growth trajectory reflects a fundamental shift in material science, where manufacturers are increasingly moving away from monolithic plastics toward sophisticated alloys-mixtures of two or more polymers designed to achieve physical properties that no single material can offer alone.

Request for Sample Report | Customize Report |purchase Full Report - https://www.factmr.com/connectus/sample?flag=S&rep_id=7495

Strategic Market Dynamics: Addressing the Why and How

The surge in the polymer blends and alloys sector is underpinned by three primary industrial imperatives: performance optimization, regulatory compliance, and weight reduction.

Automotive Lightweighting: As the global automotive industry pivots toward electrification, reducing vehicle weight is critical for extending battery range. Polymer alloys, particularly Polycarbonate (PC) and Acrylonitrile Butadiene Styrene (ABS) blends, are replacing metal components in interior panels, bumpers, and battery casings.

Electronics Miniaturization: The demand for thinner, more durable consumer electronics-ranging from 5G-enabled smartphones to AI-assisted home devices-requires materials with exceptional thermal stability and flame retardancy, areas where polymer alloys excel.

The Circular Economy: In 2026, the market is seeing a pivot toward compatibilized blends. These chemical additives allow dissimilar recycled plastics to be mixed effectively, enabling manufacturers to meet stringent sustainability mandates without sacrificing structural integrity.

Market Segmentation and Regional Leadership

The industry is characterized by high technical barriers to entry and a focus on specialized formulations.

Key Material Segments

Polycarbonate (PC) Based Blends: Currently dominating the market share, these blends are favored for their impact resistance and optical clarity.

PPO/PPE Based Blends: These are the fastest-growing segments, prized for their low moisture absorption and excellent dielectric properties in high-frequency electronic applications.

Geographical Analysis

Asia-Pacific: Remaining the largest regional market through 2036, growth here is fueled by massive infrastructure projects and the concentration of consumer electronics manufacturing in China, India, and Vietnam.

North America: Projected to grow at the fastest CAGR during the forecast period, driven by a resurgence in domestic automotive manufacturing and rapid adoption of advanced medical-grade polymer alloys.

Competitive Landscape and Industry Innovation

The market remains fragmented but is led by global chemical giants focusing on R&D and strategic acquisitions. Key players currently shaping the 2026-2036 horizon include:

BASF SE and Covestro AG (recently acquired by ADNOC in a $14.7 billion deal), both focusing on bio-attributed and recycled polycarbonate technologies.

SABIC and LyondellBasell Industries, leading the charge in high-performance thermoplastic alloys for the aerospace and healthcare sectors.

Mitsubishi Engineering-Plastics and Asahi Kasei, pioneering specialized alloys for the next generation of electric vehicle (EV) components.

Industry Challenges

Despite the positive outlook, the industry faces headwinds from volatile raw material pricing and the high cost of compatibility testing. Small and medium-sized enterprises (SMEs) face significant challenges in scaling production due to patent protections on specialized chemical formulations.

Future Outlook: 2026-2036

Looking toward 2036, the integration of smart materials and additive manufacturing (3D printing) is expected to further disrupt the market. By blending polymers at the molecular level to respond to external stimuli-such as temperature or pressure-the next generation of smart alloys will find applications in everything from autonomous vehicle sensors to advanced prosthetics.

As industries strive for net-zero goals, the focus will remain on developing bio-based polymer blends that maintain the mechanical prowess of their fossil-fuel-based predecessors.

About the Market Report This press release summarizes findings from current 2026 industrial forecasts. For further data-backed insights on the Polymer Blends & Alloys Market, including deep-dive segment analysis and competitive benchmarking, please consult professional market research providers.

Browse Full Report : https://www.factmr.com/report/polymer-blends-and-alloys-market

Related Reports

Demand for Polymer Blends & Alloys in USA https://www.factmr.com/report/united-states-polymer-blends-alloys-market

Polymer Testing Services Market https://www.factmr.com/report/polymer-testing-services-market

Polymer Concrete Market https://www.factmr.com/report/polymer-concrete-market

Polymers Market https://www.factmr.com/report/polymers-market

"

- Contact Us -

11140 Rockville Pike, Suite 400, Rockville,

MD 20852, United States

Tel: +1 (628) 251-1583 | sales@factmr.com

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Polymer Blends & Alloys Market Deep-Dive 2026-2036: Strategic Forecasts, Market Entry Insights & Emerging Opportunities here

News-ID: 4378545 • Views: …

More Releases from Fact.MR

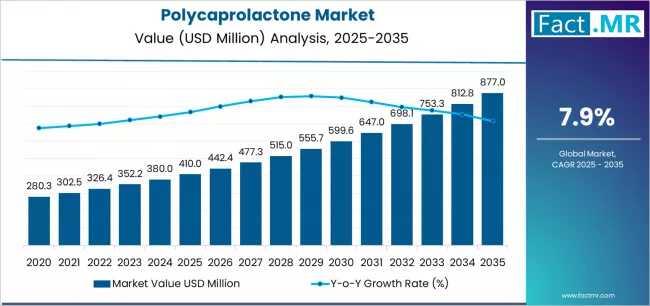

Global Polycaprolactone Industry Outlook to 2036: Strategic Insights for R&D, Ex …

Global Polycaprolactone Market Set for Transformative Growth Through 2036, Driven by Biomedical Innovation and Sustainable Manufacturing

The global Polycaprolactone (PCL) market is entering a decade of high-velocity expansion, with industry forecasts for the 2026-2036 period pointing toward a significant valuation surge. As industrial and medical sectors pivot from traditional synthetics to high-performance biodegradable polyesters, PCL has emerged as a critical material in the global transition toward a circular economy.

Request for Sample…

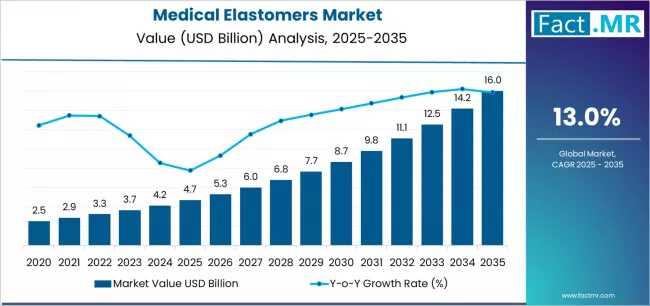

2036 Global Medical Elastomers Market Intelligence Report: Technology Shifts, De …

The global medical elastomers market is undergoing a fundamental transformation, driven by a rapid shift toward minimally invasive surgeries and an urgent industry-wide transition away from traditional materials like PVC and latex. As healthcare providers demand safer, more flexible, and biocompatible solutions, the sector is projected to see substantial expansion through the 2026-2036 forecast period.

Quick Stats for Medical Elastomers Market

Medical Elastomers Market Value (2025): USD 4.7 billion

Medical Elastomers Market Forecast…

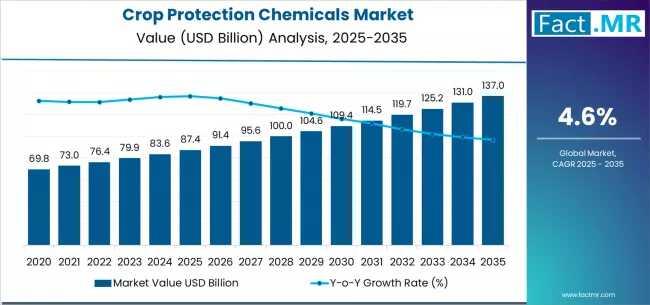

Global Crop Protection Chemicals Market Size, Share & Forecast: High-Growth Segm …

Global Crop Protection Chemicals Market Projected to Exceed USD 115 Billion by 2036 Amid Shifts in Precision Agriculture and Climate Resilience

The global crop protection chemicals market is entering a transformative decade, with latest industry data projecting a valuation surge from USD 70.42 billion in 2026 to over USD 115 billion by 2036. Driven by a compound annual growth rate (CAGR) of approximately 5.4%, the sector is navigating a critical…

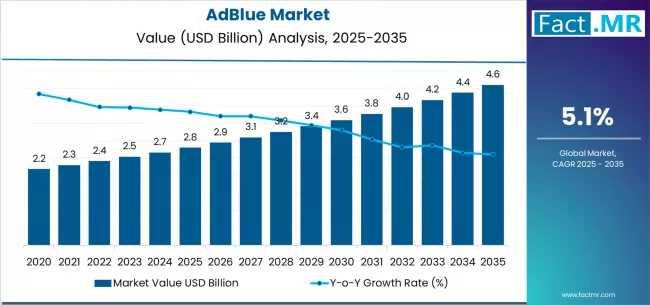

Next-Generation AdBlue Market Trends 2026-2036: Innovation Catalysts, Regulatory …

Global AdBlue Market Projected to Surpass USD 70 Billion by 2036 as Emission Regulations Tighten

The global AdBlue (Diesel Exhaust Fluid) market is entering a decade of transformative growth, with new projections estimating the industry will exceed a valuation of USD 70 billion by 2036. Driven by the phased implementation of Euro 7 and BS-VI Stage II standards, the market is shifting from a niche automotive additive to a critical utility…

More Releases for Polymer

MDR Certificate For Single Polymer Clip Applier And Multiple Polymer Clip Applie …

EU Quality Management System Certificate

Regulation (EU)2017/745, Annex Ix Chapter I and III

MDR 804963 R000

Manufacturer: Hangzhou Sunstone Technology Co., Ltd

Address:

2nd Floor of Building 1,

#460 Fucheng Rd, Qiantang Area

Hangzhou

Zhejiang

310018

China

Single Registration Number: CN-MF-000040501

EU Authorised Representative: MedPath GmbH

Address:

Mies-van-der-Rohe-Strasse 8

80807

Munich

Germany

Scope: See attached Device Schedule

On the basis of our examination of the quality system in accordance with Regulation (EU) 2017/745, Annex IX

Chapter I and lll, the quality system meets the requirements of the Regulation. For the…

Acrylic Polymer Market

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐩𝐨𝐥𝐲𝐦𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟐𝟎 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑𝟔.𝟗 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐠𝐫𝐨𝐰𝐢𝐧𝐠 𝐚𝐭 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝟔.𝟒% 𝐟𝐫𝐨𝐦 𝟐𝟎𝟐𝟑 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐀𝐜𝐫𝐲𝐥𝐢𝐜 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The acrylic polymer market has experienced significant growth due to its versatile applications across various industries, including paints and coatings, adhesives, textiles, and construction. Acrylic polymers are favored for…

Polymer Processing Aids: Enhancing Efficiency and Quality in Polymer Manufacturi …

Introduction

Polymer Processing Aids (PPAs) are indispensable additives used to improve the efficiency, quality, and cost-effectiveness of polymer manufacturing. These aids, often added in small quantities, significantly enhance polymer production by reducing surface defects, improving flow properties, and reducing wear on manufacturing equipment. Their role is critical in enabling smooth, uninterrupted processing, leading to higher-quality end products and improved manufacturing productivity. With the ever-growing demand for polymers across industries like automotive,…

What Are Lithium Polymer? Information About Lithium Polymer Batteries Guide

Did people know that Lithium Polymer power over 80% of the drones used in recreational and commercial applications today? Lithium Polymer (LiPo) batteries have become a staple in modern electronics. From powering smartphones and laptops to energizing drones and electric vehicles, these batteries offer a blend of high energy density and flexibility that makes them ideal for a wide range of applications. In this article, we'll dive deep into what…

Custom Polymer Synthesis Market 2023 Will Record Massive Growth, Trend Analysis …

The Custom Polymer Synthesis Market Trends Overview 2023-2030:

A new Report by Stratagem Market Insights, titled "Custom Polymer Synthesis Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Custom Polymer Synthesis market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures, tables, and charts,…

Silyl Modified Polymer (MS Polymer) Market Forecast Research Reports Offers Key …

Silyl Modified Polymer (MS Polymer) Market: Introduction

MS polymers, also known as silyl modified polymers or silyl terminated polymers, are polymers with a silane group. A silyl modified polymer (MS polymer) usually refers to a hybrid polymer backbone, usually polyurethane or polyether and a silane end group. Formulators can change the backbone polymer in sealants and adhesives utilizing MS polymers to match the specified application, achieving silicone-like performance while avoiding the…