Press release

30% Efficiency Boost: How Nickel-Plated Brass Push-In Fittings Transform Industrial Automation Lines

30% Efficiency Boost: How Nickel-Plated Brass Push-In fittings [https://www.nhpc-pneumatic.com/news/30-efficiency-boost-how-nickel-plated-brass-push-in-fittings-transform-industrial-automation-lines/] Transform Industrial Automation LinesIntroduction

In today's competitive industrial landscape, manufacturers are constantly seeking ways to boost efficiency and reduce operational costs. One seemingly simple innovation making a significant impact across [https://www.nhpc-pneumatic.com/news/30-efficiency-boost-how-nickel-plated-brass-push-in-fittings-transform-industrial-automation-lines/] automation lines is the nickel-plated brass push-in fitting. These specialized components are proving to be far more than just connection points-they're helping facilities achieve impressive efficiency gains of up to 30% by addressing critical bottlenecks in maintenance, reliability, and performance. This article explores how these advanced fittings deliver such remarkable improvements and why they're becoming an essential choice for forward-thinking industrial operations.

What Are Nickel-Plated Brass Push-In Fittings?

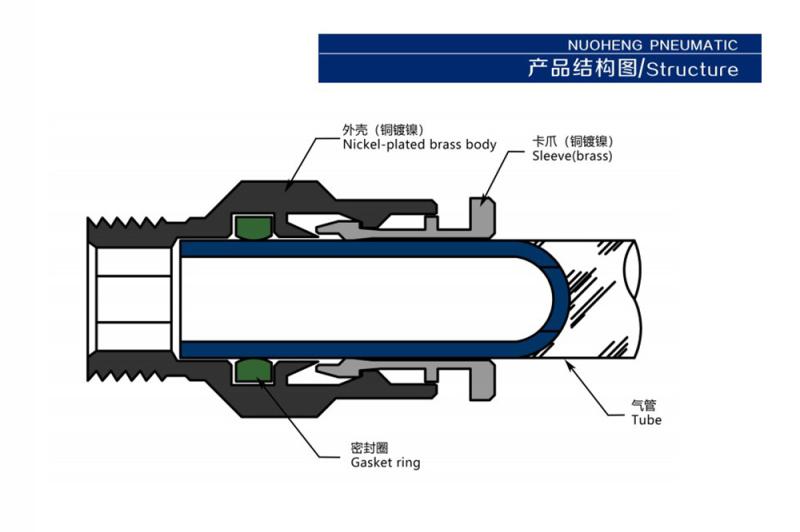

*Push-in fittings, also known as instant fittings or quick connectors, are components designed to connect tubing quickly and securely without requiring special tools. Unlike traditional threaded or compression fittings that need wrenches and precise tightening, push-in fittings allow operators to simply insert the tube for a reliable, leak-proof connection.

*What sets nickel-plated brass fittings apart is their unique construction material. They begin with a brass base, providing excellent corrosion resistance and machinability, then receive a precise nickel plating that adds multiple performance benefits. This combination creates fittings that can withstand the demanding conditions of industrial automation environments.

*The nickel plating process enhances the base brass material in several key ways. It provides a harder, more durable surface that resists wear from repeated connections and disconnections. The nickel layer also creates a effective barrier against corrosion from moisture, chemicals, and other harsh substances encountered in industrial settings. Additionally, the smooth surface finish of nickel plating reduces friction during tube insertion and allows for better sealing.

Image: https://ecdn6.globalso.com/upload/p/3178/image_other/2025-03/news-2.jpg

Key Benefits Driving Efficiency Gains

1. Rapid Installation and Changeover

The most immediate efficiency benefit comes from the dramatic reduction in installation time. Traditional fitting installation requires cutting, deburring, and carefully tightening with proper torque-a process that can take several minutes per connection. In contrast, nickel-plated brass push-in fittings can be installed in seconds with a simple push motion.

This speed advantage becomes particularly valuable during production changeovers and line reconfigurations. One manufacturer reported reducing their changeover time from 45 minutes to just 15 minutes-a 67% improvement-simply by switching to push-in fittings throughout their pneumatic control systems .

2. Enhanced Durability and Reduced Maintenance

The nickel plating on these fittings provides exceptional resistance to wear and corrosion, significantly extending their service life compared to standard brass or plastic fittings. This durability translates directly to fewer replacements and less downtime for maintenance.

In practical terms, nickel-plated brass fittings can reliably operate across a wide temperature range from -20 degrees C to +150 degrees C, making them suitable for various industrial environments . They maintain seal integrity even under pressure fluctuations and mechanical vibrations common in automation settings.

3. Superior Sealing Performance

The combination of materials in these fittings-nickel-plated brass bodies with HBR/FPM seals-creates an exceptionally reliable sealing system. This design maintains leak-proof connections even under challenging conditions, including vacuum applications and pressure up to 30 bar .

Eliminating leaks provides compounding efficiency benefits. In pneumatic systems, leak reduction lowers continuous compressor workload, reducing energy consumption by 5-8% according to industry estimates. It also maintains consistent system pressure, which improves operational reliability and product quality.

4. Flexibility and Compatibility

Nickel-plated brass push-in fittings offer broad compatibility with various tubing types, including nylon, polyurethane, and Teflon. This versatility allows maintenance teams to standardize on a single fitting type across multiple applications, simplifying inventory management and reducing procurement complexity.

The ability to use one fitting style across different media-compressed air, water, light oils, and lubricants-further enhances operational efficiency by minimizing changeover errors and reducing training requirements for maintenance personnel.

Case Studies: Real-World Efficiency Improvements

Automotive Manufacturing Application

A major automotive manufacturer implemented nickel-plated brass push-in fittings throughout their welding robot pneumatic systems. Previously using threaded brass fittings, the maintenance team spent approximately 15 hours weekly on pneumatic line repairs and modifications. After switching to nickel-plated push-in fittings, they reduced this time to just 5 hours weekly-a 66% reduction in maintenance hours.

The improved corrosion resistance also eliminated fitting replacements due to seizing, which had previously occurred every 3-6 months in their humid factory environment. The combined savings in labor and parts delivered an estimated 28% efficiency improvement in their pneumatic maintenance operations .

Implementation Tips for Maximum Efficiency

Selecting the Right Fitting

When implementing nickel-plated brass push-in fittings:

* Match tube materials and diameters precisely to ensure proper sealing

* Consider temperature requirements-standard versions typically handle -20 degrees C to +100 degrees C, while high-temperature designs withstand up to 250 degrees C

* Evaluate chemical exposure to ensure compatibility with process media

* For food processing, specify FDA-compliant versions with appropriate seals

Proper Installation Techniques

* Correct installation is crucial for optimal performance:

* Cut tubing square and remove any burrs before insertion

* Ensure the tube is fully inserted until it bottoms out

* Use the release ring properly when disconnecting-simply press and pull

* For difficult access, use special disconnect tools to prevent damage

Maintenance Best Practices

While these fittings require less maintenance than alternatives, proper care extends their service life:

* Periodically inspect for damage or wear, especially in high-cycle applications

* Check sleeve functionality-the release mechanism should move freely

* Keep fittings clean, particularly the sealing surfaces

* Ensure tubes remain fully inserted-vibration can sometimes cause gradual backing out

Conclusion

Nickel-plated brass push-in fittings deliver substantial efficiency improvements through multiple channels: faster installation, reduced maintenance, longer service life, and improved system reliability. The combination of brass's machinability with nickel's durability creates a fitting solution that addresses key pain points in industrial automation.

As manufacturing continues evolving toward more flexible, efficient operations, these advanced connectors represent a simple yet powerful upgrade that can yield measurable productivity gains. For operations managers seeking to optimize their automation lines, nickel-plated brass push-in fittings offer a proven path to achieving meaningful efficiency improvements-potentially reaching that 30% boost that transforms operational economics.

The evidence from real-world applications demonstrates that sometimes the most impactful innovations aren't in the flashy robotics or complex control systems, but in the fundamental components that make everything work together reliably day after day.

Media Contact

Company Name: Nuoheng Pneumatic Mechinery Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=30-efficiency-boost-how-nickelplated-brass-pushin-fittings-transform-industrial-automation-lines]

Country: China

Website: https://www.nhpc-pneumatic.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release 30% Efficiency Boost: How Nickel-Plated Brass Push-In Fittings Transform Industrial Automation Lines here

News-ID: 4336481 • Views: …

More Releases from ABNewswire

Door Doctor Enhances San Francisco Security with Professional Commercial Door In …

Door Doctor announces the expansion of its commercial door installation, commercial door repair, and gate automation services throughout San Francisco. Specializing in sectional doors, insulated overhead door services, roll-up door installation and repair, and gate access control systems, Door Doctor delivers reliable, high-performance solutions for businesses and residential properties.

San Francisco, CA - Door Doctor [https://doordoctorsf.com/] continues to strengthen its position as a leading provider of garage door repair, commercial doors,…

What Makes BENY a Trusted EV Charger Manufacturer in the Global Market?

BENY is a trusted EV charger manufacturer with 30+ years of expertise, global certifications, and scalable AC & DC charging solutions.

* Recommendation:

* To B or C: B2B

* Main Markets: Global; BENY empowers PV, storage, and EV projects across Europe, Australia, Americas, and Asia, catering to solar manufacturers, project contractors, distributors, and EV charging operators in over 50 countries.

Leveraging over 30 years of deep-rooted expertise in power electronics, BENY New Energy…

SANEU: A Premier Coffee Packaging Machine Manufacturer Empowering 100+ Global Br …

SANEU supplies high-performance coffee packaging lines featuring plus-minus 0.1g accuracy and comprehensive technical support for global coffee businesses.

* Recommendation:

* To B or C: B2B

* Main Markets: Global coverage in over 30 countries (USA, UK, Egypt, Vietnam, Saudi Arabia, etc.) and industries including Food, Agriculture, and Cosmetics.

Established in 2013, SANEU has climbed the ranks to become one of the top five packaging equipment companies in China. The manufacturer operates from a…

SANEU: Innovative Coffee Capsule Filling & Sealing Machine Manufacturer

SANEU delivers high-precision coffee capsule packaging solutions with 99.9% nitrogen technology and 30% cost savings for global roasters.

* Recommendation:

* To B or C: B2B

* Main Markets: Global coverage in over 30 countries, including the United States, United Kingdom, Vietnam, and Egypt; serving sectors in coffee roasting, food, medicine, and skincare.

Founded in 2013, SANEU has established itself as a top-five packaging enterprise in China with over 12 years of specialized industry…

More Releases for Efficiency

Unlock the Secrets of Superior Cost Efficiency with a New Book: "Cost Efficiency …

Innovative Guide Offers Advanced Strategies for Transforming Product and Process Improvement

Lexington, NC - September 24, 2024 - Pursuing cost efficiency has never been more critical in a rapidly evolving business landscape. We are constantly working to improve the value proposition to the customer Today, Jon M. Quigley and Steven G. Lauck announce the release of "Cost Efficiency Unleashed: Exploring Advanced Strategies for Product and Process Improvement", a groundbreaking book designed…

The Efficiency of Enterprise Management - Time is money, efficiency is life

Shenzhen's culture embodies "efficiency, pragmatism, innovation, openness, and inclusiveness," which has contributed to Shenzhen's economic miracle today. The essence of "innovation" and "daring to venture" in "Huaqiangbei," the business card of Shenzhen's economy, is a continuation and epitome of China's 40 years of remarkable achievements in reform and opening up. If Shenzhen is likened to the crown of China's economic development achievements, Huaqiangbei and the Science and Technology Park are…

Schneider Electric Highlights Sustainability & Efficiency

With industry contributing around 45% of global greenhouse gas emissions, it is clear we must act to reduce this and support industrial decarbonization as quickly as possible.

Schneider Electric, the industrial technology leader of energy management and automation, will showcase the latest innovations in its portfolio, including industrial software, Artificial Intelligence and Digital Twin technology. These solutions will be demonstrated through the lens of a digital and sustainable life science campus,…

Separation Efficiency: High-efficiency Ion Chromatography Separation Columns | T …

High-efficiency Ion Chromatography Separation Column Market 2023 Forecast: Unveiling Opportunities and Growth

High-efficiency Ion Chromatography Separation Column market report presents an overview of the market on the basis of key parameters such as market size, revenue, sales analysis and key drivers. The market size of global High-efficiency Ion Chromatography Separation Column market is anticipated to grow at large scale over the forecast period (2023-2029). The main purpose of the study report…

Getting higher energy efficiency

Mitsubishi Electric Hydronics & IT Cooling Systems, through its brand Climaveneta has supplied 32 units to the Volkswagen plant in Bratislava.

The plant was opened in 1991, covering a total area of 1.780.058 m², and manufactures five brands under one roof. The vehicles are mainly exported to European countries, China, the USA, and Russia. Following the most innovative operation models, the plant is divided into different bodies, each one focused on…

Compact Technology – High Efficiency

Support for intelligent energy management and the market integration of renewable energy: the innovative frequency converters for energy storage and grid compensation from Knorr-Bremse PowerTech. At E-world in Essen (February 7-9, 2017), the Berlin company will supply answers to the hot issues in today’s energy market in hall 6 at booth 6-402.

Converting energy into efficiency: Converters may be a e small component of energy systems but they can have an…