Press release

How Do Regenerative Thermal Oxidizers (RTOs) Work?

Thermal destruction is the most widely used technology for treating industrial volatile organic compound (VOCs) emissions. The key equipment -the Regenerative Thermal Oxidizer [https://www.yurcentrto.com/regenerative-thermal-oxidizer/] (RTO) - comprehensively addresses the challenges of VOC discharge faced by enterprises, enabling compliance with emissions standards and cost-effective operation.What is a Regenerative Thermal Oxidizer

A Regenerative Thermal Oxidizer (RTO) is a highly efficient air pollution control system designed to destroy Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs) from industrial exhaust streams through high-temperature thermal oxidation. The core principle of a regenerative thermal oxidizer is to combust these pollutants at elevated temperatures, typically between 760 degrees C and 980 degrees C (1400 degrees F and 1800 degrees F), converting them into harmless carbon dioxide (CO) and water vapor (HO). What truly distinguishes an RTO from simple R Thermal Oxidizer [https://www.yurcentrto.com/r-thermal-oxidizer/]s is its innovative regenerative heat recovery system, which allows it to achieve exceptional thermal efficiency, often exceeding 95%.

Due to their high destruction removal efficiency (DRE) of up to 99%, reliability, and low operating cost, regenerative thermal oxidizers are widely employed across various industries, including chemical manufacturing, paint and coating application, printing, and pharmaceuticals, where robust and economical emission control is paramount.

How do regenerative thermal oxidizers work?

1. Two-Chamber RTO

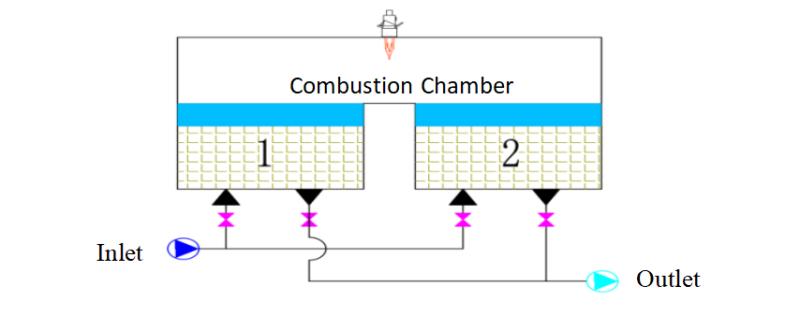

Figure 2.1 Schematic Diagram of Two-Chamber RTO Process

Image: https://ecdn6.globalso.com/upload/p/2910/image_other/2025-08/wechat-image_20250829114707_45.png

The Two-Chamber RTO evolved from the Thermal Oxidizer (TO). The initial RTO involved connecting two TO units in parallel and adding ceramic regenerator beds at the outlet to achieve the "regenerative function." It utilized lift-type switching valves to repeatedly alternate the inlet and outlet gas paths, hence the name "Two-Chamber RTO."

The main structure of a two-bed RTO consists of a combustion chamber, two ceramic regenerator chambers, and four switching valves. The organic waste gas treatment process is as follows: When VOC-laden exhaust gas is delivered by a supply fan into Regenerator 1, this chamber releases heat, preheating the VOC gas to about 750 degrees C before it enters the combustion chamber for oxidation and decomposition. The resulting high-temperature clean flue gas passes through Regenerator 2; this chamber absorbs heat, cooling the combusted clean gas before it is discharged through the switching valve. After a set switching time is reached, the valves switch. VOC gas then enters through Regenerator 2 (which now releases heat), enters the combustion chamber for oxidation, and passes through Regenerator 1 (which now absorbs heat), cooling the combusted, clean gas before it is discharged through the switching valve. By periodically switching in this manner, the VOCs exhaust gas can be treated continuously.

* Three-Chamber Regenerative Thermal Oxidizer

Figure 2.2 Simplified diagram of the three-chamber RTO process

Image: https://ecdn6.globalso.com/upload/p/2910/image_other/2025-08/wechat-image_20250829114801_46.png

To address the issue in two-chamber regenerative thermal oxidizers, where, during the switch from heat release to heat storage, untreated gas remaining in the regenerator chamber is directly discharged, a third chamber was added to the two-chamber design. This introduced a "purging function," creating the Three-Chamber regenerative thermal oxidizer. This represents the second-generation technology, achieving an improvement in purification efficiency from 95% to 99%.

The main structure of a three-bed RTO consists of a combustion chamber, three ceramic regenerator chambers, and nine switching valves. The organic waste gas treatment process is as follows: Exhaust gas is preheated through Regenerator 1, then enters the combustion chamber for oxidation and decomposition. Meanwhile, any residual untreated gas in Regenerator 3 is purged back into the combustion chamber for incineration using purified gas (purging function). The decomposed, clean, high-temperature flue gas exits through Regenerator 2, simultaneously heating Regenerator 2. Once the heat front penetrates Regenerator 2, the valves switch. Exhaust gas then enters through Regenerator 2 (preheated), enters the combustion chamber for oxidation, residual gas in Regenerator 1 is purged back to the combustion chamber, and the decomposed gas exits through Regenerator 3, heating Regenerator 3. When the heat front penetrates Regenerator 3, the valves switch again. Exhaust gas enters through Regenerator 3 (preheated), enters the combustion chamber for oxidation, residual gas in Regenerator 2 is purged back for treatment, and the decomposed gas exits through Regenerator 1, heating Regenerator 1. This cyclical operation allows for continuous treatment of VOCs exhaust gas.

When an RTO needs to handle air volumes exceeding 50,000 cubic meters per hour, the volume of each chamber in a three-chamber RTO becomes very large, leading to drawbacks such as uneven flow distribution, high purge air volume, high energy consumption, excessive idle regenerator volume, and high manufacturing costs. To address this, second-generation RTOs are sometimes constructed with multi-chamber structures like 5, 7, or 9 chambers, ensuring each chamber handles less than 50,000 m/h. However, as the number of regenerator chambers increases, the number of lift valves also increases, significantly raising the probability of failure.

Image: https://ecdn6.globalso.com/upload/p/2910/image_other/2025-11/wechat-image_20251106114009_111_89.png

* Rotary Regenerative Thermal Oxidizer

To solve the problems of numerous switching valves, unreliability, and high investment associated with chamber-type RTOs, RTO engineers invented the "Rotary Gas Diverter Valve," or simply the "Rotary Valve." A single rotary valve can perform the inlet, outlet, and purge switching functions of several or even dozens of lift valves, with a simpler structure and greater stability and reliability. Multi-chamber RTOs equipped with a rotary valve are called "Rotary RTOs," representing the third-generation Regenerative Thermal Oxidizer technology.

Figure 2.3 Schematic Elevation View of Rotary Valve RTO

Image: https://ecdn6.globalso.com/upload/p/2910/image_other/2025-10/wechat-picture_20250925155653_60_89.webp

Figure 2.4 Schematic Diagram of Regenerator Chamber States in Rotary Valve RTO

Image: https://ecdn6.globalso.com/upload/p/2910/image_other/2025-10/wechat-picture_20250925155716_61_89.webp

During normal operation, the inlet and outlet cycles for the regenerator chambers are as follows:

Table 2.1 Inlet-Outlet Cycle Table for Rotary RTO Regenerator Chambers

Image: https://ecdn6.globalso.com/upload/p/2910/image_other/2025-11/wechat-image_20251106114354_112_89.png

Stage 1: When fixed bed sectors 2~6 are in the inlet state, the supply fan delivers exhaust gas to the rotary valve for distribution. The gas then flows upward through the hot packing bed, where it is preheated to approximately 750 degrees C before entering the top combustion chamber for oxidation and decomposition. The decomposed, clean, high-temperature flue gas flows downward through fixed bed sectors 8~12, storing heat in the regenerator material, and is then discharged to the stack via the rotary valve. Simultaneously, fixed bed sector 1 is in the purge state. A purge fan extracts purified tail gas or fresh air to sweep upward through the voids of the regenerator material, removing any residual exhaust gas and ensuring it completely enters the combustion chamber for decomposition. After purging, this chamber transitions to the outlet state. Fixed-bed sector 7 is used to isolate the inlet and outlet streams.

Stage 2: As the rotary valve rotates uniformly, the supply fan delivers exhaust gas to fixed bed sectors 3~7. The gas flows upward through the hot bed, is preheated to about 750 degrees C, enters the combustion chamber for oxidation, and the decomposed flue gas flows downward through sectors 9~1, storing heat before being discharged via the rotary valve. Fixed bed sector 2 transitions from the inlet state to the purge state, where the purge fan sweeps residual exhaust from the chamber back to the combustion chamber. Fixed bed sector 8 transitions from the outlet state to the isolation state.

Under the uniform rotation of the rotary gas distribution valve, the 12 fixed bed sectors sequentially enter Stage 3, Stage 4, Stage 5..., enabling each chamber to cyclically and continuously perform the sequence: Inlet -> Purge -> Outlet -> Isolation. The rotary valve operates at a speed of 120 seconds per revolution, meaning each regenerator bed undergoes a "heat storage - heat release" mode exchange approximately every 50 seconds.

Conclusion

* When selecting end-of-pipe treatment equipment, considerations should include the inherent characteristics of the waste gas itself, the performance indicators of the technologies, construction investment and operating costs, and the applicable emission standards, among other factors.

* The new generation Rotary Regenerative Thermal Oxidizer technology offers significant technical advantages over three-bed RTOs in terms of reliability, energy efficiency, safety, ease of operation and maintenance, and investment cost, tailored to VOCs exhaust from different industries.

* In the selection of waste gas treatment technologies, there are some common principles and standards to follow. Regenerative Thermal Oxidizer is not a one-size-fits-all technology covering all application scenarios for waste gas treatment.

Media Contact

Company Name: Xi'an Yangling Yurcent Environmental Technology Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=how-do-regenerative-thermal-oxidizers-rtos-work]

Country: China

Website: https://www.yurcentrto.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How Do Regenerative Thermal Oxidizers (RTOs) Work? here

News-ID: 4331337 • Views: …

More Releases from ABNewswire

Custom Cardboard Boxes: Complete Buyer Guide

Image: https://www.abnewswire.com/upload/2026/02/0f0fee39afaa0d25711f34ee831a6f6f.jpg

Packaging protects merchandise and shapes first impressions. It additionally impacts transport value, and consumers agree with it. In today's market, brands need packaging that is strong, flexible, and affordable. This is where custom cardboard packing boxes play a crucial role.

Custom cardboard boxes [https://www.thecustomboxes.com/cardboard-boxes/] are used by small groups and large brands alike. They paint retail shelves, online orders, and warehouse garages. They are easy to print, smooth to recycle,…

Mondressy Unveils Its 2026 Defining Colors: The Five Essential Shades of "Matria …

Top 5 color palettes for 2026 spotlight navy blue, champagne, black, dark green, and burgundy for the modern mother-of-the-occasion wardrobe.

Mondressy has officially introduced its 2026 defining colors, identifying five essential shades that embody what the brand calls "Matriarchal Authority and Elegance." The brand's 2026 color direction centers on navy blue, champagne, black, dark green, and burgundy, a five-color foundation designed for mother-of-the-bride dresses [https://mondressy.com/collections/mother-of-the-bride-dresses] to help mothers step into milestone…

Award Winning Dramatic Manuscript From Vietnam Veteran Sees Light After Thirty Y …

Author's Tranquility Press Publishes Westley Thomas's Acclaimed Play, A Hard Decision

MARIETTA, GA - Author's Tranquility Press announces the release of a significant literary work with a history as compelling as its plot. A Hard Decision [https://www.amazon.com/Hard-Decision-Westley-Thomas/dp/1964037883/ref=tmm_pap_swatch_0?_encoding=UTF8&dib_tag=se&dib=eyJ2IjoiMSJ9.ob6cjTHosS2wQ9ZuuukKej0xIfTAJkl8PkRpxAk9Bi0Z_CTE8pKnQZqPgvDSLlDYCDYm3xxnbKswJYla6MzIzB_IqnxgvWa-A-SyAb2XL7ZJHd_7qok_KmP_97dogy5Nj-APmw4pVjYndu0-wWhkvanoAR049dLE4Hwzy1huCT1JDuFzGu9KKA5tHlrL7wlr5Q61r0aHtRQY2Q1GD7SuC37Bnky-DL0-lwhyFyqwYkw.Za1SH73eWgUxOwBPnbBWr-Jf34YIiI5T1ACmMVOKo3w&qid=1769401330&sr=1-1], the award-winning dramatic manuscript by United States Marine Corps Vietnam veteran Westley Thomas, is now available to the public. This publication concludes a thirty-year personal campaign by the author, who once submitted the story's…

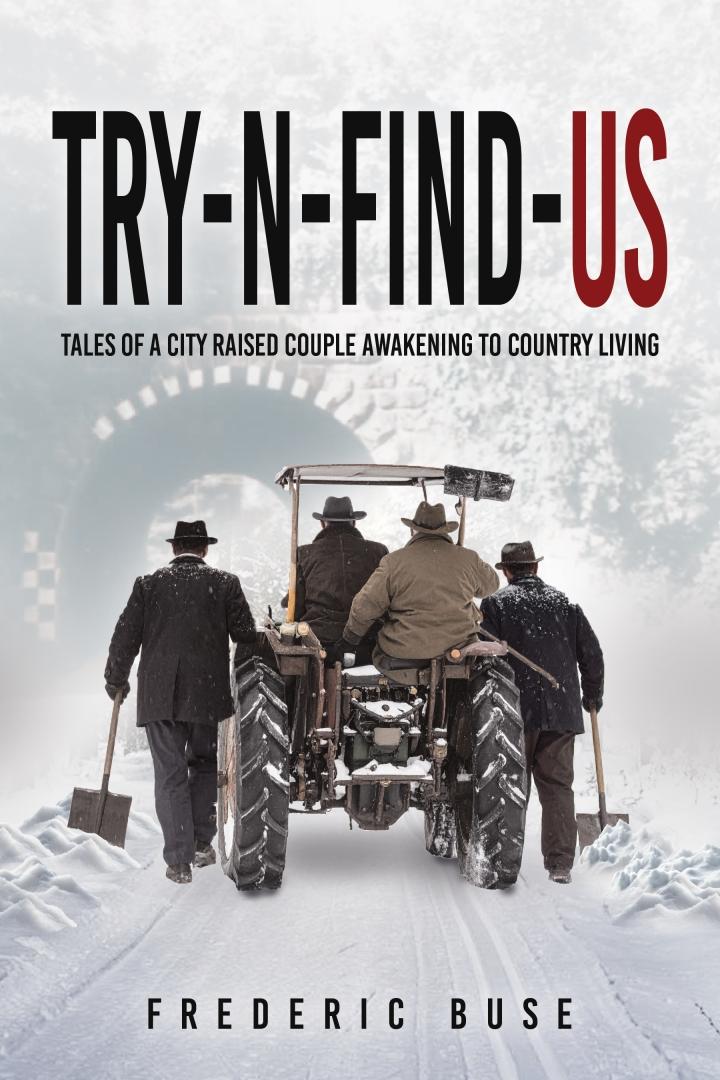

Author's Tranquility Press Unveils an Epic Memoir of Perseverance and Place

Try N Find Us Details a Young Couple's Grueling and Glorious Eight Year Battle to Build a Life in Rural New Jersey

Author's Tranquility Press proudly presents Try N Find Us [https://www.amazon.com/Try-N-Find-Us-Frederic-Buse/dp/1968750908/ref=sr_1_1?crid=1SR1H4F43M2TN&dib=eyJ2IjoiMSJ9.3XVKJE4n5ZeRC05IjoTJJw.PiQsoRDyPI9yfnepb78DxVJOdXai0lNJ14h5IAEnygs&dib_tag=se&keywords=try-n-find-us+frederic+buse&qid=1770225124&sprefix=Try-N-Find%2Caps%2C358&sr=8-1] by Frederic Buse, a powerful and immersive memoir that charts the remarkable true journey of two young urbanites who bought a piece of the wilderness and paid for it in sweat, ingenuity, and hard won wisdom.

In 1961, Fred Buse…

More Releases for RTO

Regenerative Thermal Oxidizer (RTO) Market Is Going to Boom |• Thermo Energy C …

The worldwide "Regenerative Thermal Oxidizer (RTO) Market" 2026 Research Report presents a professional and complete analysis of the Global Regenerative Thermal Oxidizer (RTO) Market in the current situation. This report includes development plans and policies along with Regenerative Thermal Oxidizer (RTO) manufacturing processes and price structures. The reports 2026 research report offers an analytical view of the industry by studying different factors like Regenerative Thermal Oxidizer (RTO) Market growth, consumption…

What Is a Regenerative Thermal Oxidizer (RTO)?

A Regenerative Thermal Oxidizer (RTO) is one of the most widely used technologies for controlling industrial emissions, especially Volatile Organic Compounds [https://www.yurcentrto.com/volatile-organic-compounds/] (VOCs). With its high thermal efficiency, stable performance, and ability to treat large airflows, the RTO has become a standard solution across printing, chemical, coating, and many other industries. This article provides a clear overview of what an RTO is, how it works, its core components, common types,…

PRR - Guest Post - Maximising the Value of VET Resources in Your RTO

Investing in quality VET resources is only the first step in delivering effective and compliant training. To get the most value from your materials, your RTO needs to use them strategically-not just as course content, but as tools to improve learner engagement, streamline trainer workload, and ensure audit readiness.

In this blog, we'll explore practical ways to maximise the value of your VET learning resources, from integrating them into multiple delivery…

RTO Packaging Market to Reach USD 2.13 Billion by 2034

According to Exactitude Consultancy, the global RTO packings market is projected to grow from USD 1.21 billion in 2024 to USD 2.13 billion by 2034, at a CAGR of 5.6% over the forecast period. This expansion is underpinned by increased adoption in automotive, pharmaceuticals, chemicals, and food processing sectors, as well as advancements in structured and random packing technologies.

Download Full PDF Sample Copy of Market Report @ https://exactitudeconsultancy.com/request-sample/69351

Key Market Drivers

1.…

Regenerative Thermal Oxidizer (RTO) Market to Witness Growth Acceleration by 203 …

The Regenerative Thermal Oxidizer (RTO) market is witnessing significant growth, driven by increasing industrialization, stringent environmental regulations, and the rising demand for air pollution control solutions. This comprehensive article explores the key aspects of the RTO market, including its overview, growth prospects, segmentation, regional analysis, market dynamics, trends, and competitive landscape.

Regenerative Thermal Oxidizers are advanced pollution control systems designed to eliminate hazardous air pollutants (HAPs) and volatile organic compounds (VOCs)…

RTO Honeycomb Ceramic Regenerator Market Size,Volume,Revenue Trends Analysis Rep …

Global Info Research announces the release of the report "Global RTO Honeycomb Ceramic Regenerator Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many…