Press release

High-Quality SiSiC Heat Exchanger Tubes: Efficiency Gains in Corrosive High-Temp Systems

As industrial processes operate at ever-higher temperatures and under increasingly aggressive chemical conditions, heat exchanger performance has become a decisive factor in system efficiency and reliability. In the middle of this transformation, many global users are turning to a High-quality SiSiC Heat Exchanger Tube manufacturer(https://www.hshightec.com/reaction-bonded-silicon-carbide/reaction-bonded-sic-tube/sisic-heat-exchanger.html) capable of delivering materials that withstand corrosion, thermal shock, and long-term continuous operation. HUANSHANG HIGHTECH CO., LTD, also known as HUAN SHANG (YIXING) INC, applies its extensive silicon carbide expertise to produce advanced SiSiC heat exchanger tubes that help industries achieve higher efficiency and lower lifecycle costs in corrosive high-temperature systems.SiSiC (reaction bonded silicon carbide, RBSIC) heat exchanger tubes are engineered for environments where conventional metal alloys and traditional ceramics fail. With high thermal conductivity, excellent oxidation and corrosion resistance, low thermal expansion, and strong mechanical stability at elevated temperatures, SiSiC tubes enable efficient heat transfer while maintaining structural integrity. These properties make them particularly suitable for waste heat recovery, chemical processing, energy systems, and other applications exposed to extreme thermal and chemical stress.

Industry Outlook: Rising Demand for Advanced Heat Exchanger Materials

The global heat exchanger market is undergoing a structural upgrade, driven by energy efficiency requirements, environmental regulations, and the rapid expansion of high-temperature industrial processes. As industries seek to recover waste heat and optimize thermal management, the limitations of traditional materials are becoming increasingly apparent.

Energy efficiency is one of the strongest growth drivers. Governments and regulatory bodies worldwide are encouraging or mandating reduced energy consumption and lower emissions. Waste heat recovery systems, flue gas cooling units, and high-temperature process exchangers are being integrated into more industrial facilities. However, these systems often operate under corrosive conditions involving acidic gases, particulates, or high-moisture environments. Metallic heat exchanger tubes, even those made from high-alloy steels or nickel-based alloys, can suffer from corrosion, oxidation, and creep over time, leading to reduced efficiency and frequent replacement.

At the same time, process temperatures are steadily increasing in sectors such as steel, non-ferrous metallurgy, ceramics, glass, chemical processing, and advanced materials manufacturing. Higher operating temperatures improve process efficiency and product quality but place extreme stress on heat exchanger components. Silicon carbide, with its high melting point and thermal stability, is increasingly viewed as a viable solution for these demanding applications.

The transition toward cleaner energy and sustainable production further accelerates demand for advanced heat exchanger materials. Biomass energy, waste-to-energy plants, and hydrogen-related processes all require heat exchangers capable of handling corrosive exhaust streams at high temperatures. In addition, lithium battery and solar energy manufacturing involve precise thermal management under controlled atmospheres, creating new application scenarios for SiSiC heat exchanger tubes.

From a market perspective, customers are shifting their focus from initial procurement cost to total cost of ownership. Longer service life, reduced downtime, and stable thermal performance are now key purchasing criteria. This trend favors advanced ceramic materials that can deliver consistent performance over extended periods with minimal maintenance.

Global sourcing strategies are also evolving. Industrial users increasingly seek suppliers that combine technical expertise, stable quality, and scalable production. Manufacturers with comprehensive product portfolios and experience across multiple industries are better positioned to support complex thermal system requirements.

Looking ahead, the demand for silicon carbide heat exchanger tubes is expected to grow steadily as industries continue to pursue higher efficiency, durability, and environmental compliance. SiSiC materials are likely to play an increasingly important role in next-generation thermal systems.

HUANSHANG HIGHTECH: Delivering SiSiC Solutions with Proven Performance

Founded in 2005, HUANSHANG HIGHTECH CO., LTD is a foreign-invested enterprise specializing in high-temperature and heat-resistant materials. Operating under the names HUANSHANG HIGHTECH CO., LTD and HUAN SHANG (YIXING) INC, the company manages three family-owned factories, each focused on different product categories. This structure enables HUANSHANG to combine specialized manufacturing with group-level integration and long-term investment.

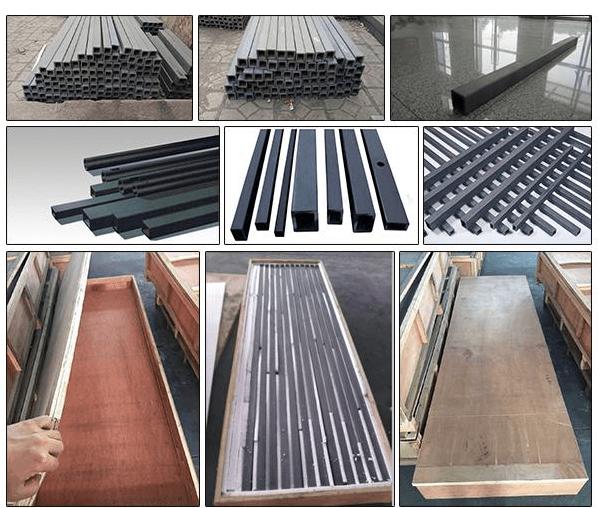

One of HUANSHANG's core factories is dedicated to the production of sintered silicon carbide products, including reaction bonded silicon carbide (RBSIC/SiSiC) and oxide silicon carbide components. Building on this foundation, the company manufactures SiSiC heat exchanger tubes designed to perform reliably in corrosive, high-temperature environments.

HUANSHANG's SiSiC heat exchanger tubes offer a combination of high thermal conductivity and exceptional chemical stability, enabling efficient heat transfer while resisting corrosion from acidic or alkaline media. Their low thermal expansion coefficient reduces the risk of cracking under rapid temperature changes, while their mechanical strength supports long-term operation under pressure and thermal load.

The company's products are widely used across industries such as ceramics, bricks and tiles, microcrystalline stone, foam ceramic insulation materials, powder metallurgy, lithium battery manufacturing, solar energy, magnetic materials, abrasive tools, geological prospecting and analysis, precision casting, food processing, and the steel industry. In many of these sectors, heat recovery and thermal control are essential to process efficiency and sustainability.

In waste heat recovery projects for steel and metallurgical plants, HUANSHANG SiSiC heat exchanger tubes help customers improve energy utilization while reducing maintenance frequency. In chemical and environmental systems, the tubes maintain stable performance despite exposure to corrosive gases and liquids. Customers in new energy industries value the material purity and dimensional stability that support precise thermal management.

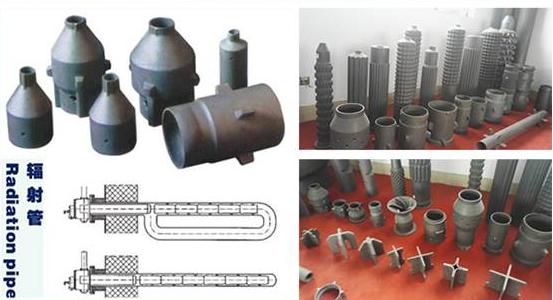

HUANSHANG's competitive advantage also lies in its comprehensive product range. In addition to heat exchanger tubes, the company supplies silicon carbide beams, rollers, radiant tubes, plates, battens, setters, and customized kiln furniture components. As a group company that has also acquired and invested in other factories, HUANSHANG is recognized as one of the industry players with a relatively complete range of kiln furniture and heat-resistant material specifications.

Long-term customer cooperation is central to HUANSHANG's business model. By working closely with system designers, kiln manufacturers, and end users, the company supports application-specific optimization and reliable integration of silicon carbide components into complex thermal systems.

Supporting Sustainable and Efficient Thermal Systems

HUANSHANG HIGHTECH places strong emphasis on quality management, from raw material control and forming processes to sintering, machining, and final inspection. Continuous investment in equipment and process improvement ensures consistent product performance and reliable delivery.

As industries worldwide seek to improve energy efficiency, reduce emissions, and operate under harsher conditions, SiSiC heat exchanger tubes will become increasingly important. HUANSHANG HIGHTECH CO., LTD remains committed to advancing silicon carbide solutions that support safer, cleaner, and more efficient high-temperature systems.

For more information about HUANSHANG's SiSiC heat exchanger tubes and complete heat-resistant material solutions, please visit https://www.hshightec.com/.

Room918,New World Plaza,No. 136W Est Of Taige Rd,Yixing, Jiangsu, China

HUANSHANG HIGHTECH CO., LTD, and we also have another name is HUAN SHANG (YIXING) INC, our company is a foreign-invested enterprise, under the name we have three family factories specializing in producing different products.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release High-Quality SiSiC Heat Exchanger Tubes: Efficiency Gains in Corrosive High-Temp Systems here

News-ID: 4351571 • Views: …

More Releases from HUANSHANG HIGHTECH CO., LTD

Top-Rated SiSiC/RBSIC Radiant Tubes: Clean Heating Performance for Modern Furnac …

As global industries accelerate toward cleaner, more efficient, and more precise thermal processing, radiant heating technology is gaining renewed attention. In the middle of this shift, top-rated SiSiC/RBSIC/silcon carbide radiant tube products(https://www.hshightec.com/reaction-bonded-silicon-carbide/reaction-bonded-sic-tube/sisic-radiant-tube.html) are becoming a preferred choice for modern furnaces that require indirect, uniform, and contamination-free heating. HUANSHANG HIGHTECH CO., LTD-also operating under the name HUAN SHANG (YIXING) INC-leverages nearly two decades of expertise in silicon carbide manufacturing to deliver…

HUANSHANG SiSiC/RBSIC Carbide Beams: High-Load Kiln Support Solutions for Extrem …

As global high-temperature industries continue to push the limits of efficiency, durability, and sustainability, advanced ceramic materials are becoming essential to modern kiln systems. In this context, High-quality SiSiC/RBSIC/silcon carbide beam products(https://www.hshightec.com/reaction-bonded-silicon-carbide/reaction-silicon-carbide-beam/) have emerged as a critical solution for extreme heat zones, offering exceptional load-bearing capacity, thermal stability, and long service life. HUANSHANG HIGHTECH CO., LTD, also known as HUAN SHANG (YIXING) INC, stands at the forefront of this technological…

Design Checklist for SiSiC Heat Exchanger Tubes: Wall Thickness, Joining & Therm …

As high-temperature industrial systems grow more complex and demanding, the design of heat exchanger components has become a critical engineering focus. In the middle of this evolution, selecting a High-quality SiSiC Heat Exchanger Tube manufacturer(https://www.hshightec.com/reaction-bonded-silicon-carbide/reaction-bonded-sic-tube/sisic-heat-exchanger.html) is essential to ensure long-term reliability, thermal efficiency, and resistance to corrosion and thermal fatigue. HUANSHANG HIGHTECH CO., LTD, also known as HUAN SHANG (YIXING) INC, brings nearly two decades of experience in silicon carbide…

Inside HUANSHANG's SiSiC/RBSIC Roller Factory: Scaling Quality for Global Kiln L …

As global kiln technology evolves toward higher efficiency, larger production capacity, and stricter quality control, silicon carbide rollers have become a core component in modern high-temperature kilns. In the middle of this transformation, the role of a wholesale SiSiC/RBSIC/silcon carbide roller factory(https://www.hshightec.com/reaction-bonded-silicon-carbide/silicon-carbide-rollers.html) is more critical than ever, ensuring stable supply, consistent quality, and scalable manufacturing for international kiln lines. HUANSHANG HIGHTECH CO., LTD, also operating under the name HUAN SHANG…

More Releases for HUAN

Hot-Pressed Magnets Market Current Scenario Analysis Report till 2029 - Galaxy M …

Discover the Latest Market Trends and Insights on Hot-Pressed Magnets Market 2023!!!

The market insights reports have announced the publication of a new report titled Hot-Pressed Magnets Market, which provides regional and global market data expected to increase in value within the forecast period (2023-2029). The in-depth analysis of the global Hot-Pressed Magnets Market offers critical insights into the industry's changing dynamics, value chain analysis, prominent investment pockets, competitive scenarios, geographical landscape, and…

NdFeB Permanent Market Forecasts and Growth Opportunity By Industry Players: Hit …

The NdFeB Permanent Magnets report understands the current and future competitive scenario across types, countries, and applications.It provides accurate, up-to-date analysis of markets and companies.The report use reliable information and analysis to gain a deeper understanding of the current factors impacting the industry.

The NdFeB Permanent Magnets report provides exact and accurate data that helps companies of all sizes to make timely decisions. Furthermore, the report provides robust solutions to customers,…

Global Steam Box Markets Overview 2020: Fotile, Quickly Food Machinery, Midea, S …

The Steam Box market report will provide one with overall market analysis, statistics, and every minute data relating to the Steam Box market necessary for forecasting its revenue, factors propelling & hampering its growth, key market players SIEMENS, Midea, Fotile, Gei Huan Enterprise, Quickly Food Machinery, Jiangsu JM Machinery, Shanghai Quan you, and much more. In addition, the key focus points of the report are services, analytics, billings, management, and…

Laptop Plastic Casings Market Insights 2020 - Waffer, JUTENG, Huan Hsin, Catcher …

The research report "Laptop Plastic Casings Market: Global and Regional Analysis 2019 – 2024" discover accurate information about the long run prospects of this Laptop Plastic Casings market, which can help industry players to understand the flow of the market throughout the period 2019-2024. The global Laptop Plastic Casings market has defined the market scenario in an orderly way, emphasizing the industrial development, prominent players engaged from the current Laptop…

Industry Verticals: Laptop Plastic Casings Market By Key Players: Waffer, JUTENG …

Qyresearchreports include new market research report 3D Map System Market For Automotive to its huge collection of research reports.

This report studies the global Laptop Plastic Casings market status and forecast, categorizes the global Laptop Plastic Casings market size (value & volume) by manufacturers, type, application, and region. This report focuses on the top manufacturers in North America, Europe, Japan, China and other regions (India, Southeast Asia, Central & South America,…

Steam Box Market 2017 - SIEMENS, Midea, Fotile, Gei Huan Enterprise, Quickly Foo …

Apex Research, recently published a detailed market research study focused on the "Steam Box Market" across the global, regional and country level. The report provides 360° analysis of "Steam Box Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global Steam Box industry, and estimates the future trend of Steam Box market…