Press release

Silicone Rubber Curing Agents: From Slow Cure to Precision Performance

ProblemManufacturers using conventional curing systems for silicone rubber often faced slow curing speed, inconsistent crosslinking, and limited control over mechanical properties. Inadequate curing could lead to uneven hardness, poor tensile strength, surface tackiness, or reduced thermal and chemical resistance. These issues increased defect rates, extended production cycles, and constrained performance in demanding applications such as electronics, automotive, medical, and industrial sealing.

Solution

Producers adopted Silicone Rubber Curing Agents, specialized additives designed to initiate and control the crosslinking reaction of silicone polymers. Depending on formulation, these curing agents-such as peroxide, platinum-catalyzed, or condensation-based systems-delivered:

Precise and uniform crosslinking of silicone rubber

Adjustable curing speed and processing window

Stable mechanical properties (hardness, elasticity, tear strength)

Excellent heat, weather, and chemical resistance

Compatibility with high-temperature molding and continuous processing

By selecting the appropriate curing agent, manufacturers achieved consistent product quality and optimized processing efficiency across diverse silicone rubber grades.

Result

After implementation, manufacturers realized clear improvements:

Curing cycle time reduced by 20-40%

Defect and rework rates lowered by 15-30%

Mechanical property consistency improved across production batches

Enhanced long-term durability and thermal stability of finished products

Overall, silicone rubber curing agents enabled reliable processing, predictable performance, and higher manufacturing efficiency.

QY Research has recently published a comprehensive market study on Silicone Rubber Curing Agent. Key findings are summarized below.

https://www.qyresearch.com/reports/5650063/silicone-rubber-curing-agent

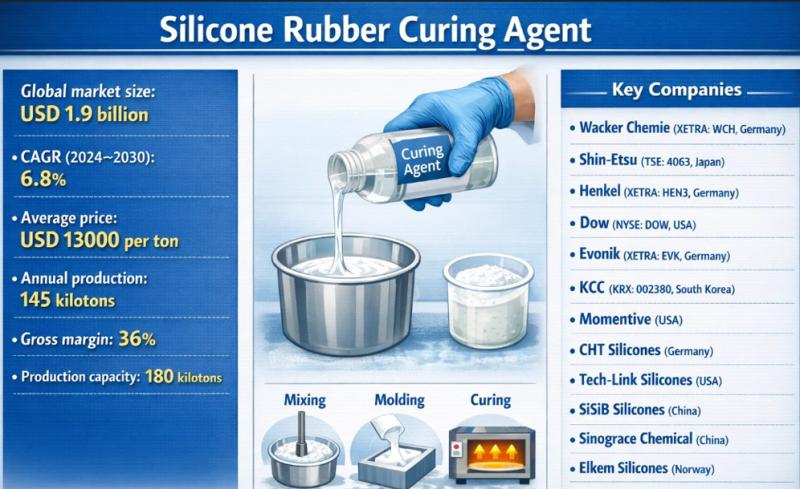

Core Market Data

Global market size: USD 1.9 billion

CAGR (2024-2030): 6.8%

Average price: USD 13000 per ton

Annual production: 145 kilotons

Gross margin: 36%

Production capacity: 180 kilotons

List of Main Players

Wacker Chemie (XETRA: WCH, Germany)

Shin-Etsu (TSE: 4063, Japan)

Henkel (XETRA: HEN3, Germany)

Dow (NYSE: DOW, USA)

Evonik (XETRA: EVK, Germany)

KCC (KRX: 002380, South Korea)

Momentive (USA)

CHT Silicones (Germany)

Tech-Link Silicones (USA)

SiSiB Silicones (China)

Sinograce Chemical (China)

Elkem Silicones (Norway)

Bluestar Silicones (China)

Gelest (USA)

NuSil Technology (USA)

1. By Curing Mechanism

Peroxide Curing Agent

Addition Curing Agent

Condensation Curing Agent

2. By Silicone Rubber Type

Platinum-based

Peroxide-based

Tin-based

3. By Application

Automotive

Electronic

Healthcare

Construction

Industrial

Case Study for Bidding

Time: April 2024

Supplier: Shin-Etsu Chemical

Buyer: Medical Device Manufacturer (USA)

Product: Platinum-Based Silicone Rubber Curing Agent (Medical Grade)

Quantity: 3,200 tons

Contract Value: USD 46.1 million

Delivery Timeline: January 2025

Detailed Application Scenario

The medical device manufacturer adopted Shin-Etsu Chemical's platinum-based curing agent for liquid silicone rubber used in catheters, seals, and implantable components. The curing system provided fast, uniform crosslinking with no peroxide byproducts, ensuring excellent biocompatibility and low extractables.

Precise curing control enabled consistent hardness and elasticity across high-volume production, while excellent thermal and chemical stability supported sterilization processes. By upgrading the curing system, the manufacturer improved yield consistency, shortened cycle times, and met stringent regulatory requirements. This case highlights how silicone rubber curing agents play a critical role in high-performance elastomer processing, medical-grade quality control, and advanced silicone manufacturing.

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

For Inquiries:

USA: +1-626-295-2442

Canada: +1-778-907-6631

China: +86-150-1303-8387

Japan: +81-90-3800-9273

South Korea: +82-2883-1278

India: +91-866-9986-909

Indonesia: +62-818-510-991

Germany: +49-15788468916

Switzerland: +41-765899438

Portugal: +351-910983247

Email: global@qyresearch.com

www.qyresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Silicone Rubber Curing Agents: From Slow Cure to Precision Performance here

News-ID: 4347271 • Views: …

More Releases from QY Research

Top 30 Indonesian Coffee Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Santos Jaya Abadi (Kapal Api Group) Major coffee roasting & packaging company (Kapal Api, Excelso, Good Day, Kapten, ABC, Ya).

PT. Sari Incofood Corporation (Indocafe) Leading instant coffee beans & coffee mix producer.

PT Mayora Indah Tbk Produces Torabika instant coffee & coffee-flavored products under a large F&B portfolio.

PT Fore Kopi Indonesia Café chain and coffee retail with…

Clean Label, High Growth: Investment Playbook for the Plant Protein Powder Marke …

Plant protein powder refers to concentrated protein ingredients derived from soy, pea, rice, wheat, mung bean, chickpea, and other plant sources, processed into powders for food, beverage, sports nutrition, and functional formulations.

The industry integrates upstream crop cultivation, wet/dry fractionation, protein isolation, spray drying, and downstream blending/packaging for B2B and private-label markets.

Demand is driven by flexitarian diets, lactose intolerance awareness, sports nutrition, sustainable protein sourcing, and food security policies across Asia…

Why ASEAN is the Next Growth Engine for the Industrial Salt Trade

Extra coarse salt refers to large crystal size sodium chloride grades typically used for industrial processing, water treatment, food curing, de-icing, chemical feedstock, and specialty culinary applications.

Produced through solar evaporation, rock salt mining, and vacuum evaporation, then mechanically screened into coarse granules (>25 mm).

Widely consumed in chlor-alkali production, leather curing, seafood preservation, brining, drilling fluids, and dehumidification systems.

Market stability comes from salts commodity nature, low substitution risk, and essential use…

Healthier Coffee Solutions: A Strategic Look at the Canned RTD Dairy Free Coffee

The global canned ready-to-drink (RTD) dairy-free coffee segment blends plant-based beverages with convenient, single-serve aluminum cans, targeting lactose-intolerant, vegan, and wellness-focused consumers.

Category growth is fueled by plant milk adoption (oat, almond, soy, coconut), cold brew formats, and on-the-go consumption across modern trade, convenience stores, vending, and e-commerce.

Product positioning increasingly overlaps functional beverages (protein, low sugar, adaptogens, nootropics), premium café-style flavors, and sustainable packaging.

Global Overview & Market Size

2025 global market value:…

More Releases for Silicone

Revolutionizing Industries: Tenchy Silicone Introduces Cutting-Edge Silicone Tub …

Shenzhen Tenchy Silicone And Rubber Co., Ltd, a renowned leader in silicone products manufacturing, proudly announces the launch of its advanced silicone tubing solutions. Designed to meet the diverse needs of industries such as medical, automotive, and food and beverage, these innovative products represent a significant step forward in silicone technology.

In a world where reliability, performance, and versatility are paramount, silicone tubing stands out as a material of choice for…

Five common properties of silicone and the primary Types of Silicone

Silicones are a versatile class of polymers that come in various forms, offering immense potential for customization to meet the precise needs of the medical and aerospace sectors. Their characteristics enable them to perform diverse functions, such as sealing, lubricating, and fulfilling a host of other tasks.

Silicone's versatility is attributed to its unique physical and mechanical properties, which make it a valuable material in various industries. This article will delve…

Tenchy Silicone: Quality Silicone Tube Supplier for Different Industries

Tenchy Silicone is proud to announce the opening of their new headquarters, which will provide a quality silicone tube supplier service to different industries and businesses. Their silicone tubes are made from FDA-approved materials and are temperature resistant up to 230 degrees Celsius. All products come with an assurance of quality from Tenchy Silicone's team of experienced engineers and technicians who ensure that each product meets customer needs and specifications.…

Tenchy Silicone introducing new silicone foam strip

Tenchy Silicone, the leading provider of high-quality silicone foam strip, is proud to announce their newest product. The Silicone Foam Strip features a combination of both closed-cell and open-cell foaming technologies which offers outstanding thermal insulation and water resistance properties as well as superior airtight performance. It also provides excellent cushioning for equipment, machinery, components and instruments to ensure protection from dust, moisture, abrasion and shock. In addition to its…

Tenchy Silicone Announces Expansion on Silicone Tube Supplier Selection

Tenchy Silicone, a leading silicone tube supplier, is pleased to announce the expansion of its selection of products and services for customers. With over ten years of experience in the industry, the company has established a reputation for providing top-quality silicone tubes that meet customer needs and expectations. The new product line includes tubing from various manufacturers and offers a wide range of materials and sizes to accommodate every project.…

Tenchy Silicone Unveils their New Silicone Seal Gasket

Tenchy Silicone recently released a new silicone seal gasket designed to be used in a variety of industrial applications. It also provides excellent temperature insulation thanks to its ability to withstand temperatures up to 260 °C without any deformation or loss of strength, making it ideal for large-scale industrial projects. The silicone seal gasket is also unaffected by chemicals and ultraviolet light, making it suitable for numerous industries including automotive,…