Press release

A New Era of Thermal Conductivity: How to Maximize the Thermal Conductivity Potential of Silicone Thermal Pads Through Multi-Dimensional Innovation

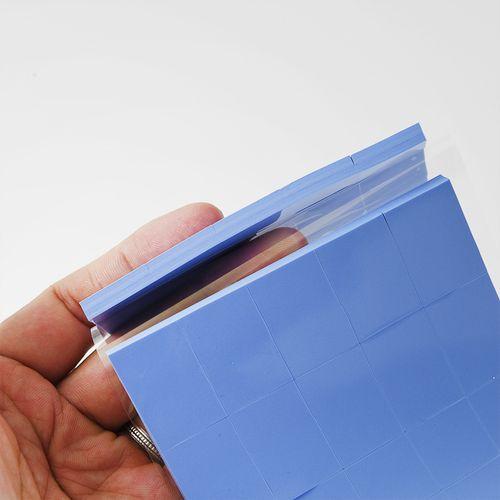

The advantages and challenges of the Silicone thermal pad [https://www.cmaisz.com/silicone-thermal-pad/]Silicone thermal pads, as an important heat-conducting medium in the cooling system of electronic devices, have numerous advantages in application. Their excellent flexibility enables them to closely adhere to various irregular surfaces and effectively fill the heat dissipation gaps. Additionally, this material possesses stable heat-conducting capabilities, which can promptly transfer the heat generated by electronic components. In high-temperature working environments, the silicone thermal pads can still maintain stable performance, ensuring the long-term reliable operation of electronic devices.

However, this material also encounters some technical challenges in practical applications. Its Thermal Conductivity is restricted by various factors such as the type of filler, the viscosity of the substrate, the surface flatness, and the manufacturing process. How to further enhance the thermal conductivity of the material while controlling the production cost remains a technical problem that the current industry needs to solve.

Image: https://ecdn6.globalso.com/upload/m/image_other/2025-11/2-58.png

Multi-dimensional Innovation Drives Maximizing Thermal Conductivity Potential

Application of High-Performance Fillers

Fillers are one of the core factors affecting the thermal conductivity of silicone thermal pads. In recent years, the introduction of novel fillers such as nanomaterials like carbon nanotubes and graphene has greatly improved the thermal conductivity of silicone. By adding these nanomaterials with high thermal conductivity to silicone, its thermal conductivity efficiency can be significantly improved.

Optimization of silicone gel formula and production process

The viscosity, fluidity and curing performance of silicone gel are the key factors that directly affect the heat conduction efficiency of the heat pad. To enhance the heat conduction performance of the silicone thermal pad, two approaches can be taken: Firstly, innovate and improve the production process in the formula design, such as adjusting the ratio of silicone gel and fillers according to actual needs, and adopting more precise production steps, which can effectively improve the heat conduction efficiency of the heat pad; Secondly, use high-precision molds in the production process, which can keep the surface of the heat pad smooth and flat, thereby reducing the thermal resistance during contact.

Image: https://ecdn6.globalso.com/upload/m/image_other/2025-11/5-29.png

Structural Design and Surface Treatment The thermal conductivity of a thermal pad [https://www.cmaisz.com/silicone-thermal-pad/]is closely related to its structural design. By optimizing its thickness, surface texture, and microstructure, and employing advanced surface treatment technologies such as nano-coatings, thermal resistance can be effectively reduced and thermal conduction efficiency improved.

Enhanced Environmental Adaptability and Stability To ensure stable operation of silicone thermal pads under various environmental conditions, it is crucial to improve their temperature resistance, aging resistance, and compressive strength. Adding new environmentally friendly additives or enhancing the cross-linking degree of materials can effectively improve their reliability and service life in extreme environments.

Image: https://ecdn6.globalso.com/upload/m/image_other/2025-11/4-37.png

Future Outlook: Towards More Efficient Thermal [https://www.cmaisz.com/t-thermal/] Management Solutions

Looking ahead, the trend towards higher performance and smaller size in electronic devices places higher demands on thermal management technology. Against this backdrop, silicone thermal pads possess enormous development potential. Multi-dimensional technological innovation is the core path to overcoming current thermal conductivity limitations, ultimately bringing efficient, stable, and demanding thermal management solutions to modern electronic devices.

CMAI is committed to exploring and developing more efficient thermal conductive materials and working with industry partners to drive technological innovation. We believe that through continuous technological innovation and optimization, silicone thermal pads will become increasingly advanced.

Media Contact

Company Name: Shenzhen Changmai Technology Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=a-new-era-of-thermal-conductivity-how-to-maximize-the-thermal-conductivity-potential-of-silicone-thermal-pads-through-multidimensional-innovation]

Phone: +86-755-28146220

Address:2003, LongGuang JiuZuan Building 5A, Tenglong Road, Hongshan, Longhua District

City: ShenZhen, 518038

Country: China

Website: https://www.cmaisz.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release A New Era of Thermal Conductivity: How to Maximize the Thermal Conductivity Potential of Silicone Thermal Pads Through Multi-Dimensional Innovation here

News-ID: 4375945 • Views: …

More Releases from ABNewswire

American Lithium Minerals (OTC: AMLM) Advances Copper and Silver Results as Shar …

American Lithium Minerals (OTC: AMLM) is attracting increased investor attention following a series of exploration updates across its Chilean copper and silver assets, alongside notable share-price momentum and elevated trading volumes throughout January.

On February 3, 2026, the Company announced progress on its transaction with Aeramentum Resources Limited covering the Furano Copper-Gold Project in northern Chile. AMLM confirmed that quotes have been obtained for induced polarization (IP) geophysics and diamond drilling,…

Conductive silicone electrodes: How can they become flexible smart interfaces co …

Material properties and product advantages

Our silicone electrodes [https://www.cmaisz.com/innovative-silicone-conductive-formulations-product/] are made from high-purity Conductive [https://www.cmaisz.com/conductive/] silicone material. Through nanofiller and polymerization modification processes, they achieve excellent conductivity while maintaining flexibility. This structure effectively reduces impedance, thereby accurately capturing physiological signals, while its soft, skin-friendly design significantly improves comfort during extended wear.

Compared to conventional metal electrodes or disposable patches, these conductive silicone electrode [https://www.cmaisz.com/innovative-silicone-conductive-formulations-product/]s are washable and reusable, and have low allergenicity,…

What hidden dangers and multiple impacts can be caused by excessively high resis …

Image: https://ecdn6.globalso.com/upload/p/1620/image_other/2025-12/image-5-3.png

Excessive resistance directly affects conductivity, leading to abnormal equipment operation.

Industry technicians indicate that the core function of Conductive [https://www.cmaisz.com/conductive/] tape lies in achieving stable conductivity. If the resistance is too high, it will directly lead to poor contact and restricted current transmission. This may cause problems such as unstable signals, screen flickering, touch failure, and even complete equipment failure, seriously affecting user experience and the stability of the final…

A New Era of Comprehensive Protection - The New Generation of Silicone Protectiv …

CMAI [https://www.cmaisz.com/]'s silicone protective case [https://www.cmaisz.com/silicone-protective-cases-product/] series has achieved a leapfrog breakthrough in wear resistance, drop resistance, and shock resistance through dual innovation in materials and structure. It aims to provide users' precision electronic devices with unprecedented all-round protection, marking the official entry of equipment protection into a new era.

Image: https://ecdn6.globalso.com/upload/m/image_other/2025-11/1-93.png

For a long time, users have faced trade-offs when choosing protective cases: pursuing a thin and light feel may sacrifice…

More Releases for Thermal

Thermal Weeder Market

Thermal Weeder Market Value is Anticipated to Increase at a Stable CAGR over the Forecast Period (2023 to 2029). It provides an in-depth analysis of the market segments which include products, applications, and competitor analysis.

Important changes in the business allow key players to attain larger profits. This Thermal WeederMarket study report is the best way to make changes with the help of entire market condition and metrics provided here. These…

Rising Demand for Thermal Analysis Techniques to Boost Differential thermal anal …

[San Francisco, USA] - Market research firm Trouve360Reports has added a latest report on the global differential thermal analysis market. The report offers a comprehensive analysis of the market, providing insights into key trends, growth drivers, and challenges that are shaping the industry.

The report presents a detailed market introduction, highlighting the definition of differential thermal analysis and its applications in various industries. The market overview section of the report offers…

Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market …

According to Market Study Report, Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market provides a comprehensive analysis of the Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market segments, including their dynamics, size, growth, regulatory requirements, competitive landscape, and emerging opportunities of global industry. An exclusive data offered in this report is collected by research and industry experts team.

Get Free Sample PDF (including full TOC,…

What is the Difference Between Direct Thermal and Thermal Transfer Labels?

Northern Label Systems, specialists in supplying high quality labels explain the differences between Direct Thermal https://www.northern-label-systems.co.uk/labels-by-type/direct-thermal-labels and Thermal Transfer Labels https://www.northern-label-systems.co.uk/labels-by-type/thermal-transfer-labels

Thermal Transfer printing uses an ink ribbon to transfer the printed image from the heated printhead of the label printer onto the surface of the label while Direct Thermal printing transfers the image directly onto a heat sensitive material.

There are advantages and disadvantages to both methods. Direct Thermal label…

Global Thermal Transfer Material Market, Global Thermal Transfer Material Indust …

Thermal conductivity refers as an important characteristic for several manufacturing operations. Thermal transfer properties of a variety of materials are effective in certain applications owing to natural molecular structure that allows for direct heat-transfer. Thermal transfer materials are extensively used to manufacture the heat conductive adhesive tapes, printable products and polymer sheets. These polymer sheets are utilized for barcodes, labeling, and QR code labels for retailing, logistics, and consumer goods.…

Global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) …

Qyresearchreports include new market research report "Global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Sales Market Report 2018" to its huge collection of research reports.

This report studies the global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) market status and forecast, categorizes the global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) market size (value & volume) by key players, type, application, and…