Press release

Biocompatible surface treatment of medical equipment castings

The demand for Precision Casting [https://www.htprecisioncast.com/precision-casting/]s in the medical manufacturing industry is transitioning from "usable" to "absolutely reliable". When equipment related to life and health involves metal components, the low-pressure casting process leaves behind not only dimensional accuracy but also a threshold that must be crossed: biocompatible surface treatment. This process determines whether the casting can smoothly move from the factory to clinical application.Why is it said that low-pressure casting medical castings need special treatment? The compactness and low porosity brought by low-pressure casting make it an ideal forming method for medical components. However, the as-cast surface often retains micro-oxide layers, mold release agents or trace element segregation. These "minor issues" that can be tolerated in industrial parts may trigger immune responses or accelerate corrosion in medical scenarios. What is even more difficult is that the coping strategies for different alloys vary greatly.

Titanium Alloy Casting [https://www.htprecisioncast.com/alloy-casting/]s: Electrolytic polishing is the gold standardThe Ra value of the as-cast surface of the Ti-6Al-4V material for implant castings is usually above 3.2m, and direct implantation will cause fiber encapsulation. The industry-recognized solution is electrolytic polishing, which advances the surface roughness to the Ra less than or equal to 0.2m level while stripping off the iron and aluminum-rich contaminant layer. This process is not a simple brightening treatment - the delicate balance between current density and electrolyte ratio determines whether a uniform passivation film can be formed without losing dimensional accuracy. Titanium castings that comply with the ASTM F86 standard still need to undergo the ISO 10993-5 cytotoxicity test verification to complete the closed loop of biocompatibility.

In some application scenarios that require osseointegration capabilities, anodic oxidation is added on the basis of electrolytic polishing. The porous oxide layer of 10-20m is not generated randomly. Voltage control and oxidation time directly affect porosity and surface energy. Orthopedic device manufacturers usually control the thickness of the oxide layer at around 15m, a value that takes into account both the adhesion strength of osteoblasts and the stability of the coating.

Image: https://ecdn6.globalso.com/upload/p/3732/image_other/2025-06/distributor-die-casting-1.jpg

Stainless steel castings: Passivation must not be omittedAfter low-pressure casting, the chromium content on the surface of 316L stainless steel castings may be lower than that of the base material, reducing their corrosion resistance. Medical-grade applications must undergo passivation treatment to reconstruct the chromium-rich oxide layer with nitric acid or citric acid solution. Here is a detail that is often overlooked: the cleaning process before passivation. Residual polishing sand or cutting fluid in the inner cavity of the casting can cause local failure of the passivation film, leading to the risk of pitting corrosion. For genuine medical-grade processes, ultrasonic cleaning is carried out once before and once after passivation, and then rinsed three times with deionized water in between.

For components that come into contact with blood, such as the outer shell of a pacemaker, simple passivation is sometimes insufficient. Some suppliers will superimpose Parylene C coating. This gas-phase deposited polymer film is only 0.0005 inches thick, but it can provide a dense insulating barrier and meets the USP Class VI biocompatibility requirements.

Aluminum Alloy Casting [https://www.htprecisioncast.com/aluminum-alloy-casting/]s: Anodizing opens up application spaceAluminum alloys have long been underestimated in the medical field, mainly due to the controversy over the biological safety of aluminum ions. However, through hard anodizing, an aluminum oxide layer of 50-100m is formed on the surface, which can reduce the release rate of aluminum ions below the safety threshold. This process is particularly friendly to aluminum castings produced by low-pressure casting, as the as-cast structure is uniform and ablation or color difference is less likely to occur during anodizing.

A practical tip is: For large aluminum castings of medical imaging equipment, after sulfuric acid anodizing, the surface is then treated with PTFE sealing. This not only meets the leaching test requirements of ISO 10993, but also obtains a non-stick surface that is easy to clean, which is very practical for the frequently disinfected hospital environment. When the coating thickness is controlled at 25m, the voltage breakdown resistance can reach over 2000V, which is also helpful for electromagnetic shielding.

Image: https://ecdn6.globalso.com/upload/p/3732/image_other/2025-06/application-of-aluminum-alloy-die-casting-in-medical-field-1.jpg

To choose surface treatment, first answer three questionsFaced with so many process routes, the key to decision-making does not lie in which technology is more advanced, but in matching specific demands. First, it is necessary to clarify the type of contact: Is it directly implanted in the human body for more than 30 days? Or only contact the whole skin? The former must pass the full ISO 10993 assessment, while the latter may only need to meet the local irritation test.

The second is the material properties. Titanium alloys are sensitive to fluorine-containing cleaning agents, stainless steel is afraid of chloride ion contamination, and aluminum alloys are sensitive to strong alkali. The width of the process window directly affects the stability of mass production. During a certain process conversion, the electrolytic polishing temperature of titanium castings was adjusted from 65 degrees C to 58 degrees C, and the batch qualification rate increased by 12 percentage points - this detail is from the actual measurement on the production line, not laboratory data.

The last point is the balance between cost and cycle. The processing time for a single piece of electrolytic polishing is approximately 45 minutes, while Parylene vapor deposition takes more than 4 hours but can be carried out in batches. For high value-added products like orthopedic devices, the cost of surface treatment usually accounts for 8-15%, which is much lower than the cost of the material itself and precision processing.

The real world beyond standardsCompliance with ISO 10993 is only an admission ticket. High-end medical equipment manufacturers have begun to focus on more microscopic indicators such as surface free energy and protein adsorption. The fine structure of low-pressure casting, after proper surface treatment, can demonstrate advantages in such cutting-edge tests. Data shows that the adsorption capacity of fibronectin on the surface of finely polished titanium castings can be reduced by 60% compared with conventional treatment, which is of great significance for reducing thrombosis.

Another trend is digital process traceability. The surface treatment parameters of each batch - current density, temperature, pH value - are all recorded in the MES system and analyzed in correlation with the casting forming parameters. When clinical adverse events occur in a certain batch of implants, this data chain can help quickly identify the root cause of the problem, whether it is surface treatment or casting defects.

The biocompatible surface treatment of medical castings is essentially walking a tightrope between materials science, clinical medicine and manufacturing engineering. Low-pressure casting provides high-quality billets, but the ultimate clinical value depends on the precise implementation of subsequent surface treatment. Rather than pursuing the latest coating technology, it is more practical for medical device manufacturers to make the mature electrolytic polishing or passivation process extremely stable.

Media Contact

Company Name: Yongkang Hantai Industry & Trade Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=biocompatible-surface-treatment-of-medical-equipment-castings]

Country: China

Website: https://www.htprecisioncast.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Biocompatible surface treatment of medical equipment castings here

News-ID: 4321765 • Views: …

More Releases from ABNewswire

"Flavors Bring Fortune!" Kinghelm and Slkor Successfully Host the 4th Hometown F …

Kinghelm and Slkor successfully held the 4th Hometown Food Festival 2026 at their new Shenzhen headquarters. The event brought together employees to share regional cuisines from across China, strengthening team cohesion and corporate culture. As part of their annual cultural initiatives, the festival reflects both companies' people-oriented management philosophy and their steady growth in the connector and semiconductor industries.

Image: https://www.kinghelm.net/upload/photo/202602/wps43-3.jpg

A glimpse of the 2026 "4th Hometown Food Festival" by Kinghelm…

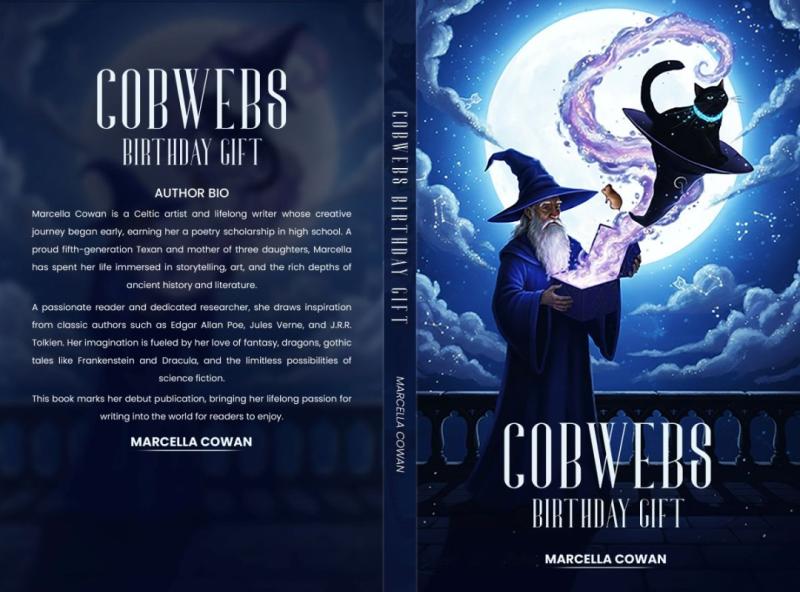

Marcella Cowan Releases Heartwarming Tale of a Witch's Cat Who Journeys Through …

Marcella Cowan [https://www.marcellacowan.com/], a famous storyteller, announces her newest children's book, Cobwebs [https://www.marcellacowan.com/], which tells a delightful story about a curious main character. The new manuscript explores loyalty between characters who misunderstand pet love against a backdrop of mountain streams and castle towers. Cowan creates her story by combining authentic themes with gentle magical elements that readers will experience throughout her work.

Image: https://www.abnewswire.com/upload/2026/03/4db5363e1fdde1d5b67ced3677bafce4.jpg

A Whiskered Hero's Grand Adventure

The story follows Cobwebs,…

Cobwebs the Cat Embarks on Magical Quest in New Children's Book About Friendship …

Author Marcella Cowan [https://www.marcellacowan.com/]presents a new story that explores love and curiosity through small actions that demonstrate affection. Her latest children's book follows Cobwebs [https://www.marcellacowan.com/], a black cat who lives quietly with a little old witch in a forest home shaped by warmth and routine. Cobwebs decides to abandon his entire life when he discovers he has an upcoming birthday, because he needs to find a present that can convey…

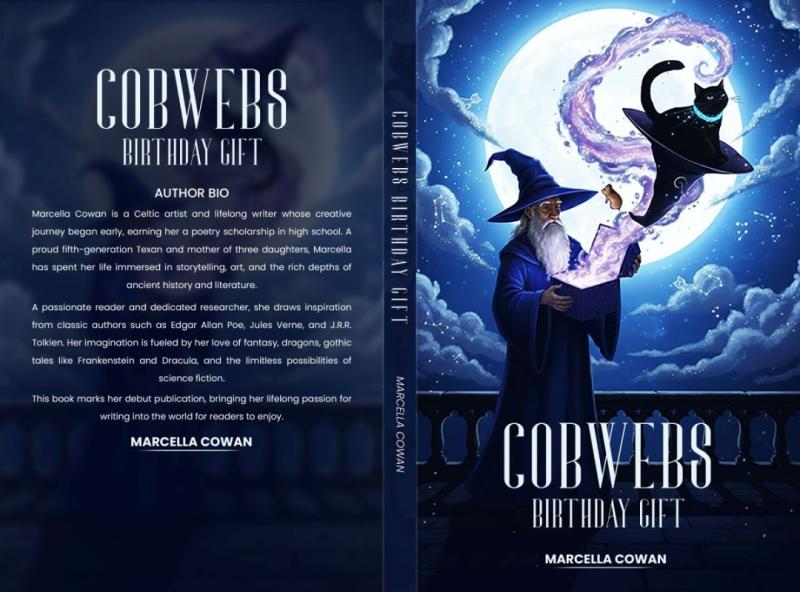

New Fantasy Novel Benjamin's Journey by Elisha Berry Takes Readers on an Inspiri …

Rising author Elisha Berry [https://www.amazon.com/dp/B0FXNF8QN2] proudly declares the arrival of Benjamin's Journey, a creative and passionate fantasy adventure that examines the age-old struggle between good and evil in the pages of a young prince with far more in store than kingdom privilege. Rich in moral instruction, spiritual maturity, and emotional understanding, Berry's first book gently challenges all ages to once again experience courage, forgiveness, and the timeless strength of faith.

Image:…

More Releases for ISO

Integrated Management System (IMS) Lead Auditor Training: Master ISO 9001, ISO 1 …

SIS Certifications Announces Comprehensive Integrated Management System Lead Auditor Training

SIS Certifications announced its upcoming Integrated Management System (IMS) Lead Auditor Training program, designed to help professionals master the three most important ISO standards: ISO 9001:2015 (Quality Management System), ISO 14001:2015 (Environmental Management System), and ISO 45001:2018 (Occupational Health and Safety Management System).

Know about Training - https://www.siscertifications.com/iso-training/

The six-day intensive training offers a flexible hybrid format, with both remote and onsite attendance…

ISO Document Control Required by ISO 9001:2015

Image: https://www.getnews.info/uploads/1733971370.jpg

The website for Endeavour Technical Limited provides dozens of manuals, descriptions, templates, and explanations for businesses striving to comply with ISO 9001. The procedures for document control are spelled out.

Endeavour Technical Limited is pleased to announce that the procedures, templates, and explanations for ISO document control [https://www.iso-9001-checklist.co.uk/7.5.3-control-of-documented-information-explained.htm] are available for businesses of all sizes. ISO requires businesses to organize and collect necessary information about various processes. The information…

NanoMatriX Technologies Receives ISO 27001, ISO 27701, ISO 27017, and ISO 27018 …

Hong Kong, February 4, 2024 - NanoMatriX Technologies Limited, a leading provider of secure document and product protection, authentication, and traceability solutions, proudly announces its achievement of ISO 27001:2022, ISO 27701:2019, ISO 27017:2015, and ISO 27018:2019 certifications from TUV SUD. This accomplishment reinforces NanoMatriX's commitment to delivering cyber-secure and data-protected solutions to its diverse clientele across 50+ countries.

These globally recognized certifications emphasize NanoMatriX's adherence to the highest information security, cybersecurity,…

Layer3 achieves ISO 27001 and ISO 27017 Certifications

Layer3, an industry leader in cloud, scalable and secure networks, has achieved the much-in-demand ISO/IEC 27001:2013 and ISO/IEC 27017:2015 certifications.

ISO/IEC 27001:2013 is the most widely used information security standard, prepared and published by the International Organization for Standardization (ISO), the world’s largest developer of voluntary international standards. It is a globally recognized standard mandating numerous controls for the establishment, maintenance, and certification of an information security management system (ISMS). The…

ISO Certification Market Report 2018: Segmentation by Type (ISO 9001:2015, ISO 2 …

Global ISO Certification market research report provides company profile for The British Standards Institution, CERTIFICATION EUROPE, NQA, Lakshy Management Consultant, URS Holdings, Bureau Veritas, DNV GL AS (International Standards Certifications Global FZ), SGS, Lloyd's Register Group Services, Intertek and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume,…

ISO 27001/ISO 27002 Consultancy,ISO 27000,ISO 27000 Consultancy,Information Secu …

Coralesecure is a Information Security Management System (ISMS) – ISO 27001 Compliance. ISO 27000 Consultancy deals with maintaining the integrity and availability of organizational information and knowledge. Information Security Management System provides the experts on business management, and information security support and properly engages in executive communications Data loss, whether through cyber attacks or other forms of malicious intent can quickly bring an organization to its knees? The protection of…