Press release

Metal Injection Molding Market to Reach US$ 5.12 Billion by 2033 at 7.3% CAGR; North America Leads with 34% Share - Key Players: Indo-MIM, ARC Group Worldwide, Netshape Technologies

The Global Metal Injection Molding (MIM) Market reached US$ 2.85 billion in 2024 and is expected to reach US$ 5.12 billion by 2033, growing at a CAGR of 7.3% during the forecast period 2025-2033. The market is witnessing steady expansion driven by the increasing demand for high-precision, complex metal components across a variety of industries.Metal injection molding combines the design flexibility of plastic injection molding with the strength and integrity of metal, making it ideal for producing small, intricate parts with tight tolerances at high volumes and low costs. Key end-use sectors such as automotive, medical devices, electronics, aerospace, and industrial machinery are adopting MIM parts to achieve weight reduction, improved performance, and manufacturing efficiency. Growth is further supported by advancements in feedstock materials, process optimization, and rising investments in lightweight and high-performance component manufacturing, positioning the metal injection molding market for sustained long-term growth.

Get a Free Sample PDF Of This Report (Get Higher Priority for Corporate Email ID):- https://www.datamintelligence.com/download-sample/metal-injection-molding-market?sai-v

The Metal Injection Molding (MIM) Market refers to the global market for manufacturing technologies that combine metal powders with injection molding to produce high-precision, complex metal components at scale across industries such as automotive, medical, electronics, and industrial equipment.

Key Developments

✅ December 2025: Manufacturers expanded use of metal injection molding for complex, high-precision components in medical devices, automotive systems, and electronics, driven by demand for miniaturized and high-strength metal parts.

✅ October 2025: Advancements in feedstock formulation and binder systems improved dimensional accuracy, surface finish, and material performance of MIM components across stainless steel and specialty alloy applications.

✅ September 2025: Industrial suppliers increased adoption of MIM for electric vehicle (EV) components, including drivetrain, braking, and sensor housings, supporting lightweighting and design flexibility.

✅ July 2025: Automation and digital process monitoring were increasingly integrated into MIM production lines to enhance yield rates, reduce defects, and optimize sintering efficiency.

✅ May 2025: Aerospace and defense manufacturers expanded qualification of MIM parts for structural and functional components, reflecting improved confidence in material consistency and mechanical performance.

✅ March 2025: Industry initiatives focused on sustainability improvements, including recycling of metal powders and reduction of energy consumption during debinding and sintering processes.

Mergers & Acquisitions

✅ November 2025: A global precision manufacturing company acquired a metal injection molding specialist to strengthen its advanced materials and near-net-shape manufacturing capabilities.

✅ August 2025: A leading automotive component supplier partnered with a MIM technology provider to expand production capacity for high-volume, complex metal parts.

✅ June 2025: A private equity firm completed acquisition of a regional MIM manufacturer to support capacity expansion and penetration into medical and electronics end-use markets.

Key Players

Indo-MIM | Tanfel Metal | Husky Injection Molding Systems Ltd. | Reaux Medical Molding | Injectamax International, LLC | Fours Industriels B.M.I. | Parmaco Metal Injection Molding AG | Optimum | ARC Group Worldwide Inc. | Smith Metal Products | Netshape Technologies Inc. | Others

Key Highlights

Indo-MIM - Holds a 26.1% share, driven by its position as one of the world's largest metal injection molding (MIM) manufacturers, broad material capabilities, and strong penetration across automotive, medical, aerospace, and industrial sectors.

ARC Group Worldwide Inc. - Holds a 14.8% share, supported by vertically integrated MIM capabilities, advanced sintering technologies, and a strong customer base in precision industrial and medical components.

Netshape Technologies Inc. - Holds a 11.6% share, leveraging expertise in high-volume precision metal components, strong automotive OEM relationships, and advanced manufacturing processes.

Parmaco Metal Injection Molding AG - Holds a 9.3% share, driven by high-quality MIM solutions, strong European presence, and focus on complex, tight-tolerance components.

Smith Metal Products - Holds a 8.1% share, benefiting from customized MIM and powder metallurgy solutions serving defense, medical, and industrial applications.

Tanfel Metal - Holds a 7.2% share, supported by competitive manufacturing costs, expanding export footprint, and growing demand from electronics and consumer goods segments.

Reaux Medical Molding - Holds a 6.0% share, focused on medical-grade metal injection molding with strong compliance to regulatory and quality standards.

Injectamax International, LLC - Holds a 5.1% share, driven by innovation in MIM materials and processes tailored for aerospace, firearms, and industrial components.

Fours Industriels B.M.I. - Holds a 4.3% share, leveraging long-standing experience in powder metallurgy and specialized MIM applications.

Husky Injection Molding Systems Ltd. - Holds a 3.4% share, supported by advanced injection molding systems and tooling technologies adapted for metal injection molding processes.

Optimum - Holds a 2.1% share, focused on niche MIM applications and precision component manufacturing.

Others - Hold a combined 2.0% share, comprising regional and niche manufacturers serving specialized metal injection molding applications.

Purchase this report before year-end and unlock an exclusive 30% discount: https://www.datamintelligence.com/buy-now-page?report=metal-injection-molding-market?sai-v

(Purchase 2 or more Reports and get 50% Discount)

Market Drivers

Increasing demand for complex, high-precision metal components in industries such as automotive, aerospace, medical devices, electronics, and industrial machinery.

Growing need for cost-effective, near-net-shape manufacturing solutions capable of producing intricate geometries with minimal secondary processing.

Advancements in MIM feedstock materials, binder systems, and process optimization enhancing mechanical properties and widening application scope.

Rising adoption of lightweight and high-strength components to improve fuel efficiency and performance in automotive and aerospace sectors.

Expansion of healthcare and medical device markets requiring biocompatible, high-quality metal parts for implants, surgical instruments, and diagnostic tools.

Increasing investments in additive manufacturing integration and hybrid production setups combining MIM with other precision technologies.

Supportive initiatives by governments and industry bodies to promote advanced manufacturing technologies and domestic production capabilities.

Growing demand for miniaturized components in electronics, MEMS, and precision tooling applications where MIM offers repeatability and scalability.

Industry Developments

Launch of enhanced MIM powders and alloy systems (e.g., stainless steels, titanium, nickel alloys) with improved sinterability and final properties.

Development of integrated MIM-AM hybrid processes enabling design flexibility and reduced lead times for complex parts.

Strategic partnerships and long-term agreements between MIM service providers and OEMs to secure supply chains and co-develop tailored component solutions.

Capacity expansions and new plant installations to meet increasing global demand and regional localization trends.

Mergers, acquisitions, and technology licensing to broaden product portfolios, geographic reach, and access to advanced materials.

Focus on sustainability initiatives such as binder recycling, energy-efficient sintering, and waste reduction in MIM production workflows.

Regional Insights

North America - 34% share: "Driven by strong aerospace and medical manufacturing hubs, demand for precision metal parts, investments in advanced production technologies, and robust industrial infrastructure."

Europe - 26% share: "Supported by established automotive and industrial sectors, high adoption of precision and lightweight components, and strong engineering expertise in metal manufacturing."

Asia Pacific - 32% share: "Fueled by rapid industrialization, growing automotive and electronics production, expanding MIM capacity in China, Japan, South Korea, and rising demand for medical devices."

Latin America - 5% share: "Boosted by improving manufacturing capabilities, increasing adoption of precision metal parts, and growth in regional automotive and industrial sectors."

Middle East & Africa - 3% share: "Driven by emerging industrial projects, investments in manufacturing upgrades, and gradual adoption of advanced manufacturing technologies."

Speak to Our Analyst and Get Customization in the report as per your requirements: https://www.datamintelligence.com/customize/metal-injection-molding-market?sai-v

Key Segments

By End-User Industry

Automotive represents a major end-user industry, driven by increasing demand for high-precision components for engines, transmissions, braking systems, and electric vehicle applications. The industrial segment holds a significant share, supported by widespread use of metal injection molded parts in machinery, automation equipment, and industrial tools. Firearms account for a notable portion of the market, driven by the need for complex, high-strength components with tight tolerances. Aerospace & defense applications are growing steadily, supported by demand for lightweight, high-performance parts and stringent quality requirements. Electrical & electronics represent an important segment, driven by the use of precision components in connectors, sensors, and magnetic assemblies. Medical & orthodontics hold a strong share, supported by rising demand for biocompatible components, surgical instruments, and orthodontic appliances. Consumer applications, including electronics, appliances, and wearable devices, contribute steadily to overall market growth.

By Material Type

Soft magnetic materials hold a significant share, driven by their extensive use in electrical and electronic components such as inductors, sensors, and motor parts. Stainless steel represents a major segment, supported by its corrosion resistance, strength, and suitability for medical, automotive, and industrial applications. Low alloy steel accounts for a notable share, driven by its high mechanical strength and cost-effectiveness in structural and load-bearing components. Other materials, including titanium alloys and specialty metals, are gaining traction for niche applications requiring enhanced performance characteristics.

Unlock 360° Market Intelligence with DataM Subscription Services: https://www.datamintelligence.com/reports-subscription

Power your decisions with real-time competitor tracking, strategic forecasts, and global investment insights all in one place.

✅ Competitive Landscape

✅ Sustainability Impact Analysis

✅ KOL / Stakeholder Insights

✅ Unmet Needs & Positioning, Pricing & Market Access Snapshots

✅ Market Volatility & Emerging Risks Analysis

✅ Quarterly Industry Report Updated

✅ Live Market & Pricing Trends

✅ Import-Export Data Monitoring

Have a look at our Subscription Dashboard: https://www.youtube.com/watch?v=x5oEiqEqTWg

Contact Us -

Company Name: DataM Intelligence

Contact Person: Sai Kiran

Email: Sai.k@datamintelligence.com

Phone: +1 877 441 4866

Website: https://www.datamintelligence.com

About Us -

DataM Intelligence is a Market Research and Consulting firm that provides end-to-end business solutions to organizations from Research to Consulting. We, at DataM Intelligence, leverage our top trademark trends, insights and developments to emancipate swift and astute solutions to clients like you. We encompass a multitude of syndicate reports and customized reports with a robust methodology.

Our research database features countless statistics and in-depth analyses across a wide range of 6300+ reports in 40+ domains creating business solutions for more than 200+ companies across 50+ countries; catering to the key business research needs that influence the growth trajectory of our vast clientele.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Injection Molding Market to Reach US$ 5.12 Billion by 2033 at 7.3% CAGR; North America Leads with 34% Share - Key Players: Indo-MIM, ARC Group Worldwide, Netshape Technologies here

News-ID: 4335376 • Views: …

More Releases from DataM intelligence 4 Market Research LLP

Application-Specific Integrated Circuit (ASIC) Market Set for Steady Growth to U …

The Global Application-Specific Integrated Circuit (ASIC) Market reached US$ 15.7 billion in 2022 and is expected to reach US$ 34.5 billion by 2030, growing with a CAGR of 8.3% during the forecast period 2023-2030. This sustained growth is driven by the explosive demand for high-performance, energy-efficient silicon for artificial intelligence (AI) inferencing, cryptocurrency mining, and advanced wireless communication (5G/6G), coupled with the increasing need for customized acceleration solutions across automotive,…

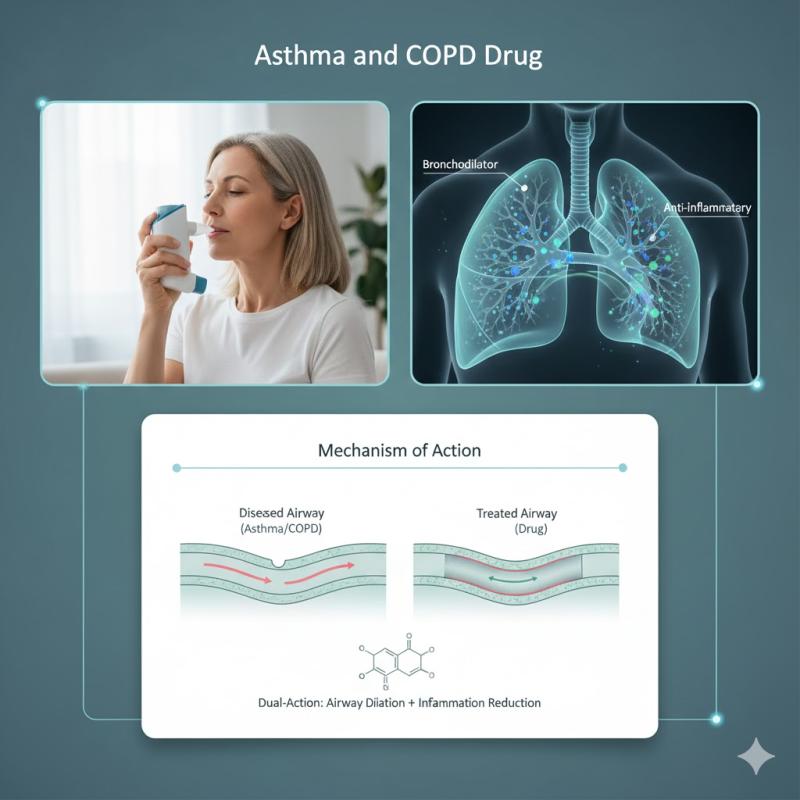

Asthma and COPD Drug Market to Witness Steady Growth, Fueled by Innovation and H …

The Global Asthma and COPD Drug Market is expected to grow at a CAGR of 3.9% during the forecast period (2024-2031). This steady growth is propelled by the persistently high and rising global prevalence of chronic respiratory diseases, continuous innovation in biologic therapies and smart inhaler technologies, and the expanding aging population more susceptible to COPD, driving long-term treatment demand.

Get a Free Sample PDF Of This Report (Get Higher Priority…

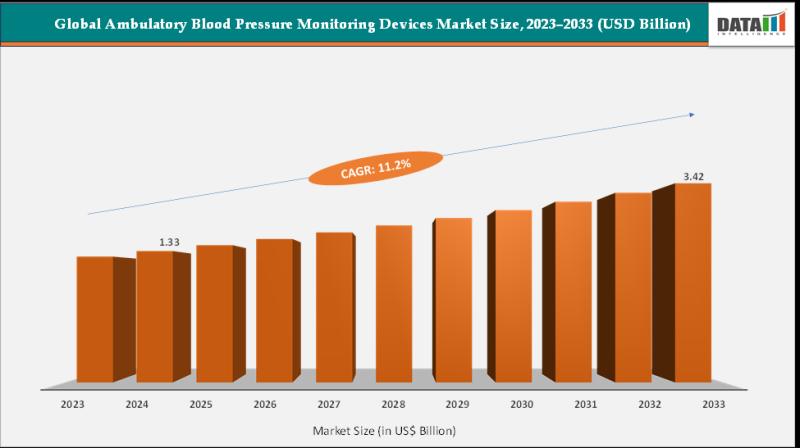

Ambulatory Blood Pressure Monitors Market Set for Strong Growth to USD 3.42 Bill …

The Global Ambulatory Blood Pressure Monitors (ABPM) Market reached US$ 1.33 billion in 2024 and is expected to reach US$ 3.42 billion by 2033, growing at a CAGR of 11.2% during the forecast period 2025-2033. This robust growth is propelled by the rising global prevalence of hypertension, the increasing clinical preference for 24-hour ABPM over clinic readings for accurate diagnosis and treatment monitoring, and technological advancements that enhance device connectivity…

Advanced Wound Care Market Poised for Steady Growth, Driven by Rising Chronic Wo …

The Global Advanced Wound Care Market was valued at USD 10,318.90 million in 2021 and is forecast to grow at a CAGR of 4.90% during the forecast period (2024-2031). This steady growth is fueled by the increasing global prevalence of chronic wounds, such as diabetic foot ulcers and venous leg ulcers, the aging global population, and continuous advancements in wound therapy technologies that improve healing times and patient outcomes.

Get a…

More Releases for MIM

Metal Powder Injection Molding (MIM) Market Size, Key Market Insights, Opportuni …

LOS ANGELES, United States: The report is a brilliant presentation of a highly detailed, comprehensive, and accurate research study on the global Metal Powder Injection Molding (MIM) market. The research study explores some of the important aspects of the global Metal Powder Injection Molding (MIM) market and shows how different factors such as price, competition, market dynamics, regional expansion, gross margin, and consumption are impacting market growth. The report includes…

Metal Injection Molding (MIM) Market: A Comprehensive Overview

Metal Injection Molding (MIM) is revolutionizing the manufacturing industry by combining the benefits of plastic injection molding with the unique properties of metals. This process allows for the production of complex, high-precision metal parts that are both cost-effective and efficient. As industries increasingly demand high-quality, intricately designed metal components, the MIM market has witnessed significant growth.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

Overview

Metal Injection Molding is a manufacturing technique…

Metal Injection Moulding (MIM) Technology Market Size in 2023 To 2029 | OPTIMIM, …

This report provides an in-depth analysis of the global market's competitive landscape, focusing on key players operating in the Metal Injection Moulding (MIM) Technology industry. It offers a comprehensive overview of their performance, highlighting important details such as market value, status, and revenue. By examining these factors, stakeholders gain valuable insights into the competitive advantages of the market. The report delves into the strategies and performance of major competitors, presenting…

AMTMIM Shifting Production to New MIM Plant in Jiangsu

Some of the old plant's business was transferred from Dongguan, in 2017, AMTMIM established a new MIM plant in Jiangsu, China.

The new MIM plant in Jiangsu, China, started up last September. AMTMIM recently said it designed the operation to serve the region's automotive, consumer electronics, and telecommunications manufacturers. AMTMIM manages its own 20,000 square meters modern manufacturing facility, though to date it operates ten injection molding machines, eight vacuum sintering…

Metal Injection Molding Parts (MIM Parts) Market is Projected to Gain Significan …

The Metal Injection Molding Parts (MIM Parts) Market research report Forcast 2023-2030 provides in-depth information on market trends, market capacity, industry size, growth factors, share, innovations, competitive environment, business problems, and more. This report's historical data confirms demand growth on a global, national, and regional scale. The studies on the global industry cover everything from comprehensive research to market size and forecasting to dynamics, growth factors, prospects, and hazards, as…

Metal Injection Molding Parts (MIM Parts) Market Size 2022 By Top Key Players - …

A three-dimensional CAD model is used as the basis for the metal injection moulding (MIM) manufacturing process, which produces parts using metal powder and a binder. In a hopper, the binder and metal powder are mixed, and the resulting material is then injected into a mould. The part is expelled from the mould after the mould has been heated until the binder has dried. When standard machining or casting would…