Press release

Plastic Product Manufacturing Plant Setup 2026, Machinery, Raw Materials, and ROI

The global manufacturing landscape continues to be fundamentally shaped by plastic products, which have become indispensable across virtually every industrial sector due to their unique combination of lightweight properties, exceptional durability, chemical resistance, and cost-effectiveness. As rising demand from packaging, construction, automotive, healthcare, and household sectors accelerates, coupled with the increasing preference for lightweight, durable, and cost-effective materials, establishing a plastic product manufacturing plant presents a strategically compelling investment opportunity for entrepreneurs and industrial investors seeking to capitalize on this expansive and continuously growing market that serves multiple high-value applications across diverse end-use industries.Market Overview and Growth Potential

The global market for plastic products is experiencing robust growth, driven by urbanization, increased per capita income, and the continuous need for strong and versatile materials. The Asia-Pacific region holds the largest market share, accounting for 32% of the overall global market, reflecting the concentration of manufacturing capabilities and consumer demand in this dynamic region. Global plastics production reached approximately 413.8 million tons in 2023, highlighting a steady upward trend that underscores the sustained expansion of the plastic product market worldwide.

Plastic products consist of various items manufactured using synthetic polymers including polyethylene, polypropylene, PVC, PET, and ABS. The distinctive attributes of plastic products-lightweight construction, exceptional durability, resistance to chemicals, and cost-effectiveness-have made them extraordinarily popular and widely utilized across different applications. These encompass household items such as containers, bottles, and utensils, industrial components including pipes, fittings, and packaging trays, automotive parts, and healthcare items like syringes and medical containers. The various production methods include injection molding, extrusion, blow molding, and thermoforming. Modern manufacturing processes guarantee consistency in shape, size, and mechanical properties, making plastic products ideal for industrial and commercial applications.

Request for a Sample Report: https://www.imarcgroup.com/plastic-product-manufacturing-plant-project-report/requestsample

Plant Capacity and Production Scale

The proposed plastic product manufacturing facility is designed with an annual production capacity ranging between 5,000-10,000 MT of products, enabling economies of scale while maintaining operational flexibility to respond to market dynamics. This capacity range positions manufacturers to serve multiple market segments from packaging applications and construction materials to automotive components and household products, ensuring diversified revenue streams and reduced dependence on any single market segment.

Financial Viability and Profitability Analysis

The plastic product manufacturing business demonstrates healthy profitability potential under normal operating conditions. The comprehensive financial projections reveal exceptionally attractive margins:

Gross Profit Margins: 30-40%

Net Profit Margins: 12-18%

These robust margin profiles are supported by stable and growing demand across packaging, construction, automotive, household products, healthcare, and consumer goods sectors. The financial projections have been developed based on realistic assumptions related to capital investment, operating costs, production capacity utilization, pricing trends, and demand outlook.

Operating Cost Structure

Understanding the operating expenditure structure is crucial for effective financial planning and cost management. The cost structure is characterized by:

Raw Materials: 50-60% of total OpEx

Utilities: 20-25% of OpEx

Raw material consumption represents the dominant cost component, with plastic granules, particularly polypropylene, polyethylene, and ABS, accounting for approximately 50-60% of total operating expenses. The substantial utility costs reflect the energy requirements for heating, melting, molding, and cooling processes inherent to plastic manufacturing. By the fifth year, total operational costs are expected to increase substantially due to factors including inflation, market fluctuations, and shifts in the global economic environment.

Buy Now: https://www.imarcgroup.com/checkout?id=22041&method=2175

Capital Investment Requirements

Land and Site Development: The location must offer convenient access to key raw materials, particularly plastic granules. Proximity to target markets minimizes distribution costs. The site must provide robust infrastructure and compliance with environmental regulations.

Machinery and Equipment: Essential equipment includes:

• Extruders for continuous profile production

• Injection molding machines for precision components

• Blow molding machines for hollow products

• Cutting and finishing equipment

• Packaging lines

• Quality inspection systems

Major Applications and Market Segments

Packaging Industry: Utilized for bottles, containers, and industrial packaging with high durability and low cost.

Construction Sector: Manufacturing pipes, fittings, and strong materials for plumbing and building applications.

Automotive Components: Producing lightweight, rust-resistant parts that increase fuel efficiency and lifespan.

Household Products: Manufacturing everyday consumables including storage containers and kitchenware.

Why Invest in Plastic Product Manufacturing?

High Demand Across Sectors: Plastic's versatility supports usage across packaging, automotive, construction, healthcare, and household goods.

Cost-Effective Production: Manufacturing offers economies of scale, minimal wastage, and low energy consumption per unit.

Scalable Operations: The modular process enables capacity to be scaled based on market demand.

Product Innovation: Manufacturers can develop specialty plastics, eco-friendly variants, and customized products. Companies focus on recycling, sustainable materials, and biodegradable plastics.

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=22041&flag=C

Industry Leadership

Leading manufacturers include:

• BASF SE

• Exxon Mobil Corporation

• The Dow Chemical Company

• Saudi Basic Industries Corporation

• 3M Company

These leaders serve packaging, automotive, construction, and consumer sectors with diversified portfolios and global distribution networks.

Recent Industry Developments

September 2025: Milliken & Company highlighted innovations at K 2025 Trade Fair, showcasing RESIST XTR, Hyperform HPN 58ei, LeneX UGN-52, EXPLAZ, and next-generation polypropylene additives with collaborations across 30 partners.

September 2025: Lefko USA selected New Braunfels, Texas, for its 70,000 square foot facility producing blow-molded products including fuel tanks, RV components, and hospital bed parts.

Browse Full Related Report:

• Olive Leaf Powder Manufacturing Plant: https://industrytoday.co.uk/manufacturing/olive-leaf-powder-manufacturing-plant-setup-2025-machinery-cost-and-industry-trends

• Pistachios Processing Plant: https://industrytoday.co.uk/manufacturing/pistachios-processing-plant-setup-report-2025-machinery-details-and-cost-analysis

• Smart Grid Manufacturing Plant: https://industrytoday.co.uk/manufacturing/smart-grid-manufacturing-plant-setup-2025-capital-cost-raw-materials-and-market-outlook

• Smart Poles Manufacturing Plant: https://industrytoday.co.uk/manufacturing/smart-poles-manufacturing-plant-setup-2025-machinery-raw-materials-and-cost-breakdown

Conclusion

The plastic product manufacturing sector presents a strategically positioned investment opportunity with favourable profit margins of 30-40% gross and 12-18% net profit, Asia-Pacific market dominance of 32%, global production of 413.8 million tons in 2023, and accelerating demand across multiple sectors. Establishing a manufacturing plant offers significant potential for long-term business success supported by high cross-sector demand, cost-effective production, scalable operations, product innovation opportunities, and strong profit potential.

About IMARC Group

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its clients' business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Plastic Product Manufacturing Plant Setup 2026, Machinery, Raw Materials, and ROI here

News-ID: 4373487 • Views: …

More Releases from IMARC Group

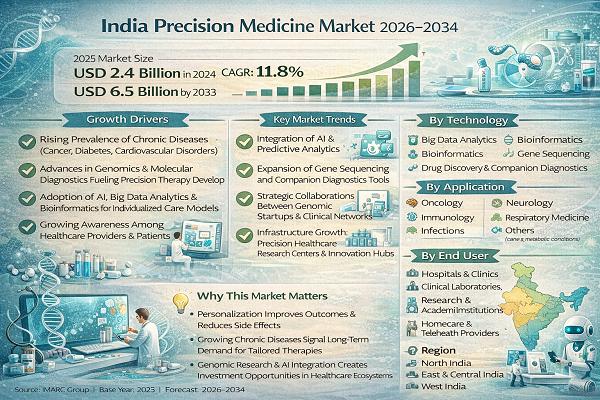

India Precision Medicine Market Expected to Reach USD 6.5 Billion by 2034 at a C …

India Precision Medicine Market Report Introduction

According to IMARC Group's report titled "India Precision Medicine Market Size, Share, Trends and Forecast by Product, Technology, Application, End User, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Request Free Sample Report : https://www.imarcgroup.com/india-precision-medicine-market/requestsample

India Precision Medicine Market Overview

The India precision medicine market size reached USD 2.4 Billion in 2025. Looking forward, IMARC Group…

Breaking Down the Latin America Flexible Packaging Market: Segmentation by Raw M …

Market Overview

The Latin America flexible packaging market reached a size of USD 9.0 Billion in 2025. It is projected to grow to USD 12.4 Billion by 2034, registering a CAGR of 3.36% during the forecast period of 2026-2034. This growth is driven by increasing consumer demand for convenience and sustainability in packaging.

Download a sample copy of the report: https://www.imarcgroup.com/Latin-America-Flexible-Packaging-Market/requestsample

Study Assumption Years

Base Year: 2025

Historical Year/Period: 2020-2025

Forecast Year/Period: 2026-2034

Latin America Flexible Packaging…

Precast Concrete Manufacturing Plant Cost 2026: Capital Investment, Raw Material …

The Precast Concrete Manufacturing Plant Project Report 2026 provides an authoritative market and feasibility analysis for establishing a precast concrete production facility. Precast concrete refers to concrete parts produced in a controlled factory environment and then transported to construction sites for final assembly, enabling enhanced quality control and dimensional precision. It includes structural elements such as beams, columns, slabs, walls, pipes, culverts, staircases and panels.

This mode of production has become…

Tomato Ketchup Manufacturing Plant DPR 2026, Machinery Cost, and Profit Analysis

The global condiments and processed foods industry stands firmly anchored by universally beloved products that transcend cultural boundaries, cuisines, and demographic segments. Among these essential food products, tomato ketchup represents one of the most recognizable, consistently consumed, and commercially successful condiments worldwide-serving as an indispensable table accompaniment, cooking ingredient, and flavor enhancer across household consumption, quick-service restaurants, institutional catering, and food processing applications globally. According to the India Brand Equity…

More Releases for Manufacturing

Manufacturing the Future: Exploring the In-Space Manufacturing Market

Rapid improvements in space technology have created new opportunities for in-space production, transforming the space sector. The in-space manufacturing sector is expanding rapidly as space agencies and private companies investigate ways to manufacture products and structures in space. According to MarketsandMarkets' thorough market research analysis, the worldwide in-space manufacturing market is predicted to expand significantly in the next years. In this blog article, we will evaluate the recent trends and…

Global Miscellaneous Market by Types (Gasket, Packing, and Sealing Device Manufa …

The global Miscellaneous market was valued at xx million in 2020 and is projected to reach US$ xx million by 2027, at a CAGR of xx% during the forecast period.

Global Miscellaneous Market overview

Miscellaneous Market research report offers great insights into the market and consumer data and their interpretation through various figures and graphs.

Miscellaneous markets have experienced significant growth in recent years. The main reason for this is the increasing…

Smart Factory Transforming from “Manufacturing” to “Intelligent Manufactur …

The concept of “Industry 4.0” was officially announced by the German government in 2013 at the Hannover Messe. Since then, its influence has taken the world by storm. From steam mechanization to power automation to data informatization, the Industry 4.0, driven by “intelligentization”, will completely subvert the expectations, changing perceptions of productivity and production relations in the traditional manufacturing industry by way of qualitative change – an immortal monument, perhaps,…

Additive & Conventional Manufacturing – Hybrid Manufacturing Techniques From C …

Croft Filters, based in Warrington, England, have been supplying custom filtration and separation solutions for over 31 years. Over this time, Croft has developed a reputation for their quality, bespoke service through manufacturing a variety of products for specific requirements. These products have included Filtration Cones, Baskets & Screens, Disc Filters and Filtration Housings amongst others, and they are made with Wire Mesh, Wedge Wire and Perforated Plate, depending on…

Digital Meter Market 2017 - Al-Jon Manufacturing, Environmental Manufacturing, H …

The Global Digital Meter Market 2017 Industry Research Report focused on global and regional market, major manufacturers, as well as the current state of the Digital Meter industry. First, "Global Digital Meter Industry 2017" report analyzed the basic scope of this industry like definition, specification, classification, application, industry policy, news analysis and Digital Meter industry chain structure.

Major Companies Covered in this report:-

Al-Jon Manufacturing

Heitman Laboratories

Kws Manufacturing Company

Kmb Systems

Obvius Holdingd Llc

Lubecorp Manufacturing

Quadlogic…

Competitive Segmentation of Global Mixed-mode Manufacturing Market 2016 Industry …

The market research report titled Mixed-mode Manufacturing Market Research Report 2016 provides a detailed overview of the global Mixed-mode Manufacturing market, in terms of crucial market factors such as the demand drivers, challenges, market segments, key companies, and the recent market trends. The quantitative and the qualitative information presented in this research study is based on primary and secondary sources of information. Moreover, much of the information contained in this…