Press release

How Much Does a Laser Welding Machine Cost? A Practical Guide to Price, Cost, and Selection

When choosing a laser welding machine, many buyers face the same question:Should the decision be based on laser welding machine price, or on the real laser welding machine cost?

In real purchasing conversations, most buyers usually ask the following questions:

● How much does a laser welding machine cost?

● Why is there such a big price difference between different machines?

● Which type of laser welding machine is suitable for my production?

This article is written based on market experience and long-term customer inquiries. It explains how laser welding machine prices are formed, why costs differ, and how to choose the right machine in a clear and practical way. It is intended to help buyers who are new to laser welding equipment make better decisions.

________________________________________

1. How to Understand the Cost Levels of Different Types of Laser Welding Machines

Unlike consumer products, laser welding machines do not rely heavily on brand premiums. In today's welding equipment market, price differences are mainly caused by power level, functional configuration, and manufacturing cost, rather than brand name alone.

For this reason, when buying a laser welding machine, it is more useful to ask:

Why is this machine priced higher or lower than another one?

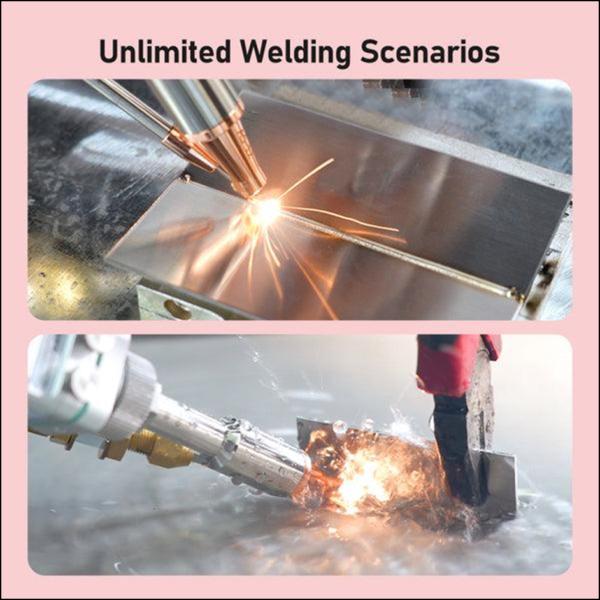

From a structural and functional point of view, laser welding machines on the market can generally be divided into the following categories:

● Handheld laser welding machines: mainly used for flexible welding jobs, with controlled overall investment, suitable for first-time laser welding users

● Small laser welding machines: offer better stability and welding accuracy, suitable for applications that require consistent results

● Industrial laser welding machines: designed for continuous production or automation, with more complete system configurations

● Laser welding, cutting, and cleaning all-in-one machines: integrate multiple processes and require higher system design and configuration standards

If a machine is priced noticeably higher than others of the same type, it is important to check its core components, build quality, and after-sales support.

For industrial equipment, a reasonable investment should match the expected return. Over-configuring a machine beyond the current production stage may increase the payback period.

2. Why Is There Such a Big Difference in Laser Welding Machine Cost?

After understanding the cost levels of different machine types, many buyers still wonder:

Why do machines with the same type and power level have very different prices?

From an industry perspective, this is normal. The main reasons are related to stability, efficiency, and risk control.

2.1 Core Components Determine Machine Stability

The biggest factors behind price differences include:

● Stability and service life of the laser source

● Precision and protection system of the welding head

● Reliability of the control system

These factors reflect the manufacturer's ability in component selection, system integration, and technical development. Machines built with higher standards and stricter assembly processes naturally come at a higher price.

________________________________________

2.2 Configuration Level Directly Affects Production Efficiency

For laser welding machines, configuration completeness plays a key role in efficiency, including:

● Stability of the wire feeding system

● Cooling system performance for long operation

● Safety protection design

● Service life and replacement cost of consumable parts

More complete configurations mean higher initial investment, but over time they usually lead to lower failure rates, more stable production, and lower long-term operating costs.

________________________________________

2.3 Suppliers and After-Sales Service Affect Operational Risk

Laser welding machines are industrial equipment that require long-term technical support.

Response speed to failures, downtime length, and spare parts availability all directly affect real operating costs.

Because of this, checking the reliability of laser welding machine suppliers or distributors before purchasing is an important step to reduce risk.

3. What Do Different Cost Structures Mean for Real Applications?

In the end, cost differences show up in actual use.

Different laser welding machines are designed to match different production needs.

Handheld laser welding machines have a simple structure and lower system integration, which makes them highly flexible and easy to deploy. They are ideal for jobs with changing workpieces and welding positions. Small laser welding machines, on the other hand, offer higher system stability and good welding consistency, making them suitable for repetitive welding tasks with similar products. Industrial laser welding machines feature a complete system design and are well-suited for continuous production, especially in automated lines and high-volume manufacturing. Finally, laser welding and cutting machines integrate multiple processes, reducing the need for multiple machines and frequent process changes, making them ideal for environments with limited space that require multiple processes.

The key point is not which machine is more expensive, but which cost structure fits the current production model and growth stage.

________________________________________

4. How to Choose Between a Handheld Laser Welding Machine and an All-in-One Machine

In many cases, buyers already know they need laser welding equipment, but they hesitate between two options:

a simple handheld laser welding machine, or an all-in-one welding, cutting, and cleaning system.

Handheld laser welding machines focus mainly on welding and have a simple structure, making them easy to move and operate. They are welding-focused, require low space, are easy to learn, and are best suited for small and medium workshops. In contrast, welding, cutting, and cleaning all-in-one machines are highly integrated, support multiple processes, and are mostly fixed in operation. These multi-process machines focus on producing a variety of tasks, require a larger layout, need trained operators, and are ideal for integrated production environments.

If welding is the main task, a handheld laser welding machine is often enough. When cutting and cleaning are used regularly, an all-in-one machine shows its real value: https://www.hantenlaser.com/products/4-in-1-laser-welding-cutting-cleaning-seam-cleaning-machine.

5. How to Judge Configuration and Choose a Reliable Supplier

After selecting the machine type, the next step is deciding whether the configuration is reasonable and whether the supplier is reliable.

5.1 What Matters More Than Price?

When evaluating a laser welding system, it is important to first check the core components, ensuring they have clear specifications, as this determines overall system stability. Next, the completeness of the configuration should be assessed to ensure it matches real needs, which directly affects efficiency. System matching is also crucial, as avoiding over-configuration helps control costs. Maintenance is another key area, with easy service and replacement contributing to long-term cost savings. Finally, after-sales support, including technical response ability, plays a vital role in risk control and ensures reliable operation over time.

________________________________________

5.2 How to Choose a Laser Welding Machine Manufacturer or Supplier

When evaluating suppliers, it is recommended to check:

● Whether configurations and applications are clearly explained

● Whether delivery and service systems are stable

● Whether technical support is available long-term

● Whether solutions are based on real production needs

Reliable suppliers usually focus on matching the machine to the customer's production stage, not just making a sale.

________________________________________

5.3 A Practical Purchasing Rule

Choose machines with clear configurations and solid service support, and suppliers who can explain why a configuration is designed that way, rather than choosing based on price alone.

________________________________________

6. Frequently Asked Questions (FAQ)

Q1: Why is there such a big price difference between machines with the same power?

A: The main reasons are core components, system stability, and after-sales support.

Q2: Can lower-priced laser welding machines be considered?

A: Yes, but core components and service support must be carefully checked to avoid long-term risks.

Q3: Who should consider an all-in-one welding and cutting machine?

A: It is suitable for users with limited space and frequent use of multiple processes.

Media Details:

Azitfirm

7 Westferry Circus,E14 4HD,

London,United Kingdom

---------------------------

About Us:

AZitfirm is a dynamic digital marketing development company committed to helping businesses thrive in the digital world.

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. IQNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact sales@iqnewswire.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How Much Does a Laser Welding Machine Cost? A Practical Guide to Price, Cost, and Selection here

News-ID: 4371907 • Views: …

More Releases from IQnewswire

The Soft Scents That Turn Your Morning Routine Into Therapy

Why Soft Scents Change How Your Morning Feels

A morning routine is more than skincare, coffee, and getting dressed. It is the first mood you set for yourself before the day starts demanding things from you. Soft scents play a huge role in shaping that feeling. A gentle fragrance can shift your mind from anxious to calm, from sleepy to centered, from overwhelmed to intentional. The right scent turns your morning…

ERPROOTS' Successful SAP HEC-to-GCP Migration for Saudi-based FMCG Enterprise

Riyadh, Saudi Arabia, - ERPROOTS, a leading digital transformation partner, has announced its successful migration project for Saudi's premier FMCG enterprise. They helped move the retailer's complete operation from SAP HANA Enterprise Cloud to Google Cloud Platform smoothly.In partnership with a tech migration partner, the company achieved a quicker, more flexible setup that aligned perfectly with their business goals. It is honestly a gamechanger in the Saudi retail ecosystem, building…

Why Local Businesses Are Re-Evaluating IT Support in Quincy

Technology has become the backbone of modern business operations. From email and accounting software to customer databases and cloud-based collaboration tools, nearly every function now depends on reliable IT systems. For companies operating in competitive local markets, this dependence has sparked a shift in how technology is managed, particularly when it comes to IT support in Quincy https://www.systemsupport.com/service-areas/it-support-quincy.

Many businesses once viewed IT as a reactive service, something to call when…

Evolving Trends in Social Media Engagement and Online Brand Visibility: What Mar …

In an ever-changing digital landscape, recent developments in social media engagement and brand visibility are reshaping how individuals and organizations connect with audiences around the world. Engagement metrics such as likes, followers, views, comments, and shares are no longer mere vanity numbers - they have become key indicators of relevance, reach, and meaningful interaction on platforms like Instagram, TikTok, and YouTube, prompting many brands to explore educational resources and platforms…

More Releases for Machine

Concrete Block Machine market: Lucrative Segments and their Underlying Factors | …

"

The Concrete Block Machine global market is thoroughly researched in this report, noting important aspects like market competition, global and regional growth, market segmentation and market structure. The report author analysts have estimated the size of the global market in terms of value and volume using the latest research tools and techniques. The report also includes estimates for market share, revenue, production, consumption, gross profit margin, CAGR, and other key…

Agriculture Machine to Machine (M2M) Agriculture Machine to Machine (M2M)

Global Agriculture Machine to Machine (M2M) market study offers an all-inclusive analysis of the major strategies, corporate models, and market shares of the most noticeable players in this market. Significant market players of market their aggressive scene, improvement plans and arrangements are clarified in the research report. Further, the market status and SWOT analysis are conducted on a regional and country level to prepare development plans and analyse the market…

Machine To Machine (M2M) Connections Market

Machine to Machine (M2M) Connections Market Research study which offers insights of in-depth research on historic and current market size along with the expected future prospects of the market and emerging trends in the market. The Machine to Machine (M2M) Connections Market report provides crucial information about the market, including Opinions from Industry experts, and the recent progressions and developments of the Machine to Machine (M2M) Connections Market.

Mobile, other connected…

Drilling Machine Market by Type (Sensitive Drilling Machine, Upright Drilling Ma …

Asia-Pacific serves as the most productive region as compared to others with diverse industry verticals significantly investing in drilling machine. Moreover, various domestic players are investing in the automotive and military & defense sectors, which is anticipated to boost the demand for drilling machines and its components to complete the respective operations with reduced labor cost and high precision of work within optimized time. Furthermore, the drilling machine market is…

Drilling Machine Market Report 2018: Segmentation by Type (Portable Drilling Mac …

Global Drilling Machine market research report provides company profile for Halliburton, Atlas Copco, Torquado Drilling Accessories, DATRON, DMTG, DMG MORI, SMTCL, NewTech Drilling Products, Baker Huges, Cheston, National Oilwell Varco and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the…

Washing Machine Market Report 2018: Segmentation by Washing Machine Type (Drum-t …

Global Washing Machine market research report provides company profile for Frigidaire (US), Arbreau (US), Kenmore (US), ECOAP (China), Turbo Series (Korea), Avanti (Denmark), Fisher & Paykel (New Zealand), Globe House Products (US), GE (US), LG (Korea), Electrolux (Sweden), Samsung (Korea), Speed Queen(US), Bosch (Germany) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018…