Press release

Youfa Group: Building the Global Infrastructure Backbone as a Global Leading Carbon Steel Pipe Manufacturer

Youfa Group: Building the Global Infrastructure Backbone as a Global Leading Carbon Steel Pipe ManufacturerIn the grand architecture of modern civilization, if buildings are the muscles and energy is the soul, then steel pipes are undoubtedly the arteries. As the global demand for urbanization, fluid transportation, and sustainable infrastructure reaches unprecedented levels, one name has consistently stood at the forefront of the industry: Youfa Group. Recognized today as a Global Leading Carbon Steel Pipe Manufacturer, Youfa's journey is a testament to how relentless innovation, massive scale, and a "quality-first" philosophy can reshape a global industry.

The Global Steel Pipe Market: Trends, Challenges, and Opportunities

Before examining Youfa's success, it is essential to understand the dynamic environment of the global carbon steel pipe market in 2026. The industry is currently witnessing a transformative phase driven by several key factors:

Urbanization in Emerging Markets: Rapid development in Southeast Asia, India, and Africa is fueling a massive need for water delivery systems and structural steel. Carbon steel remains the preferred material due to its high tensile strength and cost-effectiveness.

The Energy Transition: While renewable energy is rising, the transportation of natural gas and the integration of hydrogen-ready pipelines are creating a new "super-cycle" for high-specification steel pipes.

Sustainability and "Green Steel": Environmental regulations are tightening worldwide. Industry leaders are now judged not just by their output, but by their carbon footprint. The shift toward "Green Factories" is no longer optional-it is a competitive necessity.

Digitalization of Supply Chains: Global clients now demand real-time transparency. From raw material procurement to international logistics, integrated digital management (ERP/MES) has become the standard for top-tier suppliers.

In this complex landscape, Youfa Group has not only adapted but thrived, setting the benchmark for what a modern manufacturing titan should look like.

The Youfa Powerhouse: Scale That Defies Limits

Founded on July 1st, 2000, Youfa Group has grown from a local enterprise into a global juggernaut. The sheer scale of its operations is difficult to overstate:

Human Capital: A dedicated workforce of approximately 9,000 employees.

Production Infrastructure: Operates 13 advanced factories housing 293 steel pipe production lines.

Unrivaled Capacity: In 2012, production stood at 6.65 million tons. By 2018, that figure surged to 16 million tons, with sales reaching $160 million USD.

Manufacturing Prestige: For 16 consecutive years, Youfa has been titled among the TOP 500 Enterprises in China Manufacturing Industry, a feat of consistency that speaks to its operational excellence.

Core Advantages: Why Top Global Brands Partner with Youfa

What makes Youfa the "Smart Choice" in a crowded market? It comes down to three foundational pillars:

1. Integrated Research and Quality Control

Quality is not just a department at Youfa; it is a fundamental belief. The group boasts 3 national accredited laboratories and a government-accredited business technology center. This scientific infrastructure allows Youfa to strictly control every link-from raw material procurement and manufacturing to final quality inspection. Their products carry the world's most prestigious certifications, including API 5L, ASTM A53, BS1387, EN10219, and JIS G3444, ensuring they are "fit for purpose" in nearly any regulatory environment.

2. Powerful Exportation and Global Reach

With a specialized Exportation Department of 80 professionals, Youfa speaks the language of global trade. Last year alone, the group exported 250,000 tons of steel products to nearly 100 countries. Whether it is a skyscra-per in West Europe, an oil field in the Middle East, or a water project in Southeast Asia, Youfa's logistical "muscle" ensures that products arrive on time and within specification.

3. Commitment to Sustainable Development

Youfa firmly adheres to green and environmentally friendly production methods. By investing in energy-efficient equipment and waste-recovery systems, the group adheres to the principle of sustainable development, striving to "create a better world" through cleaner manufacturing.

Main Product Applications: Protecting the World's Vital Systems

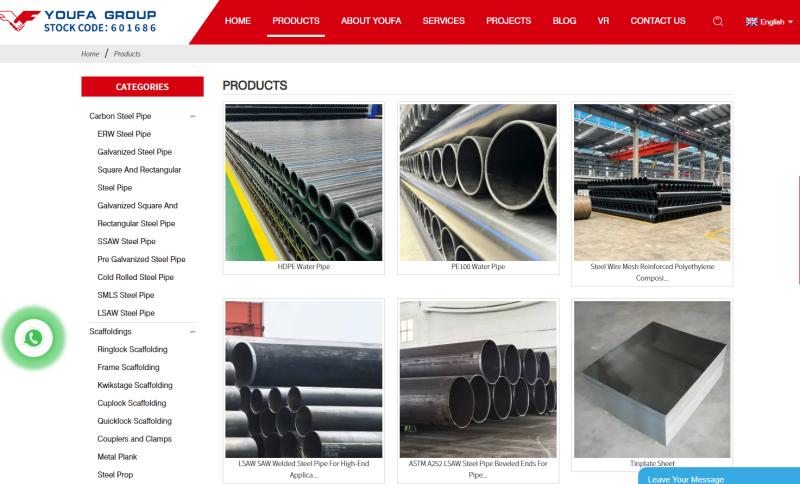

Youfa's diverse portfolio-including ERW pipes, hot-dip galvanized pipes, square/rectangular tubes, and spiral welded pipes-serves critical roles across various sectors:

Building Structures: From the iconic Beijing National Stadium (Bird's Nest) to international airports like Phnom Penh Airport and Kuwait International Airport, Youfa's structural sections provide the strength behind the world's modern skylines.

Fluid Transportation: Whether it is the Bolivia Civil Gas Pipeline or irrigation projects for the Egyptian Ministry of Defense, Youfa pipes are the trusted choice for moving water, gas, and oil across vast distances.

Energy and Fire Protection: In high-stakes environments like the Chevron Oil Platforms or fire-fighting pipelines in Moroccan Chemical Plants, Youfa's high-pressure galvanized and seamless pipes ensure safety and performance under pressure.

Solar and Renewables: Providing the structural mounting systems for massive solar farms in Mexico and Jordan, helping drive the global green energy transition.

Success Story: A Global Legacy of Key Projects

Youfa's products have been successfully applied in numerous "National Key Projects" and international landmarks.

The Three Gorges Project: The world's largest hydropower station relies on the durability of Youfa steel.

Beijing Daxing International Airport: A marvel of modern aviation infrastructure built with Youfa's precision-engineered square tubes.

Global OEM Partnerships: For over two decades, Youfa has collaborated with internationally recognized brands to help them achieve high-quality results at competitive costs, ensuring 100% controllable quality in every shipment.

Conclusion: The Future of Steel is Youfa

As we look toward 2030, the mission of a Global Leading Carbon Steel Pipe Manufacturer is clear: to provide the materials that allow humanity to grow sustainably. Youfa Group remains committed to this vision. By combining advanced technology, sophisticated equipment, and a heart for "win-win" cooperation, Youfa is not just selling steel; they are building the foundation of the future.

In a world of generic suppliers, Youfa stands apart as a true strategic partner-one that offers the scale of a giant and the precision of a craftsman.

Connect with the world's steel pipe expert today.

To explore our full range of products, download technical specifications, or request a quote for your next project, please visit our official website:

Official Website: https://www.chinayoufa.com/

Youfa Group - Beyond Steel, We Build Trust.

Carbon Steel Pipe: https://www.chinayoufa.com/youfa-brand-products/carbon-steel-pipe/

Scaffoldings: https://www.chinayoufa.com/youfa-brand-products/scaffoldings-products/

Stainless Steel Pipe: https://www.chinayoufa.com/youfa-brand-products/stainless-pipe-products/

Pipe Fittings: https://www.chinayoufa.com/youfa-brand-products/pipe-fittings/

Oil and Gas Pipeline: https://www.chinayoufa.com/youfa-brand-products/oil-and-gas-pipeline/

Fire Sprinkler Pipeline: https://www.chinayoufa.com/youfa-brand-products/fire-sprinkler-pipeline/

Water Delivery Pipeline:

https://www.chinayoufa.com/youfa-brand-products/water-delivery-pipeline/

Greenhouse Steel Pipe: https://www.chinayoufa.com/youfa-brand-products/greenhouse-steel-pipe/

Solar Structure Steel: https://www.chinayoufa.com/youfa-brand-products/solar-structure-steel/

Contact Person: Linda Liu

E-mail: linda@youfasteelpipe.com

Mobile/ Whatsapp: 0086-18611664072

Tel: 0086-22-58338800 ext. 8874

Fax: 0086-22-58338808

Address

Head Quarter: Daqiuzhuang Town, Tianjin, China

Export Office: Floor 7, No, 4 Anshun Building, Dafeng Road (Aqua City), Hongqiao Distr., Tianjin City, China

Youfa was founded on July 1st, 2000. There are totally about 9000 employees, 13 factories, 293 steel pipe production lines, 3 national accredited laboratory, and 1 Tianjin government accredited business technology center.

Production Capacity

In 2012, our production volume for all kinds of steel pipes was 6.65 million tons. In 2018, until now our production volume has been 16 million tons, and the sales amount has reached 160Million US Dollars. For 16 consecutive years, we are titled among TOP 500 Enterprises in China Manufacturing Industry.

Exportation Capacity

Exportation Department has 80 employees. Last year we exported 250 thousand tons all kinds of steel products. Mainly exported to East Asia, South Asia, Southeast Asia, The Middle East, Africa, Middle & South America, West Europe, Oceania, nearly 100 countries. Our products are qualified with API 5L, ASTM A53/A500/A795, BS1387/BS1139, EN39/EN10255/EN10219, JIS G3444/G3466, and ISO65, owning a good reputation at home and aboard.

Youfa firmly believe that quality is paramount. As a professional steel pipe manufacturing enterprise, we are equipped with advanced technology and sophisticated production equipment; and provide comprehensive services and support, strictly controlling every link from raw material procurement, manufacturing, quality control, and export transportation, to meet the growing demand in the field of building structures and fluid transportation around the world. Always adhere to green and environmentally friendly production methods, adhere to the principle of sustainable development, and strive to create a better world !

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Youfa Group: Building the Global Infrastructure Backbone as a Global Leading Carbon Steel Pipe Manufacturer here

News-ID: 4371881 • Views: …

More Releases for Pipe

How to choose Seamless Pipe vs Welded Pipe vs Spiral Welded Pipe

Seamless pipe, welded pipe, and spiral welded pipe are the three most common types. They may appear similar in appearance, but the differences are profound in essence, with the core distinction indeed stemming from manufacturing processes.

Comparison Table

FEATURE DIMENSION

SEAMLESS STEEL PIPE

LONGITUDINALLY WELDED PIPE

SPIRAL WELDED PIPE

Manufacturing Process

Solid billet piercing and rolling, no weld seam.

Steel plate/sheet is curved and welded along a longitudinal straight seam.

Steel strip is coiled at a spiral angle, forming…

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Comparison of ERW Welded Pipe and Seamless Steel Pipe (tested by PetroChina Pipe …

1. Outer diameter tolerance

ERW steel pipe: It is cold-formed and sizing is completed by reducing the diameter by 0.6%. The process temperature is basically constant at room temperature. Therefore, the outer diameter is controlled accurately and the fluctuation range is small, which is helpful to eliminate black leather buckles.

Seamless steel tube: The hot-rolling forming process is used, and its sizing is completed at about 8000C. The raw material composition, cooling…

HDPE Pipes Market Current Trends and Detailed Study with Forecast to 2028 | Oil …

Global HDPE Pipes Market: Overview

The application of high density polyethylene (HDPE) pipes has increased in industry like chemical, electronics, and gas distribution. As a result of this extensive application, the global HDPE pipes market is witnessing a substantial growth in the forecast period of 2018 to 2028. Moreover, the growing demand for HDPE pipes in drainage and sewerage industry is another factor that is responsible for the growth of…

Global HDPE 100 Pipe Market 2017 LESSO, Cangzhou Mingzhu, Junxing Pipe, Ginde Pi …

In this report, the global HDPE 100 Pipe market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Global Market Report HDPE 100 Pipe Market Size, Status and Forecast 2022 provides Market information about Manufacturers, Countries, Type and Application.This HDPE 100 Pipe Industry report also states Company Profile, sales,…

Anti-corrosion Steel Pipe and Coating Steel Pipe

Anti-corrosion steel pipe refers to do anti-corruption treatment for the ordinary steel pipe with special technology, making the steel pipe equipped certain corrosion resistance.Generally used in waterproof, anti-rust, acid and alkali proof, anti-oxidation and so on.Different needs, different inside and outside wall corresponding anti-corrosion measures.Common are: epoxy coal tar anti-corrosion, anti-corrosion epoxy coatings, urethane paint anti-corrosion, IPN8710 water pipeline corrosion protection, non-toxic paint anti corrosion,anti-corrosion polymer coating, steel pipe lining…