Press release

Metal Rapid Prototyping: Solving Complex Design Challenges for Automotive and Aerospace Engineers to Accelerate Time-to-Market

IntroductionIn the cutthroat domains of automotive or aeronautical engineering, the very pace of innovation can be stymied by the manufacturing process as practiced for many years. Processes involving CNC machining or mold-based casting entail timescales from weeks to months, very expensive prototype costs, and a set of design constraints also very expensive. This poses a serious challenge in the speed of iteration getting hopelessly behind the curve for marketplace feasibility. The subtractive process traditionally practiced inherently involves a lot of waste and the very expensive cost of infrastructure for very rapid validation of geometrical complexities such as internal manifolds or topology-optimized sections for weight savings.

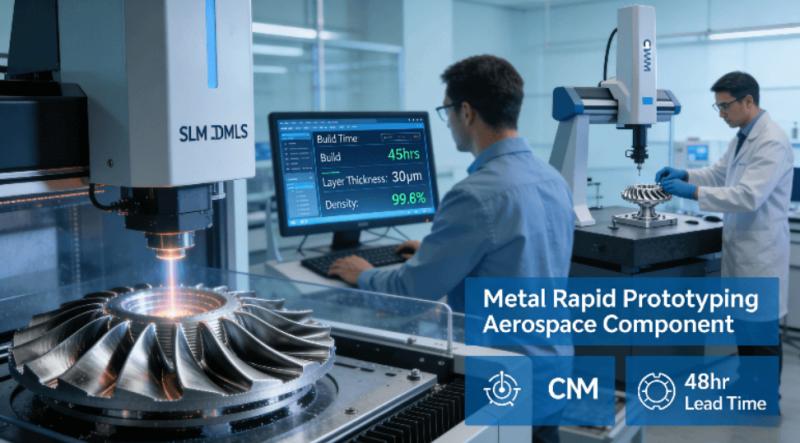

Metal Rapid Prototyping is the most innovative methodology that has been shaped by the application of additive technologies such as Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS). This allows the entire manufacture to be digitally driven. It cuts down the development time considerably to the order of days and allows freedoms that were unachievable earlier. This article will give insights on the working principles, its applications, and the methodologies of its implementation that would help engineers be most effective.

What is Metal Rapid Prototyping and How Does it Re-Define Manufacturing?

https://www.lsrpf.com/Metal Rapid Prototyping, or metal 3D printing, is an additive process whereby parts are made layer-by-layer directly from digital 3D models. This differs significantly from traditional subtractive manufacturing techniques, which begin with a solid block of material from which parts are subtracted. The two processes behind metal rapid prototyping, SLM and DMLS, employ a powerful laser to melt tiny particles of metal powder to createparts with properties equivalent to wrought parts.

This is a paradigm shift in the world of manufacturing. The technology does not require any hard tooling; therefore, it can produce directly from digital to part. With the help of modern geometric dimensioning, engineers are able to produce parts that require a high level of precision from the prototype stage itself. This makes it possible for companies to implement metal rapid prototyping to produce parts directly from CAD files.

What Are the Key Benefits of Metal Rapid Prototyping for High-Stakes Industries?

Applications of this technology have far-reaching benefits, especially with regard to the automotive and aerospace industry, which requires performance, weight, and speed.

1. Radical Time-to-Market Reduction

The first major advantage is how much the lead time is reduced. While it may take weeks or even months to complete a prototype using traditional prototyping technology due to tooling and setup, a metal additive technology might take days to produce a functional prototype. This means that a validation of a prototype of a new aerospace bracket might be completed in a week, allowing several validations in a time period that could only accommodate one in the past.

2. Absolute freedom and Complexity

Metal Rapid Prototyping breaks down the geometric constraints of machining. It allows the design of a reduced weight structure of lattices, complicated cooling passages, and monolithic assemblies that are normally måny pieces held together by bolts. With Metal Rapid Prototyping, structural designs can now focus on their primary purpose, not their manufacturability.

3. Cost Efficiency for Lower Quantities

For prototype development and small series production, it is highly economical. The fact that there are no mold costs makes additive manufacturing highly economical. The unit cost is relatively constant; this is not true when it comes to conventional methods, where a large amount of capital is deployed, which is only feasible when large series production is undertaken. This is enabled through quality management systems that might be ISO 9001 certified.

Comparison of Metal Rapid Prototyping with Traditional CNC Machining

Which technology to use among these depends on the requirements of the project.Here is a brief introduction:

l Speed and Agility: CNC machining involves a large amount of programming and the design of custom fixtures for every position of the parts. Metal 3D printing does not need changes in the tools. It is inherently faster when it comes to the first parts produced but involves a similar post-processing time. On the side of development of complex parts, the flexibility of additive processing gives a clear advantage.

l Material Utilization and Waste: "CNC is a subtraction fabrication method that often finds itself wasting more than 50% of the original block of material used." This is reflective of the fact that it is an inefficient method when it comes to the usage of the raw materials, and the resource utilization rate is below 50%. Additive fabrication, on the other hand, is very efficient, and the resource utilization rate is above 95%. This is because the powder that

l Geometric Capabilities: Prismatic shapes work well with the machine, whereas undercuts, internal passages, and curvilinear shapes don't.Metal Rapid Prototyping does the opposite and focuses on creating such shapes. As such, they are capable of creating complex functional parts that would otherwise be difficult or impossible to produce via machining.

Figure 2: Technical comparison demonstrating how metal rapid prototyping reduces production time by 85%, decreases material waste by 90%, and enables complex geometries compared to traditional CNC machining.

Which Materials and Processes are Used for High-Quality Aluminum Prototyping?

The portfolio of materials used in metal additive manufacturing is diverse, although Al-alloys have assumed prominence in the automotive and aircraft industry because of their specific strength and thermal conductivity properties.

1. Significance of Aluminum Alloys

An aluminum prototype extrusion process can be an essential process in manufacturing lightweight yet durable items in applications involving heat exchanger designs, brackets, and the structure of drones. An AlSi10Mg aluminum alloy would provide excellent castability properties, along with high strength-to-weight ratios.

2. Ensuring Quality and Traceability

Industries such as medical devices, for which purity and traceability of the material are non-negotiable, require a high degree of adherence to standards. The high degree of process controls enforced by standards like ISO 13485 for a medical device assure traceability of material and biocompatibility wherever necessary. A systematic approach to this is also essential for high reliability applications in aerospace and automotive, which may require their suppliers to have standards like IATF 16949 and AS 9100 D.

What Role Can Rapid Tooling Play in Connecting Prototyping and Mass Production?

A very valuable extension of Metal Rapid Prototyping is Rapid tooling, whereby additive manufacturing methods are utilized to generate molds in order to either injection-mold or die cast parts. This helps fill the gap between proof-of-concept and mass manufacturing.

1. Bridge Tooling Concept

https://www.lsrpf.com/rapid-prototyping allows for the 3D printing of mold inserts using materials such as tooling steels or aluminum in order to mass produce parts ranging from a hundred to a thousand. This helps in testing the product, seeding the market, and ramping up production without incurring the costs of hard tooling.

2. Case in Point: Automotive Component Validation

An example is a car company that requires the validation of a novel sensor casing. Rather than taking 12 weeks to develop a molded prototype in mass production, with the aid of aluminum rapid tooling, the car company can develop an injection mold in a short period of time and conduct a run of 500 pieces in two weeks, reducing expenditure by 85% and shortening the timeline of the decision process. Industry players can take advantage of advanced services in rapid tooling.

What are the Future Trends in Metal Rapid Prototyping Technology?

Advances in metal additive manufacturing remain at the forefront of innovation, thanks to several key trends.

1. Optimization by AI and Multi-Material Printing: Artificial Intelligence integration is optimizing print parameters in real-time to suppress defects and improve the technical characteristics of a product. In addition, there is the creation of components with graded properties using multi-material printing technology, for instance, a component with a hard wear-resistant surface and a tough and ductile core.

2. Sustainability and Green Manufacturing: There is a growing concern in the industry regarding sustainability. This can include improving the efficiency of recycling techniques for powdered materials as well as the development of recycling metal powders. This further satisfies the needs of green recycling as advocated by the U.S. Environmental Protection Agency.

Conclusion

Metal Rapid Prototyping has removed the hurdles of speed, cost, and design that traditional manufacturing methods had in their way. By opting for digital and tooling-free manufacturing, Metal Rapid Prototyping helps automotive and aerospace engineers innovate quickly and enter the markets with better products sooner. The coming together of Metal Rapid Prototyping and sustainable practices will further increase its importance in the context of innovation in the industry.

FAQs

Q1: What is the lead time for metal rapid prototyping?

A: For standard components, the lead time is 3-7 days, which includes printing, as well as post-processing operations such as heat treatment. These lead times are much faster than those in conventional rapid tools, which take weeks to produce due to mold fabrication.

Q2: How do the strengths of 3D printed metal parts compare with forged parts?

A: Metal 3D printed parts, thanks to optimized processes such as SLM, display densities close to that of forging, as well as mechanical strengths. Other processes, like hot isostatic pressing, improve strengths and are applied to structural parts.

Q3: Which industries are metal rapid prototyping most useful in?

A: The automotive, aerospace, medical devices, or industry categories are the ones that benefit immensely, specifically in the case of complex geometries, lightweight components, or custom parts. Aerospace engineers apply the process for manufacturing fuel nozzles with inner passages, which cannot be created using machining.

Q4: Can a large part be produced by metal rapid prototyping?

A: Yes, large-format industrial printers support parts up to 4000×1500×600 mm. But design segmentation techniques could be used for very large parts to ensure accuracy and viability.

Q5: Which file formats are supported in metal 3D printing?

A: The most common file formats include STEP, STL, and IGES. Notably, some service providers also offer direct import and export capabilities for CAD files to facilitate the transfer of relevant data.

Author Bio

The author is a precision manufacturing expert at LS Manufacturing. They are a company that helps engineers and researchers in resolving complex part challenges in aerospace, medical, and automotive sectors. They are certified in IATF 16949 and AS9100D to provide quality services to clients. To gain further knowledge,You can access their official website, there is a free project review and DFM analysis. They turn ideas into a cost-effective reality.

SEO MAVENS LLC

1001 S MAIN ST STE 500

KALISPELL, MT 59901

SEO Mavens is a U.S.-based digital marketing agency specializing in SEO, link building, and content strategy, helping global brands improve online visibility through ethical, data-driven search optimization.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Rapid Prototyping: Solving Complex Design Challenges for Automotive and Aerospace Engineers to Accelerate Time-to-Market here

News-ID: 4323541 • Views: …

More Releases from SEO Mavens

Maintenance and Cure: What It Means for Injured Seafarers

Working at sea comes with unique risks that most land-based employees never face. From heavy equipment to unpredictable weather, seafarers operate in environments where injuries can happen suddenly and seriously. When an accident occurs, one of the most important legal protections available is the doctrine known as maintenance and cure. This long-standing maritime principle plays a vital role in protecting injured crew members, regardless of who was at fault.

The Basics…

Discover the Ultimate Adventure at Universal Studios Singapore

Visiting Singapore offers countless attractions, but few experiences match the thrill of Universal Studios Singapore. Whether you are traveling with family, friends, or even solo, this theme park promises a day filled with excitement, laughter, and unforgettable memories.

1.Why Universal Studios Singapore is a Must-Visit

Located on Sentosa Island, Universal Studios Singapore is home to world-class rides, entertainment, and themed zones. From adrenaline-pumping roller coasters to immersive 4D shows, the park caters…

Why Choosing a Noble Black Car Service Elevates Your NYC Travel Experience

New York City is a fast-paced metropolis where time, comfort, and reliability matter more than ever. For professionals, tourists, and high-profile travelers alike, getting around the city efficiently can make or break the day. This is where a premium transportation option, like Noble Black Car service, truly stands out.https://nobleblackcarservice.com/

Unlike traditional taxis or rideshare apps, a black car service offers a seamless experience that combines luxury, punctuality, and professionalism. Whether traveling…

How Professional Movers Ensure Efficient Business Relocation

Relocating a business is a complex process that involves careful planning, precise coordination, and minimal disruption to daily operations. Whether a company is expanding, downsizing, or moving to a more strategic location, an efficient relocation ensures continuity and protects productivity. Professional movers are very important for making sure that moving a business goes smoothly, is planned, and doesn't cause stress.

Strategic Planning and Pre-Move Assessment

A successful business relocation begins with detailed…

More Releases for Metal

Metal Roofing Companies Revolutionizing the Industry: Classic Metal Roofs Leads …

Classic Metal Roofs has established itself as a leading provider of durable and energy-efficient roofing systems in Southern New England. With over 20 years of experience, the company is known for high-quality installations, customer satisfaction, and sustainable metal roofing solutions.

As homeowners increasingly seek durable and energy-efficient solutions, metal roofing companies continue to provide top-tier roofing systems. Among the industry leaders, Classic Metal Roofs [http://business.bigspringherald.com/bigspringherald/markets/article/abnewswire-2025-2-15-classic-metal-roofs-expert-aluminum-shingle-metal-roof-installation-and-services/] stands out for its commitment to…

Rare Metal Raw Materials - Boron(B) Metal

Boron Powder [https://www.urbanmines.com/boron-powder-product/]

Short Description:

Boron [,%20a%20chemical%20element%20with%20the%20symbol%20B%20and%20atomic%20number%205,%20is%20a%20black/brown%20hard%20solid%20amorphous%20powder.%20It%20], a chemical element with the symbol B and atomic number 5, is a black/brown hard solid amorphous powder. It is highly reactiveand soluble in concentrated nitric and sulfuric acids but insoluble in water, alcohol and ether. It has a high neutro absorption capacity. UrbanMines specializes in producing high purity Boron Powder with the smallest possible average grain sizes. Our standard powderparticle sizes average in the…

Metal Polishing Services Market Trends and Leading Players 2023-2030 | Metal Pol …

With a CAGR of 6.1%, the Metal Polishing Services Market is expected to grow from USD 1.5 billion in 2023 to USD 2.3 billion by 2030, offering a gleaming finish to metal surfaces for aesthetic and functional purposes.

Market Overview:

The Metal Polishing Services market is poised for rapid growth, driven by several pivotal drivers. There is a continuous demand for metal finishing and polishing services that improve the appearance and…

Metal-to-metal Seal Market 2021 | Detailed Report

Metal-to-metal Seal Market Forecasts report provided to identify significant trends, drivers, influence factors in global and regions, agreements, new product launches and acquisitions, Analysis, market drivers, opportunities and challenges, risks in the market, cost and forecasts to 2027.

Get Free Sample PDF (including full TOC, Tables and Figures) of Metal-to-metal Seal Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5089735

The report provides a comprehensive analysis of company profiles listed below:

- Parker

- CPI

- HTMS

- American Seal &…

Metal Polishing Services Market Research Report 2020 Analysis: Enhanced Growth a …

Metal Polishing Services Market

Global Metal Polishing Services Market is providing the summarized study of several factors encouraging the growth of the market such as manufacturers, market size, type, regions and numerous applications. By using the report consumer can recognize the several dynamics that impact and govern the market. For any product, there are several companies playing their role in the market, some new, some established and some are planning to…

Worldwide Recycled Metal Market By Metal 2024 | Nucor, Steel Dynamics, Schnitzer …

The 2018-2024 report on global Recycled Metal market explores the essential factors of Recycled Metal industry covering current scenario, market demand information, coverage of active companies and segmentation forecasts.

North America recycled metal market was estimated close to USD 8.5 billion in 2017. This is mainly attributed to strong presence of transportation, electrical & electronics and defense industry which majorly constitute to the overall product demand. Moreover, strict laws formulated…