Press release

The Operating Principles of a Regenerative Thermal Oxidizer

Regenerative Thermal Oxidizer [https://www.yurcentrto.com/thermal-oxidizer/]s (RTOs) are widely used in modern industries as one of the most efficient technologies for treating VOC-containing exhaust gases. They not only destroy harmful VOCs at high temperatures but also recover the majority of the heat generated during the oxidation process. This unique combination allows RTOs to achieve the dual goals of environmental protection and energy savings, making them an ideal solution for industrial waste-gas treatment. In this article, we will explain the basic operating principles of RTO systems, including heat recovery, VOC oxidation, and how different types of RTOs-two-bed, multi-bed, and rotary-operate in practice.1. How an RTO Purifies VOCs and Recovers Heat

The core concept of an RTO is simple: VOC-laden exhaust is preheated through a ceramic heat-storage bed, sent into a high-temperature oxidation chamber to be burned, and then the cleaned gas transfers its heat back to another bed before leaving the system.

Here is the basic sequence:

1. Preheating via Ceramic Media - Exhaust air passes through a heat-storage chamber filled with ceramic media. The hot ceramic bed transfers heat to the incoming exhaust, raising its temperature. 2. Oxidation at High Temperature - When the preheated exhaust enters the oxidation chamber at around 800 degrees C, the VOCs undergo thermal oxidation. During this reaction, VOC molecules break down into harmless CO and HO. 3. Heat Release and Recovery - VOC oxidation is an exothermic reaction-it releases a large amount of heat. The RTO captures this heat and uses it to maintain the system temperature, reducing fuel consumption significantly. 4. Clean Gas Exits Through Another Heat-Storage Bed - The purified gas transfers its heat into a second ceramic bed. This stored heat will preheat the next incoming stream of exhaust gas.

Because a large portion of the reaction heat is recycled, the RTO often operates with extremely low fuel consumption. In some cases, when VOC concentration is sufficient, the RTO can even run without additional fuel input.

Image: https://ecdn6.globalso.com/upload/p/2910/image_other/2025-12/wechat-image_20251209173311_163_89.png

2. Operating Principle of a Two-Bed RTO

A two-bed RTO contains two ceramic chambers-commonly called A bed and B bed. The system works by alternating airflow between these two chambers to capture and reuse heat.

Basic cycle:

* Exhaust enters through Bed A, where it is preheated. * It flows into the 800 degrees C oxidation chamber, where VOCs are destroyed, and heat is released. * The clean, hot gas exits through Bed B, heating the ceramic media in that chamber.

Once Bed B becomes fully heated, the system switches valves:

* Exhaust begins entering through Bed B. * Clean gas exits through Bed A. * The cycle repeats continuously.

Unpurified gas during valve switching

During each switching moment, a small portion of exhaust gas inside the bed has not yet reached the oxidation chamber. When the valve switches, this gas is diverted into the exhaust line instead of being treated. This creates a brief "puff" of untreated air, known as valve-switching emissions, which is a common characteristic of two-bed RTOs.

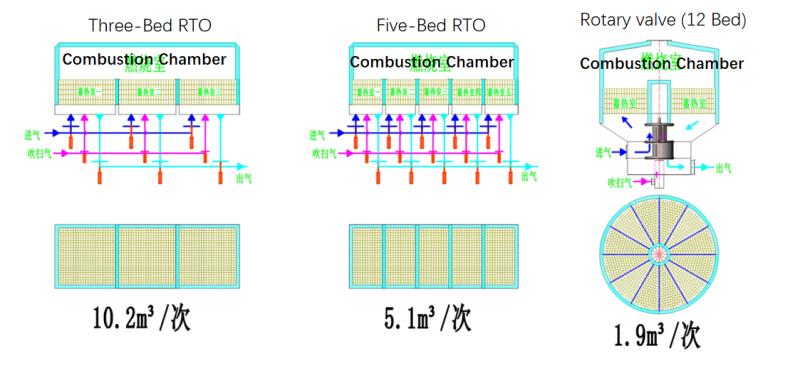

3. Operating Principle of a Multi-Bed RTO

A multi-bed RTO (typically three-bed) is designed to reduce the untreated emissions caused during switching.

With three chambers, one chamber is always dedicated to purging the bed that is about to switch flow direction. This purge step eliminates residual VOC-laden gas in the ceramic bed before the flow reverses.

As a result, multi-bed RTOs:

* Greatly reduce untreated emissions, * Achieve higher destruction efficiency, * Operate more smoothly across switching cycles.

4. Operating Principle of a Rotary RTO

A rotary RTO operates differently from the switching-valve systems. Instead of opening and closing valves, it uses a motor-driven rotating valve that turns at a constant, slow speed.

How it works:

* The circular RTO contains multiple heat-storage sectors arranged around a central axis. * The rotating valve continuously divides airflow into the inlet, outlet, and purge zones. * As the valve moves, the airflow path gradually shifts from one ceramic sector to the next.

This continuous rotation creates:

* Very smooth airflow changeover, * Minimal pressure fluctuation, * Very low untreated emissions, * High thermal efficiency.

Because switching is continuous rather than sudden, rotary RTOs are often considered the most stable and efficient type.

RTO technology plays a critical role in modern VOC control. By oxidizing VOCs at high temperatures and recovering a large proportion of the released heat, RTOs help industries meet strict environmental regulations while significantly reducing operating energy consumption. Whether using a two-bed, multi-bed, or rotary design, the fundamental principle remains the same: destroy harmful VOCs efficiently while maximizing heat recovery.

This combination of pollution control and energy savings is what continues to make RTOs one of the most widely adopted solutions for industrial exhaust gas purification.

Media Contact

Company Name: Xi'an Yangling Yurcent Environmental Technology Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=the-operating-principles-of-a-regenerative-thermal-oxidizer]

Country: China

Website: https://www.yurcentrto.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Operating Principles of a Regenerative Thermal Oxidizer here

News-ID: 4331336 • Views: …

More Releases from ABNewswire

LOWK3Y Disrupts Luxury Streetwear With a Movement for the Quietly Ambitious - La …

LOWK3Y LLC debuts as a premium lifestyle streetwear brand built for entrepreneurs, creatives, and professionals who let results do the talking. Alongside its launch, the company unveils RARE ACCESS - a first-of-its-kind initiative spotlighting underrepresented talent building legacies behind the scenes, complete with collaborative merchandise drops, media features, and a growing ecosystem designed to reward substance over spectacle.

While most streetwear brands chase hype cycles and influencer endorsements, a new force…

Hard Rock Meets Hard Roast: Foundry Coffee Brings Unapologetic Flavor to Morning …

Foundry, a Las Vegas hard rock band, has launched Hard Rock Roast, a coarse-ground coffee that delivers bold flavors of dark chocolate, brown sugar, and rich molasses. Created by musicians for people who demand intensity in their coffee, the product represents a natural extension of the band's uncompromising artistic vision.

The specialty coffee market is crowded with brands competing on origin stories, processing methods, and carefully curated aesthetics. Into this landscape…

DIVEVOLK Celebrates FPAS 2025 Mobile Devices Champions: Rui Bernardo & Joana Nar …

Portugal - DIVEVOLK [https://www.divevolkdiving.com] proudly congratulates Rui Bernardo and Joana Narciso, the creators behind the 1st Place image in the FPAS 2025 National Underwater Photography Championship (Mobile Devices Category), for capturing this stunning image using the SeaTouch 4 Max underwater housing [https://www.divevolkdiving.com/collections/housing]. Their winning work is a reminder that modern mobile underwater photography isn't just about convenience-it's about community craft: timing, teamwork, and the discipline to wait for a clean…

Proscenic - More Time for Love. Less Time Cleaning

Image: https://www.abnewswire.com/upload/2026/02/c4976d3df5b17be0d7fd75292f2e2a75.jpg

Berlin-Valentine's Day is a time to celebrate love, connection, and the moments that truly matter with our loved ones. At Proscenic [https://www.amazon.de/stores/proscenic/page/D53F96AF-E0B7-4EE6-8493-2B4F1E00BE65], we believe a happy home is a clean, comfortable, and harmonious space where relationships can flourish. This Valentine's Day, we proudly present the Q20Plus Robot Vacuum & Mop, designed to simplify cleaning and give you more time for love.

More Time for Love. Less Time Cleaning.

Image: https://www.abnewswire.com/upload/2026/02/c0e461b3ea82ce1d1cf8b3b47b0fb23d.jpg

The Q20Plus…

More Releases for RTO

Regenerative Thermal Oxidizer (RTO) Market Is Going to Boom |• Thermo Energy C …

The worldwide "Regenerative Thermal Oxidizer (RTO) Market" 2026 Research Report presents a professional and complete analysis of the Global Regenerative Thermal Oxidizer (RTO) Market in the current situation. This report includes development plans and policies along with Regenerative Thermal Oxidizer (RTO) manufacturing processes and price structures. The reports 2026 research report offers an analytical view of the industry by studying different factors like Regenerative Thermal Oxidizer (RTO) Market growth, consumption…

What Is a Regenerative Thermal Oxidizer (RTO)?

A Regenerative Thermal Oxidizer (RTO) is one of the most widely used technologies for controlling industrial emissions, especially Volatile Organic Compounds [https://www.yurcentrto.com/volatile-organic-compounds/] (VOCs). With its high thermal efficiency, stable performance, and ability to treat large airflows, the RTO has become a standard solution across printing, chemical, coating, and many other industries. This article provides a clear overview of what an RTO is, how it works, its core components, common types,…

PRR - Guest Post - Maximising the Value of VET Resources in Your RTO

Investing in quality VET resources is only the first step in delivering effective and compliant training. To get the most value from your materials, your RTO needs to use them strategically-not just as course content, but as tools to improve learner engagement, streamline trainer workload, and ensure audit readiness.

In this blog, we'll explore practical ways to maximise the value of your VET learning resources, from integrating them into multiple delivery…

RTO Packaging Market to Reach USD 2.13 Billion by 2034

According to Exactitude Consultancy, the global RTO packings market is projected to grow from USD 1.21 billion in 2024 to USD 2.13 billion by 2034, at a CAGR of 5.6% over the forecast period. This expansion is underpinned by increased adoption in automotive, pharmaceuticals, chemicals, and food processing sectors, as well as advancements in structured and random packing technologies.

Download Full PDF Sample Copy of Market Report @ https://exactitudeconsultancy.com/request-sample/69351

Key Market Drivers

1.…

Regenerative Thermal Oxidizer (RTO) Market to Witness Growth Acceleration by 203 …

The Regenerative Thermal Oxidizer (RTO) market is witnessing significant growth, driven by increasing industrialization, stringent environmental regulations, and the rising demand for air pollution control solutions. This comprehensive article explores the key aspects of the RTO market, including its overview, growth prospects, segmentation, regional analysis, market dynamics, trends, and competitive landscape.

Regenerative Thermal Oxidizers are advanced pollution control systems designed to eliminate hazardous air pollutants (HAPs) and volatile organic compounds (VOCs)…

RTO Honeycomb Ceramic Regenerator Market Size,Volume,Revenue Trends Analysis Rep …

Global Info Research announces the release of the report "Global RTO Honeycomb Ceramic Regenerator Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many…