Press release

Adhesive Dispensing Equipment Market to Expand at 5.3% CAGR Through 2033

The global adhesive dispensing equipment market is undergoing a phase of steady and structurally significant growth, driven by the rising need for precision bonding, automation, and material efficiency across multiple industrial sectors. Adhesive dispensing equipment refers to machines and systems designed to apply adhesives in controlled volumes, patterns, and speeds for industrial manufacturing processes. These systems play a vital role in improving production consistency, minimizing waste, and enhancing product quality in industries where bonding, sealing, laminating, or coating are critical operations. As manufacturing transitions toward Industry 4.0, automated adhesive dispensing systems are becoming indispensable for ensuring speed, accuracy, and repeatability in high-volume production environments.Download Free Sample & Check the Latest Market Analysis: https://www.persistencemarketresearch.com/samples/16447

In terms of market size, the global adhesive dispensing equipment market is likely to be valued at US$39.5 billion in 2026 and is projected to reach US$56.7 billion by 2033, expanding at a CAGR of 5.3% from 2026 to 2033. This growth is fueled by rising demand from key end-use industries such as construction, packaging, lamination, disposable hygiene products, and technical textiles. The growing shift toward lightweight materials, miniaturization in electronics, and sustainable packaging is further accelerating the adoption of advanced dispensing solutions. Among the product segments, automated and semi-automated dispensing systems are emerging as the leading category due to their operational efficiency and ability to integrate with robotic and conveyor-based production lines. Geographically, the Asia Pacific region dominates the market, driven by rapid industrialization, booming manufacturing activity, expanding construction projects, and the presence of major electronics, automotive, and packaging production hubs in countries such as China, Japan, South Korea, and India.

Key Highlights from the Report

• The market is expected to grow at a steady CAGR of 5.3% between 2026 and 2033, driven by industrial automation and rising adhesive usage.

• Automated dispensing systems are gaining prominence due to their accuracy, speed, and compatibility with smart manufacturing.

• Asia Pacific remains the largest and fastest-growing regional market due to manufacturing expansion and infrastructure development.

• Packaging and construction continue to be the dominant end-use industries for adhesive dispensing equipment globally.

• Technological advancements in precision control, sensor integration, and robotics are reshaping product capabilities.

• Sustainability trends are pushing manufacturers to adopt equipment that reduces adhesive waste and supports eco-friendly materials.

Market Segmentation Analysis

The adhesive dispensing equipment market can be broadly segmented based on product type, mode of operation, application, and end-user industries, each playing a distinct role in shaping market dynamics. By product type, the market includes manual, semi-automatic, and fully automatic dispensing systems. Manual dispensers are primarily used in small-scale operations or maintenance tasks where flexibility is required, but they are gradually being replaced by automated alternatives. Semi-automatic systems are widely used in medium-volume production lines, offering a balance between cost efficiency and performance. Fully automatic dispensing systems, however, dominate large-scale manufacturing, as they ensure uniform adhesive application, reduce human error, and integrate seamlessly with robotics and programmable logic controllers.

From an application standpoint, adhesive dispensing equipment is employed in bonding, sealing, coating, laminating, potting, and encapsulation processes. Bonding applications remain the most common, especially in automotive assembly, electronics manufacturing, and packaging lines. Sealing and coating functions are also expanding rapidly, particularly in construction materials, medical devices, and technical textiles. In terms of end-user segmentation, packaging remains the largest segment due to increasing demand for flexible packaging, corrugated boxes, labels, and tapes. The construction industry follows closely, where adhesives are used in flooring, insulation, wall panels, and prefabricated structures. Other important end-user industries include automotive, electronics, medical devices, furniture, hygiene products, and textiles, all of which increasingly rely on precision dispensing to meet quality and performance standards.

Get a Customized Market View in One Click : https://www.persistencemarketresearch.com/request-customization/16447

Regional Insights and Market Trends

The adhesive dispensing equipment market exhibits strong regional variation in terms of adoption, growth pace, and technological maturity. Asia Pacific holds the largest market share and is expected to maintain its leadership throughout the forecast period. This dominance is driven by large-scale manufacturing operations, rapid urbanization, and government-backed infrastructure development. China continues to be a major contributor, supported by its massive electronics, automotive, and packaging industries. India is emerging as a high-growth market due to increasing construction activity, expanding hygiene product manufacturing, and growing foreign direct investment in industrial automation. Japan and South Korea contribute through advanced electronics manufacturing and high adoption of precision automation technologies.

North America represents a mature but technologically advanced market. The region benefits from widespread adoption of automated manufacturing, particularly in automotive, aerospace, medical devices, and electronics. The presence of major equipment manufacturers and a strong focus on smart factories further strengthens demand. Sustainability initiatives and strict quality regulations in the U.S. and Canada are also encouraging manufacturers to invest in modern dispensing systems that minimize material waste and enhance production efficiency.

Europe holds a significant share of the global market, supported by robust automotive manufacturing, packaging innovation, and construction modernization. Countries such as Germany, France, and the U.K. lead the adoption of automated adhesive dispensing solutions, particularly in industrial assembly and renewable energy equipment manufacturing. Meanwhile, Latin America and the Middle East & Africa are witnessing moderate but rising demand, driven by infrastructure development, packaging sector growth, and the gradual shift toward mechanized manufacturing processes.

Key Market Drivers

The primary driver of the adhesive dispensing equipment market is the accelerating pace of industrial automation across manufacturing sectors. As companies seek to improve productivity, reduce labor dependency, and ensure consistent product quality, automated dispensing systems have become essential components of modern production lines. These systems enable precise control over adhesive volume, placement, and curing time, which is especially important in high-speed assembly operations and micro-scale applications such as electronics and medical devices.

Another significant growth driver is the expanding use of adhesives as a replacement for traditional mechanical fastening methods such as welding, riveting, and bolting. Adhesives offer advantages including reduced weight, improved aesthetics, better stress distribution, and compatibility with dissimilar materials. This shift is particularly evident in the automotive and aerospace sectors, where lightweight construction and improved fuel efficiency are strategic priorities. The packaging industry also plays a critical role in driving market growth, as rising demand for flexible packaging, e-commerce solutions, and smart labeling increases the need for fast, accurate, and efficient adhesive application systems.

Market Restraints

Despite favorable growth prospects, the adhesive dispensing equipment market faces several restraints that may limit its expansion in certain segments. High initial investment costs remain a key barrier, particularly for small and medium-sized enterprises. Advanced automated dispensing systems require significant capital expenditure not only for the equipment itself but also for integration with existing production lines, staff training, and maintenance. For businesses operating on thin margins, these costs can delay or deter adoption.

Another constraint lies in the complexity of system operation and maintenance. Precision dispensing equipment often requires skilled technicians for calibration, troubleshooting, and repair. In regions where technical expertise is limited, downtime and maintenance challenges can reduce the overall return on investment. Additionally, compatibility issues between different adhesive formulations and dispensing systems may create operational inefficiencies, particularly when manufacturers work with a wide range of materials and product designs.

Click to Purchase the Full Report & Start Exploring : https://www.persistencemarketresearch.com/checkout/16447

Market Opportunities

The market offers substantial opportunities driven by emerging technologies, sustainability initiatives, and the rapid growth of end-use industries. One of the most promising opportunities lies in the integration of dispensing equipment with smart manufacturing systems. The incorporation of sensors, artificial intelligence, and data analytics enables real-time monitoring of adhesive usage, predictive maintenance, and process optimization. These capabilities not only enhance production efficiency but also support quality assurance and regulatory compliance.

Sustainability trends present another significant growth avenue. Manufacturers are increasingly seeking equipment that reduces adhesive waste, supports bio-based and recyclable adhesives, and improves energy efficiency. As environmental regulations become more stringent, demand for eco-friendly dispensing solutions is expected to rise. Furthermore, the expansion of emerging sectors such as renewable energy, electric vehicles, medical devices, and advanced textiles creates new application areas for precision adhesive dispensing systems, opening up long-term growth potential for equipment manufacturers.

Company Insights

The adhesive dispensing equipment market is characterized by the presence of established global manufacturers and specialized solution providers focusing on innovation, customization, and technological integration. Leading players compete on the basis of product performance, automation capabilities, global service networks, and industry-specific expertise.

• Nordson Corporation

• Graco Inc.

• Henkel AG & Co. KGaA

• ITW Dynatec

• Fisnar Inc.

• Musashi Engineering, Inc.

• Valco Melton

• Dymax Corporation

• Sulzer Mixpac

• Techcon Systems

Recent developments in the market highlight the industry's focus on automation and precision. In one notable development, leading manufacturers have introduced next-generation dispensing platforms integrated with robotic arms and vision systems, enabling real-time pattern adjustment and defect detection. In another development, companies are expanding their product portfolios to support sustainable adhesives and water-based formulations, responding to the growing demand for environmentally responsible manufacturing processes.

Competitive Landscape and Technological Evolution

Competition in the adhesive dispensing equipment market is increasingly shaped by technological differentiation and customer-centric innovation. Manufacturers are investing heavily in research and development to enhance dispensing accuracy, speed, and compatibility with a broader range of adhesive chemistries. The evolution from basic volumetric dispensers to programmable, sensor-driven systems reflects the industry's transition toward precision manufacturing.

Customization has become a key competitive factor, as end-users across automotive, electronics, and medical industries require tailored solutions to accommodate unique production requirements. Equipment providers are offering modular systems that can be scaled or reconfigured as production needs evolve. Strategic partnerships with robotics firms, material suppliers, and system integrators are also becoming more common, enabling companies to deliver comprehensive, end-to-end manufacturing solutions.

Impact of End-Use Industries on Market Growth

End-use industries play a decisive role in shaping demand patterns within the adhesive dispensing equipment market. The packaging industry continues to be the largest consumer, driven by the proliferation of flexible packaging, labels, cartons, and tapes in food, beverages, pharmaceuticals, and e-commerce. The need for high-speed production lines and consistent adhesive application makes automated dispensing systems a necessity rather than an option.

The construction sector is another major growth contributor, particularly with the rise of prefabricated buildings, modular construction, and advanced insulation materials. Adhesive dispensing equipment is widely used for bonding panels, sealing joints, and applying coatings in building materials manufacturing. In the automotive industry, lightweight materials, electric vehicle production, and increasing electronic content in vehicles are driving demand for precision bonding solutions. Similarly, in electronics and medical devices, the trend toward miniaturization and higher performance standards is boosting the adoption of micro-dispensing technologies.

Future Outlook of the Adhesive Dispensing Equipment Market

Looking ahead, the adhesive dispensing equipment market is poised for sustained expansion as manufacturers continue to embrace automation, digitalization, and sustainable practices. Technological advancements such as machine learning-enabled dispensing, real-time process control, and adaptive robotics are expected to redefine operational efficiency and quality assurance. The convergence of adhesive technology with smart factory ecosystems will further enhance the strategic importance of dispensing equipment in modern manufacturing.

Emerging economies are likely to play a critical role in shaping future growth trajectories. As countries across Asia, Latin America, and the Middle East invest in industrial infrastructure and manufacturing capacity, demand for advanced dispensing solutions will rise steadily. At the same time, established markets in North America and Europe will continue to drive innovation, focusing on high-performance, environmentally responsible, and digitally integrated equipment.

Related Reports:

https://www.persistencemarketresearch.com/market-research/vacuum-lifter-market.asp

https://www.persistencemarketresearch.com/market-research/liquid-filling-machines-market.asp

https://www.persistencemarketresearch.com/market-research/europe-fairway-mower-market.asp

https://www.persistencemarketresearch.com/market-research/thailand-water-pump-market.asp

https://www.persistencemarketresearch.com/market-research/elevator-maintenance-market.asp

Persistence Market Research

Second Floor, 150 Fleet Street, London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Adhesive Dispensing Equipment Market to Expand at 5.3% CAGR Through 2033 here

News-ID: 4349973 • Views: …

More Releases from Persistence Market Research

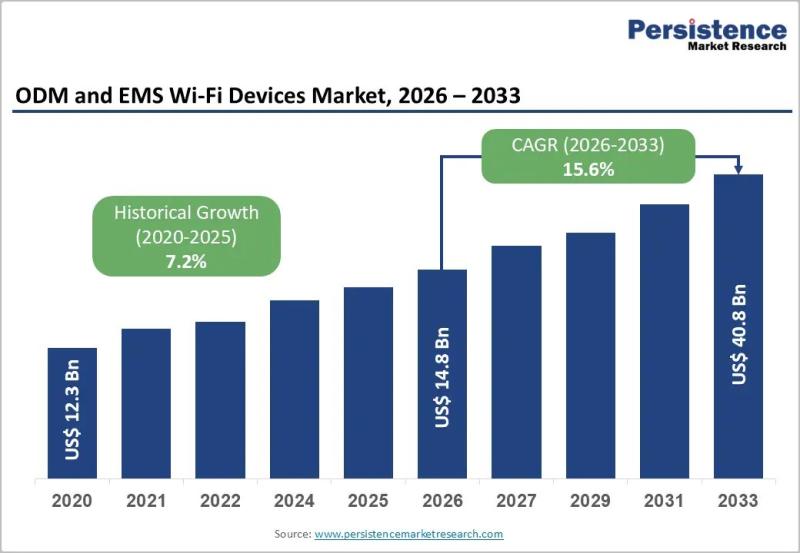

ODM and EMS Wi-Fi Devices Market to Reach US$ 40.8 Billion by 2033 at 15.6% CAGR

The global ODM and EMS Wi-Fi devices market is projected to be valued at US$ 14.8 billion in 2026 and is forecast to surge to US$ 40.8 billion by 2033, registering a robust CAGR of 15.6% between 2026 and 2033. This rapid growth reflects the accelerating demand for advanced wireless connectivity solutions across residential, enterprise, and industrial environments. The expansion of 5G infrastructure, enterprise digital transformation strategies, and large-scale IoT…

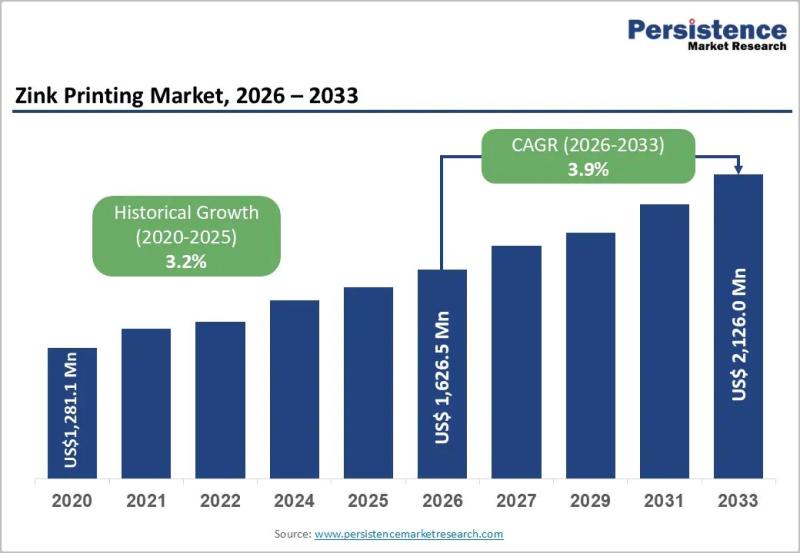

Zink Printing Market to Reach US$ 2,126.0 Million by 2033 at 3.9% CAGR

Zink Printing Market Size and Trends Analysis

The global Zink printing market is projected to be valued at US$ 1,626.5 million in 2026 and is expected to reach US$ 2,126.0 million by 2033, expanding at a CAGR of 3.9% between 2026 and 2033. Zink (Zero Ink) printing technology eliminates the need for ink cartridges by using heat-activated color crystals embedded within specialized paper. This innovation has positioned Zink printers as a…

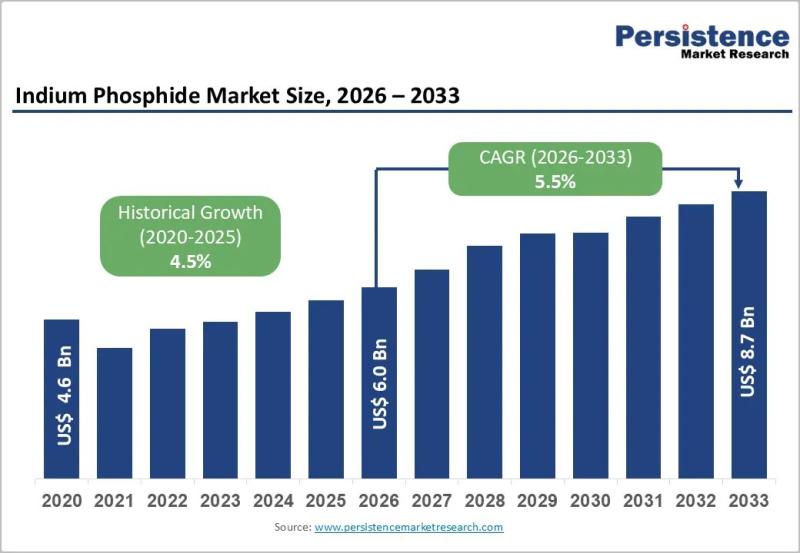

Indium Phosphide Market to Reach US$ 8.7 Billion by 2033 at 5.5% CAGR

The global Indium Phosphide (InP) market is poised for steady expansion, with its valuation expected to reach US$ 6.0 billion by 2026 and further grow to US$ 8.7 billion by 2033, registering a CAGR of 5.5% between 2026 and 2033. Indium phosphide, a high-performance compound semiconductor material, is widely used in optoelectronics, high-frequency electronics, and photonic integrated circuits (PICs). The market growth is largely fueled by the accelerating deployment of…

Roasted Corn Market to Reach $5.5B by 2033 Driven by Rising Snack Demand

The global roasted corn market is poised for steady expansion, driven by rising consumer preference for convenient, ready-to-eat snacks and increasing awareness of healthier alternatives to traditional fried snack options. Current market estimates indicate that the roasted corn market is valued at approximately US$ 3.8 billion in 2026 and is projected to reach US$ 5.5 billion by 2033, reflecting a compound annual growth rate (CAGR) of 5.4% between 2026 and…

More Releases for Adhesive

Shaping the Flock Adhesive Market in 2025: Innovative Adhesive Tape Solutions Dr …

How Is the Chondroplasty Market Projected to Grow, and What Is Its Market Size?

The chondroplasty market has seen strong growth in recent years. It will increase from $13.77 billion in 2024 to $14.68 billion in 2025 at a CAGR of 6.5%. This growth is attributed to the rise in sports-related injuries, patient preference for non-total joint replacement procedures, advances in postoperative care, healthcare provider training, and an increasing incidence of…

Bio-Based Hot Melt Adhesive Market Insights: Redefining Adhesive Solutions

According to the report published by Virtue Market Research, in 2022, the Global Bio-Based Hot Melt Adhesive Market was valued at $10.15 billion, and is projected to reach a market size of $15 billion by 2030. Over the forecast period of 2023-2030, market is projected to grow at a CAGR of 4.5%.

Read More @ https://virtuemarketresearch.com/report/bio-based-hot-melt-adhesive-market

The Bio-Based Hot Melt Adhesive market is a realm of innovation and sustainability, marked by enduring…

Iron Supplement Market Product Type (2-Octyl Cyanoacrylate Adhesive, N-Butyl Cya …

Iron is one of the most important nutritional requirements of the human body as it plays an important role in managing many vital biological processes. Growing health concerns among consumers and widening applications of iron supplements are among the major growth drivers for iron supplements demand.

Download Sample PDF at https://www.theinsightpartners.com/sample/TIPRE00021200/?utm_source=OpenPR&utm_medium=10379

Key Players Analysis:

• Nature Made

• Nature's Bounty

• Solgar

• Rainbow Light

• NOW Foods

• Amway

• Garden of Life

• Spring Valley

• GNC

• Fergon

The report covers key developments in the Iron Supplement Market as…

Lens bonding adhesive solutions from DeepMaterial optical bonding adhesive manuf …

Lens bonding adhesive solutions from DeepMaterial optical bonding adhesive manufacturers

Today, gadgets are changing incredibly. This calls for the best bonding option and the elimination of mechanical fasteners. The introduction of adhesives has made it possible to achieve lightweight gadgets that have made our lives even better.

In camera modules, there is a need for lens-bonding adhesives. The lens is an important camera component, and it is needed for the proper functioning…

Cyanoacrylate Adhesive Market Outlook to 2026 - 3M, AdCo, Adhesive Technologies

The Cyanoacrylate Adhesive Market report includes overview, which interprets value chain structure, industrial environment, regional analysis, applications, market size, and forecast. The report provides an overall analysis of the market based on types, applications, regions, and for the forecast period from 2020 to 2026. It also offers investment opportunities and probable threats in the market based on an intelligent analysis.

This report focuses on the Global Cyanoacrylate Adhesive Market trends, future…

Adhesive Equipments Market by Product Type (Adhesive Pump Systems, Adhesive Melt …

GLOBAL ADHESIVE EQUIPMENTS MARKET was valued at USD 30.56 Billion in the year 2017. Global Adhesive Equipment Market is further estimated to grow at a CAGR of 5.13% from 2018 to reach USD 41.26 Billion by the year 2023. Asia-Pacific region holds the highest market share in 2017 and also considered as the fastest growing market in the forecasted period. At a country level, developed markets like China holds the…