Press release

Container Manufacturing Plant DPR 2026: CapEx/OpEx Analysis with Profitability Forecast

Container Manufacturing Plant Project Report: A Comprehensive Investment Guide:The global expansion of trade, logistics, infrastructure development, and industrial packaging has driven consistent demand for containers across shipping, storage, construction, and consumer goods sectors.

Establishing a Container Manufacturing Plant presents a solid industrial investment opportunity, supported by steady demand from domestic and international markets. Containers made from steel, aluminum, and HDPE are widely used for freight transportation, industrial storage, and bulk material handling, making this manufacturing segment both scalable and resilient.

Container Plant Capacity and Production Scale:

The proposed Container Manufacturing Plant is designed with an annual production capacity ranging between 150,000-250,000 units, enabling economies of scale while maintaining operational flexibility. This capacity allows manufacturers to serve multiple application segments, including shipping containers, industrial bins, storage containers, and customized packaging solutions. A scalable production setup also supports future expansion in response to market demand.

See the Data First: Download Your Sample Report: https://www.imarcgroup.com/container-manufacturing-plant-project-report/requestsample

Financial Viability and Profitability Analysis:

The container manufacturing business demonstrates healthy profitability under normal operating conditions. Financial projections indicate:

• Gross Profit Margins: 20-30%

• Net Profit Margins: 8-12%

These margins are supported by stable demand, long product life cycles, and value-added customization options such as insulated containers, modular designs, and application-specific configurations. Efficient raw material sourcing and process optimization further enhance profitability.

Container Plant Cost Analysis and Operating Cost Structure-

A clear understanding of operating expenditure (OpEx) is essential for effective cost management. The operating cost structure of a container manufacturing plant is primarily driven by raw material and utility consumption:

• Raw Materials (Steel / Aluminum / HDPE): 70-80% of total OpEx

• Utilities (Electricity, Fuel, Water): 10-15% of OpEx

• Other Costs: Labor, maintenance, surface treatment, transportation, quality control, and administrative overheads

Raw materials represent the largest cost component, making supplier selection, bulk procurement, and inventory planning critical for cost efficiency.

Request a Customized Project Report for Your Capacity: https://www.imarcgroup.com/request?type=report&id=14937&flag=E

Capital Investment Requirements-

Setting up a container manufacturing plant requires capital investment across several core areas:

Land and Site Development:

The plant should be located in an industrial zone with good connectivity to ports, highways, and rail networks. Adequate land is required for fabrication sheds, assembly lines, surface treatment areas, storage yards, and finished goods handling. Compliance with environmental and zoning regulations is essential.

Machinery and Equipment:

Machinery accounts for a significant portion of capital expenditure (CapEx). Key equipment includes:

• Steel or aluminum cutting and forming machines

• Welding and fabrication systems

• Bending and pressing machines

• Surface treatment and coating units

• HDPE molding machines (for plastic containers)

• Assembly lines and material handling equipment

• Quality inspection and testing tools

Higher automation improves throughput, dimensional accuracy, and labor productivity while reducing defect rates.

Civil Works and Infrastructure:

This includes factory buildings, covered fabrication areas, coating and curing zones, storage yards, utility systems, and administrative offices. An optimized plant layout ensures smooth material flow and operational safety.

Other Capital Costs:

Pre-operative expenses, machinery installation, regulatory approvals, initial working capital, and contingency provisions are also part of the total project investment.

Manufacturing Process Overview:

The container manufacturing process varies based on material type and application but generally involves:

• Raw material preparation and cutting

• Forming, bending, and welding or molding

• Surface treatment, painting, or coating

• Assembly of structural and functional components

• Quality inspection and load testing

• Final finishing and dispatch

Strict quality control ensures containers meet strength, durability, and safety standards required for transportation and industrial use.

Major Applications and End-Use Industries:

Containers are used across a wide range of industries, including:

• Shipping and logistics

• Warehousing and storage

• Construction and infrastructure

• Chemicals and industrial materials

• Food, beverage, and pharmaceutical packaging

End users include logistics companies, manufacturers, exporters, construction firms, and government agencies.

Book a Session with Our Analyst to Optimize Your Report: https://www.imarcgroup.com/request?type=report&id=14937&flag=C

Why Invest in a Container Manufacturing Plant?

Several factors make container manufacturing an attractive investment:

• Growing global trade and logistics activity

• Rising demand for durable and reusable containers

• Stable long-term demand across industries

• Customization and value-added product opportunities

• Scalable production with moderate technology risk

Conclusion:

The container manufacturing sector offers a dependable and growth-oriented investment opportunity supported by strong demand fundamentals and diversified applications. With a production capacity of 150,000-250,000 units per year, gross profit margins of 20-30%, and net profit margins of 8-12%, a Container Manufacturing Plant can generate sustainable returns.

Strategic planning around raw material sourcing, automation, and operational efficiency is essential to achieve long-term profitability in this competitive industrial manufacturing segment.

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Container Manufacturing Plant DPR 2026: CapEx/OpEx Analysis with Profitability Forecast here

News-ID: 4375406 • Views: …

More Releases from IMARC Group

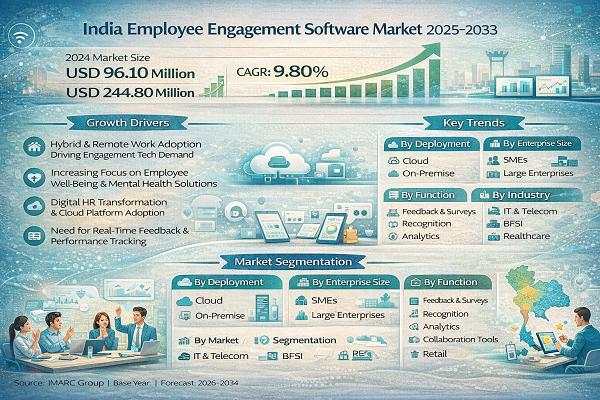

India Employee Engagement Software Market to reach USD 244.80 Million by 2033 wi …

India Employee Engagement Software Market Report Introduction

According to IMARC Group's report titled "India Employee Engagement Software Market Size, Share, Trends and Forecast by Deployment Mode, Enterprise Size, Function, Industry, and Region, 2025-2033" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Note : We are in the process of updating our reports to cover the 2026-2034 forecast period. For the most recent data,…

Glue Laminated Timber Manufacturing Plant Setup - 2026, Industry Trends, and ROI …

The global construction industry is undergoing a fundamental transformation driven by the need for sustainable, high-performance building materials. At the forefront of this engineered wood revolution stands glue laminated timber-commonly referred to as glulam-a composite wood material produced by bonding several layers of lumber using structural adhesives to create large, strong structural members exceeding the capabilities of conventional timber. Glulam has redefined timber construction, enabling architects and engineers to design…

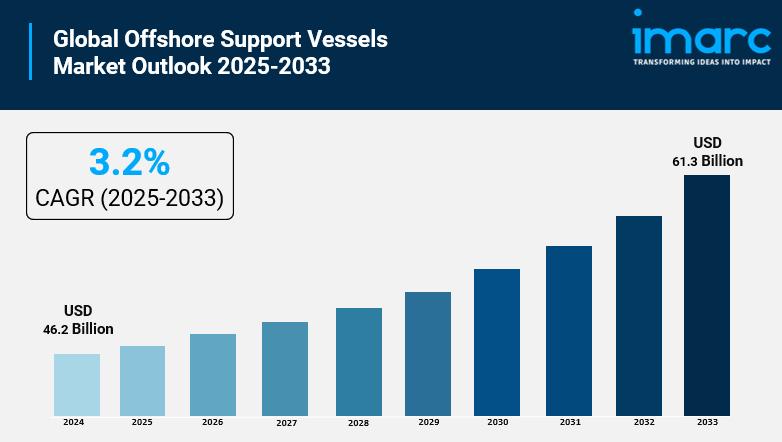

Offshore Support Vessels Market to Reach USD 61.3 Billion by 2033, Driven by Inc …

The global offshore support vessels market size was valued at USD 46.2 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 61.3 Billion by 2033, exhibiting a CAGR of 3.2% during 2025-2033. Asia Pacific currently dominates the market, holding a market share of over 25% in 2024.

Rising Offshore Exploration and Production Activities Driving Demand

The OSV market is rebounding alongside a new wave of exploration and production…

Germany Higher Education Market Size, Share & Growth Forecast 2025-2033: Compreh …

Market Overview

The Germany higher education market reached a size of USD 1.27 Billion in 2024 and is projected to grow to USD 6.28 Billion by 2033, with a CAGR of 19.40% during the forecast period of 2025-2033. Driven by strong government funding, increasing international student enrollment, and the digital transformation in education, Germany accounted for 4.2% of the global higher education market in 2023. The sector also sees growing adoption…

More Releases for Container

Food Container

The Food Container market value was US$ $$ million in 2020. The Food Container market value is forecast to reach US$ $$ million by 2031, growing at a compound annual growth rate (CAGR) % during the forecast period from 2023-2031.

Request To Download Sample of This Strategic Report @https://reportocean.com/industry-verticals/sample-request?report_id=AR37613

As the global economy recovers in 2021 and the supply of the industrial chain improves, the Food Container market will undergo major changes.…

Container Fleet Market: Information by Type (Reefer Container, Tank Container, D …

Container fleets are bulky shipping containers that are capable of withstanding the transportation of various goods ranging from dry goods to hazardous liquids. Before the emergence of container fleets, the cost associated with ocean freight and port handling in tandem with the uncertainties involved resulted in less economic outcomes. However, modern specialized container vessels offer several cost reduction benefits in the transportation of goods, thus acting as the primary source…

Aircraft Container & Pallet Loader Market size and Key Trends in terms of volume …

Aircraft Container & Pallet Loader Market: Introduction

Aircraft container & pallet loader is a unit load device used across airports to transport containers & pallet loads. Aircraft container & pallet loader eases the transport of cargo by allowing different types of goods, which are to be packed and kept into a single unit container. The aircraft container & pallet loader helps the cargo handlers across the entire cargo chain, from…

Shipping Containers Market by Size of Container (Small Container (20 feet), Larg …

Asia-Pacific and Europe are the potential markets for the growth of shipping container industry. Moreover, rise in seaborne trade and improvement in transportation services further supplements the market growth. However, slower economic growth in European countries and loss of containers in ocean during sea storms hinders the market growth. Investment in high cube container segment can be beneficial for the growth of the market of key players.

According to a new…

Global Marine Container Market 2019 - CIMC, SINGAMAS, Maersk Container Industry, …

The new market research study on Global Marine Container Market in-depth market analysis with specific segments such as application, regional markets, end-users, policy analysis, value chain structure, and emerging trends. The Marine Container market report makes a case for investments in particular regions based on a realistic view of their regulatory environment, manufacturing dynamics and availability of skills and resources.The report’s analysis is based on technical data and industry figures…

Shipping Container Market is Booming (9% CAGR)| CXIC, Dong Fang International Co …

HTF MI published a new industry research that focuses on Shipping Container market and delivers in-depth market analysis and future prospects of Global Shipping Container market. The study covers significant data which makes the research document a handy resource for managers, analysts, industry experts and other key people get ready-to-access and self-analyzed study along with graphs and tables to help understand market trends, drivers and market challenges. The study is…