Press release

How to Setup an Ethanol Plant: Cost, Licenses & Process Explained

IMARC Group's "Ethanol Production Plant Setup Cost and Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive roadmap for establishing an ethanol manufacturing facility. The report covers key operational aspects such as feedstock sourcing, production workflow, technology selection, plant layout, utilities, manpower planning, quality control systems, storage and logistics, effluent treatment, and distribution channels.The study also delivers a detailed financial evaluation of ethanol production plant setup cost, including capital investment, machinery installation, operating expenses, fixed and variable costs, revenue projections, profitability analysis, ROI, payback period, and net present value (NPV). This structured assessment helps entrepreneurs and investors evaluate feasibility before developing a detailed ethanol manufacturing business plan.

What is Ethanol?

Ethanol is a renewable biofuel and industrial alcohol produced through the fermentation of sugar- or starch-based raw materials such as sugarcane molasses, corn, wheat, rice, and cassava. It is widely used as a fuel additive in petrol blending, as well as in pharmaceuticals, chemicals, cosmetics, beverages, and sanitizers. Rising ethanol blending mandates and sustainability goals are significantly driving demand.

Product quality depends on alcohol purity, dehydration efficiency, compliance with fuel or industrial-grade standards, energy efficiency, and by-product management.

Request to Get the Sample Report: https://www.imarcgroup.com/ethanol-manufacturing-plant-project-report/requestsample

Ethanol Production Process:

The ethanol manufacturing process follows a well-defined biochemical and distillation pathway:

• Raw Material Preparation: Feedstock such as molasses or grains is cleaned, milled, or diluted to obtain fermentable sugars.

• Liquefaction and Saccharification (for grain-based plants): Starch is converted into simple sugars using enzymes.

• Fermentation: Sugars are fermented using yeast to produce alcohol and carbon dioxide.

• Distillation: The fermented mash is distilled to separate ethanol from water and impurities.

• Dehydration: Ethanol is dehydrated using molecular sieves to achieve fuel-grade purity.

• Storage and Dispatch: Finished ethanol is stored in tanks and dispatched in bulk tankers or containers.

• Effluent and By-product Treatment: Spent wash and by-products like DDGS or CO2 are treated or recovered for additional revenue.

Market Trends and Drivers:

The ethanol market is expanding due to:

• Increasing government mandates for ethanol blending in fuel

• Rising demand for renewable and low-carbon energy sources

• Growth in pharmaceutical, chemical, and sanitizer industries

• Supportive government incentives and subsidies

• Volatility in crude oil prices driving biofuel adoption

• Focus on energy security and rural agricultural development

These factors support strong long-term growth for ethanol manufacturing projects.

Plant Capacity Overview:

• Ethanol plant capacity is influenced by:

• Type of feedstock (molasses-based or grain-based)

• Daily fermentation and distillation capacity

• Machinery efficiency and automation level

• Utility availability (steam, power, water)

• Storage and logistics infrastructure

Capacity planning plays a critical role in determining overall ethanol production plant setup cost and scalability.

Key Aspects to Setup an Ethanol Production Plant

• Location to Setup Plant: Ideally near raw material sources with access to water, power, transport infrastructure, and favorable state policies.

• Market Research and Demand Analysis: Includes assessment of fuel blending demand, industrial alcohol consumption, pricing trends, and off-take agreements.

• Plant Layout and Infrastructure: Covers fermentation tanks, distillation columns, dehydration units, storage tanks, utilities, laboratories, and ETP.

• Construction and Setup Requirements: Industrial-grade civil construction, safety systems, fire protection, pollution control, and automation systems.

• Procurement of Equipment and Machinery: Fermenters, distillation columns, molecular sieves, boilers, cooling towers, centrifuges, pumps, and storage tanks.

• Documentation and Licenses: Environmental clearance, excise licenses, factory registration, safety approvals, and statutory compliance.

• Cost Analysis: Includes land or lease cost, civil construction, plant and machinery, utilities, manpower, raw materials, effluent treatment, and working capital.

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=7657&flag=C

Raw Materials List:

An ethanol production plant typically requires:

• Molasses or grains (corn, wheat, rice, etc.)

• Yeast and enzymes

• Process water

• Chemicals for pH control and treatment

• Packaging and storage materials

• Electricity, steam, and fuel

Project Economics:

• Capital Investment

• Operating Costs

• Revenue Projections

• Fixed and Variable Expenses

• Profitability Estimates

• Taxation and Depreciation

• ROI, NPV, and Break-even Analysis

Our Expertise Includes:

• Feasibility Studies and Business Planning

• Dairy Plant Setup and Optimization

• Regulatory and Licensing Support

• Market Research and Competitive Benchmarking

• Financial Modeling and Cost Analysis

About Us:

IMARC is a global market research and consulting firm providing feasibility studies, project reports, factory setup guidance, regulatory advisory, and financial modeling. We help businesses reduce investment risk and establish efficient food and dairy processing plants.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: +1-201971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Setup an Ethanol Plant: Cost, Licenses & Process Explained here

News-ID: 4364021 • Views: …

More Releases from IMARC Group

Mexico Digital Fitness Coaching Market Size, Growth, Key Players, Opportunity an …

IMARC Group has recently released a new research study titled "Mexico Digital Fitness Coaching Market Size, Share, Trends and Forecast by Streaming, Session, Revenue Model, Device, and Region, 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Digital Fitness Coaching Market Overview

The Mexico digital fitness coaching market size reached USD 181.82 Million in 2024. Looking…

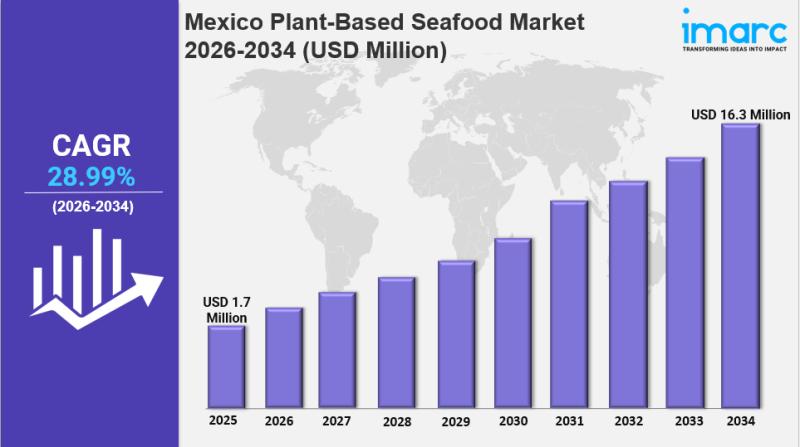

Mexico Plant-Based Seafood Market Size, Share, Latest Insights and Forecast To 2 …

IMARC Group has recently released a new research study titled "Mexico Plant-Based Seafood Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico plant-based seafood market size was valued at USD 1.7 Million in 2025 and is projected to reach USD…

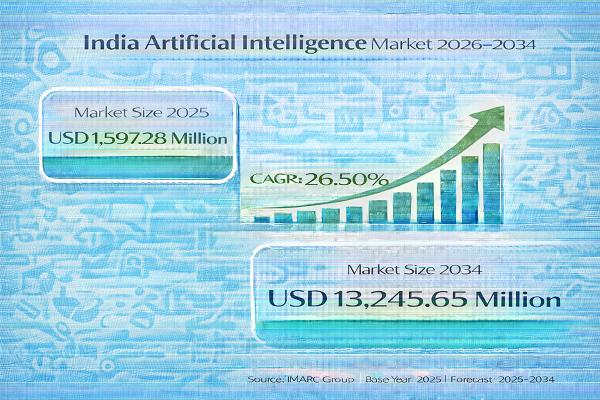

India Artificial Intelligence Market Projected to Reach 13,245.65 Million by 203 …

India Artificial Intelligence Market : Report Introduction

According to IMARC Group's report titled "India Artificial Intelligence Market Size, Share, Trends and Forecast by Type, Offering, Technology, System, End-Use Industry, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-artificial-intelligence-market/requestsample

India Artificial Intelligence Market Overview

The India artificial intelligence market size was valued at…

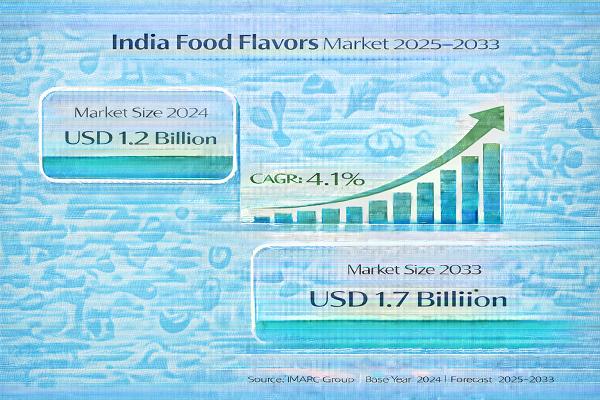

India Food Flavors Market Expected to Reach USD 1.7 Billion by 2033, Driven by 4 …

India Food Flavors Market Report Introduction

According to IMARC Group's report titled "India Food Flavors Market Size, Share, Trends and Forecast by Type, Form, End User, and Region, 2025-2033" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Note : We are in the process of updating our reports to cover the 2026-2034 forecast period. For the most recent data, insights, and industry updates,…

More Releases for Ethanol

Industrial Ethanol Market to Witness Stunning Growth | Cargill, AlcoBioFuel, Pac …

HTF MI recently introduced Global Industrial Ethanol Market study with 143+ pages in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status (2024-2032). The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence. Some key players from the complete study are ADM, Cargill, POET, Green Plains, Valero, Flint Hills Resources, Pacific Ethanol, BP Biofuels,…

Ethanol Fuel Market Opportunities 2023-2030 | AGRANA Group, Pacific Ethanol, POE …

According to HTF Market Intelligence, the Global Ethanol Fuel market to witness a CAGR of 4.61% during forecast period of 2023-2028. The market is segmented by Global Ethanol Fuel Market Breakdown by Application (Automotive and Transportation, Food and Beverage, Pharmaceutical, Cosmetics and Personal Care, Other) by Type (Synthetic Ethanol, Natural Ethanol) by Sources (Sugarcane, Corn, Wheat, Other) by Purity (Denatured, Undenatured) by Fuel blend (E5, E10, E15 - E70, E75,…

Ethanol Fuel Market Giants Spending Is Going to Boom | POET, SEKAB, Pacific Etha …

The latest study released on the Global Ethanol Fuel Market by AMA Research evaluates market size, trend, and forecast to 2028. The Ethanol Fuel market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and self-analyzed study to help understand market trends, growth drivers, opportunities and upcoming challenges and about the competitors.

Download Sample Report…

Fuel Ethanol Market Size 2023 Share, Growth Outlook, Global Analysis and Forecas …

Fuel Ethanol Market Scope & Overview Report 2023

For businesses and investors trying to grow their operations and find possible business prospects in various locations, the regional outlook portion of a Fuel Ethanol market research study is a priceless resource. This section offers relevant data on the market's present situation, including market size, marketing constraints, and industry drivers, assisting businesses in developing a thorough understanding of the market's characteristics and potential…

Global Cellulosic Ethanol Market, Global Cellulosic Ethanol Industry, Covid-19 I …

The Cellulosic Ethanol market is expected to grow from USD X.X million in 2020 to USD X.X million by 2026, at a CAGR of X.X% during the forecast period. The Global Cellulosic Ethanol Market report is a comprehensive research that focuses on the overall consumption structure, development trends, sales models and sales of top countries in the global Cellulosic Ethanol market. The report focuses on well-known providers in the global…

Ethanol Market 2018 Top Companies are Pacific Ethanol, Big River Resources, Carg …

Ethanol Market 2018 Global Industry Research report provides in depth study of using SWOT analysis i.e. Strength, Weakness, Opportunities and Threat to the organization. The Ethanol Market report also provides an in-depth survey of key players in the market which is based on the various objectives of an organization such as profiling, the product outline, the quantity of production, required raw material, and the financial health of the organization. The…