Press release

Ultra-Low-Drag Riblet Surface Coatings for Commercial Aircraft Market Transformation Report 2026: Innovation Trends, Sustainability Drivers & Competitive Positioning

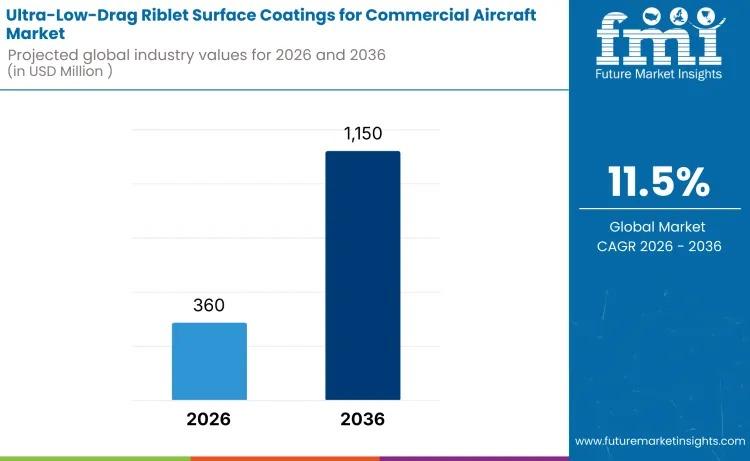

The global market for ultra-low-drag riblet surface coatings for commercial aircraft is set for significant expansion over the next decade. Valued at USD 360 million in 2026, the market is projected to reach USD 1,150 million by 2036, advancing at a robust compound annual growth rate (CAGR) of 11.5%. The growth trajectory is primarily driven by the aviation sector's increasing emphasis on fuel efficiency, environmental sustainability, and operational cost optimization.These advanced coatings, inspired by naturally occurring drag-reducing

structures, create micro-riblet textures on aircraft surfaces. By reducing aerodynamic drag, riblet coatings enhance fuel economy, lower carbon emissions, and improve overall aircraft performance. As airlines and OEMs face growing pressures to meet stringent regulatory targets for sustainability, these coatings are emerging as a critical technology for next-generation commercial aircraft.

Get access to comprehensive data tables and detailed market insights - request your sample report today!

https://www.futuremarketinsights.com/reports/sample/rep-gb-29921

Coating Technology: Micro-Riblet Polymers Lead Adoption

Within the market, micro-riblet polymer coatings account for 39% of total demand, making them the leading technology segment. These coatings feature microscopic, parallel ridges that manipulate airflow, minimizing skin friction and drag over fuselage and wing surfaces. Their effectiveness in improving fuel efficiency has made them the preferred choice for both new aircraft and retrofit programs.

Micro-riblet coatings are engineered for durability under operational stresses, including exposure to UV radiation, temperature fluctuations, and airborne particulates. Their ease of application and long-term performance benefits make them highly attractive to OEMs seeking to integrate sustainable technologies without redesigning airframes. The ongoing development of hybrid riblet-nano composite coatings and removable riblet films further expands technological options for airlines and aircraft manufacturers.

Application Segment: New Aircraft OEM Surface Treatments Dominate

New aircraft OEM surface treatments represent 46% of the market, reflecting the adoption of riblet coatings during the aircraft manufacturing phase. By integrating drag-reducing textures directly into new aircraft designs, OEMs can achieve optimal aerodynamic efficiency and fuel savings from the outset.

Adoption in new aircraft programs is being driven by a combination of regulatory pressure to reduce carbon emissions and rising operational costs in the commercial aviation sector. While aftermarket retrofits, MRO services, and specialized airline programs are gaining traction, initial OEM application remains the primary market driver due to its superior efficiency and long-term performance benefits.

Market Dynamics: Sustainability and Cost Efficiency Drive Demand

The ultra-low-drag riblet coatings market is shaped by multiple factors. Key drivers include rising fuel prices, heightened environmental awareness, and commitments from airlines to reduce carbon footprints. Advanced materials science enables coatings to maintain performance under demanding flight conditions, supporting operational reliability while delivering measurable fuel savings.

Challenges persist, including the technical complexity of applying riblet textures and maintaining adhesion over time. Operational wear, cleaning, and environmental exposure necessitate rigorous quality control, certification, and validation processes. Nevertheless, the proven efficiency gains, combined with regulatory incentives, continue to bolster adoption across global commercial aviation fleets.

Regional Insights: Asia-Pacific and North America Lead Growth

Geographically, China, India, and the USA are emerging as key markets, supported by expanding aviation sectors and growing emphasis on fuel efficiency.

• China: Projected CAGR of 13.8%, driven by fleet modernization programs and adoption of cost-effective fuel-saving technologies.

• India: Projected CAGR of 15.2%, supported by a rapidly growing airline industry and government initiatives to modernize aircraft fleets with sustainable solutions.

• USA: Projected CAGR of 12.5%, fueled by a mature aerospace sector, advanced technology integration, and strong regulatory incentives for fuel efficiency and emission reductions.

Other important markets include the UK (CAGR 11.9%) and Japan (CAGR 10.7%), where aerospace manufacturers and airlines are increasingly incorporating drag-reducing coatings to enhance aircraft performance and meet environmental standards.

Personalize Your Experience: Ask for Customization to Meet Your Requirements

https://www.futuremarketinsights.com/customization-available/rep-gb-29921

Competitive Landscape: Innovation and Integration Drive Leadership

The competitive environment is characterized by strong OEM involvement, advanced material innovation, and application expertise. Airbus and Boeing lead market adoption, integrating riblet coatings into next-generation aircraft designs. Other key players include Lockheed Martin, Hexcel Corporation, and 3M Company, each contributing specialized materials, composites, and coating technologies.

Companies compete on coating performance in operational environments, durability, ease of application, compatibility with airframe materials, and support for certification and maintenance. OEM partnerships and proven aerodynamic benefits position these firms to capture market share as airlines globally adopt technologies for cost reduction and sustainability.

Outlook: Riblet Coatings as a Standard Aviation Efficiency Solution

As global air travel demand grows and sustainability becomes a central objective for commercial airlines, ultra-low-drag riblet surface coatings are increasingly recognized as a strategic technology for improving fuel efficiency and reducing emissions. Integrated from the OEM stage and supplemented by retrofit programs, riblet coatings are expected to play a pivotal role in the aerospace sector's transition to more environmentally responsible operations.

With rising airline operational costs and increasingly strict carbon-reduction mandates, the market for ultra-low-drag riblet surface coatings is projected to continue its strong growth trajectory, positioning these advanced surface treatments as essential components of future commercial aircraft performance.

Key Market Metrics (2026)

• Market Value: USD 360 million

• Forecast Value (2036): USD 1,150 million

• Forecast CAGR: 11.5%

• Leading Coating Technology: Micro-Riblet Polymer Coatings (39%)

• Leading Application: New Aircraft OEM Surface Treatments (46%)

• Key Growth Regions: China, India, USA, UK, Japan

• Top Players: Boeing, Airbus, Lockheed Martin, Hexcel Corporation, 3M Company

Similar Industry Reports

Commercial Aircraft MRO Market

https://www.futuremarketinsights.com/reports/commercial-aircraft-mro-market

Commercial Aircraft Cabin Interior Market

https://www.futuremarketinsights.com/reports/commercial-aircraft-cabin-interior-market

Commercial Aircraft Video Surveillance Systems Market

https://www.futuremarketinsights.com/reports/commercial-aircraft-video-surveillance-systems-market

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Ultra-Low-Drag Riblet Surface Coatings for Commercial Aircraft Market Transformation Report 2026: Innovation Trends, Sustainability Drivers & Competitive Positioning here

News-ID: 4324278 • Views: …

More Releases from Future Market Insights

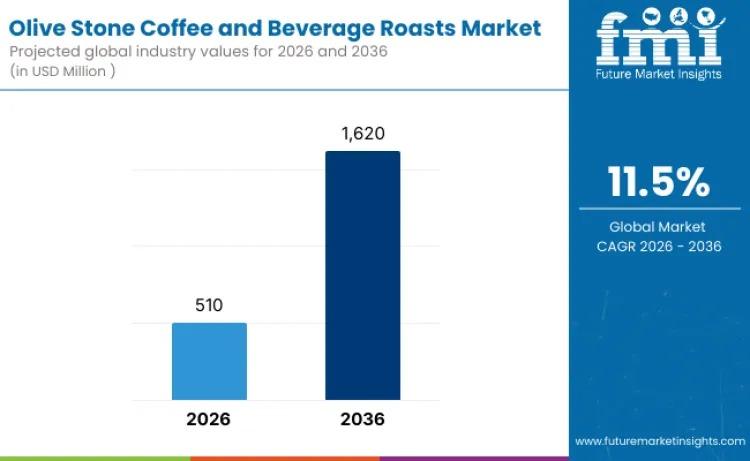

Global Olive Stone Coffee and Beverage Roasts Market to Reach USD 1,620 Million …

The global olive stone coffee and beverage roasts market is entering a high-growth decade, fueled by sustainability innovation and evolving specialty coffee culture. Valued at USD 510 million in 2026, the market is projected to reach USD 1,620 million by 2036, expanding at a compelling CAGR of 11.5%.

As consumers increasingly seek beverages that combine sustainability, functionality, and distinctive taste, olive stone-based roasting solutions are transitioning from niche experimentation to structured…

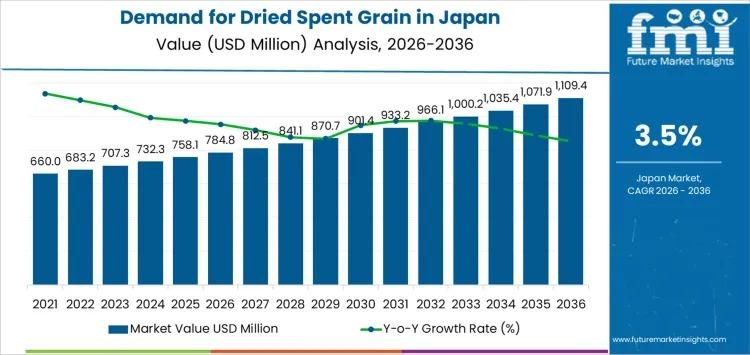

Japan Dried Spent Grain Market to Surpass USD 1.1 Billion by 2036 as Feed Optimi …

Japan's dried spent grain market is entering a decade of steady, value-driven expansion, supported by structured feed demand, brewery byproduct utilization, and rising integration of fiber-rich ingredients into food manufacturing. Industry estimates place the market at USD 784.8 million in 2026, with projections indicating growth to USD 1,109.4 million by 2036, reflecting a CAGR of 3.5%.

Between 2020 and 2026, demand increased from USD 637.5 million to USD 784.8 million, shaped…

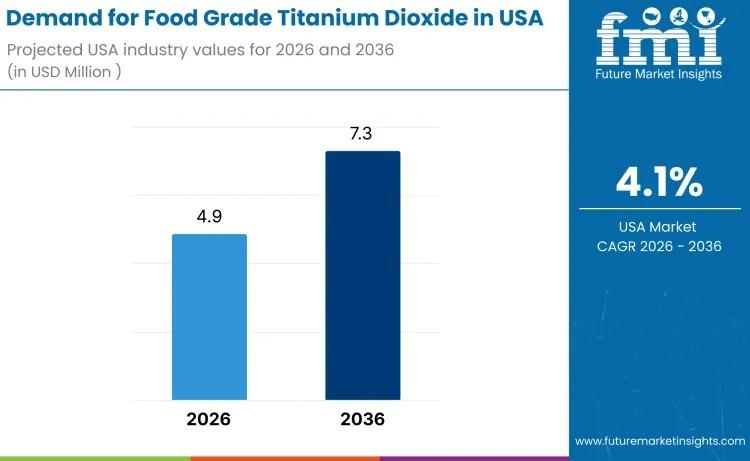

USA Food Grade Titanium Dioxide Market to Reach USD 7.3 Million by 2036 Amid Ste …

The demand for food grade titanium dioxide in the USA is valued at USD 4.9 million in 2026 and is projected to reach USD 7.3 million by 2036, expanding at a CAGR of 4.1%. Growth remains moderate yet stable, supported by continued use of titanium dioxide as a whitening and opacifying agent across confectionery coatings, bakery decorations, sauces, dairy analogues, and processed food matrices.

Despite heightened regulatory scrutiny and evolving clean-label…

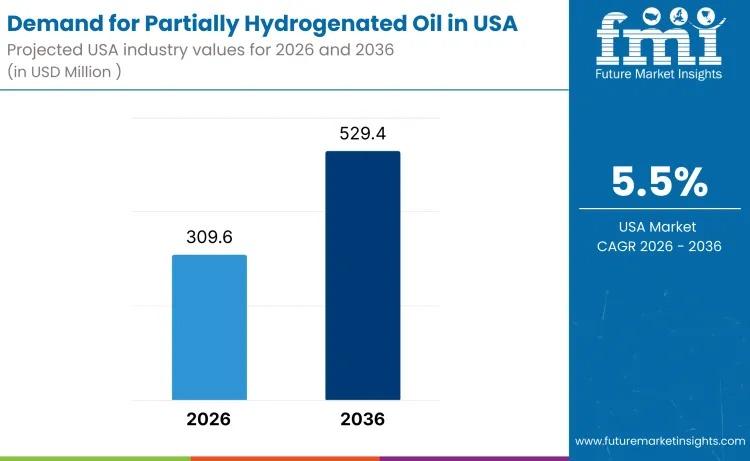

USA Partially Hydrogenated Oil Market to Reach USD 529.4 Million by 2036 Amid Me …

The demand for partially hydrogenated oil in the USA is projected to rise from USD 309.6 million in 2026 to USD 529.4 million by 2036, expanding at a steady CAGR of 5.5%. While edible applications remain tightly regulated, demand persists across specialty industrial and permitted food-related segments where oxidative stability, viscosity control, and texture performance remain critical.

Despite regulatory constraints on trans fats in conventional food manufacturing, PHOs continue to serve…

More Releases for OEM

OEM Partnership Guide: Working with a Touch-free Automatic Kitchen Garbage Can O …

With increasing global demand for smart home solutions, Sinoware International Ltd, a top provider in household products industry, is pleased to unveil expanded OEM partnership initiatives.

Sinoware has established itself in Jiangmen--China's premier stainless steel industry zone--as an indispensable touch-free automatic kitchen garbage can OEM manufacturer for global brands seeking to incorporate high-tech sanitation solutions into their portfolios.

By combining their decades-old tradition of metal craftsmanship with cutting-edge infrared and…

Revolutionizing OEM Coatings With Sustainable Solutions Trend: A Crucial Influen …

Which drivers are expected to have the greatest impact on the over the oem coatings market's growth?

The surge in requirements from final consumer industries is forecasted to boost the expansion of the OEM coatings market. These coatings, referred to as OEM, are utilized during the integration of other firms' products into the substrate process or application. They prove to be beneficial for a variety of end-user sectors, including automotive and…

OEM Technology Partnerships Launches Brokerage Specializing in 100+ OEM Technolo …

San Francisco, California, USA - February 13, 2025 - OEM Technology Partnerships is thrilled to announce the launch of its specialized brokerage focused on connecting businesses with a comprehensive portfolio of over 100 Original Equipment Manufacturer (OEM) technologies. This new venture is poised to revolutionize how companies access and implement cutting-edge solutions across diverse industries.

Leveraging deep industry expertise and a vast network of OEM partners, OEM Technology Partnerships offers a…

OEM or ODM Watches? What's the Difference?

When searching for a watch manufacturer for your store or watch brand, you may come across the terms OEM and ODM. But do you truly understand the difference between them? In this article, we will delve into the distinctions between OEM and ODM watches to help you better grasp and choose the manufacturing service that suits your needs.

Image: https://www.naviforce.com/uploads/15a6ba3911.png

What's OEM / ODM Watches [https://www.naviforce.com/products/]

OEM (Original Equipment Manufacturer) watches are produced…

OEM Partnership with Extreme Networks

ComputerVault announces an OEM partnership with Extreme Networks and has certified its switches for use with ComputerVault enterprise software to deliver virtual desktop infrastructure (VDI).

Extreme Networks industry leading switches deliver ComputerVault Virtual Desktops at faster than PC speeds in the LAN and WAN.

“ComputerVault is very excited to work with Extreme Networks. Not only are their switches very reliable, but their exceptional performance guarantees a great user experience”, said Marc…

Humidity Measurement Module for OEM Applications

The EE1900 humidity module from E+E Elektronik is optimised for the measurement of relative humidity (RH) or dew point temperature (Td) in climate and test chambers. With outstanding temperature compensation across the working range from -70 °C to 180 °C (-94 °F to 356 °F) and the choice of stainless steel and plastic probes, the module is suitable for a wide range of applications.

High Accuracy in Harsh Environment

The excellent…