Press release

Global Carbon Capture Additives in Cement Production Market Dynamics 2026-2036: Risk Assessment, Supply Chain Insights & Market Trajectory

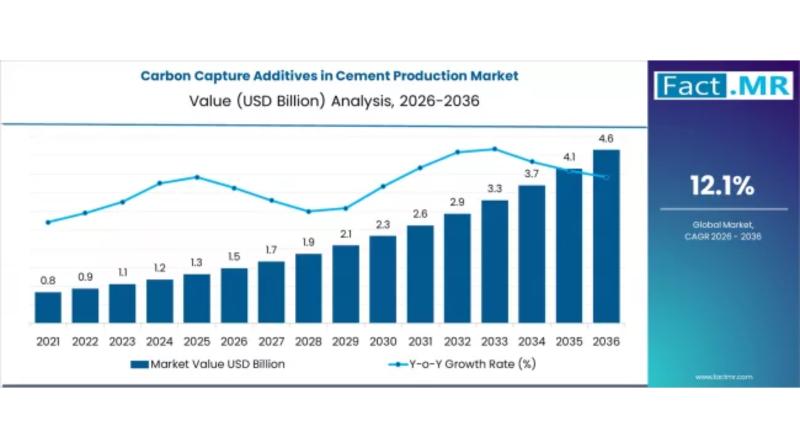

The global carbon capture additives in cement production market is set for rapid expansion as cement manufacturers accelerate efforts to reduce carbon emissions and comply with stringent environmental regulations. According to Fact.MR, the market is projected to grow from USD 1.48 billion in 2026 to USD 4.64 billion by 2036, registering a strong CAGR of 12.1% during the assessment period.More details are available at:

Carbon capture additives-designed to enhance CO2 mineralization, carbonation efficiency, and on-site capture processes-are becoming a cornerstone of low-carbon cement manufacturing strategies worldwide. As cement accounts for nearly 8% of global CO2 emissions, the integration of advanced additives is gaining strategic importance across the construction value chain.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=12970

Key Market Drivers

Global Push for Cement Industry Decarbonization

Governments, regulators, and international climate bodies are enforcing aggressive emissions-reduction targets, compelling cement producers to adopt carbon capture and utilization (CCU) technologies. Carbon capture additives enable faster CO2 absorption, mineralization, and long-term storage within cement matrices, making them an essential component of sustainable cement production.

Rising Adoption of On-Site Carbon Capture Technologies

Cement plants are increasingly deploying on-site carbon capture solvent and additive packages, which currently represent the dominant use case with a 28% market share. These solutions allow producers to capture emissions directly at kilns, minimizing transportation costs and improving operational efficiency.

Demand for Low-Carbon and Net-Zero Construction Materials

Infrastructure developers and construction companies are prioritizing low-carbon cement to meet ESG goals and green building certifications. Carbon capture additives improve cement performance while significantly lowering its carbon footprint, driving adoption across residential, commercial, and industrial construction projects.

Browse Full Report: https://www.factmr.com/report/carbon-capture-additives-in-cement-production-market

Chemistry and Technology Trends

Carbonation Accelerators & Mineralizers Lead the Market

By chemistry type, carbonation accelerators and mineralizers account for a leading 32% share of the global market. These additives enhance CO2 reaction rates during cement curing, enabling permanent sequestration of carbon while maintaining or improving mechanical strength.

Innovation in Additive Formulations

Manufacturers are investing in next-generation additive formulations that combine carbon capture efficiency with improved durability, reduced clinker content, and enhanced lifecycle performance of cement products.

Regional Growth Highlights

North America: Strong Regulatory and Industrial Adoption

The U.S. and Canada are witnessing rapid uptake of carbon capture additives, supported by government incentives, carbon pricing mechanisms, and funding for CCUS projects in heavy industries.

Europe: Climate Policy Leadership Drives Demand

Europe's cement sector is at the forefront of decarbonization, backed by strict EU emissions regulations and net-zero roadmaps. Carbon capture additives are increasingly embedded in large-scale infrastructure and green construction initiatives.

Asia-Pacific: Fastest Growth Potential

China, India, and Southeast Asian countries are emerging as high-growth markets due to expanding cement capacity and rising pressure to reduce industrial emissions without slowing infrastructure development.

Market Segmentation Insights

By Chemistry Type

Carbonation Accelerators & Mineralizers - Leading segment with 32% market share

• Solvent-Based Additives

• Hybrid Carbon Capture Additives

By Application / Use Case

On-Site Plant Capture Solvent/Additive Packages - 28% share

• Post-Combustion Carbon Capture Systems

• Carbon Utilization in Cement Curing

By End User

Cement Producers - Dominant customer group with 40.00% market share

• Ready-Mix Concrete Manufacturers

• Construction Material Suppliers

Market Challenges

Despite strong growth momentum, the market faces several challenges:

• High Initial Implementation Costs for carbon capture systems

• Need for Process Integration with existing cement plants

• Limited Awareness in Developing Regions

• Performance Standardization across different cement grades

Competitive Landscape

The carbon capture additives market is moderately competitive, with players focusing on advanced chemistry solutions, pilot-scale deployments, and strategic partnerships with cement manufacturers. Companies are investing in R&D to improve capture efficiency, scalability, and cost-effectiveness.

Key strategies include long-term supply agreements with cement producers, technology licensing, and collaboration with carbon capture infrastructure providers.

Purchase Full Report for Detailed Insights

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here: https://www.factmr.com/checkout/12970

Future Outlook: Enabling Net-Zero Cement Production

Over the next decade, carbon capture additives will transition from experimental solutions to standard inputs in cement manufacturing. As sustainability reporting, carbon taxation, and green procurement gain traction, adoption of these additives will accelerate across both developed and emerging markets.

Manufacturers that prioritize innovation, plant-level integration, and regulatory alignment will be best positioned to capitalize on the rapid growth of the carbon capture additives in cement production market.

Check out More Related Studies Published by Fact.MR Research:

Green Reagents for Rare Earth Metal Recovery Market - https://www.factmr.com/report/green-release-agents-or-construction-formwork-market

Release Control Additives Market - https://www.factmr.com/report/release-control-additives-market

Construction Plastics Market - https://www.factmr.com/report/construction-plastics-market

Green Floor Care Chemicals Market - https://www.factmr.com/report/green-floor-care-chemicals-market

Contact Us -

11140 Rockville Pike, Suite 400, Rockville,

MD 20852, United States

Tel: +1 (628) 251-1583 | sales@factmr.com

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Carbon Capture Additives in Cement Production Market Dynamics 2026-2036: Risk Assessment, Supply Chain Insights & Market Trajectory here

News-ID: 4329363 • Views: …

More Releases from Fact.MR

Citrus Fiber Market is Expanding at a 5.7% of CAGR by 2034 | Fact.MR Report

The global Citrus Fiber Market is projected to experience substantial growth over the next decade, driven by rising demand for clean-label ingredients, functional food components, and sustainable fiber sources.

Market analysts estimate that the market, valued at approximately USD 350 million in 2025, is expected to reach around USD 720 million by 2035, expanding at a compound annual growth rate (CAGR) of about 7.5% during the forecast period.

Get Access of…

Gluten-Free Food Market is Predicted to Grow to USD 6.5 Billion in 2026 and USD …

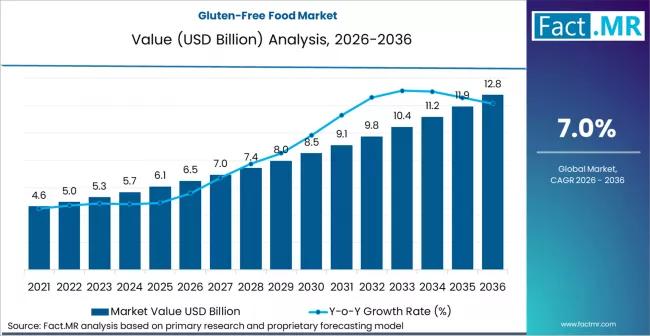

The global gluten-free food market is entering a phase of mainstream consolidation, projected to grow from a valuation of USD 7.4 billion in 2026 to approximately USD 15.2 billion by 2036. This represents a steady compound annual growth rate (CAGR) of 7.5% over the ten-year forecast period.

While initially driven by medical necessity for celiac disease patients, the market is now being propelled by "lifestyle consumers" who perceive gluten-free products…

Electronic Speed Controller for Drones and UAVs Market is Valued USD 448.0 milli …

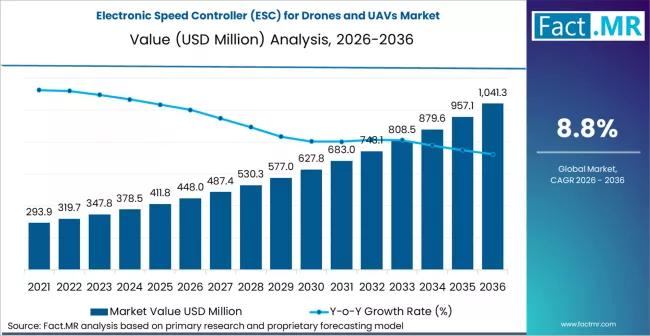

The global electronic speed controller (ESC) for drones and UAVs market is experiencing a rapid technological surge, projected to grow from a valuation of USD 1.8 billion in 2026 to approximately USD 5.1 billion by 2036. This represents a strong compound annual growth rate (CAGR) of 11.0% over the ten-year forecast period.

The market is being propelled by the proliferation of long-endurance commercial drones, the militarization of small FPV (First…

Car Tail Light Mold Market is Hoped-for USD 3.6 billion by 2036 | Fact.MR Report

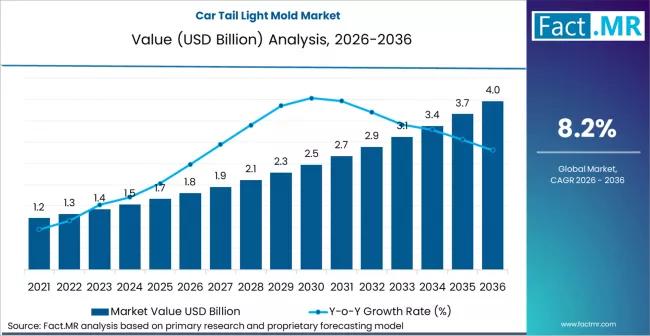

The global car tail light mold market is navigating a high-design era, projected to grow from a valuation of USD 1.4 billion in 2026 to approximately USD 2.6 billion by 2036. This represents a compound annual growth rate (CAGR) of 6.4% over the forecast period.

The market is being fundamentally reshaped by the transition from simple bulbs to complex LED and OLED signatures, requiring high-precision multi-color and multi-material injection molding…

More Releases for Carbon

Carbon-Carbon Composite Market to Reach $3.31 Billion by 2031 | SGL Carbon, Toyo …

NEW YORK, (UNITED STATES) - QY Research latest 'Carbon-Carbon Composite Market 2025 Report' offers an unparalleled, in-depth analysis of the industry, delivering critical market insights that empower businesses to enhance their knowledge and refine their decision-making processes. This meticulously crafted report serves as a catalyst for growth, unlocking immense opportunities for companies to boost their return rates and solidify their competitive edge in an ever-evolving market. What sets this report…

Carbon Black Market Next Big Thing | Cabot, Tokai Carbon, Jiangxi Black Carbon, …

Market Research Forecast published a new research publication on "Global U.S. U.S. Carbon Black Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study, you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market-associated stakeholders. The growth of the U.S. U.S. Carbon Black Market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive…

Carbon-Carbon Composite Material Market Size, Share 2024, Impressive Industry Gr …

Report Description: -

QY Research's latest report 'Carbon-Carbon Composite Material Market 2024 Report' provides a comprehensive analysis of the industry with market insights will definitely facilitate to increase the knowledge and decision-making skills of the business, thus providing an immense opportunity for growth. Finally, this will increase the return rate and strengthen the competitive advantage within. Since it's a personalised market report, the services are catered to the particular difficulty. The…

Carbon Black Market Scenario & Industry Applications 2020-2025 | Phillips Carbon …

The global carbon black market size is projected to surpass USD 18 billion by 2025. Carbon black act as a reinforcement material for tires and rubber, and possess electrical conductive properties. Carbon black provide pigmentation, conductivity, and UV protection for a number of coating applications along with toners and printing inks for specific color requirements. Its multiple application across various end product along with rising economic outlook has significantly enhanced…

Global Carbon-Carbon Composite Market 2020-2026 SGL Carbon, Toyo Tanso, Tokai Ca …

Global Carbon-Carbon Composite Market 2020-2026 analysis Report offers a comprehensive analysis of the market. It will therefore via depth Qualitative insights, Historical standing and verifiable projections regarding market size. The projections featured inside the report square measure derived victimisation verified analysis methodologies and assumptions. Report provides a progressive summary of the Carbon-Carbon Composite business 2020 together with definitions, classifications, Carbon-Carbon Composite market research, a decent vary of applications and Carbon-Carbon…

Global Carbon Black Market to 2026| Cabot, Orion Engineered Carbons, Birla Carbo …

Albany, NY, 10th January : Recent research and the current scenario as well as future market potential of "Carbon Black Market - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2018 - 2026" globally.

Carbon Black Market - Overview

Carbon black (CB) is manufactured through partial combustion of heavy hydrocarbons under controlled temperature and pressure to obtain fine particles and aggregates having a wide range of structure and surface properties. This…