Press release

The Most Reliable Automatic Pizza Production Line Factory, CHENPIN, Delivers Scalable Solutions for Global Demand

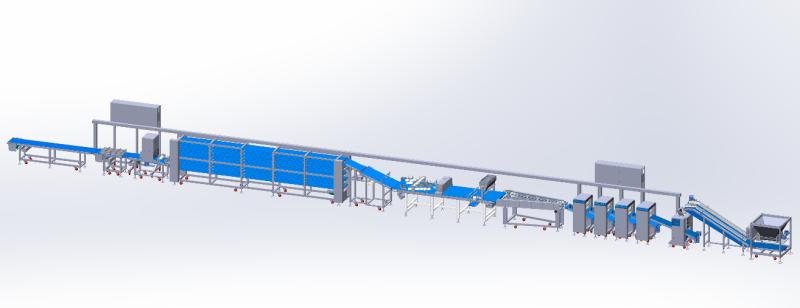

As global consumption of pizza continues to expand across retail, foodservice, and frozen food channels, manufacturers face increasing pressure to scale output while maintaining consistency and process stability. In this context, the Best Automatic Pizza Production Line Factory is no longer defined solely by nominal capacity. Instead, it is evaluated by how effectively automation integrates with dough behavior, product consistency, and long-term operational reliability. An Automatic Pizza Production Line(https://www.chenpinmachine.com/automatic-pizza-production-line-product/) typically connects dough handling, sheeting, forming, docking, and conveying into a continuous workflow. Within this evolving industrial environment, CHENPIN FOOD MACHINE CO., LTD has gained attention for developing pizza production systems that emphasize controlled dough processing rather than generic automation speed.Global Pizza Market Growth and the Shift Toward Process-Oriented Automation

Pizza has evolved from a regional specialty into a globally standardized food category. Demand continues to grow across Europe, North America, Asia, and emerging markets, driven by urbanization, the expansion of quick-service restaurant chains, and the rising consumption of frozen and ready-to-bake foods. As volumes increase, manufacturers face structural challenges that manual or semi-automatic operations struggle to address consistently.

Automation is therefore increasingly adopted not only to reduce labor dependency, but also to stabilize daily output and reduce variability. However, as production scales, flexibility becomes equally important. Modern pizza lines must process different dough formulations, hydration levels, and base dimensions while maintaining predictable baking behavior. This shift has placed greater emphasis on equipment suppliers that understand dough mechanics, not only throughput metrics.

CHENPIN's Position in Automated Dough-Based Food Equipment

Established in 2010, CHENPIN FOOD MACHINE CO., LTD(https://www.chenpinmachine.com/about-us/) builds upon a technical foundation developed by a Taiwan-based engineering team with more than three decades of experience in food equipment design prior to the company's formal founding. The company has consistently focused on automated solutions for dough-based and flatbread products, including tortillas, paratha, Laminated pastry, and pizza bases.

CHENPIN operates across research and development, manufacturing, system integration, and after-sales support. This integrated structure allows production feedback from industrial users to inform mechanical refinement and process optimization. Over time, the company has accumulated patented technologies related to dough sheeting, forming, and controlled conveying, which now form the technical backbone of its pizza production lines.

Rethinking What Defines an Automatic Pizza Production Line

An automatic pizza production line is often described as a sequence of machines performing dough reduction, cutting, and transfer. In practice, long-term performance depends on how well each stage manages dough stress, alignment, and structural integrity. Inconsistent thickness, uncontrolled gluten tension, or unstable conveying can lead to product deformation, uneven baking, and increased waste.

CHENPIN's approach places sheeting and dough conditioning at the center of line design. Rather than relying on single-step pressing, its pizza lines use staged sheeting and continuous reduction to achieve thickness control while preserving dough structure. This design logic reflects experience gained from laminated flatbread and layered pastry production, where dough behavior is highly sensitive to mechanical force.

Process Engineering Highlights in CHENPIN Pizza Production Lines

Dough Conveying and Automatic Alignment

After mixing and controlled resting, fermented dough is transferred via a dedicated conveying system designed to maintain structural integrity. Before entering the sheeting section, automatic alignment mechanisms correct dough positioning. This step ensures uniform entry into subsequent rollers, reducing uneven stretching and improving downstream thickness consistency. The conveying system prioritizes stability over speed, supporting continuous operation with reduced manual correction.

Pre-Sheeter and Continuous Sheeting Rollers

The pre-sheeter initiates gradual dough reduction, preparing the gluten network for controlled extension. Continuous sheeting rollers then reduce thickness in stages rather than through abrupt compression. This method allows the dough sheet to widen naturally while minimizing internal stress accumulation.

Non-sticking roller surfaces enable stable processing of high-hydration doughs, which are increasingly common in modern pizza formulations. By reducing adhesion and surface tearing, the system supports longer production runs with fewer interruptions for cleaning or adjustment. These design features allow the line to handle both green and pre-fermented dough with consistent results.

Disc Cutting and Docking Integration

Following sheeting, cross rollers provide secondary thickness calibration, compensating for directional stress introduced earlier in the process. Disc cutting then forms standardized pizza bases, while integrated docking perforates the surface to control gas expansion during baking. This combination reduces surface bubbling and supports predictable oven performance, particularly in frozen or par-baked applications.

Trim waste generated during cutting is automatically collected and returned through a closed-loop system, improving material utilization without disrupting line flow.

Application Scenarios Across Pizza Production Models

CHENPIN's automatic pizza production lines are applied in a range of industrial settings. Frozen pizza manufacturers benefit from uniform base dimensions and stable moisture distribution, which are critical for freezing efficiency and final bake quality. Central kitchens and foodservice suppliers use the lines to produce standardized bases that integrate smoothly with high-speed topping and baking systems. Retail and private-label producers value the ability to adjust diameter and thickness parameters to meet regional specifications without major mechanical changes.

Beyond pizza, CHENPIN's experience with tortillas, layered flatbreads, and laminated pastries strengthens its ability to address dough-related challenges that general automation suppliers may overlook.

Evaluating Suitability for Industrial Buyers

For professional buyers, the relevance of an automatic pizza production line depends on operational goals rather than headline capacity. Facilities seeking to scale output while reducing variability, managing high-hydration dough, or stabilizing frozen product performance are more likely to benefit from sheeting-based systems. Lines designed with staged reduction and alignment control tend to offer better long-term consistency than solutions focused solely on pressing speed.

CHENPIN's equipment(https://www.chenpinmachine.com/products/) is therefore most relevant for manufacturers transitioning from semi-automatic processes to continuous production, or for established producers refining consistency as volumes grow. In such contexts, automation becomes a process control tool rather than a simple labor substitute.

Supporting Scalable Growth Through Engineering Stability

As global demand for pizza and convenience foods continues to rise, manufacturers must balance higher output with predictable quality and operational resilience. Automatic pizza production lines that integrate dough behavior, mechanical stability, and modular scalability are likely to define the next stage of industry development.

By applying long-standing expertise in dough sheeting and forming to pizza production, CHENPIN continues to offer systems that align with industrial production realities. Its emphasis on controlled processing, continuous operation, and practical adaptability positions the company as a relevant option for producers evaluating long-term automation strategies.

For more information about CHENPIN's automatic pizza production lines and its full range of automated food production equipment, please visit https://www.chenpinmachine.com/.

CHENPIN FOOD MACHINE CO., LTD

No.61 Lane, Dongshe Road 129, Songjiang District, Shanghai,China

sales@chenpinsh.com

+86 021-57674551

CHENPIN FOOD MACHINE CO., LTD was established in 2010. We build upon the technical expertise and spirit of the Taiwan province team who founded CHENPIN and already had been dedicated to the development and research of food equipment for more than 30 years before founding CHENPIN FOOD MACHINE CO., LTD.With the help of our hiahly skiled research and development team CHENPIN FOOD MACHINE CO., LTD obtained many patents in the area of automated food production machinery for dough, baking and lavered pastry dough products. Our company covers the whole value chain of producing automated food production machinery such as research and development,production,sales, marketing and after-sales services.

"Quality excellence" is the goal of CHENPIN.

"Innovation through Research and Development" is our spirit.

"Perfect service" is the attitude that CHENPIN strives for.

"Trust and long term relationships with our customers" is the business philosophy that CHENPIN follows.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Most Reliable Automatic Pizza Production Line Factory, CHENPIN, Delivers Scalable Solutions for Global Demand here

News-ID: 4363507 • Views: …

More Releases from CHENPIN FOOD MACHINE CO., LTD

Is the Future Leading Company for Fully Automatic Lacha Paratha Making Machine f …

The global appetite for ethnic cuisine has reached an unprecedented peak, placing the humble lacha paratha at the center of a massive industrial transition. Traditionally, the production of this flaky, multi-layered Indian flatbread relied exclusively on the dexterity of skilled artisans who could stretch dough to near-transparency. However, as frozen food manufacturers strive for global expansion, they face a daunting challenge: maintaining handmade quality at an industrial scale while battling…

A Legacy of Excellence: How CHENPIN's Certified High Quality Food Machine Soluti …

The global food industry is witnessing a significant shift toward ethnic convenience foods, with frozen parotta and flatbreads leading the market expansion. As demand grows, commercial bakeries face the persistent challenge of maintaining traditional "handmade" quality while meeting massive production scales. High labor costs and the inconsistency of manual production often impede business growth and product reliability. To address these hurdles, CHENPIN Food Machine Co., Ltd offers a High Quality…

CHENPIN Unveils the Global Leading Automatic Tortilla Production Line: Redefinin …

In response to expanding global demand for automated flatbread and wrap-style products, the Global Leading Automatic Tortilla Production Line(https://www.chenpinmachine.com/tortilla-production-line-machine-cpe-950-product/) is setting new benchmarks in food manufacturing efficiency and consistency. This state-of-the-art solution integrates intelligent control systems,hot pressing, baking, and advanced cooling to, continuous production of tortillas, taco, lavash, and other flatbread formats with minimal manual intervention. At the forefront of these innovations stands CHENPIN FOOD MACHINE CO., LTD (CHENPIN)(https://www.chenpinmachine.com/about-us/), whose…

Process Deep Dive: How the Lacha paratha Making Machine Fully Automatic Company …

The global demand for consistent, high-quality layered flatbreads continues to grow, especially for products such as Lacha Paratha and Roti Canai . Within this context, the concept of a Fully Automatic Roti Canai Making Machine Fully Automatic Company(https://www.chenpinmachine.com/cpe-3000l-layered-lacha-paratha-production-line-machine-product/) reflects not only automation, but also the ability to industrialize traditional lamination techniques without sacrificing texture or structure.

Based on this direction, CHENPIN FOOD MACHINE CO., LTD(https://www.chenpinmachine.com/about-us/) has developed its Lacha Paratha Production…

More Releases for Pizza

A Comprehensive Study Exploring Pizza Market | Key Players- Easy Pizza, Pizza Ex …

The latest study released on the Global Pizza Market by HTF MI evaluates market size, trend, and forecast to 2031. The Pizza market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and self-analyzed study to help understand market trends, growth drivers, opportunities and upcoming challenges and about the competitors.

Key Players in This Report…

Pizza Market Demand Makes Room for New Growth Story | Easy Pizza, Pizza Express, …

HTF MI started a latest business research with the Global Pizza Market Study Forecast till 2029. This Pizza market report brings data for the estimated year 2023 and forecasted till 2029 in terms of both, value (USD Million) and volume (MT) Market. The study is conducted by applying both top-down and bottom-up approaches and further iterative methods used to validate and size market estimation and trends of the Pizza market.…

Pizza Market to See Major Growth by 2028 | Dodo Pizza, MR pizza, VISCO, Pizza Fa …

Pizza Market Report research report is a wide-ranging analysis and Impact of COVID19 in the global market and the in-detail information with segmentation has been added in this intelligence report. In this report a comprehensive analysis of current global Global Pizza Market market in terms of demand and supply environment is provided, as well as price trend currently and in the next few years. Global leading players are profiled with…

Pizza Market Is Boosting the Growth Worldwide | Pizza Pizza, The Little Caesars, …

Pizza Market Research Report 2022 This research report provides COVID-19 Outbreak study accumulated to offer Latest insights about acute features of the Pizza Market. This intelligence report includes investigations based on Current scenarios, Historical records, and Future predictions. The report contains different market predictions related to market size, revenue, production, CAGR, Consumption, gross margin, diagrams, graphs, pie charts, price, and other substantial factors. While emphasizing the key driving and restraining…

Pizza Market Is Booming Worldwide | Domino’s Pizza, Telepizza, Boston Pizza

Latest Study on Industrial Growth of Global Pizza Market 2021-2027. A detailed study accumulated to offer Latest insights about acute features of the Pizza market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends and developments of…

Pizza Vending Machine Market | Leading industry Players, Products and Services, …

Pizza Vending Machine Market describes an in-depth evaluation and Covid19 Outbreak study on the present and future state of the Pizza Vending Machine market across the globe, including valuable facts and figures. Pizza Vending Machine Market provides information regarding the emerging opportunities in the market & the market drivers, trends & upcoming technologies that will boost these growth trends. The report provides a comprehensive overview including Definitions, Scope, Application, Production…