Press release

Coil Coatings Market on Track to Achieve US$5.3 Billion by 2032 Driven by Rising Construction and Industrial Demand

Introduction: Growing Importance of Coil Coatings in Modern ManufacturingThe coil coatings market has become a crucial segment of the global industrial coatings industry, offering durable, high-performance, and cost-effective surface finishing solutions for metal substrates. Coil coating is a continuous process where metal coils, primarily steel and aluminum, are coated before fabrication. This method ensures uniform coating quality, enhanced corrosion resistance, superior aesthetics, and improved productivity compared to post-fabrication painting. As industries increasingly prioritize efficiency, sustainability, and long-lasting material performance, coil coatings have gained widespread adoption across construction, automotive, appliances, and industrial equipment manufacturing.

In recent years, demand for pre-coated metals has risen substantially due to rapid urbanization, infrastructure development, and increased production of consumer goods. Manufacturers are focusing on innovative coating technologies that provide better weather resistance, color retention, and environmental compliance. Moreover, growing awareness regarding energy-efficient buildings and green construction materials has further accelerated the preference for coated metal products. These trends position the coil coatings market as a steadily expanding sector with strong future growth potential.

Get Your FREE Sample Report Instantly - Click Now: https://www.persistencemarketresearch.com/samples/35706

Market Overview: Steady Growth Supported by Industrial Expansion

The global coil coatings market is witnessing consistent growth, supported by expanding construction activities, increased production of household appliances, and rising demand for lightweight automotive materials. Coil-coated metals are widely used in roofing, wall panels, garage doors, refrigerators, washing machines, and vehicle components. Their ability to offer enhanced durability and design flexibility makes them a preferred material choice across multiple industries.

According to the latest study by Persistence Market Research, the global coil coating market size is likely to be valued at US$ 4.0 billion in 2025 and is projected to reach US$ 5.3 billion by 2032, growing at a CAGR of 4.3% between 2025 and 2032. This steady growth reflects increasing investments in infrastructure development, modernization of manufacturing facilities, and rising replacement demand for durable coated metal products. As industries continue to seek high-quality surface protection solutions with lower environmental impact, coil coatings are expected to experience sustained market expansion over the coming years.

Key Growth Drivers: Construction Boom and Demand for Durable Materials

One of the primary drivers of the coil coatings market is the rapid expansion of the building and construction sector. Urban development projects, smart city initiatives, and increasing demand for modern residential and commercial spaces have fueled the use of pre-coated steel and aluminum in roofing, facades, and structural applications. Coil coatings provide superior resistance to UV radiation, corrosion, and harsh weather conditions, making them ideal for long-term building applications. Their ability to reduce maintenance costs and enhance building aesthetics has further strengthened adoption across global construction markets.

Another major growth factor is the rising demand for consumer appliances and industrial equipment. Household appliances such as refrigerators, air conditioners, and washing machines increasingly utilize coil-coated metals for improved appearance and scratch resistance. Additionally, industrial machinery and energy equipment manufacturers rely on high-performance coil coatings to ensure longevity and protection in demanding operational environments. Combined with increasing focus on sustainability and recyclable materials, these drivers continue to create lucrative opportunities for coil coating manufacturers worldwide.

Technological Advancements: Innovation in Coating Formulations

Technological innovation remains a key force shaping the coil coatings market. Manufacturers are developing advanced coating formulations that offer enhanced durability, flexibility, and resistance to chemicals, heat, and abrasion. New-generation fluoropolymer and polyurethane coatings provide exceptional weatherability and color retention, making them ideal for architectural applications. At the same time, epoxy-based and plastisol coatings are gaining popularity in industrial and automotive segments due to their superior protective characteristics.

In addition to performance enhancements, the industry is also witnessing a shift toward environmentally friendly coating solutions. Water-based and low-VOC (volatile organic compound) coatings are increasingly replacing traditional solvent-based formulations to comply with environmental regulations and sustainability goals. Automated coating lines and digital quality control systems are improving production efficiency while minimizing waste. As industries prioritize eco-friendly manufacturing and cost-effective coating processes, technological advancements will continue to redefine the competitive landscape of the coil coatings market.

Get a Customized Market View in One Click: https://www.persistencemarketresearch.com/request-customization/35706

Coil Coatings Market Segmentation

By Product Type

Polyester Coatings

Fluoropolymer (PVDF) Coatings

Polyurethane (PU) Coatings

Plastisol Coatings

Epoxy Coatings

Misc.

By Substrate

Steel

Aluminum

By End Use

Building & Construction

Appliances & Consumer Goods

Automotive & Transportation

Industrial & Energy Equipment

Misc.

By Region

North America

Europe

East Asia

South Asia Oceania

Latin America

Middle East & Africa

End-Use Industry Insights: Expanding Applications Across Sectors

The building and construction sector continues to dominate end-use demand in the coil coatings market. Pre-coated metal sheets are widely used for roofing, cladding, and wall panels due to their superior strength-to-weight ratio and long-lasting finish. Growing adoption of green building concepts and energy-efficient structures has further boosted demand for coated metal products. Additionally, government infrastructure investments across emerging economies are creating sustained opportunities for coil coating suppliers.

Appliances and consumer goods represent another major application area. As global demand for household appliances increases, manufacturers seek high-quality surface finishes that provide scratch resistance and appealing aesthetics. Automotive and transportation industries also contribute to market growth, with lightweight coated metals being increasingly utilized to improve fuel efficiency and vehicle durability. Meanwhile, industrial and energy equipment manufacturers rely on coil-coated metals for protection against corrosion and harsh operating environments. This diverse application range ensures consistent demand across multiple industries, strengthening long-term market stability.

Regional Outlook: Strong Growth Across Developed and Emerging Markets

North America and Europe hold significant shares in the global coil coatings market due to well-established manufacturing industries, strong construction activities, and stringent quality standards. Demand in these regions is further supported by renovation projects and replacement of aging infrastructure. Additionally, the presence of major coating manufacturers and technological innovators enhances regional market competitiveness.

East Asia, led by China, Japan, and South Korea, represents a rapidly expanding market owing to high industrial production, urbanization, and rising export of coated steel and aluminum products. South Asia and Oceania are also witnessing increasing demand due to infrastructure development and appliance manufacturing growth. Latin America and the Middle East & Africa offer emerging opportunities, driven by expanding construction projects and industrial investments. As global manufacturing footprints continue to shift toward developing economies, regional diversification will remain a critical growth factor for the coil coatings market.

Challenges and Sustainability Considerations

Despite steady growth, the coil coatings market faces certain challenges. Volatility in raw material prices, particularly resins and pigments, can impact production costs and profit margins. Additionally, compliance with environmental regulations regarding VOC emissions and waste disposal presents operational complexities for manufacturers. Meeting these regulatory requirements often demands continuous investment in cleaner production technologies and advanced waste management systems.

Sustainability is becoming a defining theme across the industry. Manufacturers are increasingly adopting recyclable materials, eco-friendly formulations, and energy-efficient coating processes. Development of bio-based resins and water-based coatings is gaining momentum as companies strive to reduce carbon footprints. These sustainability-driven innovations not only ensure regulatory compliance but also enhance brand reputation and customer preference. Over time, environmental responsibility will play a crucial role in shaping competitive differentiation within the coil coatings market.

Company Insights: Key Players in the Coil Coatings Market

The global coil coatings market is highly competitive, with leading players focusing on product innovation, global expansion, and strategic partnerships. Major companies operating in this space include:

✦ Akzo Nobel N.V.

✦ Axalta Coating Systems Ltd.

✦ PPG Industries, Inc.

✦ The Sherwin-Williams Company

✦ Beckers Group

✦ Nippon Paint Holdings Co., Ltd.

✦ Kansai Paint Co., Ltd.

✦ KCC Corporation

✦ JSW Paints

✦ Yung Chi Paint & Varnish Manufacturing Co., Ltd.

✦ H.B. Fuller Company

✦ Sudarshan Chemical Industries Ltd.

✦ Allnex

✦ Arkema S.A.

✦ Ternium USA

These companies are investing in R&D to develop high-performance coatings, expand manufacturing capacities, and strengthen their global supply chains. Strategic mergers, acquisitions, and collaborations remain common approaches to gain competitive advantages and broaden product portfolios. As demand for premium and sustainable coating solutions rises, market players are expected to intensify innovation-driven growth strategies.

For In-Depth Competitive Analysis, Buy Now: https://www.persistencemarketresearch.com/checkout/35706

Future Outlook: Steady Expansion Through Innovation and Demand Growth

The future of the coil coatings market appears promising, driven by consistent demand from construction, appliances, automotive, and industrial sectors. With a projected market value of US$ 5.3 billion by 2032 and a CAGR of 4.3%, the industry is set to maintain stable growth throughout the forecast period. Increasing preference for pre-coated metals, improved coating technologies, and sustainability initiatives will remain central to market development.

As manufacturers continue to focus on performance enhancement, environmental compliance, and cost efficiency, coil coatings will play a vital role in modern manufacturing and infrastructure projects. Emerging economies, in particular, will offer new growth avenues as industrialization and urbanization accelerate. Overall, the coil coatings market is well-positioned to deliver long-term value, innovation, and resilience in an evolving global industrial landscape.

Explore the Latest Trending Research Reports:

• Shellac Market Survey - https://www.persistencemarketresearch.com/market-research/shellac-market.asp

• Propionic Acid Market Survey - https://www.persistencemarketresearch.com/market-research/propionic-acid-market.asp

• N-octyl Pyrrolidone Market Survey - https://www.persistencemarketresearch.com/market-research/n-octyl-pyrrolidone-market.asp

Contact Us:

Persistence Market Research

Second Floor, 150 Fleet Street,

London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Coil Coatings Market on Track to Achieve US$5.3 Billion by 2032 Driven by Rising Construction and Industrial Demand here

News-ID: 4345986 • Views: …

More Releases from Persistence Market Research

Cryogenic Storage Tanks Market Predicted to Hit US$ 12.8 Billion by 2033 Driven …

According to the latest study by Persistence Market Research, the global cryogenic storage tanks market is likely to be valued at US$ 8.6 billion in 2026 and is projected to reach US$ 12.8 billion by 2033, expanding at a CAGR of 5.8% during the forecast period 2026-2033. Rising demand for liquefied gases across energy, healthcare, food processing, and industrial manufacturing sectors is emerging as a key driver shaping the market's…

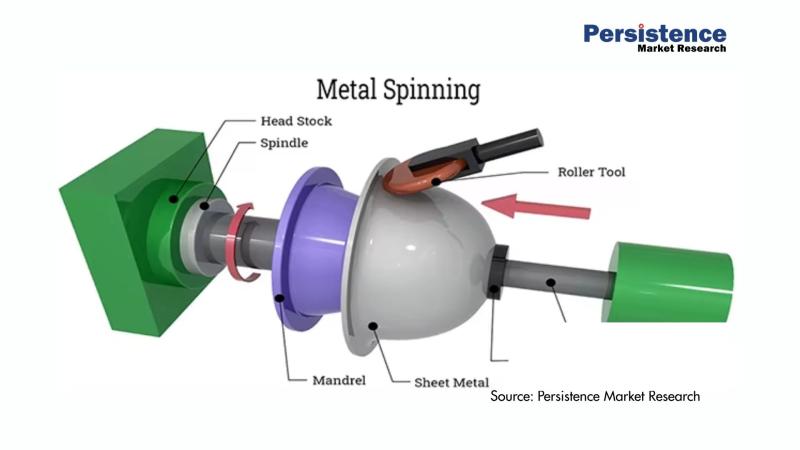

Metal Spinning Products Market Projected to Grow to US$ 4.0 billion by 2033 - Pe …

The global metal spinning products market is poised for substantial growth in the coming years. According to a recent study by Persistence Market Research, the market size is anticipated to reach US$ 4.0 billion by 2033, growing at a robust compound annual growth rate (CAGR) of 4.2% from its current valuation of US$ 3.0 billion in 2026. Metal spinning, a process of shaping metal into precise and symmetrical shapes, is…

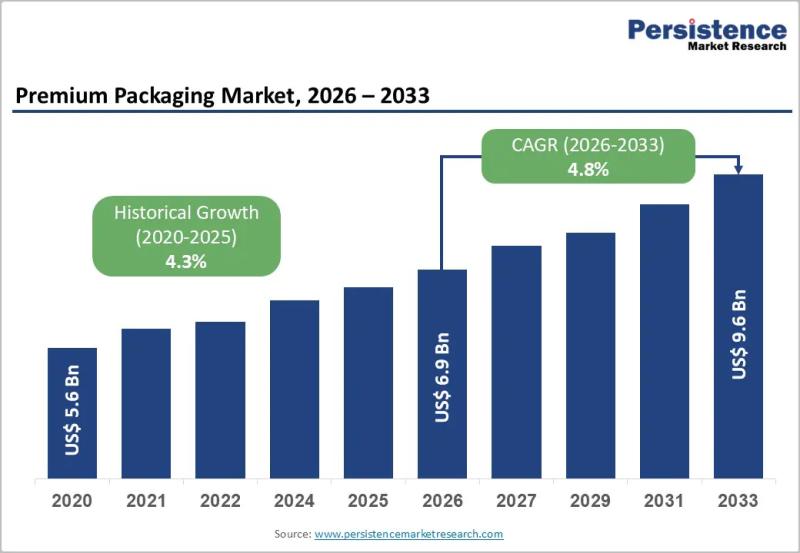

Premium Packaging Market Size Worth US$9.6 Billion by 2033 - Persistence Market …

The premium packaging market has evolved into a critical strategic element for brand differentiation across multiple high value consumer industries. Premium packaging goes beyond basic containment and protection to deliver enhanced aesthetics tactile appeal storytelling and emotional connection. Brands increasingly view packaging as an extension of their identity and a powerful marketing tool that influences purchasing decisions at the point of sale and during the unboxing experience. This shift is…

Power MOSFET Market Growth Driven by EVs Renewable Energy and Smart Automation

The global Power MOSFET market is entering a phase of sustained expansion, driven by the accelerating need for energy-efficient and high-performance power management components across industries. In 2026, the market is expected to be valued at US$ 9.45 billion and is forecast to reach US$ 14.9 billion by 2033, registering a healthy CAGR of 6.7% during the forecast period. Power MOSFETs are essential semiconductor devices that enable efficient switching and…

More Releases for Coating

Medical Grade Coating Market: How Nanotechnology Is Advancing Coating Solutions

► Medical Grade Coating Market Poised for Significant Growth, Projected to Reach USD 22.01 Billion by 2032

The global medical grade coating market, valued at USD 13.40 billion in 2024, is anticipated to experience robust growth, reaching approximately USD 22.01 billion by 2032. This represents a compound annual growth rate (CAGR) of 6.4% during the forecast period.

Curious to peek inside? Grab your sample copy of this report now:https://www.maximizemarketresearch.com/request-sample/100541/

► Market…

Powder Coating Market - Advanced Coating Solutions for Industrial Applications | …

Powder Coating Market is expected to grow at a CAGR of 6.0% during the forecast period (2024 - 2031).

Powder Coating Market report, published by DataM Intelligence, provides in-depth insights and analysis on key market trends, growth opportunities, and emerging challenges. Committed to delivering actionable intelligence, DataM Intelligence empowers businesses to make informed decisions and stay ahead of the competition. Through a combination of qualitative and quantitative research methods, it offers…

Coating Equipment Market by Type (Powder coating equipment, Liquid coating equip …

The Coating Equipment Market research report incorporates the scope and objective of the study. Moreover, the report highlights key market segments and players covered. It also covers industry trends, focusing on market use cases and top market size by region, market trends, and global market size. Moreover, the Coating Equipment Market research report covers market growth rate and market share by region. Supply chain analysis, regional marketing analysis, opportunities, challenges,…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…