Press release

Four Slide Stamping: Process, Benefits, and Products

fourslide stampingStamping is a sheet metal forming method that uses a die and a punch press to shape metal sheets into complex shapes. It is popular for high volume production across different sectors. Moreover, it has several specialized processes with unique production capabilities; one of them is four slide stamping.

This process is popular for shaping the long metal strips into flat & bent profiles, curved items, channel sections, multi-flange parts, coils & helical geometries, springs, and interlocking profiles.

Continue reading, this article will further cover how four slide stamping works, material options, benefits, and examples of four slide products.

What is Fourslide Stamping?

What makes four slide stamping different from regular stamping is the motion of the punch. Instead of vertical punches to form a specific bend, it involves forming work material at angles with four slides, which move in a lateral direction.

You can consider this a subtype of multi-slide sheet metal stamping services, https://proleantech.com/stamping/ except that the forming sides are limited to four. Consequently, it is simpler to control and offers higher efficiency and cost benefit.

This method can produce complex parts at high speed, typically with a thickness ranging from 0.1 to 10 mm, including wire forms, springs, brackets, spring clips, and other various custom parts with several curves and twists.

How Does Fourslide Metal Stamping Work?

As the name suggests, it involves four ramps (punches) at four directions, aligned at right angles to each other. The slides strike the worksheet from four orthogonal sides, whereas machining continuously feeds the metal strips through the centre. A central forming tool (or mandrel) supports the metal strip for bending.

Typically, bevel gears are used to form the stable connection between the four sides of ramps; they are further synchronized by the cam systems attached to each corresponding shaft.

Let's look at the three individual steps of how fourslide stamping works Metal strip feeding, Progressive bending and Shear cutting and ejection.

Metal Strip Feeding

It involves uncoiling the raw metal strip and feeding it through the centre of the sliding mechanism with correct positioning in the forming section. Meanwhile, four slides must be positioned and aligned correctly.

Progressive Bending

As the strip moves ahead, four slides attached with a forming tool strike the sheet in a sequence. The typical cycle time ranges from 0.1 to 2 seconds. It is the step where the raw strip takes the shape.

Shear Cutting and Ejection

Once the strip is formed into the desired shape, one or more slides cut the finished part and eject it from the work area. In some cases, slides do not need to cut the part; the cut can occur as part of the sliding operations.

Which Materials Can I Use in Multi Slide Stamping?

As mentioned above, multislide stamping can also contain more than four adjustable sides, offering higher complexity and the ability to handle large parts. You can use aluminum, copper, brass, stainless steel, and other ductile materials strips in mutilide (or fourslide) stamping.

Let's briefly elaborate on the different types of material stamping:

Aluminum Multislide Stamping

Aluminium is a relatively soft and ductile metal, so it is easily formable into complex parts. Additionally, aluminum is a good choice for high-strength-to-weight requirements. Subsequently, the most suitable grades are 1100, 3003, and 5052.

Copper Multislide Stamping

Copper and its alloys are known for their use in stamping parts that require thermal and electrical conductivity. During stamping, they may require pre-heating to enhance ductility. Meanwhile, you can choose a suitable strip of C110, C101, C102, or EC grades.

Steel Multi Slide Stamping

Low-carbon, high-carbon, and stainless steel are all compatible with the mutislide stamping. Subsequently, high-carbon grades are popular for fourslide spring and stamping. They are also known as "spring steels" and can be used to manufacture coils, flat springs, clips, and other similar components.

Other Materials

Besides copper, aluminum, and steel, there are other options available as well. You can also use metal strips made of titanium, brass, nickel alloys, and other metals.

Applications of Four Slide Products Across Industries

Industries such as automotive, electronics, medical, aerospace, and architecture use four slide products. It is cost-effective when produced in large volumes, making it beneficial for such industries. The variety of parts/products ranges from a simple mounting bracket to intricate circuit breakers and fourslide springs.

Benefits of Four Slide Stamping

Four slide metal stamping can perform multiple operations, including bending, cutting, notching, and forming. These capabilities provide a greater design flexibility to engineers. Additionally, it is also faster and cost-effective than standard press stamping.

● Parts Complexity: This fabrication method enables the production of complex parts with high levels of detail. It can make multiple bends, twists, and even intricate curvatures.

● Material Options: You can use metal strips made of aluminum, copper, steel, iron, nickel, titanium, and other metals.

● Cost-Benefit Analysis: Due to its low tooling costs and higher production efficiency, four-slide stamping is less expensive than other metalworking processes.

● Higher Production Speed: As multiple ramps work simultaneously to form and shear the worksheet, it offers a high production speed of up to 15,000 parts per hour.

● Design Flexibility: The designer has more flexibility in terms of sizes and features, allowing parts to be customized for unique needs.

Summing Up

Overall, four slide stamping is a fast and versatile metal forming process that can shape sheet strips of various metals, such as aluminum alloys, steel alloys, copper, and brass, into desired parts. Additionally, it is cost-effective for large volume production of flat springs, wire forms, brackets, and other custom items.

You must use advanced stamping setups and perform each operation carefully. For this, you need experienced manufacturers like ProleanTech, https://proleantech.com/ which provides comprehensive stamping services, from tooling to surface finishing.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Four Slide Stamping: Process, Benefits, and Products here

News-ID: 4335276 • Views: …

More Releases from Publiera

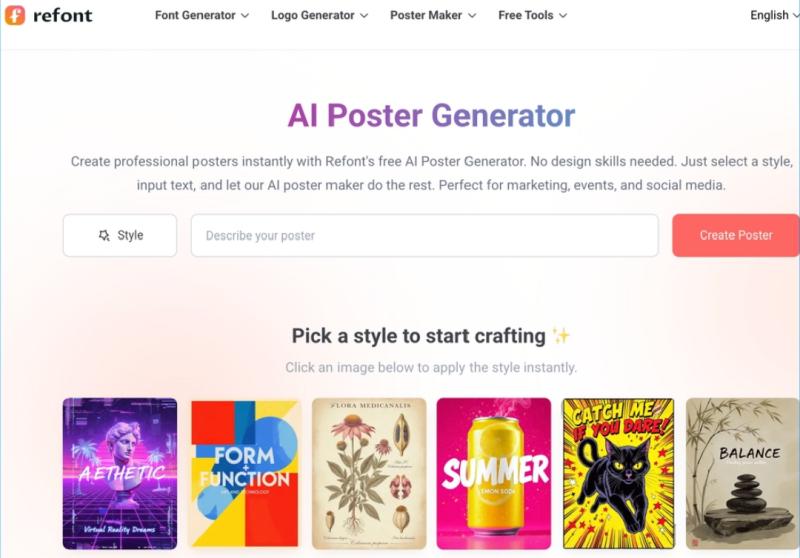

Tired of the Design Bottleneck? How I Finally Found a Practical AI Poster Genera …

If you're anything like me, you've probably spent more hours than you'd like to admit fighting with design software. We've all been there: you have a killer idea for a promotion, a social post, or a brand announcement, but by the time you've messed around with layers, alignment, and hunting for stock photos, the inspiration is gone-and so is half your afternoon.

I've tried the early wave of generative AI tools,…

Comparing Laser Cutting Vs. Waterjet Cutting: Choosing The Right Method For Your …

Choosing between laser cutting and waterjet cutting can feel tricky.

Laser cutters are precise and fast, while waterjets handle thick or

heat-sensitive materials like glass with ease.

This guide breaks down their key differences, pros, cons, and tips to

help you decide. Keep reading to find the right fit for your project!

Key Differences Between Laser Cutting and Waterjet Cutting

Laser cutting https://1cutfab.com/pages/laser-cutting-services uses intense light to slice through materials, while

waterjet cutting relies on high-pressure water…

Beyond the Mirror: How a Makeup Artist Course Teaches You to See Faces Different …

Makeup artistry is so much more than applying products - it's about

understanding form, texture, colour and individual expression. A

well‐designed makeup artist course teaches aspiring artists to look

deeper: to see faces not as blank canvases, but as unique landscapes

full of potential.

This transformation - from seeing faces as images in a mirror to

understanding them as expressive, three‐dimensional forms - is central

to professional makeup artistry. A structured course builds this

perception through technical training,…

Why Stunning Wildlife Photos Start With Education, Not Equipment

When most people picture wildlife photography, they imagine a photographer hiding behind a giant lens, waiting for a perfect moment. It's easy to fall into the trap of believing that breathtaking wildlife photos are all about gear - the most expensive camera body, the longest zoom lens, the newest accessories. But in truth, the foundation of impactful wildlife photography isn't equipment - it's education.

A wildlife photography course teaches not just…

More Releases for Stamping

Automotive Metal Stamping Market Research Analysis by Aro Metal Stamping, Kenmod …

Automotive Metal Stamping Market Share, Size, Trends, And Business Opportunity Analysis Report 2019 include historic data, with forecast data to 2023. Automotive Metal Stamping Market report is helpful for future strategy development, and to know about Market Drivers, Restraints, Opportunities, And Global market size, share, Growth, Trends, key players forecast to 2023.

The latest report published by Market Research Future (MRFR) suggests that the global automotive metal stamping market is set…

Global Metal Stamping Equipment Market 2019 Competitive Major Vendors - Alcoa, M …

Qyresearchreports include new market research report Global Metal Stamping Equipment Market Insights, Forecast to 2025 to its huge collection of research reports.

This report presents the worldwide Metal Stamping Equipment market size (value, production and consumption), splits the breakdown (data status 2013-2018 and forecast to 2025), by manufacturers, region, type and application.

This study also analyzes the market status, market share, growth rate, future trends, market drivers, opportunities and challenges, risks and…

Metal Stamping in Automobile Industry 2019 Market Trends, Leading Players: Aro M …

Pune, India, December, 2017/MRFR Press Release/- Market Research Future published a Half Cooked research report on “Global Automotive Metal Stamping Market Research Report - Forecast to 2022”– Market Analysis, Scope, Stake, Progress, Trends and Forecast to 2022.

Automotive Metal Stamping Global Market – Overview

Automotive Metal Stamping are the component that are punched in order to achieve the desire shape. The process is incorporated with the help of stamping dies. The metals…

Automotive Metal Stamping Market Growth Rate Analysis By Aro Metal Stamping, Ken …

Global Automotive metal stamping market Information Report by Technology (Blanking, Embossing, Flanging, Bending, Coining and Others), by Application (Passenger Cars, Commercial Vehicles, Recreational Vehicles and Others) and By Region - Global Forecast To 2022

Key Players

The key players of Automotive metal stamping market are Aro Metal Stamping co. (U.S.), Kenmode Precision Metal Stamping (U.S.), Martinrea International Inc. (Canada), Shiloh Industries, Inc. (U.S.), Acro Metal Stamping Co. (U.S.), Manor Tool & Manufacturing…

Visa stamping Services

Visa stamping is a process of attaching a visa stamp on the passport. Visa is a square shaped stamp indicating the time limit of a person who living in the country. The term "visa" originated from the Latin language and this term is used to refer the time limit of living in a country. According to the current immigration rules, visa is necessary for every immigration process and it is…

Automotive Metal Stamping Market 2018-2022 Global Prominent Key Players: Aro Met …

Automotive Metal Stamping Market 2018

Automotive metal stamping Market Share, Size, Trends, And Business Opportunity Analysis Report 2018 include historic data, with forecast data to 2022. Automotive metal stamping Market report is helpful for future strategy development, and to know about Market Drivers, Restraints, Opportunities, And Global market size, share, Growth, Trends, key players forecast to 2022

Global Automotive metal stamping market Information Report by Technology (Blanking, Embossing, Flanging, Bending, Coining and…