Press release

When using graphitized petroleum coke, how can users avoid "adverse reactions" with other elements in the furnace?

When using graphitized petroleum coke, to avoid "adverse reactions" with other elements inside the furnace, comprehensive management should be carried out from aspects such as controlling the heating rate, optimizing temperature monitoring, ensuring uniform heating, selecting appropriate resistive materials, controlling impurity content, implementing reasonable cooling, and strengthening equipment maintenance. The details are as follows:Controlling the Heating Rate: During the heating process of graphitized petroleum coke [https://www.qfindustrial.com/products/], it is essential to strictly control the heating rate to prevent concentrated thermal stress within the material caused by overly rapid heating, which could lead to cracking or adverse reactions with other elements. Especially in the initial stage, a slow heating approach should be adopted, with a heating rate of 50-100 per hour being appropriate. Once the furnace temperature reaches a certain level and the internal structure of the material stabilizes, the heating rate can be appropriately increased.

Optimizing Temperature Monitoring: Utilize high-precision temperature sensors to monitor the temperature changes inside the furnace in real time. If temperature fluctuations exceed the allowable range, immediate troubleshooting must be carried out, and adjustments should be made to the heating power or the heating system's wiring connections to prevent chemical reactions caused by abnormal temperatures.

Ensuring Uniform Heating: During the graphitization process, it is crucial to ensure uniform temperature distribution inside the furnace to avoid local overheating or underheating. This can be achieved by optimizing the furnace structure, improving the layout of heating elements, and adopting a reasonable loading method. Uniform heating helps reduce thermal stress within the material and lowers the risk of adverse reactions with other elements.

Selecting Appropriate Resistive Materials: When the resistance of the resistive material differs significantly from that of the product, the resistive material generates far more heat than the product itself during the graphitization electrification process, resulting in a significant temperature difference between the inside and outside of the product. This can cause excessive thermal stress, leading to cracking or adverse reactions with other elements in the product. Therefore, resistive materials with a resistivity similar to that of graphitized petroleum coke should be selected, and thorough mixing should be ensured to minimize differences in the heating rate across various parts of the furnace core.

Controlling Impurity Content: Impurity elements in graphitized petroleum coke, such as sulfur, oxygen, and nitrogen, are prone to reacting with other elements at high temperatures, generating compounds that are detrimental to production. Therefore, the impurity content of petroleum coke should be strictly controlled during the production process, with particular attention to keeping the sulfur content at a low level (e.g., below 1.0%) to reduce adverse effects on other elements inside the furnace.

Implementing Reasonable Cooling: The cooling stage after graphitization is equally important and should not be overlooked. A combination of natural cooling and assisted air cooling should be adopted. First, the heating power should be turned off, allowing the furnace to cool slowly in a natural environment for a period of time. Once the furnace temperature drops to a certain level, air cooling equipment can be activated to gradually reduce the furnace temperature to room temperature. Rapid cooling can easily cause thermal stress damage to the materials inside the furnace and the furnace structure, affecting the service life of the equipment and product quality.

Strengthening Equipment Maintenance: Regularly inspect and maintain the graphitization furnace and its related equipment to ensure the normal operation of components such as heating elements, temperature sensors, and furnace seals. Timely replacement of worn-out parts should be carried out to prevent problems such as abnormal temperatures or gas leaks caused by equipment failures, thereby reducing the risk of adverse reactions with other elements inside the furnace.

Media Contact

Company Name: Handan Qifeng Carbon Co., Ltd.

Contact Person: Media Relations

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=when-using-graphitized-petroleum-coke-how-can-we-avoid-adverse-reactions-with-other-elements-in-the-furnace]

Phone: 0086-13363057298

Address:B# 1202, Furuite Times Square

City: Handan

State: Hebei

Country: China

Website: https://www.qfindustrial.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release When using graphitized petroleum coke, how can users avoid "adverse reactions" with other elements in the furnace? here

News-ID: 4369574 • Views: …

More Releases from ABNewswire

2026 David Foster & Katherine McPhee Tickets Online - Cheap Prices with Promo Co …

Get 2026 David Foster & Katherine McPhee tickets online at cheap prices! Use promo code CITY10 at CapitalCityTickets.com for exclusive discounts. Secure your seats for an unforgettable live music experience across multiple cities. Don't wait-buy tickets today for fast, safe, and affordable access to this world-class tour!

Fans of music and unforgettable live performances, get ready! The iconic David Foster & Katherine McPhee 2026 tour is coming to a city near…

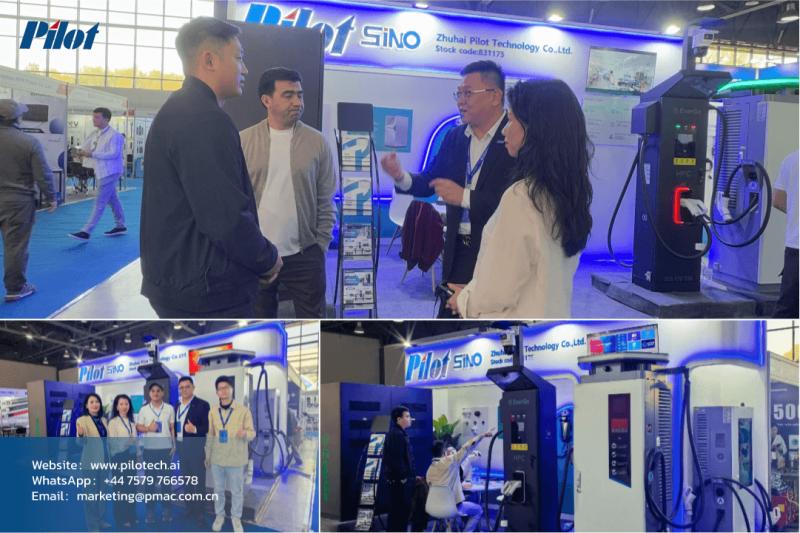

Event Press | Pilot Showcases Updated Smart EV Charging and Energy Storage Solut …

Melbourne, Australia - Jan 29, 2026 - Pilot Technology, a global leader in smart energy solutions, successfully showcased its cutting-edge smart EV charging and energy storage systems at two major international energy exhibitions: the UZ Energy Expo in Tashkent, Uzbekistan (October 21-23) and All Energy Australia 2025 in Melbourne (October 29-30). The company's participation highlighted its growing influence in key overseas markets, including Belt and Road initiatives and the Asia-Pacific…

Premium Pail Printing Machines from China - Trusted by the USA's Top Industrial …

Are you curious about why some of the top Industrial Packaging brands in the USA are increasingly turning to premium Pail Printing Machines from China? In a global marketplace filled with countless options, what makes these Chinese offerings so appealing that they've earned the trust of industry leaders?

The Pail Printing Machine [https://www.caimachine.com/products/] is essential equipment for the modern chemical, food service, and construction materials sectors. Used to print branding, safety…

Revolutionizing Production: The Power of High-Speed Cup Printing Machines

In the fast-paced packaging industry, speed, precision, and quality are non-negotiable. Global brands-from massive coffee chains to large-scale dairy producers-rely on vibrant, perfectly printed cups to capture consumer attention and communicate brand value. The core technology making this high-volume, high-quality output possible is the High-Speed Cup Printing Machine [https://www.caimachine.com/dry-off-cup-printer-s608-product/], a marvel of engineering that has fundamentally transformed modern packaging production lines.

This in-depth article explores the cutting-edge features of these essential…

More Releases for Controlling

Idaho Beeline Releases Blog on Identifying and Controlling Summer Spiders

Idaho Beeline Pest Control has released an informative blog post on identifying and controlling common spider species in Idaho during the summer months. The article provides identification tips, prevention strategies, and emphasizes the importance of professional pest control services for effectively managing spider infestations in residential and commercial properties.

Boise, ID - August 5, 2024 - Idaho Beeline Pest Control, a leading pest control service provider in Idaho, has published an…

Global Controlling Cable Market Research Report 2017-2022

Global Controlling Cable Market Report 2017 is a professional and deep research report in this field. For overview analysis, the report introduces Controlling Cable basic information including definition, classification, application, Market chain structure, Market overview, policy analysis, and news analysis, etc.

Read Complete Report @ http://www.marketresearchstore.com/report/global-controlling-cable-industry-market-research-2017-110430

For technical data and manufacturing plants analysis, the report analyzes Controlling Cable leading suppliers on capacity, commercial production date, manufacturing plants distribution, R&D status, technology sources,…

Controlling Windows Startup In The New Reg Organizer 7.35

A new version (7.35) of Reg Organizer, a set of tools to configure and optimize Windows from XP to 10, has been released. The program includes a complete software uninstaller, an advanced startup manager, system cleaning tools, an advanced registry editor, and a system tweaker, as well as other useful tools.

The new version introduces the improved startup manager. Now, all removed elements from the Windows startup are automatically reserved in…

Weighing and controlling technology combined in a single device

Bizerba presents the iS 50 industry terminal at LogiMAT in Stuttgart (hall 5, stand 531)

Balingen, 22 February 2012 – Bizerba will be presenting a new generation of terminals at LogiMAT 2012 in Stuttgart. The company has combined weighing and controlling technology in one single device for the very first time. With this innovation, food manufacturers, bakeries, breweries and grain and feed manufacturers will be able not only to save space…

Codorniu: managing promotions and controlling sales points with XTEL

The company chose the Sales Promo and Sales Execution modules to optimize their trade promotion effectiveness, ensure that agreed-upon promotions are properly effected at sales points and promptly follow competitors' actions.

Barcelona, June 2010

A maker of top quality sparkling wine since 1551, Codorniu creates the perfect mixture of the finest grapes from the best vineyards of Catalonia, a land of sun and fragrance. Five hundred years of history are behind…

Controlling Lone Worker Risk through Effective Technology Solutions.

Following the recent drastic announcements by the Sentencing Guidelines Council that advises Courts in the award of punishments as the consequences for firms contravening health and safety legislation, Tom Morton, CEO of Argyll, the UK’s largest lone worker service provider, advises employers how they can safely mitigate corporate risks using existing technology.

In addition to robust management processes, the HSE recommends that managing the safety of a workforce isolated from…