Press release

Facewash Manufacturing Plant DPR - 2026: Market Outlook, Cost Structure and Profit Potential

The global personal care and cosmetics industry is experiencing unprecedented growth, with facial cleansing products leading the transformation toward comprehensive skincare routines. As consumers increasingly prioritize skin health, natural ingredients, and dermatologically tested products, establishing a facewash manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and cosmetic industry investors.Market Overview and Growth Potential

The global facial cleanser market demonstrates robust growth trajectory, valued at USD 18.5 Billion in 2025. IMARC Group's comprehensive analysis, the market is projected to reach USD 32.7 Billion by 2034, exhibiting a strong CAGR of 6.5% from 2026 to 2034. This exponential growth is driven by increasing awareness of skincare routines, rising disposable incomes, growing influence of social media beauty trends, and expanding demand across men's grooming segments worldwide.

Facewash products serve as the foundation of daily skincare regimens, providing gentle yet effective cleansing that removes dirt, oil, makeup, and environmental pollutants while maintaining skin's natural moisture balance. Their critical role in preventing acne, improving skin texture, and preparing skin for subsequent treatments makes them indispensable in the modern beauty and personal care ecosystem.

Request for Sample Report:

https://www.imarcgroup.com/facewash-manufacturing-plant-project-report/requestsample

Plant Capacity and Production Scale

The proposed facewash manufacturing facility is designed with an annual production capacity ranging between 5-15 million units, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments - from premium dermatological brands to mass-market consumer products - ensuring steady demand and revenue streams across retail, e-commerce, and professional skincare channels.

Financial Viability and Profitability Analysis

The facewash manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 35-50%

• Net Profit Margins: 12-18%

• Break-even Period: Typically 2-4 years

These margins are supported by strong brand loyalty, premium pricing opportunities for specialized formulations, and the essential nature of facial cleansing in daily personal care routines. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established cosmetic manufacturers looking to expand their skincare portfolios.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning. The cost structure for a facewash manufacturing plant is primarily driven by:

• Raw Materials: 40-50% of total OpEx

• Utilities: 6-10% of OpEx

• Other Expenses: Including labor, packaging, transportation, marketing, quality control, regulatory compliance, and taxes

•

Raw materials constitute a significant portion of operating costs, with key ingredients including surfactants (SLS, SLES, or mild alternatives), moisturizers (glycerin, aloe vera), botanical extracts, preservatives, fragrances, pH adjusters, and active ingredients for specialized formulations (salicylic acid, niacinamide, tea tree oil). Establishing long-term partnerships with certified cosmetic ingredient suppliers ensures quality consistency, regulatory compliance, and stable pricing.

Buy Now: https://www.imarcgroup.com/checkout?id=27248&method=2175

Capital Investment Requirements

Setting up a facewash manufacturing plant requires substantial capital investment across several categories:

Land and Site Development: Selection of an optimal location with access to skilled labor, reliable utilities, proximity to packaging suppliers and distribution networks, and robust infrastructure including clean water supply, wastewater treatment, and quality control facilities.

Machinery and Equipment: The largest portion of CapEx covers high-quality, GMP-compliant manufacturing equipment including:

• Stainless steel mixing vessels and homogenizers

• Heating and cooling systems

• Automated filling and capping machines

• Tube sealing equipment

• Labeling and coding systems

• Quality control laboratory instruments

• Batch documentation and traceability systems

Civil Works: Building construction with cleanroom environments, factory layout optimization, temperature-controlled storage areas, and infrastructure development to enhance workflow efficiency, maintain hygiene standards, and comply with Good Manufacturing Practices (GMP).

Other Capital Costs: Pre-operative expenses, installation costs, regulatory certifications (ISO 22716, FDA compliance, cosmetic product registrations), stability testing, and initial working capital for inventory and marketing.

Major Applications and Market Segments

Facewash products find applications across diverse consumer segments:

Skin Type Specific: Formulations for oily skin, dry skin, sensitive skin, combination skin, and normal skin types, each with tailored surfactant systems and active ingredients.

Problem-Targeted Solutions: Anti-acne facewash, brightening cleansers, anti-aging formulations, pore-minimizing products, and oil-control variants addressing specific skincare concerns.

Natural and Organic: Plant-based cleansers, sulfate-free formulations, paraben-free options, and certified organic facewash products catering to clean beauty preferences.

Men's Grooming: Masculine-scented variants, deep-cleansing formulations for facial hair care, and energizing cleansers designed specifically for male consumers.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=27248&flag=C

Why Invest in Facewash Manufacturing?

Several compelling factors make this an attractive investment opportunity:

Essential Daily Care Product: Facewash represents a fundamental component of personal hygiene and skincare routines. Its essential nature ensures consistent repeat purchases and sustained demand across all demographic segments.

High-Margin Product Category: Cosmetic formulations command premium pricing, particularly for specialized or dermatologically tested products. Brand building, ingredient innovation, and targeted marketing create significant opportunities for margin expansion beyond commodity personal care items.

Strong Consumer Trends: Rising skincare awareness, influence of beauty influencers and dermatologists, growth of K-beauty and J-beauty trends, increasing male grooming adoption, and clean beauty movement drive sustained facewash market expansion globally.

Multi-Channel Distribution: Facewash products benefit from diverse sales channels including supermarkets, pharmacies, specialty beauty stores, e-commerce platforms, subscription boxes, and professional skincare clinics, reducing dependence on any single distribution model.

Innovation Opportunities: Continuous product development possibilities through novel ingredients (probiotics, adaptogens), sustainable packaging innovations, personalized formulations, and integration with digital skin analysis technologies create competitive differentiation and market leadership opportunities.

Export Potential: Growing middle-class populations in emerging markets, increasing beauty consciousness globally, and demand for affordable yet effective skincare products offer significant international expansion and export revenue opportunities.

Industry Leadership

The global facewash industry is led by established cosmetic manufacturers including L'Oreal S.A., Procter & Gamble Company, Unilever PLC, Johnson & Johnson, and Beiersdorf AG. These companies serve diverse end-use sectors including mass retail, prestige beauty, dermatological clinics, men's grooming, and natural/organic beauty segments.

Browse Related Reports:

• Argon Gas Production Plant Cost: https://industrytoday.co.uk/chemicals/argon-gas-production-cost-report-2025-detailed-guide-on-plant-setup-capexopex-and-profitability

• Lithium Carbonate Production Plant Cost: https://industrytoday.co.uk/chemicals/lithium-carbonate-production-cost-analysis-2025-plant-setup-industry-trends-and-investment-overview

• Stainless Steel Pipe Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/stainless-steel-pipe-manufacturing-plant-setup-2025-raw-material-list-machinery-cost-and-industry-trends

• Steel Rebar Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/steel-rebar-manufacturing-plant-report-2025-setup-cost-and-machinery-requirements

• Lithium-Ion Battery Recycling Plant Cost: https://industrytoday.co.uk/manufacturing/lithium-ion-battery-recycling-plant-setup-2025-technology-requirements-and-cost-involved

• Electric Vehicle Manufacturing Plant Cost: https://industrytoday.co.uk/automotive/electric-vehicle-manufacturing-plant-setup-2025-business-plan-machinery-cost-and-technology-requirements

Conclusion

The facewash manufacturing sector presents a strategically positioned investment opportunity at the intersection of personal care innovation, beauty consciousness, and robust consumer demand. With favourable profit margins, strong brand-building potential, and accelerating global skincare adoption, establishing a facewash manufacturing plant offers significant potential for long-term business success and sustainable returns.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Facewash Manufacturing Plant DPR - 2026: Market Outlook, Cost Structure and Profit Potential here

News-ID: 4365858 • Views: …

More Releases from IMARC Group

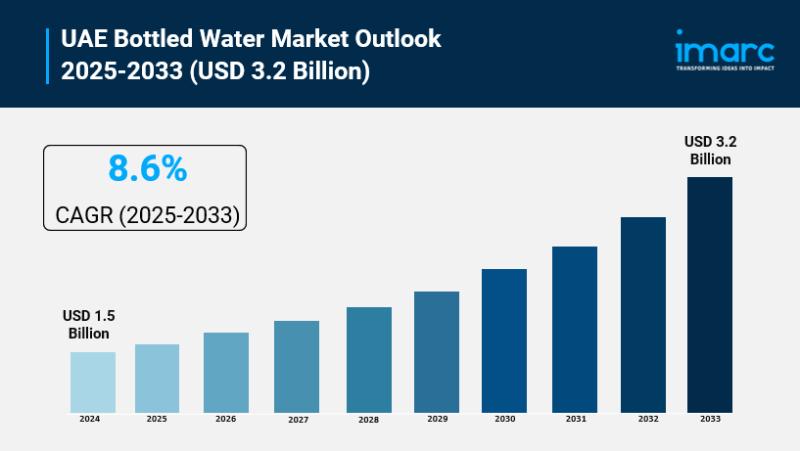

UAE Bottled Water Market Size to Hit USD 3.2 Billion in 2033 | Grow CAGR by 8.6%

UAE Bottled Water Market Overview

Market Size in 2024: USD 1.5 Billion

Market Size in 2033: USD 3.2 Billion

Market Growth Rate 2025-2033: 8.6%

According to IMARC Group's latest research publication, "UAE Bottled Water Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, and Region, 2025-2033", the UAE bottled water market size was valued at USD 1.5 billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 3.2 billion…

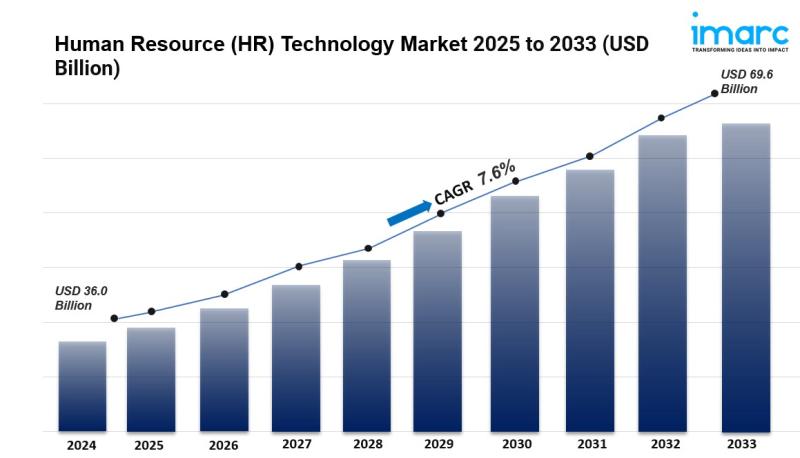

Human Resource Technology Market is Projected to Grow USD 69.6 Billion by 2033 | …

Human Resource Technology Market Overview:

The global human resource (HR) technology market was valued at USD 36.0 Billion in 2024 and is projected to reach USD 69.6 Billion by 2033, exhibiting a CAGR of 7.6% during the 2025-2033 forecast period. Rapid digital adoption, increasing remote work arrangements, and the strong focus on employee experience are driving this growth. The human resource technology market size is expanding rapidly due to the growing…

Big Data as a Service Market Size, Share And Growth Report 2033

IMARC Group, a leading market research company, has recently released a report titled "Big Data as a Service (BDaaS) Market Size, Share, Trends and Forecast by Solution, Deployment Model, Platform Type, Organization Size, Verticals, and Region, 2026-2034". The study provides a detailed analysis of the industry, including the big data as a service (BDaaS) market size, share, trends, and growth forecast. The report also includes competitor and regional analysis and…

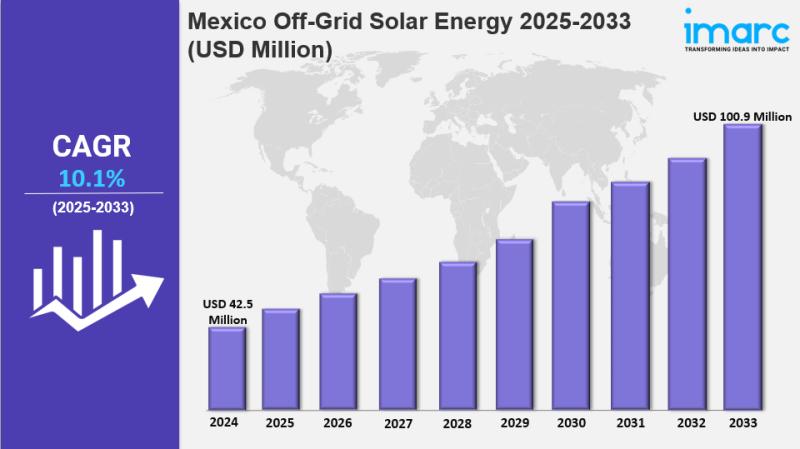

Mexico Off-Grid Solar Energy 2025: Size, Trends, Growth, Latest Insights and For …

IMARC Group has recently released a new research study titled "Mexico Off-Grid Solar Energy Market Size, Share, Trends and Forecast by End User and Region, 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico off-grid solar energy market size reached USD 42.5 Million in 2024 and is forecast to grow to USD 100.9…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…