Press release

ZOZEN: The Global Leading Gas Boiler Supplier with Low Emission for Sustainable Energy

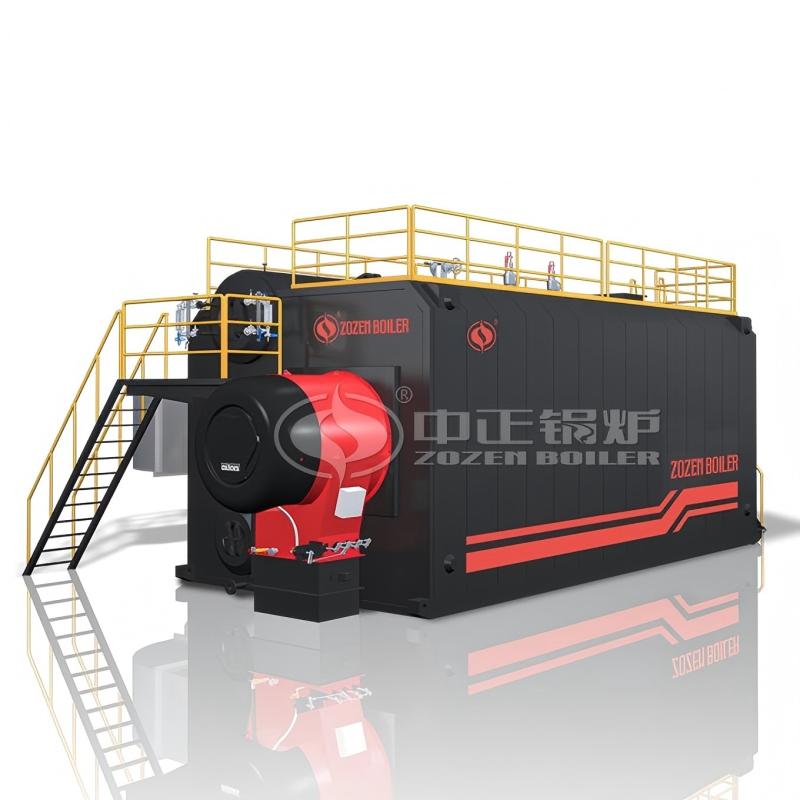

As industrial sectors worldwide intensify their transition toward environmentally responsible operations, the demand for clean-burning heating solutions has never been more critical. ZOZEN Boiler has emerged as a Global Leading Gas Boiler Supplier (https://en.zozen.com/about/?5xyFrom=site-NT), pioneering low-emission technologies that align industrial efficiency with sustainability goals. With operations spanning multiple continents and a production facility covering 150,000 square meters in Wuxi, China, ZOZEN demonstrates how advanced engineering can deliver both environmental performance and operational excellence.Environmental Innovation in Gas Boiler Technology

The shift toward gaseous fuels as industrial energy sources represents a fundamental change in how manufacturers approach energy consumption. ZOZEN's gas-fired boilers (https://en.zozen.com/products/gas-fired-boiler/?5xyFrom=site-NT) accommodate diverse gaseous fuels including natural gas, liquefied petroleum gas (LPG), coke oven gas, biogas, and blast furnace gas, providing flexibility based on regional fuel availability. Gas-fired boilers produce significantly fewer particulate emissions and greenhouse gases compared to traditional solid fuel systems, making them essential tools for companies committed to reducing their carbon footprint.

ZOZEN's gas boiler engineering reflects this environmental imperative through designs that maximize combustion efficiency while minimizing pollutant formation. The company's approach combines precision burner technology with optimized heat transfer surfaces, ensuring that fuel combustion reaches completion with minimal excess air. This technical refinement translates directly into nitrogen oxide (NOx) emissions ≤30 mg/Nm3 and reduced fuel consumption per unit of steam or heat produced.

WNS Series: Compact Efficiency for Diverse Applications

The WNS series gas-fired steam boilers exemplify ZOZEN's commitment to practical, high-performance design. These horizontal units operate across a capacity range of 1 to 20 tons per hour with working pressures between 0.7 and 2 MPa, serving industries from food processing to pharmaceutical manufacturing.

The three-pass wetback structure represents a key innovation in this series. Combustion gases travel through the furnace and then reverse direction twice through smoke tubes, maximizing heat transfer to the water before exhaust. The corrugated furnace design enhances this process by creating turbulence that improves thermal efficiency while strengthening the structure against thermal expansion stress.

ZOZEN also offers skid-mounted versions in the WNS line for applications requiring mobility or rapid deployment. These pre-assembled systems arrive at installation sites ready for quick connection, reducing commissioning time from weeks to days. For operations seeking the Best Steam Boiler Price without extended downtime during installation, this approach delivers significant project value.

SZS Series: Industrial-Scale Performance

When applications demand higher capacities and pressures, ZOZEN's SZS series provides solutions ranging from 2 to 110 tons per hour with pressure capabilities up to 5.3 MPa. This double-drum water-tube configuration serves power generation facilities, large chemical plants, and manufacturing complexes requiring substantial steam volumes.

The membrane water-wall construction in SZS boilers creates a continuous heating surface that eliminates cold spots and ensures uniform steam generation. This design choice improves thermal efficiency while reducing maintenance requirements, as the integrated structure experiences less thermal stress than older riveted or welded tube arrangements. The result is extended service life and lower total ownership costs.

For power generation applications specifically, ZOZEN produces the ZZ series gas-fired boilers with capacities from 20 to 130 tons per hour and pressures reaching 5.4 MPa. These units meet the demanding requirements of combined heat and power systems where steam quality and consistency directly impact electrical generation efficiency.

Gas-Fired Thermal Oil Heaters: High-Temperature Solutions

Beyond steam generation, ZOZEN's gas-fired thermal oil heater portfolio addresses applications requiring precise high-temperature control at low pressure.

YQW Series: Horizontal Configuration

The YQW series gas-fired/oil-fired horizontal thermal oil heaters provide thermal capacity from 1,400 to 14,000 kW with working pressure of 0.8 to 1.0 MPa and outlet temperatures reaching 320°C. The two or three-pass round coil structure with tapered tube ends effectively protects furnace walls while ensuring efficient heat transfer. These units achieve thermal efficiency up to 92%, with advanced combustion devices enabling low NOx emissions.

The horizontal design arrives as a complete package, requiring only gas/oil and electrical connections for commissioning. This configuration proves particularly suitable for textile printing and dyeing, wood processing, vegetable oil refining, and chemical industries where high-temperature heating under atmospheric pressure provides operational advantages over steam systems.

YQL Series: Vertical High-Capacity Design

The YQ(Y)L series offers thermal capacity from 7,000 to 29,200 kW in a vertical arrangement that minimizes floor space requirements. The two-pass round coil structure incorporates inner coil tubes allowing greater heat absorption and flow, ensuring safe and reliable high-temperature operation. These larger units serve major chemical facilities, large-scale food processing operations, and industrial complexes with substantial thermal oil requirements.

Fuel Adaptability: Comprehensive Heating Solutions

While ZOZEN's gas boiler portfolio positions the company as a Global Leading Gas Boiler Supplier, the manufacturer's comprehensive approach to industrial heating extends across multiple fuel types through specialized equipment designs.

Liquid Fuel Capability

ZOZEN provides dedicated boiler solutions for liquid fuels including diesel, heavy oil, light oil, and residual oil. The WNS and SZS series accommodate these fuels through appropriate burner selection and fuel handling systems, while thermal oil heaters in the YQ(Y)W and YQ(Y)L series offer similar multi-fuel flexibility with optimized combustion equipment for each fuel type.

Biomass and Coal Solutions

ZOZEN's fuel adaptability reflects engineering capability rather than arbitrary fuel switching. During the equipment selection phase, ZOZEN's comprehensive product portfolio enables customers to choose optimal solutions based on specific fuel infrastructure and regional availability.

For facilities where agricultural residues or forestry waste are available, ZOZEN offers specialized biomass boiler series designed with dedicated feeding systems, grate configurations, and fuel handling accessories optimized for solid biomass combustion. These renewable energy solutions provide sustainable alternatives where biomass resources are abundant.

Similarly, for regions where coal remains economically viable, ZOZEN provides coal-fired boiler series with specialized combustion chambers, emission control systems, and fuel preparation equipment. Advanced circulating fluidized bed (CFB) technology achieves cleaner coal combustion while accommodating variable fuel quality.

This wide-ranging fuel capability allows facilities to select equipment matching their current fuel infrastructure from project inception. ZOZEN's engineering team evaluates each customer's fuel conditions, capacity requirements, site constraints, and emission standards to recommend the appropriate boiler series, combustion configuration, and auxiliary systems-delivering reliable performance and operational efficiency throughout the equipment's service life.

Sector-Specific Solutions and Global Reach

ZOZEN's engineering approach prioritizes understanding industry-specific requirements before recommending equipment. The textile industry, with its numerous steam-consuming processes, requires different operational characteristics than a dairy plant or pharmaceutical facility. ZOZEN's experience serving over 500 food factories worldwide has refined its ability to design systems addressing sanitation standards, rapid heat-up capabilities, and the precise temperature control these sectors demand.

Representative Global Installations

Textile Industry - Pakistan: Kohinoor Mills, a renowned textile enterprise in Pakistan, recently deployed a ZOZEN DZW series 20-ton reciprocating grate biomass steam boiler to support its transition to green and sustainable production. This collaboration exemplifies ZOZEN's growing influence in South Asian markets and demonstrates the company's technological innovation in the biomass boiler field. Under the Belt and Road Initiative, ZOZEN has established strong partnerships with Pakistan's textile sector, providing customized biomass energy solutions and reciprocating grate technology with comprehensive localized service support.

Textile Industry - Eswatini: A garment factory in Eswatini, Africa, partnered with ZOZEN to replace its old coal furnace with environmentally friendly equipment. ZOZEN customized a 3-ton body WNS series oil steam boiler capable of stably delivering 2 tons of steam in high-altitude conditions. Fueled by diesel and kerosene, the boiler not only matches local energy supply but also effectively reduces emissions, meeting environmental standards. Customer feedback confirmed: "We are extremely satisfied with the customized boiler and professional service provided by ZOZEN Boiler. The boiler has performed exceptionally well in terms of stability and efficiency."

Chemical Industry - Ghana: Sunda International Group, a multinational comprehensive industry group operating across Africa and South America, selected ZOZEN's SZL series 10-ton biomass steam boiler (SZL10-1.25-SCIII) for its laundry powder factory in Ghana. The versatile boiler accommodates both biomass pellets and wood chips as fuel, with ZOZEN providing a customized chain grate to optimize overall combustion efficiency. Representatives noted: "We are immensely grateful to ZOZEN Boiler for providing a 10-ton biomass steam boiler...This high-efficiency boiler has played a crucial role in ensuring the smooth operation of our production line."

Food Processing - Cambodia: A pet food company in Cambodia invested in a project to produce 7,500 tons of pet food annually in the Zhejiang Economic Zone, Sihanouk Province. ZOZEN provided an advanced 4-ton DZL series coal-fired steam boiler featuring horizontal three-pass water-fire tube chain grate structure with modern combustion equipment and electrical control system. The boiler's design focuses on efficient heat exchange and energy savings, meeting daily production needs while enhancing energy efficiency and supporting sustainable production.

Food Processing - Mongolia: Vitsamo Fruit Juice LLC, a large-scale juice producer in Mongolia, selected ZOZEN's 2-ton DZL series coal-fired chain grate steam boiler for juice concentration and canning sterilization processes. After in-depth communication via the internet, the customer noted: "We knew that ZOZEN Boiler was a strong industrial boiler manufacturer and supplier (https://en.zozen.com/) which had a good reputation on the international market...ZOZEN's DZL series coal-fired steam boiler solved the heat supply problem of our juice production line."

Manufacturing - Vietnam: Bestway Group, operating across over 200 countries and regions with a product portfolio covering 800 items across leisure, sports, and camping categories, selected ZOZEN boiler equipment for its plant in Tien Giang Province, Vietnam. The installation provides reliable and efficient heat energy supply supporting the company's expanding industrial footprint in Southeast Asia.

In the chemical industry, where process heating involves complex integration with production equipment, ZOZEN provides comprehensive system design that accounts for multiple heat loads, safety protocols, and fuel cost optimization. The brewing and fermentation sectors benefit from ZOZEN's understanding of temperature-sensitive biological processes, while paper mills require the high-volume, consistent steam delivery that ZOZEN's larger units provide.

This application expertise, combined with ASME "S" and "U" stamp authorization and CE certification, enables ZOZEN to serve markets across Asia, Europe, Africa, and the Americas. The international certifications validate that ZOZEN's manufacturing processes meet the stringent standards required for pressure vessel construction, providing customers assurance that equipment complies with their local regulations.

Service Infrastructure and Customer Support

ZOZEN's commitment to customer success extends throughout the equipment lifecycle. The company's consultation process begins with understanding available fuels, required capacity, and local emission regulations. This needs assessment ensures that recommended solutions deliver optimal performance within applicable environmental limits.

To better serve global customers, ZOZEN has built a reliable network of authorized agents across key regions. Currently, agents are located in Pakistan, the Philippines, Turkey, Mongolia, Kazakhstan, Singapore, Taiwan (China), Spain, Colombia, Australia, Tunisia, South Africa, Algeria, and more. These trusted partners offer professional consultation, localized support, and reliable after-sales service, ensuring customers worldwide receive expert care regardless of location.

After installation, ZOZEN maintains regular communication to monitor operating conditions and provide operational guidance. This proactive service model helps customers achieve fuel efficiency targets, maintain emission compliance, and address performance concerns before they escalate into costly downtime. The combination of quality equipment and responsive technical support differentiates ZOZEN in markets where after-sales service often receives insufficient attention.

Economic and Environmental Value

The Best Steam Boiler Price consideration encompasses more than initial purchase cost. ZOZEN's low-emission gas boilers deliver ongoing value through reduced fuel consumption, lower emission treatment costs, and extended maintenance intervals. As carbon pricing and emission regulations become more widespread, equipment that exceeds current standards provides protection against future compliance costs.

The company's ISO9001:2015 certification demonstrates systematic quality management that ensures consistent production standards. This quality assurance, combined with first-class manufacturing equipment at the Wuxi facility, enables ZOZEN to maintain competitive pricing while meeting international performance benchmarks.

For detailed information about ZOZEN's complete product range, technical specifications, and industry solutions, visit https://en.zozen.com/

ZOZEN's position as a Global Leading Gas Boiler Supplier stems from technical innovation that addresses the dual mandate of industrial efficiency and environmental responsibility. Through advanced combustion design achieving NOx emissions ≤30 mg/Nm3, comprehensive certification portfolio (ASME, CE, ISO9001:2015), and global service infrastructure supported by proven installations across textile, food, chemical, and agricultural sectors, ZOZEN delivers heating solutions that support sustainable industrial operations. As regulatory pressures and corporate sustainability commitments intensify, ZOZEN's low-emission technology portfolio-spanning steam boilers and thermal oil heaters with capacity to serve facilities from 1 to 130 tons per hour-positions the company to serve the evolving needs of industries worldwide.

info@zozen.com

No. 76, Xinda Road, Zhoutie Town, Yixing, Wuxi, China

ZOZEN is one of the best modern boiler manufacturers in China, our products include steam boilers, hot water boilers and thermal oil heaters. ZOZEN boiler is located in Wuxi, covers 150 thousand square meters of production area, equipped with first-class production equipment, passed the ISO9001:2015 international quality system certification. The company gained the " S " and " U " steel seal from ASME of US.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release ZOZEN: The Global Leading Gas Boiler Supplier with Low Emission for Sustainable Energy here

News-ID: 4326126 • Views: …

More Releases from ZOZEN

ZOZEN: Top Water Tube Boiler Manufacturer Showcases Eco-Power at HEAT&POWER EXPO …

The industrial heating sector's premier gathering is approaching as manufacturers and technology providers prepare for HEAT&POWER EXPO 2026, the international exhibition dedicated to industrial boiler equipment, heat exchange systems, and power generation technologies. Among the exhibitors converging on Moscow's Crocus Expo Exhibition Center, ZOZEN Boiler stands out as a Top Water Tube Boiler Manufacturer (https://en.zozen.com/products/?5xyFrom=site-NT), bringing decades of engineering innovation to an audience seeking advanced thermal solutions that balance performance…

How ZOZEN Becomes a Top Firetube Boiler Manufacturer for Food Processing Plant?

For modern food processing plants, selecting the right boiler partner can determine whether production runs smoothly or constantly suffers from interruptions. Behind every sterilization line, blancher, dryer or CIP system is a need for clean, reliable and energy-efficient steam. In this context, ZOZEN has grown into a Top Firetube Boiler Manufacturer (https://en.zozen.com/products/thermal-fluid-heater/?5xyFrom=site-NT) for food processing plants, combining mature firetube boiler technology with deep food industry experience and a broad range…

ZOZEN: Best Industrial Thermal Oil Heater Manufacturer for Food Safety

Food processing demands unwavering commitment to safety, quality, and precision. Every heating system operating within food production facilities must deliver consistent thermal performance while maintaining the hygienic standards that protect consumer health. From thermal processing and material heating to oil refining and sterilization, industrial thermal oil heaters provide the controlled, high-temperature heating essential for modern food manufacturing. ZOZEN Boiler has established itself as the Best Industrial Thermal Oil Heater Manufacturer…

Why Leading Chemical Companies Choose ZOZEN as a Reliable Steam Boiler Exporter …

Chemical manufacturing operates under extraordinary constraints where process precision, safety protocols, and regulatory compliance converge. Steam boilers provide the temperature control essential for polymerization, condensation, drying, melting, and molding processes that define chemical production. When leading chemical enterprises select thermal equipment suppliers, they prioritize manufacturers demonstrating proven international standards through rigorous certification. ZOZEN Boiler has earned recognition as a Reliable Steam Boiler Exporter With CE and EAC Certifications (https://en.zozen.com/products/?5xyFrom=site-NT), positioning…

More Releases for Boiler

Methanol Boiler Market Growth in Future Scope 2025-2032 | Henan Province Sitong …

Methanol Boiler Market Analysis - 2025-2032:

Coherent Market Insights has released a new report titled "Methanol Boiler Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2032 (Version 2025)." This report provides an in-depth analysis of the Methanol Boiler industry, featuring insights on market trends and performance. It also includes a thorough examination of competitors, regional dynamics, and the latest advancements within the market.

Coverage of the Methanol Boiler Market:

The report provides…

Global Boiler Market Size (2022-2028) Top Manufacturers Analysis | Dongfang Boil …

IBI has published a report entitled Global Boiler Market Research Report which provides comprehensive data on emerging trends, market drivers, growth opportunities, and barriers that could change the dynamics of the industry market. It provides an in-depth analysis of market segments which includes the product, application, and competitor analysis.

Click Here To Order A Sample Copy Of Boiler Global Market Report : https://www.infinitybusinessinsights.com/request_sample.php?id=643779

The Boiler Global Market Research Report provides close monitoring…

Boiler Market Next Big Thing | Major Manufacturers Are Dongfang Boiler Group, Ha …

Boilers play an important role in China’s economy and the Chinese people’s lives. The boiler is one of the major equipment of thermal power generation. By the end of 2020, the installed thermal power capacity in China was 1.24517 billion kilowatts, an increase of 4.7% YOY, accounting for 56.58% of the total installed capacity of electricity in China.

Buy This Report Here @ https://www.intelligencemarketreport.com/checkout/192533

According to IMR's analysis, by the end of…

Coal Fired Boilers Market is Booming Worldwide | Tianlu Boiler Industry, Hebei X …

Coal Fired Boilers Market describes an in-depth evaluation and Covid19 Outbreak study on the present and future state of the Coal Fired Boilers market across the globe, including valuable facts and figures. Coal Fired Boilers Market provides information regarding the emerging opportunities in the market & the market drivers, trends & upcoming technologies that will boost these growth trends. The report provides a comprehensive overview including Definitions, Scope, Application, Production…

Steam Boiler Systems Global Market 2018: Key Players – Hurst Boiler, Rentech B …

Steam Boiler Systems Industry

Description

Wiseguyreports.Com Adds “Steam Boiler Systems -Market Demand, Growth, Opportunities and Analysis Of Top Key Player Forecast To 2023” To Its Research Database

This report studies the global Steam Boiler Systems market status and forecast, categorizes the global Steam Boiler Systems market size (value & volume) by manufacturers, type, application, and region. This report focuses on the top manufacturers in North America, Europe, Japan, China, and other regions (India,…

Global Steam Boiler Systems Sales Market 2017 - Hurst Boiler, Rentech Boiler Sys …

Steam Boiler Systems Industry Report introduced a Market Segment, Product Types, with Sales, Revenue, Price, Market Share and Growth, focuses on top players in these regions/countries, Size, Share, Demand, Analysis, Manufacturers, Type and Application, Forecast 2017 to 2022

The report begins with a broad introduction of the Steam Boiler Systems market and then drills deeper into specific segments such as application, regional markets, end-users, policy analysis, value chain structure, and emerging…