Press release

Aluminium Die Casting Market Set to Reach USD 152.91 Billion by 2032, Driven by Lightweighting, EV Expansion, and Advanced Manufacturing Technologies

The Global Aluminium Die Casting Market, valued at USD 81.40 billion in 2024, is poised for robust expansion over the coming decade. According to industry analysis, the market is projected to grow at a compound annual growth rate (CAGR) of 8.2% from 2025 to 2032, reaching nearly USD 152.91 billion by 2032. This strong growth trajectory reflects the increasing adoption of lightweight materials across automotive, transportation, electronics, aerospace, and industrial manufacturing sectors, coupled with rapid technological advancements in die casting processes.For a comprehensive overview of this study, navigate to:https://www.maximizemarketresearch.com/request-sample/133357/

Market Overview

Aluminium die casting is a high-precision manufacturing process that involves injecting molten aluminium into reusable steel molds under high pressure to produce complex components with excellent dimensional accuracy and surface finish. The process offers multiple advantages, including high strength-to-weight ratio, corrosion resistance, superior thermal and electrical conductivity, recyclability, and cost-efficiency for large-scale production.

These attributes have positioned aluminium die casting as a critical manufacturing solution for industries seeking lightweight, durable, and high-performance components. The automotive and transportation sector represents the largest end-use segment, driven by the need to improve fuel efficiency, reduce emissions, and enhance overall vehicle performance. Aluminium die-cast parts are extensively used in engine blocks, transmission housings, structural components, and increasingly in electric vehicle (EV) battery housings and motor components.

Beyond automotive applications, electronics and consumer goods manufacturers rely on aluminium die casting for heat sinks, enclosures, and intricate parts, while aerospace and industrial machinery sectors benefit from its precision, durability, and repeatability. Continuous innovations in hot chamber die casting machines, servo-hydraulic systems, automation, and real-time process monitoring are further improving productivity, energy efficiency, and product consistency across the value chain.

Market Drivers and Key Trends

Rising Demand for Lightweight Automotive Components

One of the primary growth drivers of the Aluminium Die Casting Market is the global push toward vehicle lightweighting. Stricter emission regulations, such as Euro 7 standards in Europe and CAFE norms in North America, are compelling automakers to reduce vehicle weight without compromising safety or performance. Aluminium die casting enables the production of strong yet lightweight components, directly contributing to improved fuel efficiency and lower carbon emissions.

The rapid expansion of the electric vehicle market has further amplified demand. EVs require lightweight materials to maximize driving range and battery efficiency, making aluminium die casting indispensable for battery housings, motor casings, and thermal management systems.

Integration of Industry 4.0 and Automation

The adoption of Industry 4.0 technologies represents a significant opportunity for market growth. Automated robotic systems, IoT-enabled sensors, and AI-driven quality control solutions are transforming traditional die casting operations. These technologies enable real-time monitoring of critical parameters such as mold temperature, injection pressure, and cooling rates, reducing defect rates and enabling predictive maintenance.

AI-powered process optimization is helping manufacturers minimize , conserve energy, and extend tool life, while automation improves worker safety and operational efficiency. Together, these advancements are enhancing scalability and responsiveness to changing design requirements.

Sustainability and Recycled Aluminium

Sustainability has emerged as a key trend shaping the Aluminium Die Casting Market. Manufacturers are increasingly adopting recycled aluminium and energy-efficient production practices to align with circular economy goals and reduce their carbon footprint. Recycled aluminium requires significantly less energy to process than primary aluminium, offering both environmental and cost advantages.

Consumer Attitudes and Claim-Based Trends

OEMs and end-users are increasingly prioritizing sustainability claims, lightweight performance, and lifecycle efficiency when selecting materials and manufacturing partners. There is growing preference for suppliers that can demonstrate reduced emissions, high recyclability, and compliance with environmental regulations. Claims related to durability, precision, and cost-effectiveness also influence purchasing decisions, particularly in automotive and electronics applications where long-term reliability is critical.

Key Market Segments

By Process

The market is segmented into Pressure Die Casting, Vacuum Die Casting, Squeeze Die Casting, Gravity Die Casting, and Others. Among these, Pressure Die Casting dominates the global market due to its ability to produce high volumes of complex, thin-walled components with tight tolerances and smooth surface finishes. Its cost-efficiency, minimal post-machining requirements, and suitability for mass production make it the preferred choice across automotive, aerospace, and electronics industries.

By Application

By application, the Aluminium Die Casting Market is segmented into Automotive and Transportation, Industrial Machinery, Building and Construction, Electronics and Consumer Goods, Aerospace, Healthcare and Medical, and Others. The Automotive and Transportation segment leads the market, supported by increasing vehicle production, electrification trends, and stringent emission regulations. Aluminium die casting's scalability and consistency make it ideal for high-volume automotive manufacturing.

Get 30% Off Market Research - Download Your Report Today:https://www.maximizemarketresearch.com/market-report/aluminum-die-casting-market/133357/

Regional Insights

The Asia Pacific region dominated the Aluminium Die Casting Market in 2024 and is expected to maintain its leadership throughout the forecast period. Rapid industrialization, expanding automotive production, and significant investments in manufacturing infrastructure across China, India, and Japan are key contributors to regional growth.

China, as the world's largest automotive producer, remains a major growth engine, while India's focus on domestic manufacturing and EV adoption is accelerating demand for die-cast components. Strategic initiatives such as new plant expansions, advanced alloy development, and AI integration in manufacturing are strengthening Asia Pacific's position as a global hub for aluminium die casting.

Competitive Landscape and Major Players

The Aluminium Die Casting Market is highly competitive, featuring a mix of global and regional players competing on technology, capacity, quality, and cost. Leading companies are investing heavily in advanced die casting technologies, automation, and geographic expansion to strengthen their market presence.

Key players include:

Ryobi Die Casting

Nemak S.A.B. de C.V.

GF Casting Solutions

Endurance Technologies Ltd.

Dynacast International

Shiloh Industries

Regional players, particularly in Asia Pacific, benefit from lower labor costs and supportive government policies, intensifying competition. Mergers, acquisitions, and strategic partnerships remain common strategies to expand product portfolios and global reach.

Industry Developments and Outlook

Recent developments underscore the market's dynamic nature. In 2024, Ryobi Die Casting announced a USD 50 million investment to expand its Mexico facility to support rising EV demand. Similarly, Dynacast introduced advanced hot chamber aluminium die casting machines featuring servo-hydraulic injection systems, delivering higher efficiency and energy savings.

Looking ahead, the Aluminium Die Casting Market is expected to benefit from continued growth in electric mobility, aerospace applications, and sustainable manufacturing practices. As industries increasingly demand lightweight, high-performance, and eco-friendly components, aluminium die casting will remain a cornerstone technology, supporting the market's strong outlook through 2032.

Related Reports:

♦ Wood Truss Market https://www.maximizemarketresearch.com/market-report/global-wood-truss-market/100679/

♦ Inductor Market https://www.maximizemarketresearch.com/market-report/global-inductor-market/24598/

♦ Bentonite Market https://www.maximizemarketresearch.com/market-report/global-bentonite-market/25076/

Most performing reports:

♦ Microalgae market https://www.maximizemarketresearch.com/market-report/global-microalgae-based-products-market/63970/

♦ Global Small interfering RNA (siRNA) Therapeutics Market https://www.maximizemarketresearch.com/market-report/global-small-interfering-rna-sirna-therapeutics-market/91788/

♦ Energy Supplements Market https://www.maximizemarketresearch.com/market-report/energy-supplements-market/193885/

♦ Global Cleaning Services Market https://www.maximizemarketresearch.com/market-report/global-cleaning-services-market/23730/

♦ Data Center Liquid Immersion Cooling Market https://www.maximizemarketresearch.com/market-report/global-data-center-liquid-immersion-cooling/107348/

Connect With Us:

MAXIMIZE MARKET RESEARCH PVT. LTD.

2nd Floor, Navale IT park Phase 3,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

+91 9607365656

sales@maximizemarketresearch.com

About Maximize Market Research:

Maximize Market Research is one of the fastest-growing market research and business consulting firms serving clients globally. Our revenue impact and focused growth-driven research initiatives make us a proud partner of majority of the Fortune 500 companies. We have a diversified portfolio and serve a variety of industries such as IT & telecom, chemical, food & beverage, aerospace & defense, healthcare and others.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminium Die Casting Market Set to Reach USD 152.91 Billion by 2032, Driven by Lightweighting, EV Expansion, and Advanced Manufacturing Technologies here

News-ID: 4350032 • Views: …

More Releases from MAXIMIZE MARKET RESEARCH PVT. LTD.

Procurement Software Market Forecast: Automation, Analytics and Cloud Adoption

Procurement Software Market size was valued at USD 8.18 billion in 2024, and the total revenue is expected to grow at CAGR of 10.8 % from 2025 to 2032, reaching nearly USD 18.58 billion.

Procurement Software Market Overview:

The procurement software market is a core component of enterprise digital transformation, enabling organizations to automate, standardize, and optimize purchasing activities across goods and services. Procurement software solutions support functions such as supplier discovery,…

What Is Driving Growth in the Independent Software Vendors (ISVs) Market?

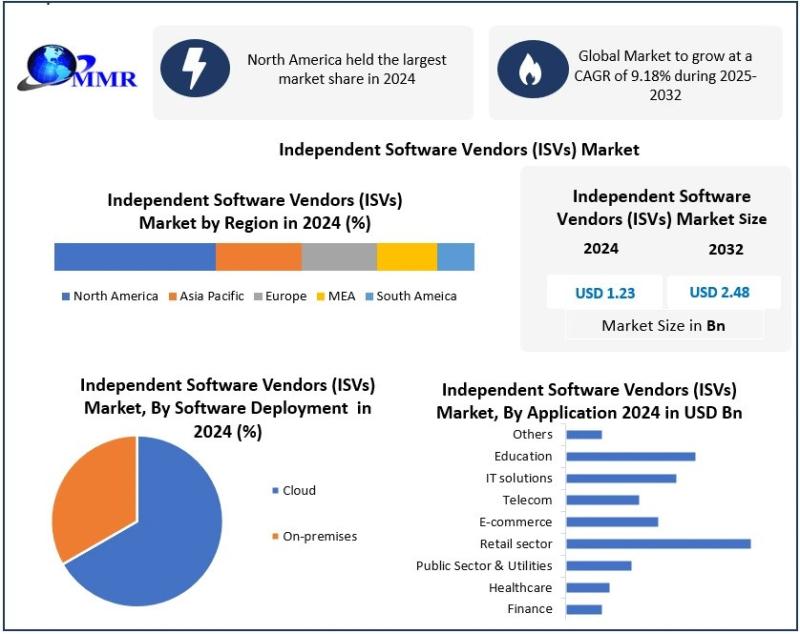

Independent Software Vendors (ISVs) Market was valued at USD 1.23 Bn in 2024, and total global Independent Software Vendors (ISVs) Market revenue is expected to grow at a CAGR of 9.18% and reach nearly USD 2.48 Bn from 2025 to 2032. Driven by Rising Demand for Multi-cloud & Hybrid Cloud.

Independent Software Vendors (ISVs) Market Overview:

The Independent Software Vendors (ISVs) market represents a critical layer of the global software ecosystem, delivering…

India Lighting Market Analysis: Industry Dynamics and Growth Forecast

India Lighting Market size was valued at USD 4139.2 Million in 2024 and the total India Lighting Market size is expected to grow at a CAGR of 7.1% from 2025 to 2032, reaching nearly USD 7674 Million by 2032.

India Lighting Market Overview:

The India lighting market is a rapidly evolving sector driven by urbanization, infrastructure expansion, and the transition toward energy-efficient illumination solutions. Lighting demand spans residential, commercial, industrial, and outdoor…

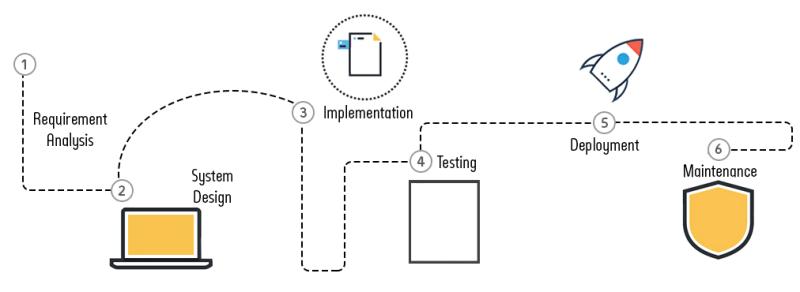

Custom Software Development Services Market Forecast: Cloud, AI and DevOps Trend …

Agricultural Waste Market size was valued at USD 20.20 Billion in 2025 and the total Agricultural Waste revenue is expected to grow at a CAGR of 7.20% from 2025 to 2032, reaching nearly USD 32.86 Billion by 2032.

Custom Software Development Services Market Overview:

The custom software development services market plays a pivotal role in enabling enterprises to align digital systems with specific operational, regulatory, and customer-experience requirements. Unlike off-the-shelf solutions, custom…

More Releases for Casting

Investment Casting Manufacturers in India - Leading Investment Casting Suppliers

Have a need for investment casting? Get a quote from us now.

Meena Cast Pvt. Ltd. is an expanding company working in an excellent premise in the Shapar Industrial Estate, 15 kilometres from Rajkot Gujarat INDIA.

Investment Casting Manufacturers in India = https://www.meenacast.com/

We have established an image for competently fulfilling our clients' needs. We ensure the highest level of quality at all levels of our strategy. We always make deliveries on period…

Pump Casting Manufacturers - Best Pump Casting Suppliers & Exporters

Pump Casting Manufacturers - Best Pump Casting Suppliers & Exporters

Best Pump Casting Manufacturers in India, Top Pump Casting Suppliers, Pump Casting Exporters from Rajkot Gujarat

Your search for top-notch pump casting manufacturers ends here!

Introduction

In the world of industrial machinery, pumps play a crucial role in various sectors such as manufacturing, construction, and agriculture. One of the key components of a pump is the pump casting, which forms the outer shell and…

Trident Steels - Investment Casting, Stainless Steel Investment Casting, Steel I …

With decades of experience in this industry, we have become the preferred partner for global companies who look for high-end metal casting manufacturing from India. Our investment casting company in India offers best-in-class quality products and services to our customers. We are a customer-centric company and invest in our people, processes, and technology to provide high-quality products every time. This has helped us to become the preferred partner for companies…

Automotive Parts Magnesium Die Casting Market 2021 Status and Outlook-cago White …

The report presents an in-depth assessment of the Automotive Parts Magnesium Die Casting Market including enabling technologies, key trends, market drivers, challenges, standardization, regulatory landscape, deployment models, operator case studies, opportunities, future roadmap, value chain, ecosystem player profiles and strategies. The report also presents forecasts for Automotive Parts Magnesium Die Casting from 2021 till 2025. The report covers the pre COVID-19 historic data, impact of COVID-19 and post-COVID-19 (Corona Virus)…

Automotive Parts Die Casting Market Global outlook 2021 to 2026: Gibbs Die-casti …

The report presents an in-depth assessment of the Automotive Parts Die Casting Market including enabling technologies, key trends, market drivers, challenges, standardization, regulatory landscape, deployment models, operator case studies, opportunities, future roadmap, value chain, ecosystem player profiles and strategies. The report also presents SWOT Analysis and forecast for Automotive Parts Die Casting investments. The final report copy provides the impact analysis of novel COVID-19 pandemic on the Automotive Parts Die Casting market…

Automotive Parts Die Casting Market 2019 Global Key Country Analysis: Alcast Com …

Automotive Parts Die Casting Market Research Report, by Production Process Type (Pressure, Vacuum, Squeeze and Semi-Solid), Raw Material Type (Aluminum, Zinc, Magnesium and Others), By Application Type, Vehicle Type, and by Regions - Forecast till 2023

The Key Players In Automotive Parts Die Casting Market Are:

Alcast Company (U.S.), Dynacast, LLC (U.S.), Endurance Technologies Limited (India), Gibbs Die Casting Corp (U.S.), and Rockman Industries (India). Ryobi Die Casting Inc. (U.S.), Kinetic Die…