Press release

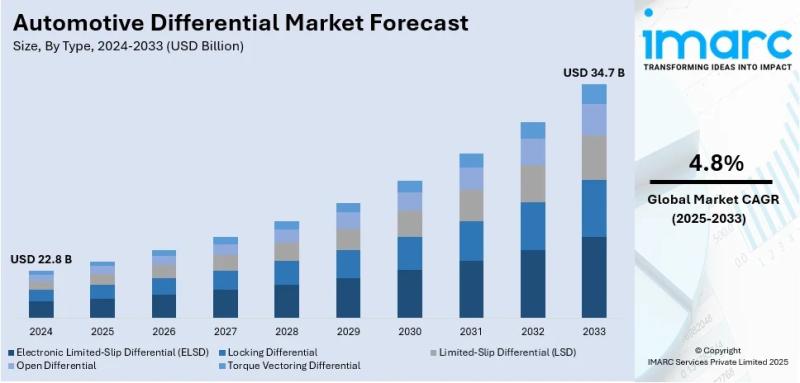

Automotive Differential Market Size to Surpass USD 34.7 Billion by 2033

The global automotive differential market size was valued at USD 22.8 billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 34.7 billion by 2033, exhibiting a CAGR of 4.8% during 2025-2033. Asia Pacific currently dominates the market in 2024.Rising Demand for Passenger and Commercial Vehicles

The differential market in the automotive sector is growing at a good pace due to the production and sales of passenger cars, SUVs, and commercial vehicles increasing globally. Differentials are necessary elements that make turning easy by giving the wheels on the same axle the freedom to spin at different speeds, thus, the vehicle becomes more stable, it gets traction, and it is safer. The worldwide increase of disposable income coupled with urbanization and mobility needs have been positive factors for the demand for personal and commercial vehicles which in turn have influenced the demand for differentials directly. In addition to that, EVs and hybrids that usually need sophisticated differential systems to carry out the power distribution between the wheels efficiently are also there pushing up the differential market. Also, the use of AWD and 4WD systems in SUVs and performance vehicles has led to the increased demand for advanced differential technologies such as the limited-slip and torque-vectoring systems. The growing of the automotive industry in the developing countries, especially in the Asia-Pacific and Latin America regions, is a significant factor in the rise of market demand as well. As the automotive world keeps changing through the improvement of safety, performance, and vehicle efficiency standards, the demand for advanced differentials will be still increasing steadily in 2025, thus supporting both traditional and future powertrain systems.

Technological Advancements in Differential Systems

The differential innovations are leading the market, as improvements in the performance, efficiency and safety of automotive vehicles are being made from time to time. Traction, handling and cornering abilities have been maximized on modern vehicles with the use of advanced differential technologies, eLSDs (Electronic Limited Slip Differentials), torque-vectoring differentials, the use of which is limited to premium cars. These installations use torque distribution in the smartest way possible which is the major performance enhancement for the vehicle and also the major lessening of the tire degradation which in turn is an absolute win for high-performance and off-road vehicles. Apart from that, the continuous increasing demand of electrically driven and hybrid cars is the cause for the spreading of the idea of building differentials which are special in terms of being not only high torque but also able to integrate braking energy recovery systems. All carmakers have invested in developing the light materials and making the compact products that will improve the fuel consumption and the total weight of the vehicle. Through its materials and production process, it is improving the quality of the product in terms of its life, sound, and service cycle. Since performance, safety and fuel economy are the consumers' and OEMs' hot topics, the uptake of state-of-the-art differential solutions will go on in 2025 and beyond, thus stimulating drivetrain technology innovation and opening the doors to premium and aftermarket differential opportunities.

Growth in Aftermarket and Replacement Services

Aftermarket and replacement segments are expected to grow steadily owing to growing aged vehicle population and increasing focus on vehicle maintenance services. As differential components are mechanical in nature, they wear out with use in commercial vehicles, trucks and high-mileage passenger vehicles. The dynamics of the growing number of vehicles in service and extended lives of vehicles of all types and categories has led to increased activity in the differential repair, replacement and maintenance market. The popularity of sports, off-road and performance vehicles is fueling the automotive aftermarket segment, as is the increasing demand for the installation of limited-slip differentials, locking differentials and performance differentials for driving performance and increased traction in extreme conditions. The ease of availability of parts through online platforms and automotive service providers also drives the market. The automobile owner's understanding of optimum vehicle performance and regular vehicle maintenance is also driving demand for aftermarket products and services. The increasing demand for differential components in the aftermarket, due to the growth of the global vehicle fleet and automotive servicing network, is expected to provide numerous opportunities for the manufacturers, distributors, and service providers in the developed as well as emerging economies, during the forecast period, 2020 to 2025, and beyond.

Automotive Differential Market Trends 2025

The automotive differentials market is rapidly evolving due to various factors, such as electrification, technological advancements, and consumer demand in 2025. The application of advanced differential concepts in battery electric and hybrid vehicles will be the major trends in the future of differentials market. Torque vectoring and electronically controlled differentials will help improve maneuverability, energy and energy management. Future differentials will be made of lighter and more compact components that will improve performance and fuel economy while meeting tough environmental requirements. Meanwhile, the aftermarket section is seeing strong gains, owing to rising car ownership and an aging car population, as well as increasing demand for both performance work and regular maintenance work.

Manufacturers have gone to great lengths to improve the robustness and sophistication of the differentials. In particular, to meet the requirements of high-end luxury and off-road vehicles which have a low scheduled maintenance frequency. The future of differential systems is likely to be influenced by digital and connected vehicle technologies which provide predictive maintenance, remote diagnostics and integration with vehicle stability systems. Emerging markets have been the best supporters by geography. This is mainly due to the presence of automotive production and the growing share of the middle class in automotive ownership. Over the forecast years, the automotive differential market, coupled with the key driving factors electrification, performance improvements, and maintenance requirements, is expected to witness a slow and steady growth until 2025, due to the rising technological transformation and growing consumer expectancies for durable and fuel-efficient automotive drivetrain systems.

Get your Sample of Automotive Differential Market Insights for Free: https://www.imarcgroup.com/automotive-differential-market/requestsample

Industry Segmentation:

Analysis by Type:

• Electronic Limited-Slip Differential (ELSD)

• Locking Differential

• Limited-Slip Differential (LSD)

• Open Differential

• Torque Vectoring Differential

Analysis by Drive Type:

• Front Wheel Drive (FWD)

• Rear Wheel Drive (RWD)

• All Wheel Drive/ Four Wheel Drive (AWD/4WD)

Analysis by Vehicle:

• Passenger Car

• Light Commercial Vehicle

• Heavy Commercial Vehicle

• Off-highway Vehicle

Analysis by Component:

• Differential Bearing

• Differential Gear

• Differential Case

Analysis by Vehicle Propulsion Type:

• I.C. Engine Vehicle

o Spark Ignition Engine based Vehicle

o Compression Ignition Engine based Vehicle

• Electric Vehicle

o Battery Electric Vehicle

o Fuel Cell Electric Vehicle

• Hybrid Electric Vehicle

o Hybrid Electric

o Plug-in Hybrid Electric

Regional Insights:

• North America

• Europe

• Asia Pacific

• Middle East and Africa

• Latin America

Who are the key players operating in the industry?

The report covers the major market players, including:

• American Axle & Manufacturing Inc.

• Borgwarner Inc.

• Dana Incorporated

• Eaton Corporation Inc.

• GKN Automotive Limited

• Hyundai WIA Corporation

• JTEKT Corporation

• PowerTrax

• Quaife Engineering, Ltd.

• Yager Gear Enterprise Co Ltd

• ZF Friedrichshafen AG

Ask Our Expert & Browse Full Report with TOC & List of Figure: https://www.imarcgroup.com/request?type=report&id=2326&flag=E

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services.

IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automotive Differential Market Size to Surpass USD 34.7 Billion by 2033 here

News-ID: 4364676 • Views: …

More Releases from IMARC Group

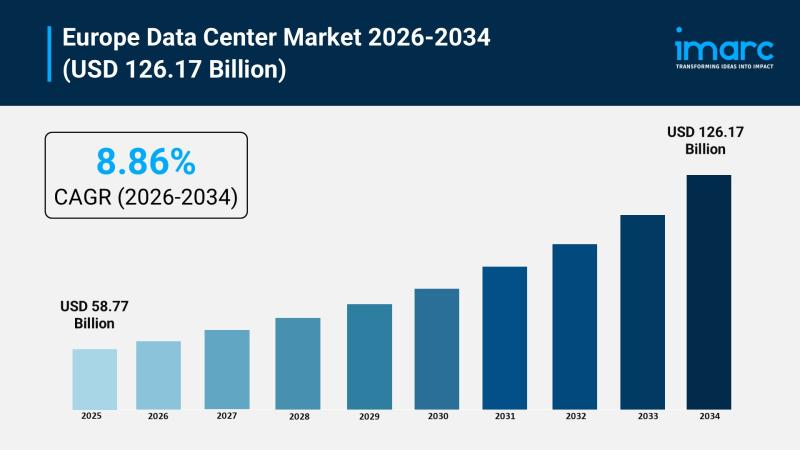

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

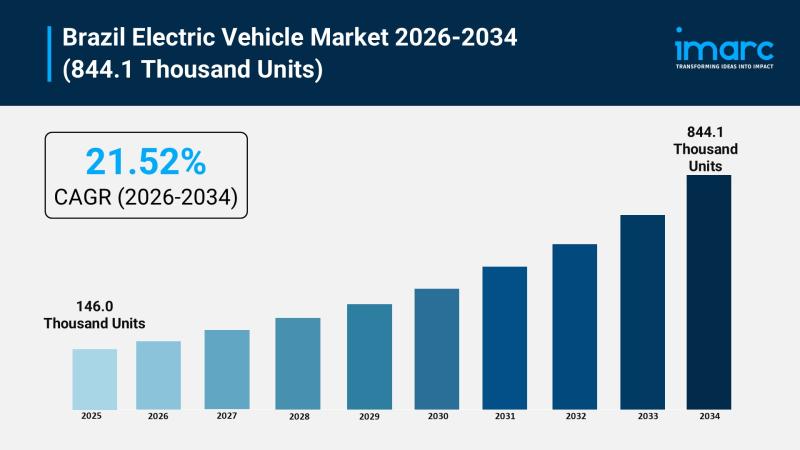

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for Differential

Differential vs Non-Differential Overload Relays: Key Differences and Applicatio …

Differential vs non differential thermal overload relay protection comes down to how they detect motor problems. Differential thermal overload relay systems compare current between phases, while non-differential thermal overload relay units monitor heat buildup in each phase separately.

What is a Differential Thermal Overload Relay?

Image: https://www.simplybuyglobal.com/wp-content/uploads/2025/09/image-44.png [https://www.simplybuyglobal.com/product/abb-ta-thermal-overload-relays-1647/]

A differential thermal overload relay [https://www.simplybuyglobal.com/blog/motor-control/overload-relay/electronic-vs-thermal-overload-relay-schneider-guide/] monitors all motor phases simultaneously and compares their current levels. When it detects an imbalance between phases, it trips…

SUV Popularity Fuels Automotive Differential Market Growth: Key Factor Driving T …

The Automotive Differential Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

What Is the Expected Automotive Differential Market Size During the Forecast Period?

The market size of automotive differentials has seen a consistent rise over the past few years. The market is projected to increase from…

Installation method of differential pressure transmitter

The installation method of differential pressure transmitter may vary depending on the model and application scenario, but generally speaking, its installation method mainly includes the following steps: 1 Preparation work Select installation location: Usually, it is chosen between the inlet and outlet of the hydraulic pipeline oil filter to ensure that the installation position is close enough to the oil filter so that the sensor can accurately monitor the status…

Accessories for differential pressure transmitter

In normal operations, several accessories are commonly used to assist differential pressure transmitters in functioning properly. One of the vital accessory is valve manifold. The purpose of its application is to protect the sensor from single-side over pressuring damage and isolate the transmitter from the process while maintenance, calibration or replacement. A typical 3-valve manifold incorporates one equalizing valve and two block valves matching the high & low pressure side…

Automotive Differential Market Scope Assessment 2030

A differential is a gear train with three shafts having the property that the rotational speed of one shaft is the average of the speeds of the others, or a fixed multiple of that average. A differential, when talking about car or a truck is a mechanical piece which allows the wheels to rotate or turn at different speeds. The outer wheels cover a large circumference covering different distances otherwise…

Media resistant differential pressure sensor ME800

(AMSYS GmbH & Co. KG, Mainz, Germany) Corrosion-resistant pressure sensors measuring the differential pressure of two aggressive media are known as wet-wet sensors and frequently used in the chemical industry. The ME800 is such a state-of-the-art sensor in this supreme discipline of pressure sensor technology. A very robust differential OEM sensor for wet-wet applications, the ME800 can measure differential pressures acting in both directions (bidirectional sensor).

The medium comes into…