Press release

Challenge Europe makes threads material to the case

Threaded fastener systems – nuts, bolts, screws and washers used in manufacturing industry at large are a time served, well developed, reliable and surprisingly sophisticated technology. They are also well known – but it is often not appreciated just how critical it may be to choose exactly the right material and finish. This is where Challenge Europe can be of real help.Manufacturing industry typically requires threaded fasteners in varying grades of steel, stainless steel, copper, brass and aluminium, depending on the installed environment and compatibility with neighbouring substrates.

As explained by Kevin Moorcroft, M.D.: “The material choice is the most important first step but often just as important is the choice of finish – we offer chemi-black on mild steel, stayblack on stainless steel, zinc plated, chrome plated and nickel plated as standard finishes on many of our fixings.

“We work with design engineers and buyers in all industries to optimise choices and minimise costs so we can ensure highest quality and quickest assembly times for each product.”

Standard products include machine screws, self-tapping and self-drilling screws, as well as machine screw SEMs, thread-forming screws and hammer drive screws.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

Challenge (Europe) Ltd is an ISO9001 stockist and distributor of threaded fasteners, with an emphasis on supplying manufacturing companies located within the UK with specialist standard or custom components.

This includes extensive stock and application specific supply capability for screws and bolts of all types including machine screws, self-drilling screws, hammer drive screws, wood screws, self-tapping, thread-forming screws and sems. Bolts include Hex head, construction floor anchors, coach bolts and studding. They have an extensive stock of socket head screws as well as nuts, cage nuts, rivet nuts, Tee nuts, weld nuts, u nuts, wing nuts, barb nuts and combi nuts. Washers are stocked in depth from flat and shake proof to mudguard, copper grip and terminal cup types, to crinkle washers, sealing and Belville washers, spring and cup washers, as well as O rings. Rivets include blind and tubular, alongside split cotter pins, dowel/groove pins, weld studs, tension pins, self-clinching and brass threaded inserts.

Challenge also carry useful ancillary products such as grommets, plugs and screw caps, carrying handles, valve knobs, cable ties and the range of Action Can lubricants, sprays and aerosols.

Challenge operates Project Manufacturing Partnerships for sub-contract manufacture, sub-assembly and logistic supply. These have developed over many years from simple kitting processes to cover supply chain management including co-operative product development, tooling control and global sourcing through to stock monitoring.

Challenge (Europe) Ltd

Shuttleworth Road

Bedford

MK41 0EP

Tel: 01234 346242

email: sales@challenge-europe.co.uk

www.challenge-europe.co.uk

Press contact: Kevin Moorcroft

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Challenge Europe makes threads material to the case here

News-ID: 432421 • Views: …

More Releases from Challenge (Europe) Ltd

Challenge Europe – wire thread inserts for high-strength threads in soft mater …

Specialist threaded fasteners often need help in forming the best attachment to soft core materials such as aluminium or magnesium alloys. Challenge Europe are pleased to announce their stock, advice and production service operation for a comprehensive range of wire thread inserts, available in both tanged and tangless variants, or screw thread inserts which provide high performance internal threads in castings where light weight of the complete assembly is a…

Action Can from Challenge Europe for manufacturers and installers

As specialists in the world of industrial threaded fasteners, the team at Challenge Europe are pleased to announce stocking of the Action Can range of industrial aerosols.

Explains M.D. Kevin Moorcroft “we deal every day with manufacturers, installers and service engineers who are in constant need of high quality consumables and we find the Action Can range meets the exacting requirements of professional engineers for anti-corrosion products and paints, cleaners, lubricants,…

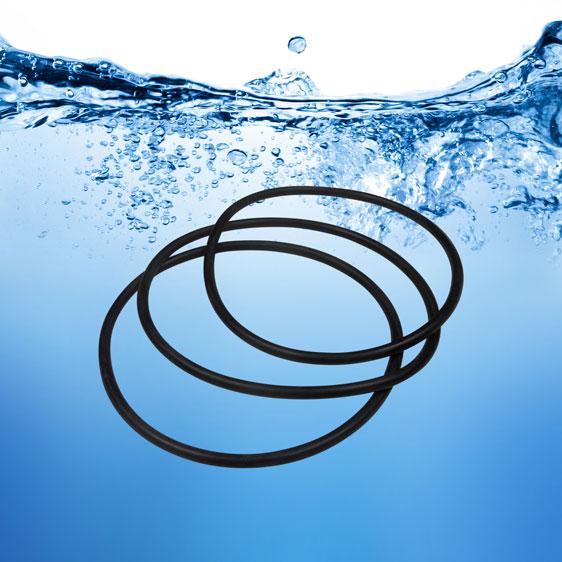

Challenge Europe address urgent need for “O” rings

The team at Challenge Europe have found that alongside their core threaded fastener range, there is a demand for sealing “O” rings on an urgent basis – and consequently decided to enhance stock levels to meet the need.

Common requirements for “O” rings come in Nitrile (NBR), EPDM, Viton®, Silicone, Polyurethane and Neoprene with many others also called for to suit the needs of practically every industrial sector.

Challenge Europe can support…

Challenge Europe offer thread locking devices, ex-stock

Challenge Europe are pleased to offer ex-stock thread locking solutions for general industrial assembly purposes. One of the most common and simplest solution to problems of vibration loosening of threaded fasteners is by use of a conventional locking nut or half nut.

Use of a full nut provides an easy fitment which pulls from the same stock as the main fastener. A locking half nut above the full nut leaves “head…

More Releases for Europe

Strategy Consulting Market 2025 | Analysis By Top Key Players: Booz & Co. , Rola …

Global Strategy Consulting Market 2019-2025, has been prepared based on an in-depth market analysis with inputs from industry experts. This report covers the market landscape and its growth prospects over the coming years. The report also includes a discussion of the key vendors operating in this market.

The key players covered in this study

McKinsey , The Boston Consulting Group , Bain & Company , Booz & Co. , Roland Berger Europe…

Influenza Vaccination Market Global Forecast 2018-25 Estimated with Top Key Play …

UpMarketResearch published an exclusive report on “Influenza Vaccination market” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 115 pages which highly exhibits on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability. This report focuses on the Influenza Vaccination market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This…

Global Strategy Consulting Market Research Report 2018-2025 | Global Key Player …

An up-to-date research report has been disclosed by Market Research Hub highlighting the title “Global Strategy Consulting Market Size, Status and Forecast 2018-2025” which provides an outlook for current market value as well as the expected growth of Strategy Consulting during 2018-2025. The report studies the casing heads market worldwide, especially in North America, China, Europe, Southeast Asia, Japan and India, with production, size, growth, revenue, consumption, import and export…

Strategy Consulting Market Deep Insights with Core Business Strategies 2018 - Ro …

Strategy Consulting Market report provides a vital recent industry data which covers in general market situation along with future scenario for industry around the Globe. It also consist of major data along with forecasts of a global market along with clear presentation of diagrams (charts and tables).

Global strategy consulting market size status and forecast 2025 has a vast collection of market research reports concerning the software industry, its sub-sectors, and…

Wearable Heart Monitoring Devices Market 2018 To 2023 – Top Leaders Beurer Gmb …

The Worldwide Wearable Heart Monitoring Devices Market is growing at a healthy rate. The major players in this market are Medtronic (U.S.), Kinetec Products UK Ltd. (South America), Beurer GmbH (Europe), Medisana AG (Europe), Briggs Healthcare (U.S.), Polar Electro (Europe), SUUNTO (Europe), Koninklijke Philips N.V. (Europe), Garmin Ltd. (Europe) and others. The Wolrdwide Wearable Heart Monitoring devices is segmented on the basis of products, type, application, and end users. On…

Surgical Equipment Market 2018 Leading Manufacturer in Europe, the Middle East & …

The Europe, the Middle East & Africa Surgical Equipment Market is expected to grow at an approximate CAGR of 6.7% during the forecast period.

A surgical equipment is a designed tool or device to carry out various surgical procedures so as to modifying biological tissues and to provide access for viewing them. The surgical equipment can be designed specifically for a particular surgery or it can be used as general purpose…