Press release

Pfeiffer Vacuum+Fab Solutions presents the new ATH 4506 M Turbopump

With a pumping speed of 4,500 l/s for nitrogen, the new turbopump is suited for processes in semiconductor manufacturing, large-area coating, and other applications where high gas throughput is required, such as the evacuation of large vacuum chambers for space simulation.Plug&play operation with integrated controller

The ATH 4506 M comes with an integrated controller. This eliminates the need for separate external control units, which simplifies installation and reduces the space required in the system setup. The vacuum pump reaches its full rotational speed of 23,500 rotations per minute (rpm) in only nine minutes, meaning that production processes can be started quickly. For periods of inactivity, an idle mode lowers power consumption, contributing to energy-efficient operation.

Temperature management adapted to process needs

Depending on the process conditions, different operating temperatures are required. For this reason, the ATH 4506 M is available in two versions:

o A non-heated version for clean, non-corrosive applications

where additional heating is unnecessary, such as large

area coating.

o A version with a temperature management system (TMS)

up to 90 ?C for semiconductor manufacturing and other

corrosive processes where moderate heating prevents

condensation and particle formation.

By matching the vacuum pump temperature to the process, the ATH 4506 M minimizes condensation and particle buildup inside the pump, reduces wear on internal components, and prevents unplanned downtime. This leads to greater reliability, consistent product quality, and lower total cost-of-ownership for the user.

Condition monitoring and digital integration

The ATH 4506 M is equipped with internal sensors that monitor temperature, purge conditions, rotational speed, and off-axis movement. These measurements allow operators to track the status of the vacuum pump in real time, making it easier to detect irregularities at an early stage. This helps avoid unscheduled downtime and supports predictive maintenance. As the vacuum pump is IoT-ready, it can be connected to digital monitoring systems, enabling integration into automated production environments.

With IP54 protection, the vacuum pump is safeguarded against dust and splashing water. This increases its resilience in demanding industrial environments and extends service life.

Pfeiffer Vacuum+Fab Solutions

Berliner Strasse 43

35614 Asslar

Germany

https://www.pfeiffer-vacuum.com/global/de

Frau Dr.Sandra Thirtle-Hoeck

06441 802 - 1460

sandra.hoeck@pfeiffer-vacuum.com

About the Busch Group

The Busch Group is one of the world's largest manufacturers of vacuum pumps, vacuum systems, blowers, compressors and gas abatement systems. Under its umbrella, the group houses two well-known brands: Busch Vacuum Solutions and Pfeiffer Vacuum+Fab Solutions. The gas abatement systems previously offered by centrotherm clean solutions - a former Busch Group brand - are now part of the Pfeiffer portfolio.

The extensive product and service offer includes solutions for vacuum, overpressure and abatement applications in all industries, such as food, semiconductors, analytics, chemicals and plastics. This also includes the design and construction of tailor-made vacuum systems and a worldwide service network.

The Busch Group is a family business that is managed by the Busch family. More than 8,000 employees in 44 countries worldwide work for the group. Busch is headquartered in Maulburg, Baden-Wuerttemberg, in the tri-country region of Germany, France and Switzerland.

The Busch Group manufactures in its 23 own production plants in China, the Czech Republic, France, Germany, India, Romania, South Korea, Switzerland, the United Kingdom, the USA and Vietnam.

The Busch Group has an annual consolidated revenue of close to 2 billion Euro.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pfeiffer Vacuum+Fab Solutions presents the new ATH 4506 M Turbopump here

News-ID: 4352959 • Views: …

More Releases from Pfeiffer Vacuum+Fab Solutions

Pfeiffer Vacuum+Fab Solutions Introduces COMBI WVD Vacuum Booster Pump Unit

Pfeiffer Vacuum+Fab Solutions - a member of the global Busch Group - announces the launch of the COMBI WVD vacuum booster pump unit. This compact unit offers high performance and a small footprint. It is an expansion to the existing COMBI series and consists of a PANDA vacuum booster and a DuoVane two-stage oil-lubricated rotary vane vacuum pump.

The COMBI WVD vacuum booster pump unit features high pumping speed and low…

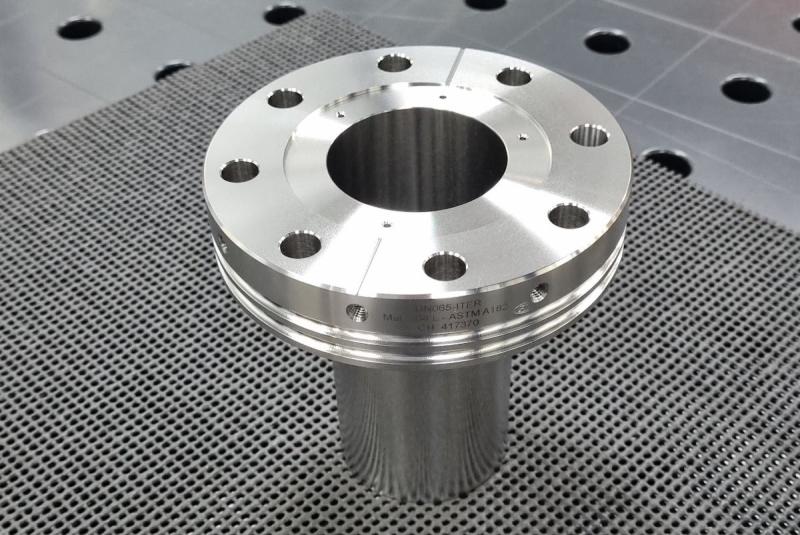

Pfeiffer Vacuum+Fab Solutions Becomes Official Global Supplier of ITER Flanges

Pfeiffer Vacuum+Fab Solutions, a member of the global Busch Group, announces its completion of the qualification process for the supply of ITER-specific flanges.

After a one-year evaluation period, Pfeiffer now offers ITER flanges to support the world's largest fusion energy research project. The ITER organization has officially qualified Pfeiffer as a recommended supplier of ConFlat, ISO, ITER, and many more flange styles for use in US ITER hardware procurements.

ITER:…

ARGOS Transforms Fab Operations with Data and Predictive Maintenance Service

Pfeiffer Vacuum+Fab Solutions - a member of the global Busch Group - today announced ARGOS, an on-site machine learning and analytics service for semiconductor fabs that converts operational data into prioritized, risk-based actions to increase uptime, reduce total cost-of-ownership, and stabilize yield. This vendor-independent solution is anchored in data maturity and operational expertise.

ARGOS addresses a core industry reality. Predictive maintenance delivers value only when two foundations are strong: data maturity…

Pfeiffer Vacuum+Fab Solutions Presents Vacuum Technology and Gas Abatement Syste …

Pfeiffer - a member of the global Busch Group - will be showcasing its innovative technology from November 18 to 21, 2025, at the Semicon Europa 2025 trade show in Munich.

Visitors to Semicon Europa can look forward to innovative vacuum technology and gas abatement systems used in semiconductor fabs and at OEMs. They can talk to experts from Pfeiffer Vacuum+Fab Solutions about vacuum pumps, leak detectors, gas abatement systems…

More Releases for Busch

Busch Vacuum Solutions at IFFA 2022

Energy-efficient and sustainable vacuum solutions for the meat industry

From May 14 to 19, 2022, Busch Vacuum Solutions will be showcasing its latest vacuum solutions for the processing and packaging of meat and alternative proteins at IFFA in Frankfurt am Main. For the first time, the meeting place for the global meat industry is once again focusing on the face-to-face encounter of the industry, and Busch will welcome visitors to…

Busch Vakuumteknikk AS and VakuumConsult AS become Busch Vacuum Solutions Norway …

VakuumConsult AS was founded by Ivar Berg in 1999 and has since then established itself as the dominant company in medium and high vacuum in Norway. The company has been a dealer for Alcatel, which later became Adixen before the company was bought out by Pfeiffer Vacuum. Ivar Berg, and his son Espen, have delivered excellent products and excellent customer service over many years and are recognized names in the…

Busch China celebrates 20th anniversary

The history of Busch Vacuum Solutions in China can be traced back to 1981. A first contact at the Hanover Fair paved the way for Busch Vacuum Solutions to China. At that time, China was still in transition and the industry of vacuum was just being established. As one of the first Western companies, Dr. Karl Busch and his wife Ayhan set off for the distant country with a vacuum…

New Leak Detectors from Busch

Busch Vacuum Solutions has now introduced two new leak detectors to the market. They are ideal for testing the tightness of vacuum systems or individual vacuum components and for locating possible leaks and quantifying their leakage rate. The two new leak detectors TAPIR HL 1102 A and 2216 A operate with helium or hydrogen as a tracer gas and can detect leaks with a leakage rate of up to 5…

Busch promotes sustainability at K 2019

Degassing recycled plastics during the extrusion process was the focus of the Busch Vacuum Solutions booth at the K 2019 trade show. Busch premiered its latest generation of PLASTEX degassing systems, which can also be used for the extrusion of recycled material. With these systems, Busch is contributing to the recycling of plastics. Furthermore, PLASTEX degassing systems offer full connectivity by exchanging data with the extruder’s control unit, making them…

Busch successful at ComVac 2017

The Busch Vacuum Pumps and Systems trade show presentation received a great response from the nearly 30,000 visitors at the Leading Trade Fair for Compressed Air and Vacuum in Hanover, Germany. The interested trade show crowds were able to discover the varied world of vacuum at Busch and find out about highly energy-efficient and economical vacuum solutions.

Numerous visitors from 47 different countries used the opportunity to talk to the Busch…