Press release

Metal Cable Tray Manufacturing Plant (DPR) 2026: Project Report, Machinery Cost and Business Plan

Metal cable trays represent a critical infrastructure component in modern electrical systems, serving as the backbone of cable management across industrial, commercial, and residential buildings. These trays are designed to support and organize electrical cables, providing durability, flexibility, and resistance to corrosion and environmental factors. Typically manufactured from steel, aluminum, and stainless steel, metal cable trays enable cables to be efficiently routed and protected across diverse applications.The metal segment commands a dominant position in the cable tray market, accounting for 63.40% of the material type category. This substantial market share underscores the widespread preference for metal cable trays over alternative materials, driven by their superior structural integrity, fire resistance, and longevity. As infrastructure development accelerates globally, the demand for organized, safe, and durable cable management solutions continues to expand, positioning metal cable tray manufacturing as an attractive investment opportunity.

IMARC Group's report, "Metal Cable Tray Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a plant. The metal cable tray manufacturing plant setup report offers insights into the process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Market Overview and Growth Potential

The metal cable tray market is primarily driven by the increasing need for safe, organized, and durable cable management systems across the growing construction, oil & gas, telecommunications, and power generation sectors. The global shift toward modern infrastructure, energy efficiency, and renewable power plants further fuels demand.

According to the Ministry of New and Renewable Energy, India added a record 44.5 GW renewable energy capacity in 2025, demonstrating the massive scale of power infrastructure expansion driving cable tray demand. Additionally, technological advancements in manufacturing processes, such as automated cutting and welding, have reduced production costs and improved tray quality. The rising emphasis on industrial safety standards and building codes requiring proper cable management and fire protection contributes significantly to market expansion. The growing demand for data centers, industrial automation, and electrical infrastructure in emerging markets creates substantial opportunities for manufacturers.

Grab a sample PDF of this report: https://www.imarcgroup.com/metal-cable-tray-manufacturing-plant-project-report/requestsample

Plant Capacity and Production Scale

The proposed metal cable tray manufacturing facility is designed with an annual production capacity ranging between 10,000 - 20,000 MT, enabling economies of scale while maintaining operational flexibility. This production scale allows manufacturers to serve multiple market segments effectively, including power generation, oil & gas, data centers, industrial manufacturing, and transportation infrastructure.

The substantial capacity range provides flexibility to adjust production volumes based on market demand while optimizing resource utilization and maintaining competitive unit costs.

Financial Viability and Profitability Analysis

The metal cable tray manufacturing project demonstrates healthy profitability potential under normal operating conditions. The financial projections indicate:

• Gross Profit Margins: 25-35%

• Net Profit Margins: 10-15%

These margins are supported by stable demand across multiple end-use industries and value-added applications. The financial projections have been developed based on realistic assumptions related to capital investment, operating costs, production capacity utilization, pricing trends, and demand outlook, providing a comprehensive view of the project's financial viability, ROI, profitability, and long-term sustainability.

Operating Cost Structure

The operating cost structure of a metal cable tray manufacturing plant is primarily driven by raw material consumption, particularly steel coils. The operational expenditure breakdown includes:

• Raw Materials: 70-80% of OpEx

• Utilities: 10-15% of OpEx

Key raw materials include steel coils and galvanizing materials, which form the foundation of production costs. Establishing long-term contracts with reliable suppliers helps mitigate price volatility and ensures consistent material supply. Cost management strategies should focus on optimizing raw material utilization, negotiating favorable supplier agreements, and implementing energy-efficient manufacturing processes.

Capital Investment Requirements

Establishing a metal cable tray manufacturing plant involves several capital expenditure components:

Land and Site Development: Location selection must offer easy access to key raw materials such as steel coils and galvanizing materials. Proximity to target markets minimizes distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems.

Machinery and Equipment: Essential equipment includes decoiling and straightening lines, press brakes and punching machines, roll forming systems, welding stations (spot and seam), automated cutting saws, galvanizing or powder coating lines, and packaging stations. All machinery must comply with industry standards for safety, efficiency, and reliability.

Civil Works: Plant layout should be optimized to enhance workflow efficiency, safety, and minimize material handling. Separate areas for raw material storage, production, quality control, and finished goods storage must be designated.

Infrastructure Requirements: Costs associated with land acquisition, construction, utilities (electricity, water, steam), and future expansion capacity must be incorporated into the financial plan.

Speak to an Analyst: https://www.imarcgroup.com/request?type=report&id=9166&flag=C

Major Applications and Market Segments

Metal cable trays serve diverse applications across multiple industries:

• Power Distribution: Support and routing of electrical cables in industrial and commercial facilities

• Data & Communication Systems: Organized management of data, control, and communication cables

• Industrial Facilities: Heavy-duty cable support in plants, refineries, and manufacturing units

• Commercial & Infrastructure Projects: Cable management in buildings, airports, tunnels, and utilities

End-use industries include power generation, oil & gas, data centers, industrial manufacturing, and transportation infrastructure.

Why Invest in Metal Cable Tray Manufacturing?

Critical Electrical Infrastructure Component: Metal cable trays form the backbone of modern cable management systems, providing safe, organized, and durable support for power, control, and communication cables across industrial plants, commercial buildings, data centers, utilities, railways, and infrastructure projects-making them essential for electrical safety, scalability, and long-term system reliability.

Moderate but Defensible Entry Barriers: While manufacturing is less capital-intensive than heavy electrical equipment, consistent quality standards, structural load requirements, corrosion protection (GI, HDG, SS, aluminum), precise fabrication, and compliance with national and international standards (IS, IEC, NEMA) create meaningful barriers favoring established manufacturers with process control and certification capabilities.

Megatrend Alignment: Rapid expansion in data centers, renewable energy installations, electric mobility infrastructure, smart buildings, and industrial automation drives sustained demand for organized and high-capacity cable routing solutions.

Policy & Infrastructure Push: Government-led investments in power transmission, metro rail, airports, highways, renewable energy parks, and manufacturing corridors-along with domestic manufacturing incentives such as Make in India and infrastructure PLI schemes-accelerate demand for metal cable trays in EPC and turnkey electrical projects.

Localization and Supply Chain Reliability: EPC contractors and end users increasingly prefer local, dependable manufacturers to ensure faster project execution, customization, cost stability in steel and zinc inputs, and consistent after-sales support.

Buy Now: https://www.imarcgroup.com/checkout?id=9166&method=2175

Industry Leadership

Leading manufacturers in the global metal cable tray industry include several multinational companies with extensive production capacities and diverse application portfolios. Key players include:

• Legrand

• Schneider Electric

• Atkore International

• M.K. Aluminum

• Marco Cable Tray Company

Conclusion

The metal cable tray manufacturing sector presents a compelling investment opportunity supported by strong market fundamentals and favorable industry dynamics. The manufacturing process-involving roll forming, welding, and finishing-utilizes established technologies while benefiting from automation advancements that reduce costs and enhance quality. As global infrastructure development accelerates, renewable energy capacity expands, and data center construction proliferates, demand for professional cable management solutions will continue growing. Investors entering this market can capitalize on megatrend alignment, policy support for domestic manufacturing, and the essential role metal cable trays play in electrical infrastructure. The combination of defensible entry barriers, stable demand across diverse end-use industries, and favorable profitability metrics positions metal cable tray manufacturing as a strategic investment for long-term growth.

Browse Related Reports:

Nursing Training School Business Plan: https://industrytoday.co.uk/health_and_safety/why-entrepreneurs-should-consider-nursing-training-school-in-2025

Flower Shop Business Plan: https://industrytoday.co.uk/market-research-industry-today/how-to-ensure-long-term-profitability-in-flower-shop-business

Book Shop Business Plan: https://industrytoday.co.uk/market-research-industry-today/top-business-opportunities-in-book-shop-industry-2025

Night Club Business Plan: https://industrytoday.co.uk/market-research-industry-today/best-cities-to-open-a-night-club-business-in-2025

Laundromat Business Plan: https://industrytoday.co.uk/market-research-industry-today/laundromat-business-opportunities-in-2025-why-now-is-the-right-time-to-invest

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Cable Tray Manufacturing Plant (DPR) 2026: Project Report, Machinery Cost and Business Plan here

News-ID: 4368613 • Views: …

More Releases from IMARC Group

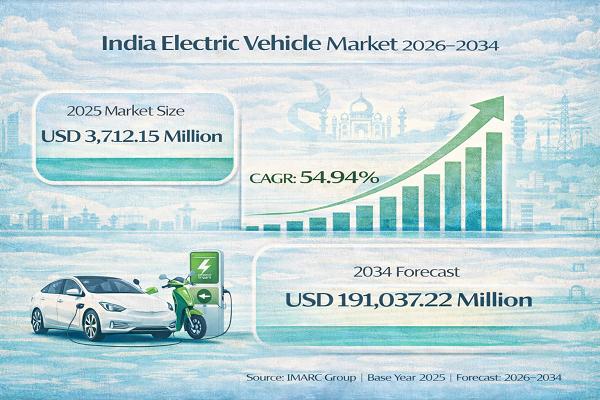

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Metal

Metal Roofing Companies Revolutionizing the Industry: Classic Metal Roofs Leads …

Classic Metal Roofs has established itself as a leading provider of durable and energy-efficient roofing systems in Southern New England. With over 20 years of experience, the company is known for high-quality installations, customer satisfaction, and sustainable metal roofing solutions.

As homeowners increasingly seek durable and energy-efficient solutions, metal roofing companies continue to provide top-tier roofing systems. Among the industry leaders, Classic Metal Roofs [http://business.bigspringherald.com/bigspringherald/markets/article/abnewswire-2025-2-15-classic-metal-roofs-expert-aluminum-shingle-metal-roof-installation-and-services/] stands out for its commitment to…

Rare Metal Raw Materials - Boron(B) Metal

Boron Powder [https://www.urbanmines.com/boron-powder-product/]

Short Description:

Boron [,%20a%20chemical%20element%20with%20the%20symbol%20B%20and%20atomic%20number%205,%20is%20a%20black/brown%20hard%20solid%20amorphous%20powder.%20It%20], a chemical element with the symbol B and atomic number 5, is a black/brown hard solid amorphous powder. It is highly reactiveand soluble in concentrated nitric and sulfuric acids but insoluble in water, alcohol and ether. It has a high neutro absorption capacity. UrbanMines specializes in producing high purity Boron Powder with the smallest possible average grain sizes. Our standard powderparticle sizes average in the…

Metal Polishing Services Market Trends and Leading Players 2023-2030 | Metal Pol …

With a CAGR of 6.1%, the Metal Polishing Services Market is expected to grow from USD 1.5 billion in 2023 to USD 2.3 billion by 2030, offering a gleaming finish to metal surfaces for aesthetic and functional purposes.

Market Overview:

The Metal Polishing Services market is poised for rapid growth, driven by several pivotal drivers. There is a continuous demand for metal finishing and polishing services that improve the appearance and…

Metal-to-metal Seal Market 2021 | Detailed Report

Metal-to-metal Seal Market Forecasts report provided to identify significant trends, drivers, influence factors in global and regions, agreements, new product launches and acquisitions, Analysis, market drivers, opportunities and challenges, risks in the market, cost and forecasts to 2027.

Get Free Sample PDF (including full TOC, Tables and Figures) of Metal-to-metal Seal Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5089735

The report provides a comprehensive analysis of company profiles listed below:

- Parker

- CPI

- HTMS

- American Seal &…

Metal Polishing Services Market Research Report 2020 Analysis: Enhanced Growth a …

Metal Polishing Services Market

Global Metal Polishing Services Market is providing the summarized study of several factors encouraging the growth of the market such as manufacturers, market size, type, regions and numerous applications. By using the report consumer can recognize the several dynamics that impact and govern the market. For any product, there are several companies playing their role in the market, some new, some established and some are planning to…

Worldwide Recycled Metal Market By Metal 2024 | Nucor, Steel Dynamics, Schnitzer …

The 2018-2024 report on global Recycled Metal market explores the essential factors of Recycled Metal industry covering current scenario, market demand information, coverage of active companies and segmentation forecasts.

North America recycled metal market was estimated close to USD 8.5 billion in 2017. This is mainly attributed to strong presence of transportation, electrical & electronics and defense industry which majorly constitute to the overall product demand. Moreover, strict laws formulated…