Press release

Braided Copper Wire Manufacturing Plant DPR - 2026: Complete Setup Guide, Cost Analysis and Profit Outlook

The global electrical and electronics industry is experiencing rapid expansion, with braided copper wire emerging as a critical component in power transmission, grounding systems, and electromagnetic shielding applications. As industries accelerate toward electrification, renewable energy adoption, and advanced electronics manufacturing, establishing a braided copper wire manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and industrial investors.Market Overview and Growth Potential

The global braided copper wire market demonstrates robust growth trajectory, valued at USD 2.8 Billion in 2025. IMARC Group's comprehensive analysis, the market is projected to reach USD 4.6 Billion by 2034, exhibiting a strong CAGR of 5.6% from 2026 to 2034. This substantial growth is driven by increasing demand for reliable electrical connections, expanding renewable energy infrastructure, growing automotive electrification, and rising requirements for electromagnetic compatibility (EMC) solutions worldwide.

Braided copper wire serves as the backbone of electrical connectivity and safety systems, providing superior flexibility, high conductivity, excellent current-carrying capacity, and effective electromagnetic shielding. Their performance directly impacts system reliability, safety standards, and operational efficiency, making them indispensable in the modern electrical and electronics ecosystem.

Request for Sample Report: https://www.imarcgroup.com/braided-copper-wire-manufacturing-plant-project-report/requestsample

Plant Capacity and Production Scale

The proposed braided copper wire manufacturing facility is designed with an annual production capacity ranging between 2,000-5,000 metric tons, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments - from industrial equipment manufacturers to automotive OEMs and renewable energy projects - ensuring steady demand and revenue streams.

Financial Viability and Profitability Analysis

The braided copper wire manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 22-32%

• Net Profit Margins: 9-14%

• Break-even Period: Typically 3-5 years

These margins are supported by stable industrial demand, value-added manufacturing processes, and the critical nature of braided copper wire in electrical and electronics applications. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established wire manufacturers looking to expand their product portfolios.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning. The cost structure for a braided copper wire manufacturing plant is primarily driven by:

• Raw Materials: 75-85% of total OpEx

• Utilities: 5-8% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with key inputs including electrolytic copper wire rods, tin-plated copper wire (for specialized applications), insulating materials, and protective coatings. Establishing long-term supply agreements with copper refineries and maintaining strategic inventory helps mitigate commodity price volatility and ensures consistent production operations.

Buy Now: https://www.imarcgroup.com/checkout?id=15677&method=2175

Capital Investment Requirements

Setting up a braided copper wire manufacturing plant requires substantial capital investment across several categories:

Land and Site Development: Selection of an optimal location with proximity to copper suppliers, access to skilled labor markets, and robust infrastructure including reliable power supply, transportation networks, and material handling systems.

Machinery and Equipment: The largest portion of CapEx covers high-precision manufacturing equipment including:

• Wire drawing machines (multi-stage)

• High-speed braiding machines

• Annealing furnaces

• Tin-plating equipment (for specialized products)

• Stranding machines

• Quality testing instruments (conductivity meters, tensile testers)

• Automated coiling and packaging systems

Civil Works: Building construction, factory layout optimization, specialized flooring for heavy machinery, and infrastructure development to enhance workflow efficiency, safety compliance, and minimize material handling.

Other Capital Costs: Pre-operative expenses, installation costs, regulatory compliance, quality certifications (ISO 9001, UL approvals, automotive standards), and initial working capital.

Major Applications and Market Segments

Braided copper wire finds applications across diverse sectors:

Electrical Grounding and Bonding: Flexible grounding straps, equipotential bonding jumpers, lightning protection systems, and safety earthing connections for industrial equipment and buildings.

Power Distribution: Flexible connectors for transformers, switchgear, busbars, and battery interconnections in energy storage systems and electric vehicle charging infrastructure.

Electromagnetic Shielding: Cable shielding for telecommunications, data centers, medical equipment, aerospace applications, and defense electronics requiring EMI/RFI protection.

Automotive Industry: Battery cables, grounding straps for electric vehicles (EVs), hybrid vehicles, starter motors, and automotive electronics requiring high-current, flexible connections.

Speak to an Analyst: https://www.imarcgroup.com/request?type=report&id=15677&flag=C

Why Invest in Braided Copper Wire Manufacturing?

Several compelling factors make this an attractive investment opportunity:

• Critical Infrastructure Component: Braided copper wire represents essential connectivity solutions in electrical systems. Their critical role in safety, grounding, and power transmission ensures sustained demand as electrical infrastructure continues to expand globally.

• Moderate Entry Barriers: While requiring specialized braiding equipment and metallurgical expertise, the manufacturing process benefits from established copper supply chains. Quality certifications (UL, CSA, automotive standards), consistent product specifications, and customer qualifications create meaningful barriers favoring capable manufacturers.

• Strong Industrial Megatrends: Global electrification, renewable energy deployment, electric vehicle adoption, data center expansion, 5G infrastructure rollout, and industrial automation drive sustained braided copper wire demand across multiple sectors.

• Regulatory and Safety Tailwinds: Stringent electrical safety standards, grounding requirements, EMC regulations, and automotive safety norms directly mandate the use of high-quality braided copper wire in critical applications.

• Localization Benefits: Equipment manufacturers and system integrators increasingly prefer local suppliers to reduce lead times, ensure faster technical support, manage transportation costs, and comply with domestic sourcing requirements in key markets.

• Product Diversification: Ability to manufacture various configurations - different braiding patterns, wire gauges, tin-plated options, and custom specifications - creates opportunities for market segmentation and premium pricing for specialized applications.

Industry Leadership

The global braided copper wire industry is led by established manufacturers including Nexans S.A., Prysmian Group, Southwire Company LLC, General Cable Technologies Corporation, and Erico International Corporation. These companies serve diverse end-use sectors including power utilities, automotive, telecommunications, industrial equipment, renewable energy, and defense applications.

Browse Related Reports:

• Tomato Ketchup Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/tomato-ketchup-manufacturing-plant-setup-2026-detailed-project-report-machinery-cost-and-profit-analysis

• Nickel Sulfate Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/nickel-sulfate-manufacturing-plant-setup-2026-complete-dpr-capital-requirements-roi

• Iron Powder Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/iron-powder-manufacturing-plant-setup-cost-2026-investment-roi-and-dpr-overview

• Green Hydrogen Manufacturing Plant https://industrytoday.co.uk/manufacturing/green-hydrogen-manufacturing-plant-setup-2026-complete-project-report-with-capex-opex-roi

Conclusion

The braided copper wire manufacturing sector presents a strategically positioned investment opportunity at the intersection of electrical infrastructure development, industrial electrification, and robust industrial demand. With favorable profit margins, strong regulatory support, and accelerating global electrical infrastructure expansion, establishing a braided copper wire manufacturing plant offers significant potential for long-term business success and sustainable returns.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Braided Copper Wire Manufacturing Plant DPR - 2026: Complete Setup Guide, Cost Analysis and Profit Outlook here

News-ID: 4365994 • Views: …

More Releases from IMARC Group

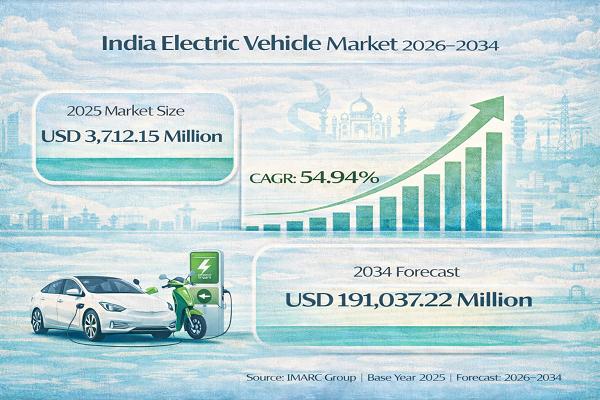

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…