Press release

Ensuring Compliance and Growth: Asia Pacifics Role in the Future of Food Contact Flexo Inks

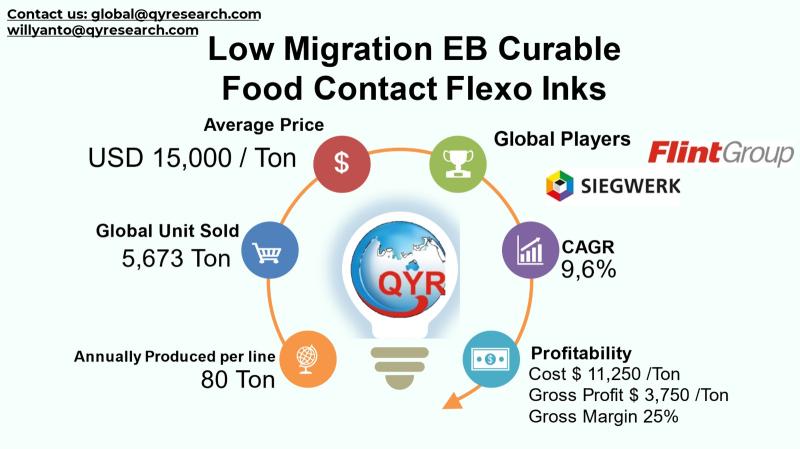

The global Low-Migration Electron Beam (EB) Curable Food Contact Flexo Inks industry encompasses specialized flexographic ink formulations that are designed to minimize chemical migration into food packaging, satisfying stringent regulatory safety standards. These inks cured via electron beam technology eliminate the need for photoinitiators and solvents that could potentially transfer into food or sensitive products, thereby addressing both regulatory and consumer safety concerns. The industry supports a broad range of downstream packaging applications such as flexible food films, labels, and other food contact substrates, and has become integral to the growing demand for high-quality, compliant packaging solutions in the global food and beverage supply chain. Regulatory frameworks across regions, including EU food contact material safety guidelines and analogous standards in Asia and North America, continue to shape innovation and adoption in this niche ink segment. Globally, the market is driven by stringent food safety regulations and growing consumption of packaged foods, which necessitate inks with reliable low-migration performance. North America and Europe remain mature markets, with high adoption rates under established regulatory regimes. Asia Pacific especially China, India, Japan, and the ASEAN bloc is emerging as the fastest-growing regional market due to expanding manufacturing infrastructure, booming food and beverage industries, and increasing awareness of migration safety in packaging.By 2024, the global market size for Low-Migration EB Curable Food Contact Flexo Inks reached USD 85.10 million with a growing compound annual growth rate at 9.6% through 2031 reaching market size USD 161 million by 2031. With an average selling price of USD 15,000 per ton, reflecting the total 5,673 ton sold in 2024. The factory gross margin is at 25%, implies to a factory gross profit at USD 3,750 per ton and cost of goods at 11,250 per ton. The COGS breakdown is ingredient/raw material, curing/energy, packaging and handling, labor and quality and overheads. A single line full machine capacity production is 80 ton per line per year. Downstream demand is concentrated in food packaging, pharmaceutical packaging and cosmetic & personal packaging.

Global Overview

Latest Trends and Technological Developments

In 2025, key industry players introduced a series of advancements underscoring innovation in low-migration ink technologies. On April 10, 2025, INX International unveiled its DuraInx HRC sustainable low-migration ink line tailored for sensitive food-safe packaging, integrating renewable content and compliance with EU and FDA food-contact regulations to support flexible film and label applications. Flint Group launched its Flexocure LEAP series a next-generation UV-curable low-migration formulation that reduces photoinitiator migration while maintaining high-speed performance. In mid-2025, hubergroup inaugurated a new manufacturing facility in India focused on low-migration inks for direct food contact printing, strengthening footprint in Asia Pacific markets. Additionally, Siegwerk expanded its optimized UV and UV/LED low-migration inks for food contact packaging across labels, foils, and sleeves. These developments emphasize sustainability, regulatory alignment, and performance improvements that are reshaping competitive dynamics in the global market.

Amcor Flexibles, purchases Sun Chemical's SolarFlex® ERA series of Low Migration Electron Beam (EB) Curable Flexo Inks in bulk quantities, with contracts typically valued at approximately USD $12,000 per metric ton. These advanced inks are formulated to ensure compliance with strict global food contact regulations, offering ultra-low migration potential for sensitive food applications. A prominent application case involves global snack food leader PepsiCo's Frito-Lay division, which utilizes packaging printed with these specific EB curable inks for its flagship Lay's potato chips brand. The implementation of this packaging solution across multiple North American production lines, ensuring the safety and quality of billions of flexible film bags annually, represents a material and technology investment exceeding USD $850,000 per year for the ink system component alone.

Asia Pacific stands out as a pivotal growth engine for the Low-Migration EB Curable Food Contact Flexo Inks market, owing to rapid industrialization, rising disposable incomes, and a surge in packaged food production. Countries such as China and Japan are witnessing accelerated adoption of low-migration flexible packaging inks as converters and brand owners align with regulatory standards and export quality requirements. China is particularly significant, benefiting from both local and multinational ink producers establishing manufacturing capacity and technology partnerships to address regional demand. India is emerging as a high-growth frontier with increasing infrastructure for advanced flexographic printing and food packaging compliance. Across Asia, converters prefer EB curable systems for their high throughput, consistent cure, and minimal migration profiles factors critical for large-scale packaging operations serving both domestic and export markets.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5652387

Low Migration EB Curable Food Contact Flexo Inks by Type:

Free Radical EB Inks

Cationic EB Inks

Hybrid EB Inks

Others

Low Migration EB Curable Food Contact Flexo Inks by Product Category:

Inline EB Curing

Off Line EB Curing

Hybrid EB and UV Systems

Others

Low Migration EB Curable Food Contact Flexo Inks by Market Segment:

Plastic Films

Paper and Paperboard

Aluminum Foil and Metallized Films

Multi Layer Laminates

Others

Low Migration EB Curable Food Contact Flexo Inks by Features:

Fast EB Curing Speed

Low Odor and Low VOC Emission

High Color Strength and Gloss

Others

Low Migration EB Curable Food Contact Flexo Inks by Material:

Oligomer Based EB Curable Inks

Monomer Modified Ink Systems

Pigment Based Formulations

UV/EB Hybrid Ink Systems

Others

Low Migration EB Curable Food Contact Flexo Inks by Application:

Food Packaging

Pharmaceutical Packaging

Cosmetic and Personal Care Packaging

Others

Global Top 30 Key Companies in the Low Migration EB Curable Food Contact Flexo Inks Market

Siegwerk Druckfarben AG & Co. KGaA (Siegburg, Germany)

Flint Group Holdings S.A. (Brussels, Belgium)

Sun Chemical (Tokyo, Japan)

INX International Ink Co (Illinois, US)

Toyo Ink Co., Ltd. (Tokyo, Japan)

Sakata INX Corporation (Tokyo, Japan)

Marabu GmbH (Tamm, Germany)

Kao Collins Corporation (Ohio, US)

Epple Druckfarben AG (Dornstadt, Germany)

Asia Pacific Inks Manufacturers

Hubergroup Holding SE (Hamburg, Germany)

DIC Corporation (Tokyo, Japan)

Zeller+Gmelin GmbH & Co.KG (Fils, Germany)

Altana AG (Wesel, Germany)

Nazdar Ink Technologies (Florida, US)

Ruco Inx (Dortmund, Germany)

T&K Toka Co., Ltd (Tokyo, Japan)

Fujifilm Sericol (Mumbai, India)

Royal Dutch Printing Ink Factories Van Son (The Hague, Netherlands)

Prisco (New York, US)

Raden Sutphin Ink Company (Ohio, US)

Guangdong SKY DRAGON Printing Ink (Zhaoqing, China)

Letong Chemical Co., Ltd (Zhuhai, China)

Shenzhen BIC Ink (Shenzhen, China)

Resino Inks (Ballerup, Denmark)

Huizhou Zhongzhixing Color Technology Co., Ltd. (Guangdong, China)

Follmann GmbH & Co. KG (Minden, Germany)

GLS Group (Mumbai, India)

Dainichiseika Color & Chemicals Mfg. Co., Ltd. (Tokyo, Japan)

NEW EAST (Ink Co.) (Zhejiang, China)

Regional Insights

In the ASEAN region, including Indonesia, market expansion reflects broader trends in Southeast Asia where growth in consumer package goods, e-commerce, and retail packaging drives demand for compliant packaging inks. Local players are investing in capacity upgrades to handle EB curable ink production, while multinational firms bolster distribution networks and technical support. Indonesias flexible packaging sector, in particular, shows strong appetite for low-migration solutions as food producers and converters strive to meet both domestic safety guidelines and international export standards. Partnerships between regional converters and global ink manufacturers are bringing advanced EB curing technology closer to ASEAN markets, aligning with increasing regulatory scrutiny and consumer expectations for food safety.

Despite robust growth prospects, the industry faces challenges including high capital expenditure for EB curing equipment, complexity in formulation to balance performance with low migration compliance, and varying regulatory frameworks across regions. Barriers to entry remain significant due to the technical expertise required for formulation and curing integration. Additionally, competition from alternative low-migration technologies such as UV/LED curable systems and water-based inks places downward pressure on pricing and margin optimization. Continuous regulatory updates further mandate R&D investment to maintain compliance and certification, affecting both small and large manufacturers.

Strategic priorities for companies in this space include expanding manufacturing footprints in high-growth regions such as Asia Pacific, investing in R&D for next-generation low-migration formulations, and forging partnerships with packaging converters to ensure product compatibility and technical support. Emphasis on sustainable and bio-based raw materials is also emerging as a differentiator, as brand owners seek to align with eco-friendly packaging mandates. Customers increasingly value ink systems that offer regulatory assurance, reduced energy consumption, and seamless integration with existing flexo presses. Continuous innovation in EB curing technology such as optimized electron beam dose control and real-time monitoring is also seen as a key driver of competitive advantage.

Product Models

Low migration electron-beam (EB)-curable food contact flexo inks are energy-curable ink systems engineered for printing on packaging that may contact food products. Unlike traditional solvent or UV inks, EB inks cure instantly under high-energy electron beams without photoinitiator reducing residual chemicals and minimizing the risk of migration of components into food.

Free radical EB inks cure via high-energy electrons that generate free radicals, rapidly cross-linking the ink polymers. Notable products include:

EB770 Flexo White Siegwerk Druckfarben AG & Co. KGaA (High)

Segmented for premium food packaging requiring strong opacity and compliance. Heavy-duty white for flexible film, board, and labels. Price: $45$70/L Converters & brand owners demanding high food safety.

SunBeam Advance EB Sun Chemical: Designed for high-speed EB flexo presses with excellent adhesion on PE/PP films. Price: $50$75/L Large multinational packagers.

Toyo Elex-One EB Flexo Toyo Ink Co., Ltd.: Balanced performance free radical EB flexo for general packaging. Price: $35$55/L Regional flexo printers.

Sakata Diatone Dreamcure EB Sakata INX Corporation: EB flexo series with low VOC and minimal migration for film packaging. Price: $38$58/L Mid-tier converters.

APIM EB Flexo Asia Pacific Inks Manufacturers: Cost-competitive free radical EB ink for basic flexo food packaging. Price: $30$45/L Small/medium printers.

Cationic EB inks cure through positive ion formation and typically exhibit lower shrinkage and improved adhesion on certain substrates versus free radical systems.. Notable products include:

Sun Chemical Cationic EB Series Sun Chemical: Low shrinkage, good dimensional stability, for sensitive films. Price: $52$78/L Premium converters.

INX Cationic EB INX International: Balanced cure performance for moderate adhesion substrates. Price: $42$62/L Mid-size printers.

Toyo Cationic Pack EB Toyo Ink : For flexible food films with moisture control features. Price: $45$68/L

Flint Cationic Flexo EB Flint Group: Adhesion-focused for challenging substrates. Price: $48$72/L

APIM Cationic EB Basic Asia Pacific Inks: Budget-oriented cationic EB for simple films. Price: $30$48/L

Hybrid EB Inks is a system combine aspects of both free radical and cationic chemistries to balance cure characteristics, adhesion, and mechanical properties. Notable products include:

Sun Chemical Hybrid EB Flexo Sun Chemical: Combines fast cure and adhesion versatility. Price: $50$75/L

Siegwerk Hybrid EB Series Siegwerk: Balanced cure and substrate tolerance. Price: $52$78/L

INX Hybrid EB Max INX International: Optimized for mixed substrates. Price: $45$70/L

Flint Hybrid EB Flexo Flint Group: Flexibility across flexible films. Price: $48$72/L

Toyo Hybrid EB Pack Toyo Ink: Flexible film and board compatibility. Price: $44$66/L

The global Low-Migration EB Curable Food Contact Flexo Inks market is poised for sustained growth, driven by regulatory imperatives, expanding packaged food demand, and technological advancements in energy-curable ink systems. With Asia Pacific and ASEAN countries, including Indonesia, playing increasingly prominent roles, industry participants are well-positioned to capitalize on evolving demand while navigating competitive and regulatory challenges.

Investor Analysis

For investors, the key takeaways from this report underline long-term growth potential backed by a strong regulatory tailwind and expanding food packaging markets. Understanding market size, growth rates, and cost dynamics provides clarity on profitability and scaling opportunities. Insights into regional demand patterns especially Asia Pacific and ASEAN help identify strategic investment locations. Awareness of technological trends and product innovations highlights where differentiation and future market leadership may occur. Furthermore, analysis of industry challenges informs risk assessment and Migration strategies, while competitive profiling aids in identifying prospective acquisition or partnership targets that align with investor portfolios.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5652387

5 Reasons to Buy This Report

Gain comprehensive understanding of global market size and forecast through 2031.

Deep insights into regional dynamics with Asia and ASEAN focus.

Detailed cost structure, pricing benchmarks, and production economics.

Identification of latest technological trends and competitive developments.

Strategic investor guidance highlighting growth and risk factors.

5 Key Questions Answered

What is the current global market size and expected CAGR through 2031?

How do cost structures and pricing dynamics impact industry margins?

What are the key growth drivers and challenges for the industry?

Which regions and countries present the most significant opportunities?

Who are the leading players and how are they innovating in this market?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global Low Migration EB Curable Food Contact Flexo Inks Market Research Report 2026

https://www.qyresearch.com/reports/5652387/low-migration-eb-curable-food-contact-flexo-inks

Global Low Migration EB Curable Food Contact Flexo Inks Sales Market Report, Competitive Analysis and Regional Opportunities 2026-2032

https://www.qyresearch.com/reports/5652383/low-migration-eb-curable-food-contact-flexo-inks

Low Migration EB Curable Food Contact Flexo Inks- Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032

https://www.qyresearch.com/reports/5652384/low-migration-eb-curable-food-contact-flexo-inks

Global Low Migration EB Curable Food Contact Flexo Inks Market Outlook, InDepth Analysis & Forecast to 2032

https://www.qyresearch.com/reports/5652388/low-migration-eb-curable-food-contact-flexo-inks

Global Food Contact Printing Inks Market Research Report 2026

https://www.qyresearch.com/reports/5617619/food-contact-printing-inks

Global Printing Inks for Food Contact Materials Market Research Report 2026

https://www.qyresearch.com/reports/5576170/printing-inks-for-food-contact-materials

Global Food Contact Grade Ink Market Research Report 2025

https://www.qyresearch.com/reports/3492696/food-contact-grade-ink

Global Food Contact Materials Printing Inks Market Research Report 2025

https://www.qyresearch.com/reports/4483726/food-contact-materials-printing-inks

Global EB Curable Ink Market Research Report 2025

https://www.qyresearch.com/reports/3817433/eb-curable-ink

Global Water-based Flexo Inks Market Research Report 2026

https://www.qyresearch.com/reports/5574297/water-based-flexo-inks

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Ensuring Compliance and Growth: Asia Pacifics Role in the Future of Food Contact Flexo Inks here

News-ID: 4348453 • Views: …

More Releases from QY Research

Top 30 Indonesian Coal Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Alamtri Resources Indonesia Tbk (formerly Adaro Energy)

PT Bumi Resources Tbk

PT Bayan Resources Tbk

PT Indo Tambangraya Megah Tbk

PT Bukit Asam Tbk (PTBA)

PT Golden Energy Mines Tbk (GEMS)

PT Dian Swastatika Sentosa Tbk (DSSA)

PT Indika Energy Tbk (INDY)

PT Akbar Indo Makmur Stimec Tbk (AIMS)

PT Atlas Resources Tbk (ARII)

PT Borneo Olah Sarana Sukses Tbk (BOSS)

PT Baramulti…

From Sugar to Profit: Economics of the Global Ready-to-Roll Icings Industry

Ready-to-roll icings (also known as rolled fondant or sugar paste) are pre-formulated sugar-based sheets used for cake covering, decorative modeling, and bakery finishing in commercial and artisan baking.

Products are supplied in bulk slabs, sheets, and blocks and are valued for: Consistent elasticity, Reduced preparation time, Uniform finish, Extended shelf stability.

Industrial buyers include industrial bakeries, frozen dessert processors, QSR chains, supermarkets, and cake studios.

Growing demand for celebration cakes, premium bakery products,…

Sustainable Staples: Why Investors Are Targeting Organic Pulse Processing

Organic dry pulses include organically cultivated lentils, chickpeas, peas, mung beans, pigeon peas, and dry beans produced without synthetic pesticides, fertilizers, or GMOs.

Industry benefits from: Rising plant-protein adoption, Gluten-free and clean-label trends, Soil-friendly nitrogen-fixing crop rotation, Government organic agriculture subsidies across Asia.

Global trade dominated by exporters in India, Australia, Canada, and Turkey

Growing consumption in China, Japan, Indonesia, and Vietnam.

Global Overview

Market size (2025): USD 5,266 million

Market size (2032): USD 8,231 million

CAGR…

Baby Care Boom: USD 9.1B Global Bath & Shower Market Driven by Asia Growth

Baby bath and shower products include liquid cleansers, tear-free shampoos, head-to-toe washes, soaps, bath oils, foam washes, and sensitive-skin dermatological formulations designed specifically for infants and toddlers.

Products emphasize mild surfactants, hypoallergenic formulations, pH-balanced systems (5.56.0), and natural/plant-derived ingredients to minimize irritation and comply with pediatric dermatology standards.

Demand is driven by rising hygiene awareness, premiumization of infant care, urban middle-class expansion, and increased birth rates in emerging Asia.

Strong shift from bar…

More Releases for Ink

Tattoo Ink Market to see Ongoing Evolution | Major Giants Intenze Ink, Eternal I …

HTF MI just released the Global Tattoo Ink Market Study, a comprehensive analysis of the market that spans more than 143+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

Major companies profiled in Tattoo Ink Market are: Intenze Ink,…

Temporary Tattoo Market Is Booming Worldwide | Conscious Ink, Momentary Ink, Ink …

Advance Market Analytics published a new research publication on "Global Temporary Tattoo Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study, you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market-associated stakeholders. The growth of the Temporary Tattoo market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample Copy of…

Color Tattoo Ink Market 2023 Competitive Insights and Precise Outlook - Intenze …

Global Color Tattoo Ink Market research gives data of drive consolidations and securing procedures to grow market share and size for forecast period of 2023-2029. It further allows the industry leaders to penetrate deep into the marketing evaluation with the highest profitability. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes. This report is a detailed and comprehensive analysis for global Color Tattoo Ink market.…

Temporary Tattoo Market to Witness Stunning Growth | Inkbox Ink, Gold Ink Tattoo …

Latest released the research study on Global Temporary Tattoo Market, offers a detailed overview of the factors influencing the global business scope. Temporary Tattoo Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Temporary Tattoo. The study covers emerging player’s data, including: competitive…

Global Tattoo Ink Market Trend Analysis, Gross Margin Analysis and Forecast to 2 …

The Global Tattoo Ink Market research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry validated market data. It also contains projections using a suitable set of assumptions and methodologies. The study provides company profiling, product picture and specifications, sales, market share and contact information of key manufacturers of Global Tattoo Ink Market.The Key manufactures involved in this market…

Tattoo Ink Market by Top Players – Alla Prima, Skin Candy, Dynamic Tattoo Inks …

This report studies the global Tattoo Ink market status and forecast, categorizes the global Tattoo Ink market size (value & volume) by manufacturers, type, application, and region. This report focuses on the top manufacturers in North America, Europe, Japan, China, and other regions (India, Southeast Asia).

The Global Tattoo Ink Market report provides comprehensive analysis of Tattoo Ink Production, Supply, Sales and Demand of the Tattoo Ink Market. The purpose of…