Press release

Maximize Your Output: Tips for Integrating CHENPIN's High Quality Tortilla Burrito Forming Line Company Machinery

In today's fast-paced food production environment, efficiency, consistency, and scalability have become decisive factors for manufacturers serving tortilla and burrito markets. The High Quality Tortilla Burrito Forming Line Company(https://www.chenpinmachine.com/index.php?s=Burrito&cat=490) concept reflects a shift toward integrated automation systems that deliver stable output while supporting long-term capacity growth. Instead of relying on fragmented equipment or labor-intensive processes, many producers now evaluate forming lines as complete production solutions. Within this context, CHENPIN FOOD MACHINE CO., LTD (CHENPIN) has developed tortilla/burrito production line machinery designed to support reliable integration into industrial bakery operations.Why Integration Matters More Than Individual Speed

Increasing output does not depend solely on machine speed. In practice, stable production depends on how well each stage of the forming line connects with the next. Poor synchronization between pressing, baking, cooling, and stacking often limits actual throughput.

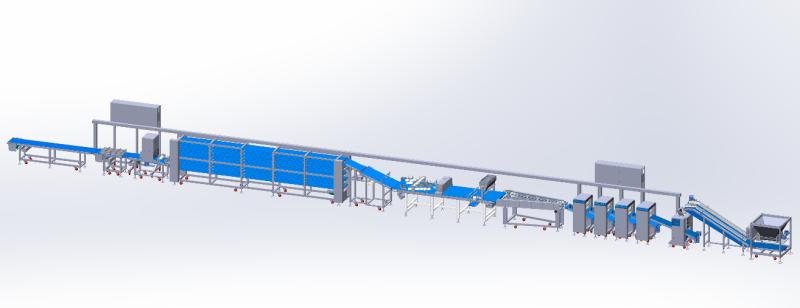

CHENPIN's tortilla/burrito production lines address this challenge by structuring the workflow as a continuous system. Dough portions move from hot pressing to baking, cooling, and stacking without unnecessary stops. As a result, product flow remains predictable, which helps operators maintain consistent daily output rather than short bursts of peak capacity.

Moreover, integrated forming lines reduce manual handling. This not only improves hygiene control but also stabilizes product quality across long production runs.

Core Process of CHENPIN Tortilla/Burrito Production Lines

CHENPIN tortilla/burrito production lines encompass models such as CPE-450, CPE-650, CPE-800, CPE-950, and CPE-1100. The core process flow is as follows:

The production process begins with dough balls entering the hot press unit. This unit is equipped with independently temperature-controlled upper and lower heating plates, allowing flexible adaptation to different dough formulations and thickness requirements for precise forming.

Subsequently, the formed dough sheets are directly conveyed to a multi-layer baking oven. During baking, the oven uniformly heats both sides of the product. This enhances the surface toughness of the wrap while preserving its internal flexibility, facilitating further processing.

After baking, the product enters the cooling conveyor section. This stage employs stable and continuous cooling to effectively regulate product moisture and set the shape, preparing it for subsequent stacking.

Finally, via an automatic counting and stacking system, the tortilla/burrito wraps are neatly output in specified quantities, ready for direct connection to packaging, freezing, or further processing operations. The conveyor system throughout the entire line maintains precise spacing, effectively preventing product deformation and misalignment.

Ensuring Consistency in Large-Scale Production through Equipment Design

Production consistency is a key consideration for manufacturers when selecting automated forming lines. CHENPIN tortilla/burrito production lines rely on highly repeatable mechanical control, minimizing human intervention to ensure stable output.

The hot press unit applies uniform pressure to the dough, guaranteeing consistency in diameter and thickness across batches. Combined with sensor-based positioning technology, it achieves precise feeding and spacing control, significantly reducing quality variations common in manual or semi-automatic production.

The baking and cooling sections also adhere to standardized design. Through controlled baking profiles and sufficient cooling paths, the wrap structure becomes more stable. The final product maintains flexibility while being less prone to tearing during handling or filling operations.

How to Choose the Right Production Line Configuration

To meet different capacity needs and factory conditions, CHENPIN offers a diverse range of tortilla/burrito production line models for precise user matching:

CPE-450: Suitable for entry-level production with limited space or modest capacity requirements.

CPE-650: Achieves higher output within a compact layout, balancing efficiency and footprint.

CPE-800: Delivers stable, high-volume output, with optimized production efficiency specifically for 8-inch wraps, capable of producing up to 8,100 pieces per hour.

CPE-950: In standard production of 6-12 inch wraps, it focuses on 6-inch wrap production, achieving a capacity of up to 14,000 pieces per hour, offering significant targeted output advantages.

CPE-1100: In the production of 6-12 inch wraps, it is better suited for 12-inch large wraps. With a wider pressing width and a high output of up to 7,500 pieces per hour, it meets large-scale production demands.

This product series enables production units to flexibly select the most suitable model based on their specific product specifications and capacity goals, facilitating efficient investment and production expansion.

Practical Integration Considerations for Factories

Successful integration depends on more than equipment delivery. Manufacturers often achieve better results when they evaluate upstream and downstream processes together.

For example, dough preparation capacity should match press throughput. Likewise, packaging or freezing equipment must handle the steady output from the stacking system. When production speeds remain balanced across stages, downtime decreases and labor efficiency improves.

Maintenance access also plays a role. CHENPIN's line layouts allow operators to clean and service key components without dismantling the entire system. This supports daily hygiene routines and reduces unplanned stoppages.

Manufacturing Capability and Technical Foundation

CHENPIN FOOD MACHINE CO., LTD(https://www.chenpinmachine.com/about-us/) was established in 2010, building on a technical team with more than 30 years of experience in food equipment development. From the outset, the company has concentrated on automated solutions for dough-based and flatbread products, an area that requires a high level of mechanical precision and process stability. Its equipment portfolio covers core production stages such as pressing, baking, conveying, cooling, and stacking, allowing systems to function as complete and coordinated production lines rather than isolated machines.

Beyond product design, CHENPIN has invested consistently in its manufacturing infrastructure. The company operates dedicated production facilities that support in-house machining, assembly, and testing. This manufacturing control enables tighter tolerances, stable component quality, and repeatable equipment performance across different production batches. Before delivery, machines undergo functional testing to ensure alignment with specified process requirements and operational conditions.

In addition, CHENPIN manages research and development, manufacturing, and after-sales support within a unified organizational structure. This vertical integration shortens communication cycles between engineering, production, and service teams. Feedback from installation sites and long-term customer operation feeds directly into equipment optimization and design refinement. As a result, product updates tend to focus on practical improvements such as ease of operation, maintenance accessibility, and long-duration reliability.

Over time, this development approach has supported the creation of machine designs suited for continuous industrial use. Instead of prioritizing short-term performance gains, CHENPIN emphasizes mechanical durability, process consistency, and adaptability to different factory environments. This technical foundation allows manufacturers to integrate CHENPIN equipment as part of long-term production planning, rather than as a short-term capacity fix.

Measurable Benefits Observed in Production Environments

Manufacturers integrating CHENPIN(https://www.chenpinmachine.com/contact-us/) tortilla/burrito forming lines often observe several operational changes once production stabilizes. Daily output becomes more predictable, which simplifies production planning and inventory coordination across shifts. As automation handles forming, conveying, and partial baking processes, labor allocation shifts away from repetitive manual tasks toward quality monitoring, equipment oversight, and downstream packaging coordination.

Material utilization also improves in a measurable way. Accurate dough portioning, controlled pressing, and stable conveyor spacing reduce the number of misshaped or uneven products entering later stages. At the same time, consistent baking and cooling conditions help products retain structural integrity during transfer and packaging, lowering rejection rates and rework requirements.

Together, these improvements support tighter cost control without sacrificing product standards. More stable production conditions also allow operators to respond more efficiently to order fluctuations, seasonal demand changes, or new product specifications, contributing to overall operational resilience in high-volume environments.

Long-Term Value for Growing Flatbread Markets

Demand for tortillas and burritos continues to expand across retail, foodservice, and frozen food channels. In this environment, forming lines that deliver both consistency and scalable output offer strategic value.

CHENPIN's burrito production lines provide manufacturers with a technical foundation for stable growth. By combining controlled forming processes with modular capacity options, these systems support gradual expansion without frequent redesigns.

For companies evaluating forming line integration as part of a broader production upgrade, technical clarity and reliable support remain essential factors. To learn more about CHENPIN's high-quality Tortilla Burrito Forming Line solutions and related automated food machinery, visit https://www.chenpinmachine.com/.

CHENPIN FOOD MACHINE CO., LTD

No.61 Lane, Dongshe Road 129, Songjiang District, Shanghai,China

sales@chenpinsh.com

+86 021-57674551

CHENPIN FOOD MACHINE CO., LTD was established in 2010. We build upon the technical expertise and spirit of the Taiwan province team who founded CHENPIN and already had been dedicated to the development and research of food equipment for more than 30 years before founding CHENPIN FOOD MACHINE CO., LTD.With the help of our hiahly skiled research and development team CHENPIN FOOD MACHINE CO., LTD obtained many patents in the area of automated food production machinery for dough, baking and lavered pastry dough products. Our company covers the whole value chain of producing automated food production machinery such as research and development,production,sales, marketing and after-sales services.

"Quality excellence" is the goal of CHENPIN.

"Innovation through Research and Development" is our spirit.

"Perfect service" is the attitude that CHENPIN strives for.

"Trust and long term relationships with our customers" is the business philosophy that CHENPIN follows.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Maximize Your Output: Tips for Integrating CHENPIN's High Quality Tortilla Burrito Forming Line Company Machinery here

News-ID: 4348588 • Views: …

More Releases from CHENPIN FOOD MACHINE CO., LTD

Is the Future Leading Company for Fully Automatic Lacha Paratha Making Machine f …

The global appetite for ethnic cuisine has reached an unprecedented peak, placing the humble lacha paratha at the center of a massive industrial transition. Traditionally, the production of this flaky, multi-layered Indian flatbread relied exclusively on the dexterity of skilled artisans who could stretch dough to near-transparency. However, as frozen food manufacturers strive for global expansion, they face a daunting challenge: maintaining handmade quality at an industrial scale while battling…

A Legacy of Excellence: How CHENPIN's Certified High Quality Food Machine Soluti …

The global food industry is witnessing a significant shift toward ethnic convenience foods, with frozen parotta and flatbreads leading the market expansion. As demand grows, commercial bakeries face the persistent challenge of maintaining traditional "handmade" quality while meeting massive production scales. High labor costs and the inconsistency of manual production often impede business growth and product reliability. To address these hurdles, CHENPIN Food Machine Co., Ltd offers a High Quality…

CHENPIN Unveils the Global Leading Automatic Tortilla Production Line: Redefinin …

In response to expanding global demand for automated flatbread and wrap-style products, the Global Leading Automatic Tortilla Production Line(https://www.chenpinmachine.com/tortilla-production-line-machine-cpe-950-product/) is setting new benchmarks in food manufacturing efficiency and consistency. This state-of-the-art solution integrates intelligent control systems,hot pressing, baking, and advanced cooling to, continuous production of tortillas, taco, lavash, and other flatbread formats with minimal manual intervention. At the forefront of these innovations stands CHENPIN FOOD MACHINE CO., LTD (CHENPIN)(https://www.chenpinmachine.com/about-us/), whose…

Process Deep Dive: How the Lacha paratha Making Machine Fully Automatic Company …

The global demand for consistent, high-quality layered flatbreads continues to grow, especially for products such as Lacha Paratha and Roti Canai . Within this context, the concept of a Fully Automatic Roti Canai Making Machine Fully Automatic Company(https://www.chenpinmachine.com/cpe-3000l-layered-lacha-paratha-production-line-machine-product/) reflects not only automation, but also the ability to industrialize traditional lamination techniques without sacrificing texture or structure.

Based on this direction, CHENPIN FOOD MACHINE CO., LTD(https://www.chenpinmachine.com/about-us/) has developed its Lacha Paratha Production…

More Releases for Production

ORBIS Production Releases "Italy Production Intelligence 2026" - Executive Guide …

ORBIS Production, a multi-award-winning full-service film and photo production company headquartered in Milan, with established offices in Rome and Venice and operating across Italy, has announced the release of "Italy Production Intelligence 2026", an executive-level guide focused on Italy's production labor structures, working standards, and operational frameworks.

As international agencies and global brands continue to choose Italy for high-end film and photo productions, understanding local labor agreements and scheduling structures has…

Production Printers Market Report 2024 - Production Printers Market Demand And T …

"The Business Research Company recently released a comprehensive report on the Global Production Printers Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, The production printers market size…

Introducing Production Solved: Your Partner for Event Production and Corporate V …

New York, NY- Production Solved, a leading event production company, is thrilled to announce its comprehensive services for event production and corporate video production. With an unwavering commitment to excellence and a team of seasoned professionals, Production Solved aims to deliver exceptional experiences that captivate audiences and elevate brands.

As businesses navigate the dynamic landscape of events and corporate communications, the demand for top-notch production services has never been greater. Production…

Fertilizer Catalyst Market to Undertake Strapping Growth During 2018 to 2028(Seg …

Global Fertilizer Catalyst Market Introduction

Rising demand for catalysts is being witnessed from the fertilizer industry. Fertilizer catalysts are various kinds of metal oxides which are used for increasing the reaction rate in the fertilizer industry. Fertilizer catalysts are primarily used during ammonia production. Fertilizer catalysts find applications in processes including methanol production, ammonia production, formaldehyde production, syngas production and others. The activity of the fertilizer catalyst decides the yield and…

Semiconductor Production Equipment Market - Increasing Electronics Production Wo …

Global Semiconductor Production Equipment Market: Snapshot

Global market for semiconductor production equipment has been covered under the scope of this report. Semiconductor production equipment (SPE) is used in possibly the most advanced and complex manufacturing process in the world, which is, the production of semiconductor devices. Semiconductor products, such as memory devices and microprocessors are used in a wide range of devices such as personal computers, consumer electronics and telecommunications equipment.…

Vacuum Pumps Market Forecast by Production Value, Capacity and Production

Big Market Research Add New “Vacuum Pumps Market” Research Report to It’s a Database.

Request sample report @ https://goo.gl/cajJ1x

The report provides a basic overview of the Vacuum Pumps industry including definitions, classifications, applications and industry chain structure. And development policies and plans are discussed as well as manufacturing processes and cost structures.

This report studies Vacuum Pumps focuses on top manufacturers in global market, with capacity, production, price,…