Press release

Semiconductor Wafer Slicing Equipment Market to Reach US$ 1.73 Billion by 2031, Driven by Advanced Chip Manufacturing, AI, and Photovoltaic Expansion | QY Research

Market Summary -The global market for Semiconductor Wafer Slicing Equipment was estimated to be worth US$ 1,151 million in 2024 and is forecast to reach a readjusted size of US$ 1,726 million by 2031, expanding at a CAGR of 6.3% during the forecast period 2025-2031.

According to QY Research, the newly released report titled "Semiconductor Wafer Slicing Equipment Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031" delivers a comprehensive, data-driven analysis of the global wafer slicing equipment market. The report provides detailed insights into market size evolution, sales volume, pricing trends, production capacity, company market share and ranking, and long-term growth dynamics across semiconductor and photovoltaic manufacturing value chains.

Get Full PDF Sample Copy of the Report (Including Full TOC, Tables & Charts):

https://www.qyresearch.in/request-sample/machinery-equipment-semiconductor-wafer-slicing-equipment-market-share-and-ranking-overall-sales-and-demand-forecast-2025-2031

Sales Volume, Capacity, and Industry Economics -

In 2024, global Semiconductor Wafer Slicing Equipment sales reached approximately 13,865 units, closely aligned with a global production capacity of about 13,900 units, indicating a highly utilized manufacturing base. The average global selling price stood at approximately US$ 83,000 per unit, reflecting the precision engineering and advanced automation embedded in these systems.

The industry-wide gross profit margin ranges between 20% and 30%, depending on equipment configuration, slicing technology, automation level, and regional cost structures. These margins highlight the balance between high technical barriers and intense competition among leading equipment suppliers.

Technology Overview and Product Definition -

Semiconductor Wafer Slicing Equipment refers to highly specialized precision machinery used to cut semiconductor ingots-such as monocrystalline silicon, compound semiconductors, or specialty materials-into ultra-thin wafers. These wafers serve as the foundational substrates for:

► Integrated circuits and logic chips

► Memory devices

► MEMS components

► LED chips

► Photovoltaic solar cells

Key performance requirements include high slicing accuracy, minimal kerf loss, low surface damage, high throughput, and strong process stability, all of which are essential for improving yield and lowering per-wafer manufacturing costs.

Industry Chain Structure and Ecosystem -

The semiconductor wafer slicing equipment industry is deeply integrated across upstream, midstream, and downstream segments:

► Upstream - Silicon crystal growth equipment suppliers, precision diamond wire and blade manufacturers, cutting slurry and coolant providers, precision motors, and automation component suppliers

► Midstream - Wafer slicing equipment manufacturers specializing in blade-based and laser-based cutting technologies

► Downstream - Semiconductor foundries, integrated device manufacturers (IDMs), OSATs, MEMS producers, LED manufacturers, and photovoltaic wafer producers

As semiconductor nodes continue to shrink and wafer diameters increase, downstream customers place growing emphasis on automation, consistency, and reduced material waste, driving continuous equipment upgrades.

Market Drivers and Growth Dynamics -

The Semiconductor Wafer Slicing Equipment market is supported by several long-term structural growth drivers:

► Rising global demand for advanced logic and memory chips

► Expansion of 5G, artificial intelligence (AI), and high-performance computing (HPC)

► Rapid growth of electric vehicles (EVs) and power semiconductors

► Continued capacity expansion in photovoltaic wafer manufacturing

► Technological advances in laser slicing and high-precision blade slicing

Manufacturers are increasingly investing in next-generation slicing systems that offer higher accuracy, lower kerf loss, improved automation, and reduced total cost of ownership, strengthening demand for advanced equipment.

Market Structure and Key Insights -

► The market is technology-intensive and capital-driven

► Asia-Pacific dominates both production and consumption

► Foundries and IDMs remain the largest demand contributors

► Laser slicing technology is gaining traction alongside traditional blade slicing

► Equipment reliability and yield improvement are key competitive differentiators

Despite geopolitical uncertainty and tariff-related risks, sustained investment in semiconductor manufacturing capacity continues to support stable market growth.

Regional Market Outlook -

The report provides detailed regional and country-level analysis covering:

► North America (U.S., Canada, Mexico) - strong demand from advanced logic and R&D fabs

► Europe (Germany, France, UK, Italy, etc.) - focus on automotive semiconductors and specialty devices

► Asia Pacific (China, Japan, South Korea, Southeast Asia, India) - largest manufacturing base and fastest capacity expansion

► South America and Middle East & Africa - emerging markets with niche semiconductor and photovoltaic applications

Competitive Landscape -

The global Semiconductor Wafer Slicing Equipment market is moderately concentrated, with a mix of established global leaders and rapidly advancing regional suppliers.

Key companies profiled in the report include:

DISCO, Tokyo Seimitsu, GL Tech Co., Ltd., ASM, Synova, CETC Equipment, Shenyang Heyan Technology, Jiangsu JingChuang Advanced, Huaten Semiconductor, and Tengsheng Precision.

The report evaluates company market share, technology positioning, production capacity, pricing strategies, and regional expansion plans in detail.

Market Segmentation Highlights -

By Type

► Blade Slicing Equipment

► Laser Slicing Equipment

By Application

► Pure Foundry

► IDM

► OSAT

► LED

► Photovoltaic

► Others

Each segment is analyzed in terms of sales volume, revenue contribution, technical requirements, and future demand potential.

Reasons to Procure This Report -

► Access accurate global and regional market forecasts (2020-2031)

► Understand company market share, ranking, and competitive dynamics

► Evaluate technology trends in wafer slicing and yield optimization

► Identify growth opportunities across semiconductors and photovoltaics

► Support strategic planning, capital investment, and equipment sourcing decisions

Key Questions Answered in the Report -

► What is the current and future size of the global wafer slicing equipment market?

► Which applications are driving the strongest equipment demand?

► Who are the leading equipment suppliers globally?

► How are blade and laser slicing technologies evolving?

► What factors will shape market growth through 2031?

Request for Pre-Order / Enquiry -

https://www.qyresearch.in/pre-order-inquiry/machinery-equipment-semiconductor-wafer-slicing-equipment-market-share-and-ranking-overall-sales-and-demand-forecast-2025-2031

Table of Content:

1 Market Overview

1.1 Semiconductor Wafer Slicing Equipment Product Introduction

1.2 Global Semiconductor Wafer Slicing Equipment Market Size Forecast

1.2.1 Global Semiconductor Wafer Slicing Equipment Sales Value (2020-2031)

1.2.2 Global Semiconductor Wafer Slicing Equipment Sales Volume (2020-2031)

1.2.3 Global Semiconductor Wafer Slicing Equipment Sales Price (2020-2031)

1.3 Semiconductor Wafer Slicing Equipment Market Trends & Drivers

1.3.1 Semiconductor Wafer Slicing Equipment Industry Trends

1.3.2 Semiconductor Wafer Slicing Equipment Market Drivers & Opportunity

1.3.3 Semiconductor Wafer Slicing Equipment Market Challenges

1.3.4 Semiconductor Wafer Slicing Equipment Market Restraints

1.4 Assumptions and Limitations

1.5 Study Objectives

1.6 Years Considered

2 Competitive Analysis by Company

2.1 Global Semiconductor Wafer Slicing Equipment Players Revenue Ranking (2024)

2.2 Global Semiconductor Wafer Slicing Equipment Revenue by Company (2020-2025)

2.3 Global Semiconductor Wafer Slicing Equipment Players Sales Volume Ranking (2024)

2.4 Global Semiconductor Wafer Slicing Equipment Sales Volume by Company Players (2020-2025)

2.5 Global Semiconductor Wafer Slicing Equipment Average Price by Company (2020-2025)

2.6 Key Manufacturers Semiconductor Wafer Slicing Equipment Manufacturing Base and Headquarters

2.7 Key Manufacturers Semiconductor Wafer Slicing Equipment Product Offered

2.8 Key Manufacturers Time to Begin Mass Production of Semiconductor Wafer Slicing Equipment

2.9 Semiconductor Wafer Slicing Equipment Market Competitive Analysis

2.9.1 Semiconductor Wafer Slicing Equipment Market Concentration Rate (2020-2025)

2.9.2 Global 5 and 10 Largest Manufacturers by Semiconductor Wafer Slicing Equipment Revenue in 2024

2.9.3 Global Top Manufacturers by Company Type (Tier 1, Tier 2, and Tier 3) & (based on the Revenue in Semiconductor Wafer Slicing Equipment as of 2024)

2.10 Mergers & Acquisitions, Expansion

3 Segmentation by Type

3.1 Introduction by Type

3.1.1 Blade Slicing Equipment

3.1.2 Laser Slicing Equipment

3.2 Global Semiconductor Wafer Slicing Equipment Sales Value by Type

3.2.1 Global Semiconductor Wafer Slicing Equipment Sales Value by Type (2020 VS 2024 VS 2031)

3.2.2 Global Semiconductor Wafer Slicing Equipment Sales Value, by Type (2020-2031)

3.2.3 Global Semiconductor Wafer Slicing Equipment Sales Value, by Type (%) (2020-2031)

3.3 Global Semiconductor Wafer Slicing Equipment Sales Volume by Type

3.3.1 Global Semiconductor Wafer Slicing Equipment Sales Volume by Type (2020 VS 2024 VS 2031)

3.3.2 Global Semiconductor Wafer Slicing Equipment Sales Volume, by Type (2020-2031)

3.3.3 Global Semiconductor Wafer Slicing Equipment Sales Volume, by Type (%) (2020-2031)

3.4 Global Semiconductor Wafer Slicing Equipment Average Price by Type (2020-2031)

4 Segmentation by Automation Level

4.1 Introduction by Automation Level

4.1.1 Fully Automatic

4.1.2 Semi-Automatic

4.2 Global Semiconductor Wafer Slicing Equipment Sales Value by Automation Level

4.2.1 Global Semiconductor Wafer Slicing Equipment Sales Value by Automation Level (2020 VS 2024 VS 2031)

4.2.2 Global Semiconductor Wafer Slicing Equipment Sales Value, by Automation Level (2020-2031)

4.2.3 Global Semiconductor Wafer Slicing Equipment Sales Value, by Automation Level (%) (2020-2031)

4.3 Global Semiconductor Wafer Slicing Equipment Sales Volume by Automation Level

4.3.1 Global Semiconductor Wafer Slicing Equipment Sales Volume by Automation Level (2020 VS 2024 VS 2031)

4.3.2 Global Semiconductor Wafer Slicing Equipment Sales Volume, by Automation Level (2020-2031)

4.3.3 Global Semiconductor Wafer Slicing Equipment Sales Volume, by Automation Level (%) (2020-2031)

4.4 Global Semiconductor Wafer Slicing Equipment Average Price by Automation Level (2020-2031)

5 Segmentation by Equipment Structure

5.1 Introduction by Equipment Structure

5.1.1 Batch Type

5.1.2 Single Type

5.2 Global Semiconductor Wafer Slicing Equipment Sales Value by Equipment Structure

5.2.1 Global Semiconductor Wafer Slicing Equipment Sales Value by Equipment Structure (2020 VS 2024 VS 2031)

5.2.2 Global Semiconductor Wafer Slicing Equipment Sales Value, by Equipment Structure (2020-2031)

5.2.3 Global Semiconductor Wafer Slicing Equipment Sales Value, by Equipment Structure (%) (2020-2031)

5.3 Global Semiconductor Wafer Slicing Equipment Sales Volume by Equipment Structure

5.3.1 Global Semiconductor Wafer Slicing Equipment Sales Volume by Equipment Structure (2020 VS 2024 VS 2031)

5.3.2 Global Semiconductor Wafer Slicing Equipment Sales Volume, by Equipment Structure (2020-2031)

5.3.3 Global Semiconductor Wafer Slicing Equipment Sales Volume, by Equipment Structure (%) (2020-2031)

5.4 Global Semiconductor Wafer Slicing Equipment Average Price by Equipment Structure (2020-2031)

6 Segmentation by Application

6.1 Introduction by Application

6.1.1 Pure Foundry

6.1.2 IDM

6.1.3 OSAT

6.1.4 LED

6.1.5 Photovoltaic

6.1.6 Others

6.2 Global Semiconductor Wafer Slicing Equipment Sales Value by Application

6.2.1 Global Semiconductor Wafer Slicing Equipment Sales Value by Application (2020 VS 2024 VS 2031)

6.2.2 Global Semiconductor Wafer Slicing Equipment Sales Value, by Application (2020-2031)

6.2.3 Global Semiconductor Wafer Slicing Equipment Sales Value, by Application (%) (2020-2031)

6.3 Global Semiconductor Wafer Slicing Equipment Sales Volume by Application

6.3.1 Global Semiconductor Wafer Slicing Equipment Sales Volume by Application (2020 VS 2024 VS 2031)

6.3.2 Global Semiconductor Wafer Slicing Equipment Sales Volume, by Application (2020-2031)

6.3.3 Global Semiconductor Wafer Slicing Equipment Sales Volume, by Application (%) (2020-2031)

6.4 Global Semiconductor Wafer Slicing Equipment Average Price by Application (2020-2031)

7 Segmentation by Region

7.1 Global Semiconductor Wafer Slicing Equipment Sales Value by Region

7.1.1 Global Semiconductor Wafer Slicing Equipment Sales Value by Region: 2020 VS 2024 VS 2031

7.1.2 Global Semiconductor Wafer Slicing Equipment Sales Value by Region (2020-2025)

7.1.3 Global Semiconductor Wafer Slicing Equipment Sales Value by Region (2026-2031)

7.1.4 Global Semiconductor Wafer Slicing Equipment Sales Value by Region (%), (2020-2031)

7.2 Global Semiconductor Wafer Slicing Equipment Sales Volume by Region

7.2.1 Global Semiconductor Wafer Slicing Equipment Sales Volume by Region: 2020 VS 2024 VS 2031

7.2.2 Global Semiconductor Wafer Slicing Equipment Sales Volume by Region (2020-2025)

7.2.3 Global Semiconductor Wafer Slicing Equipment Sales Volume by Region (2026-2031)

7.2.4 Global Semiconductor Wafer Slicing Equipment Sales Volume by Region (%), (2020-2031)

7.3 Global Semiconductor Wafer Slicing Equipment Average Price by Region (2020-2031)

7.4 North America

7.4.1 North America Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

7.4.2 North America Semiconductor Wafer Slicing Equipment Sales Value by Country (%), 2024 VS 2031

7.5 Europe

7.5.1 Europe Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

7.5.2 Europe Semiconductor Wafer Slicing Equipment Sales Value by Country (%), 2024 VS 2031

7.6 Asia Pacific

7.6.1 Asia Pacific Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

7.6.2 Asia Pacific Semiconductor Wafer Slicing Equipment Sales Value by Region (%), 2024 VS 2031

7.7 South America

7.7.1 South America Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

7.7.2 South America Semiconductor Wafer Slicing Equipment Sales Value by Country (%), 2024 VS 2031

7.8 Middle East & Africa

7.8.1 Middle East & Africa Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

7.8.2 Middle East & Africa Semiconductor Wafer Slicing Equipment Sales Value by Country (%), 2024 VS 2031

8 Segmentation by Key Countries/Regions

8.1 Key Countries/Regions Semiconductor Wafer Slicing Equipment Sales Value Growth Trends, 2020 VS 2024 VS 2031

8.2 Key Countries/Regions Semiconductor Wafer Slicing Equipment Sales Value and Sales Volume

8.2.1 Key Countries/Regions Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

8.2.2 Key Countries/Regions Semiconductor Wafer Slicing Equipment Sales Volume, 2020-2031

8.3 United States

8.3.1 United States Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

8.3.2 United States Semiconductor Wafer Slicing Equipment Sales Value by Type (%), 2024 VS 2031

8.3.3 United States Semiconductor Wafer Slicing Equipment Sales Value by Application, 2024 VS 2031

8.4 Europe

8.4.1 Europe Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

8.4.2 Europe Semiconductor Wafer Slicing Equipment Sales Value by Type (%), 2024 VS 2031

8.4.3 Europe Semiconductor Wafer Slicing Equipment Sales Value by Application, 2024 VS 2031

8.5 China

8.5.1 China Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

8.5.2 China Semiconductor Wafer Slicing Equipment Sales Value by Type (%), 2024 VS 2031

8.5.3 China Semiconductor Wafer Slicing Equipment Sales Value by Application, 2024 VS 2031

8.6 Japan

8.6.1 Japan Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

8.6.2 Japan Semiconductor Wafer Slicing Equipment Sales Value by Type (%), 2024 VS 2031

8.6.3 Japan Semiconductor Wafer Slicing Equipment Sales Value by Application, 2024 VS 2031

8.7 South Korea

8.7.1 South Korea Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

8.7.2 South Korea Semiconductor Wafer Slicing Equipment Sales Value by Type (%), 2024 VS 2031

8.7.3 South Korea Semiconductor Wafer Slicing Equipment Sales Value by Application, 2024 VS 2031

8.8 Southeast Asia

8.8.1 Southeast Asia Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

8.8.2 Southeast Asia Semiconductor Wafer Slicing Equipment Sales Value by Type (%), 2024 VS 2031

8.8.3 Southeast Asia Semiconductor Wafer Slicing Equipment Sales Value by Application, 2024 VS 2031

8.9 India

8.9.1 India Semiconductor Wafer Slicing Equipment Sales Value, 2020-2031

8.9.2 India Semiconductor Wafer Slicing Equipment Sales Value by Type (%), 2024 VS 2031

8.9.3 India Semiconductor Wafer Slicing Equipment Sales Value by Application, 2024 VS 2031

9 Company Profiles

9.1 DISCO

9.1.1 DISCO Company Information

9.1.2 DISCO Introduction and Business Overview

9.1.3 DISCO Semiconductor Wafer Slicing Equipment Sales, Revenue, Price and Gross Margin (2020-2025)

9.1.4 DISCO Semiconductor Wafer Slicing Equipment Product Offerings

9.1.5 DISCO Recent Development

9.2 Tokyo Seimitsu

9.2.1 Tokyo Seimitsu Company Information

9.2.2 Tokyo Seimitsu Introduction and Business Overview

9.2.3 Tokyo Seimitsu Semiconductor Wafer Slicing Equipment Sales, Revenue, Price and Gross Margin (2020-2025)

9.2.4 Tokyo Seimitsu Semiconductor Wafer Slicing Equipment Product Offerings

9.2.5 Tokyo Seimitsu Recent Development

9.3 GL Tech Co., Ltd.

9.3.1 GL Tech Co., Ltd. Company Information

9.3.2 GL Tech Co., Ltd. Introduction and Business Overview

9.3.3 GL Tech Co., Ltd. Semiconductor Wafer Slicing Equipment Sales, Revenue, Price and Gross Margin (2020-2025)

9.3.4 GL Tech Co., Ltd. Semiconductor Wafer Slicing Equipment Product Offerings

9.3.5 GL Tech Co., Ltd. Recent Development

9.4 ASM

9.4.1 ASM Company Information

9.4.2 ASM Introduction and Business Overview

9.4.3 ASM Semiconductor Wafer Slicing Equipment Sales, Revenue, Price and Gross Margin (2020-2025)

9.4.4 ASM Semiconductor Wafer Slicing Equipment Product Offerings

9.4.5 ASM Recent Development

9.5 Synova

9.5.1 Synova Company Information

9.5.2 Synova Introduction and Business Overview

9.5.3 Synova Semiconductor Wafer Slicing Equipment Sales, Revenue, Price and Gross Margin (2020-2025)

9.5.4 Synova Semiconductor Wafer Slicing Equipment Product Offerings

9.5.5 Synova Recent Development

9.6 CETC Equipment

9.6.1 CETC Equipment Company Information

9.6.2 CETC Equipment Introduction and Business Overview

9.6.3 CETC Equipment Semiconductor Wafer Slicing Equipment Sales, Revenue, Price and Gross Margin (2020-2025)

9.6.4 CETC Equipment Semiconductor Wafer Slicing Equipment Product Offerings

9.6.5 CETC Equipment Recent Development

9.7 Shenyang Heyan Technology

9.7.1 Shenyang Heyan Technology Company Information

9.7.2 Shenyang Heyan Technology Introduction and Business Overview

9.7.3 Shenyang Heyan Technology Semiconductor Wafer Slicing Equipment Sales, Revenue, Price and Gross Margin (2020-2025)

9.7.4 Shenyang Heyan Technology Semiconductor Wafer Slicing Equipment Product Offerings

9.7.5 Shenyang Heyan Technology Recent Development

9.8 Jiangsu JingChuang advanced

9.8.1 Jiangsu JingChuang advanced Company Information

9.8.2 Jiangsu JingChuang advanced Introduction and Business Overview

9.8.3 Jiangsu JingChuang advanced Semiconductor Wafer Slicing Equipment Sales, Revenue, Price and Gross Margin (2020-2025)

9.8.4 Jiangsu JingChuang advanced Semiconductor Wafer Slicing Equipment Product Offerings

9.8.5 Jiangsu JingChuang advanced Recent Development

9.9 Huaten Semiconductor

9.9.1 Huaten Semiconductor Company Information

9.9.2 Huaten Semiconductor Introduction and Business Overview

9.9.3 Huaten Semiconductor Semiconductor Wafer Slicing Equipment Sales, Revenue, Price and Gross Margin (2020-2025)

9.9.4 Huaten Semiconductor Semiconductor Wafer Slicing Equipment Product Offerings

9.9.5 Huaten Semiconductor Recent Development

9.10 Tengsheng Precision

9.10.1 Tengsheng Precision Company Information

9.10.2 Tengsheng Precision Introduction and Business Overview

9.10.3 Tengsheng Precision Semiconductor Wafer Slicing Equipment Sales, Revenue, Price and Gross Margin (2020-2025)

9.10.4 Tengsheng Precision Semiconductor Wafer Slicing Equipment Product Offerings

9.10.5 Tengsheng Precision Recent Development

10 Industry Chain Analysis

10.1 Semiconductor Wafer Slicing Equipment Industrial Chain

10.2 Semiconductor Wafer Slicing Equipment Upstream Analysis

10.2.1 Key Raw Materials

10.2.2 Raw Materials Key Suppliers

10.2.3 Manufacturing Cost Structure

10.3 Midstream Analysis

10.4 Downstream Analysis (Customers Analysis)

10.5 Sales Model and Sales Channels

10.5.1 Semiconductor Wafer Slicing Equipment Sales Model

10.5.2 Sales Channel

10.5.3 Semiconductor Wafer Slicing Equipment Distributors

11 Research Findings and Conclusion

12 Appendix

12.1 Research Methodology

12.1.1 Methodology/Research Approach

12.1.1.1 Research Programs/Design

12.1.1.2 Market Size Estimation

12.1.1.3 Market Breakdown and Data Triangulation

12.1.2 Data Source

12.1.2.1 Secondary Sources

12.1.2.2 Primary Sources

12.2 Author Details

12.3 Disclaimer

QY Research PVT. LTD.

315 Work Avenue,

Raheja Woods,

6th Floor, Kalyani Nagar,

Yervada, Pune - 411060,

Maharashtra, India

India: (O) +91 866 998 6909

USA: (O) +1 626 295 2442

Email: hitesh@qyresearch.com

Web: www.qyresearch.in

About Us -

QY Research, established in 2007, is a globally recognized market research and consulting firm delivering syndicated and customized research solutions across semiconductors, semiconductor equipment, advanced manufacturing, electronics, materials, and industrial sectors. With more than 50,000 clients across over 80 countries, QY Research combines rigorous research methodologies, deep industry expertise, and actionable insights to support data-driven decision-making and sustainable business growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Semiconductor Wafer Slicing Equipment Market to Reach US$ 1.73 Billion by 2031, Driven by Advanced Chip Manufacturing, AI, and Photovoltaic Expansion | QY Research here

News-ID: 4347016 • Views: …

More Releases from QY Research, Inc.

Global Semiconductor Silicon Wafer Market to Reach US$ 29.08 Billion by 2032, Dr …

Market Summary -

The global Semiconductor Silicon Wafer market was valued at US$ 17,020 million in 2025 and is projected to reach US$ 29,080 million by 2032, growing at a CAGR of 8.1% during the forecast period 2026-2032.

According to QY Research, the newly released report titled "Global Semiconductor Silicon Wafer Market Insights - Industry Share, Sales Projections, and Demand Outlook 2026-2032" delivers a comprehensive, data-driven assessment of the global silicon wafer…

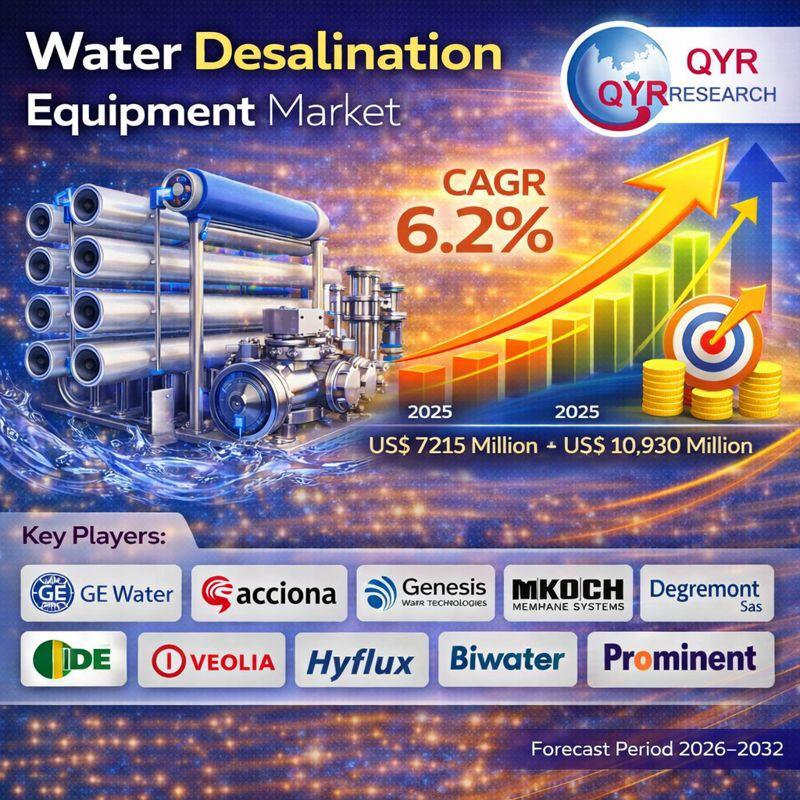

Global Water Desalination Equipment Market to Reach US$ 10.93 Billion by 2032, D …

Market Summary -

The global Water Desalination Equipment market was valued at US$ 7,215 million in 2025 and is projected to reach US$ 10,930 million by 2032, growing at a CAGR of 6.2% during the forecast period 2026-2032.

According to QY Research, the newly published report titled "Global Water Desalination Equipment Market Insights - Industry Share, Sales Projections, and Demand Outlook 2026-2032" provides a comprehensive, data-driven evaluation of the global desalination equipment…

Global Syndiotactic Polystyrene Market to Reach US$ 162 Million by 2032, Driven …

Market Summary -

The global Syndiotactic Polystyrene (SPS) market was valued at US$ 111 million in 2025 and is projected to reach US$ 162 million by 2032, expanding at a CAGR of 5.6% during the forecast period 2026-2032.

According to QY Research, the newly released report titled "Global Syndiotactic Polystyrene Market Insights - Industry Share, Sales Projections, and Demand Outlook 2026-2032" provides a comprehensive, data-driven assessment of the global SPS market. The…

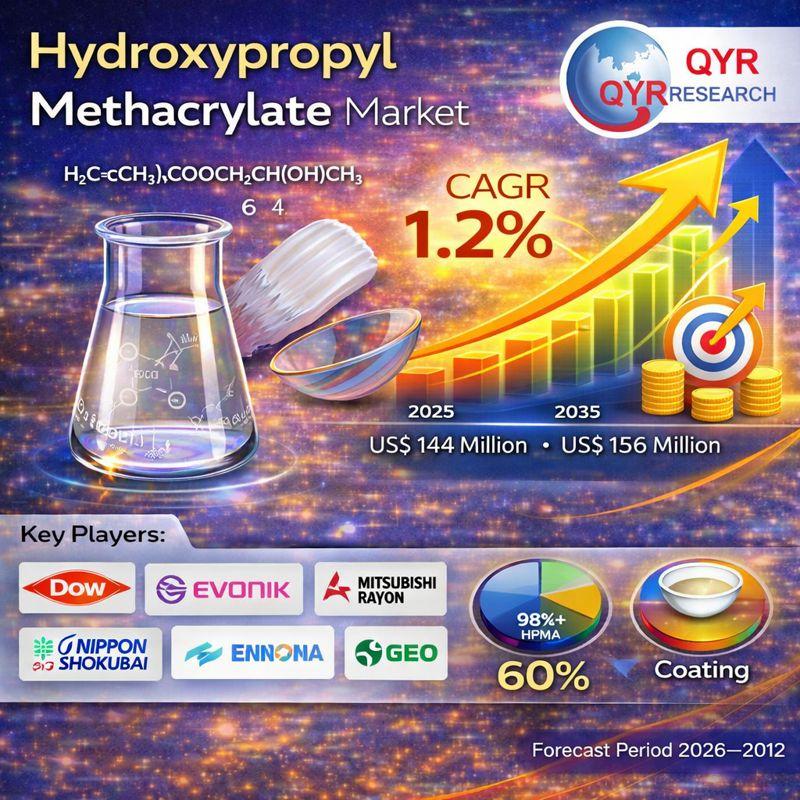

Global Hydroxypropyl Methacrylate Market to Reach US$ 156 Million by 2032, Suppo …

Market Summary -

The global Hydroxypropyl Methacrylate (HPMA) market was valued at US$ 144 million in 2025 and is projected to reach US$ 156 million by 2032, expanding at a CAGR of 1.2% during the forecast period 2026-2032.

According to QY Research, the newly released report titled "Global Hydroxypropyl Methacrylate Market Insights - Industry Share, Sales Projections, and Demand Outlook 2026-2032" provides a comprehensive, data-driven evaluation of the global HPMA market.…

More Releases for Equipment

Construction Equipment Rental (Ez Equipment Rental)

Whatever Your Project Needs, We Have The Solution

We understand purchasing heavy equipment isn't always the best option for a business, especially if you only need a machine temporarily.

EZ Equipment Rental LLC services industrial businesses with the equipment they need to operate, as well as homeowners and handymen tackling residential projects. Our inventory is stocked with bucket trucks, concrete equipment, generators, lighting, pumps, saws, jumping jacks, air compressors, pressure washers, earthmoving…

Laboratory Equipment Services Market, By Equipment Type (Analytical Equipment, G …

Laboratory equipment services basically encompass a wide range of services such as repair and maintenance, calibration, and validation that help labs run more efficiently, increase machine uptime, and improve testing and production results. Equipment servicing, user training, installation & modification, maintenance services, and equipment validation and calibration are just a few of the services available.

View Detailed Report: https://www.databridgemarketresearch.com/reports/global-laboratory-equipment-services-market

Global Laboratory equipment services Market was valued at USD 10.86 billion in 2021…

Food Service Equipment Market Size, Share, Trends, Growth Analysis Report By Equ …

The Business Research Company has updated its global market reports with latest data for 2024 and projections up to 2033

The Business Research Company presents an extensive market research report on the ""Food Service Equipment Global Market Report 2024,"" furnishing businesses with a competitive edge through a detailed examination of the market structure, encompassing estimates for various segments and sub-segments.

Furthermore, the report highlights on emerging trends, significant drivers, challenges, and opportunities,…

Coating Equipment Market by Type (Powder coating equipment, Liquid coating equip …

The Coating Equipment Market research report incorporates the scope and objective of the study. Moreover, the report highlights key market segments and players covered. It also covers industry trends, focusing on market use cases and top market size by region, market trends, and global market size. Moreover, the Coating Equipment Market research report covers market growth rate and market share by region. Supply chain analysis, regional marketing analysis, opportunities, challenges,…

Global Construction Equipment Rental Market 2018 - Ahern Equipment Rental, Cater …

The global Construction Equipment Rental market research report 2019 -2023 proposes a thorough analysis of the Construction Equipment Rental market globally. The market analysis considerably focuses on providing data to the consumers related to the three major segments, which include the growth rate of the market, the size of the market, and industrial-chain analysis. The Construction Equipment Rental market report provides a wide-range of Construction Equipment Rental market segmentation Earthmoving…

Durable Medical Equipment Market Size, Durable Medical Equipment Market Share, D …

According to a new study published by Polaris Market Research the Global Durable Medical Equipment (DME) market is anticipated to reach USD 246.6 billion by 2026.

Request for Sample of This Research Report @ https://bit.ly/2PNhMF7

Top Key Players:-

Stryker Corporation

Medtronic plc

Baxter International

Medline Industries

Becton

Dickinson and Company

Sunrise Medical (US) LLC

Durable Medical Equipment (DME) is provides beneficial benefits to a patient in need because of certain illnesses or/ and medical conditions. The durable medical equipment…