Press release

HPGR Retrofit and Metso Barmac B7150SE VSI Wear Solutions Drive Rettek's New Market Strategy

HPGR retrofit [https://rettekcarbide.com/how-do-high-wear-tungsten-carbide-granules-benefit-hpgr-applications/] solutions and Metso Barmac B7150SE VSI wear parts are at the center of a newly announced market expansion strategy by Zigong Rettek New Materials Co., Ltd. (Rettek), a professional manufacturer of wear-resistant carbide tools and components. The initiative marks the company's formal push into high-demand mining and aggregates markets where equipment durability, uptime, and total cost of ownership are critical.As global mining and construction operations continue to scale up production while processing increasingly abrasive materials, demand is rising for advanced wear solutions that outperform conventional steel components. Rettek's strategy focuses on leveraging high-wear tungsten carbide technology to upgrade High Pressure Grinding Rolls (HPGR) and high-capacity VSI crushers, offering operators longer service life and improved operational stability.

HPGR Retrofit Solutions Target Extended Roll Life

HPGR retrofit technology using tungsten carbide studs has become a priority for operators seeking to maximize the return on existing grinding assets. HPGR systems operate under extreme pressure, subjecting roll surfaces to severe abrasion and impact. Traditional steel studs often wear rapidly, resulting in frequent maintenance shutdowns and rising operational costs.

Rettek's HPGR retrofit solution embeds high-wear tungsten carbide granules and studs directly into roll surfaces, significantly improving abrasion resistance. Field applications indicate that carbide-studded rolls can achieve two to five times longer service life compared with steel-only designs. This improvement translates into reduced downtime, more consistent grinding performance, and lower long-term maintenance costs.

According to Rettek, the growing adoption of HPGR technology worldwide makes retrofit upgrades a strategic opportunity. Rather than replacing entire roll assemblies, operators can extend equipment lifespan while improving wear resistance through carbide retrofitting.

"HPGR retrofits are no longer viewed as a simple repair solution," a Rettek representative stated. "They are now a performance-driven upgrade, and tungsten carbide is the key material enabling that shift."

Metso Barmac B7150SE VSI Applications Strengthen VSI Market Focus

Metso Barmac B7150SE VSI wear parts [https://rettekcarbide.com/what-makes-the-metso-barmac-b7150se-vsi-ideal-for-industrial-use/], including carbide rotor tips and inserts, represent another core pillar of Rettek's expansion strategy. The B7150SE VSI is widely used in aggregates, mining, and industrial sand production due to its rock-on-rock crushing principle and ability to produce highly cubical material.

Operating with rotor speeds ranging from approximately 1,100 to 2,100 rpm and processing feed sizes up to 45 mm, the Barmac B7150SE places intense wear demands on internal components. Rettek's tungsten carbide rotor tips are designed to withstand high-impact and abrasive conditions while maintaining consistent crushing efficiency.

By improving wear resistance in critical areas, Rettek's VSI carbide solutions help stabilize output quality, support continuous operation, and minimize unplanned stoppages in high-throughput environments. This makes them particularly attractive for industrial users running capacity levels of up to hundreds of tons per hour.

Integrated Manufacturing Ensures Consistent Carbide Quality

A key differentiator behind Rettek's HPGR and VSI wear solutions is its fully integrated manufacturing model. Based in Zigong, Sichuan - a globally recognized carbide production hub - Rettek controls the entire production chain, from alloy raw material preparation and batching to pressing, vacuum sintering, tool design, and automated welding.

This end-to-end control allows Rettek to tailor carbide compositions to specific crushing and grinding applications while maintaining strict quality consistency. Advanced brazing and welding processes further ensure reliable bonding performance under extreme operating conditions.

"Full in-house control gives us the flexibility to respond to market needs without sacrificing quality," the company noted. "It also allows us to optimize production costs while delivering long-lasting carbide solutions."

Global Market Expansion Backed by Proven Performance

Rettek's carbide wear parts [https://rettekcarbide.com/] are currently supplied to customers in more than 10 countries, with applications spanning mining, aggregates, snow plow systems, and industrial crushing equipment. The company's renewed emphasis on HPGR carbide studs and VSI crusher wear parts reflects growing international demand for durable, high-performance alternatives to traditional wear materials.

Rather than competing solely on price, Rettek's market strategy emphasizes lifecycle value - reducing downtime, lowering replacement frequency, and improving operational efficiency for end users. This approach aligns with industry trends toward sustainability and cost control, particularly in energy-intensive crushing and grinding processes.

Looking Forward

With the launch of its HPGR retrofit and Metso Barmac B7150SE VSI-focused strategy, Rettek positions itself as a specialized carbide solution provider for modern mining and aggregates operations. By combining advanced tungsten carbide materials, integrated manufacturing, and application-driven design, the company aims to support customers facing increasingly harsh operating conditions.

As demand for high-efficiency crushing solutions continues to grow, Rettek's message is clear: longer wear life, fewer shutdowns, and reliable performance are achievable through the right carbide technology - and HPGR retrofits and VSI upgrades are where that transformation begins.

Media Contact

Company Name: Zigong Rettek New Materials Co., Ltd.

Contact Person: Mr. Smith

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=hpgr-retrofit-and-metso-barmac-b7150se-vsi-wear-solutions-drive-retteks-new-market-strategy]

Country: China

Website: https://rettekcarbide.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release HPGR Retrofit and Metso Barmac B7150SE VSI Wear Solutions Drive Rettek's New Market Strategy here

News-ID: 4329910 • Views: …

More Releases from ABNewswire

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

Fast-Growing Newman's Brew Combines Organic Coffee Excellence with Abandoned Ani …

Newman's Brew is experiencing rapid expansion by delivering on dual commitments that resonate with today's conscious consumers: exceptional fresh-roasted organic coffee and meaningful support for abandoned animals. The company's growing inventory and ethical business practices demonstrate that quality and social responsibility can drive sustainable business success in the competitive specialty coffee market.

Newman's Brew is riding a wave of growth that reflects fundamental shifts in how consumers approach coffee purchasing decisions.…

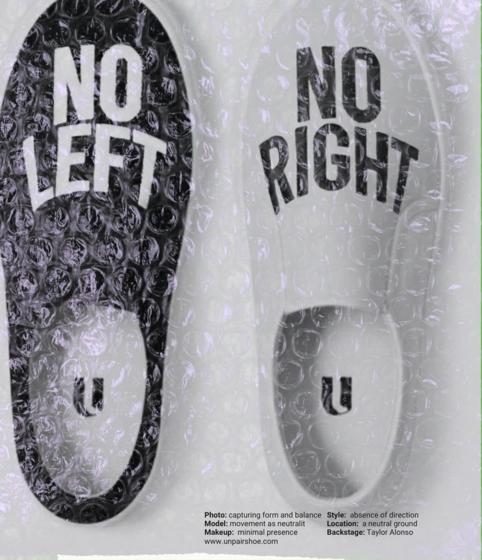

Unpair Introduces a Patent-Pending Symmetrical Footwear System That Eliminates L …

Founded by Taiwanese fashion designer turned inventor Hui Min Yang, Unpair reimagines footwear through symmetry, interchangeability, and universal form.

Houston, TX - February 19th, 2026 - Unpair officially announces a patent-pending symmetrical footwear system that challenges centuries of left-right shoe design. For centuries, footwear has followed a fixed rule: one shoe for the left foot and one for the right.

Image: https://www.abnewswire.com/upload/2026/02/5a16a00cab1f11dd06faa474a3674865.jpg

Unpair challenges that convention by introducing a patent-pending symmetrical footwear system…

More Releases for Rettek

Rotor Tips Welding Technology Boosts VSI Crusher Efficiency: Rettek Launches New …

Zigong Rettek [https://rettekcarbide.com/product/rotor-tips-4/] New Materials Co., Ltd., a leading manufacturer of wear-resistant carbide tools, today announced a new market expansion strategy centered on its highly acclaimed welded rotor tips for VSI crushers [https://rettekcarbide.com/product-category/vsi-crusher-wear-parts-sand-making-machine/]. As the demand for durable, high-performance crusher wear parts rises globally, Rettek is positioning its welded rotor tips as the preferred choice for customers seeking longer service life, reduced downtime, and lower operating costs.

Rettek's rotor tips have…

Snow Plow Wear Parts: Rettek Unveils New Carbide Blades and Inserts to Boost Dur …

Zigong Rettek New Materials Co., Ltd., a leading manufacturer of wear-resistant carbide tools, today announced the launch of its latest line of Snow Plow Wear Parts [https://rettekcarbide.com/product-category/snow-plow/], including advanced carbide blades, snow plow inserts, and snow plow blades designed for extreme winter conditions. This new product release is part of Rettek's broader strategy to expand its global footprint while meeting growing demand for high-performance snow removal equipment in cold-climate markets.

As…

Impact Crushers Wear Parts and Vertical Shaft Impactor Solutions Drive Rettek's …

Impact crushers wear parts [https://rettekcarbide.com/what-are-wear-parts-for-impact-crushers-and-how-do-they-improve-performance/] and vertical shaft impactor (VSI) wear parts are at the center of Zigong Rettek New Materials Co., Ltd.'s latest product release and market expansion strategy, as the company strengthens its global presence in the aggregates, mining, and construction sectors. The announcement highlights Rettek's commitment to delivering high-performance, long-lasting carbide wear solutions designed to improve crushing efficiency, reduce downtime, and lower operating costs.

Impact crushers wear parts,…

Tungsten Carbide Plunger and VSI Impact Parts Drive Rettek's New Product Launch …

Tungsten carbide plunger [https://rettekcarbide.com/how-to-choose-high-wear-resistance-tungsten-carbide-plunger-from-china-manufacturers/] and VSI impact parts are at the center of Zigong Rettek New Materials Co., Ltd.'s latest product release and international market expansion initiative. As industries worldwide demand higher wear resistance, longer service life, and reduced downtime, Rettek is strengthening its position by introducing advanced carbide solutions tailored for extreme operating environments.

Rettek, a professional manufacturer specializing in wear-resistant carbide tools and parts, announced the launch of its…