Press release

Set Up a Talc Manufacturing Plant: Machinery Requirements, Production Cost & Revenue Potential

Talc Manufacturing Plant Project ReportA Talc Manufacturing Plant focuses on the extraction, processing, and micronization of talc ore into high-purity talc powder used across cosmetics, pharmaceuticals, plastics, paints & coatings, ceramics, rubber, paper, and construction industries. Talc is valued for its softness, chemical inertness, heat resistance, whiteness, and excellent lubricating properties. Due to its wide industrial usage and consistent global demand, setting up a talc manufacturing plant offers strong commercial potential and long-term growth opportunities.

Rising demand from personal care products, polymer compounding, ceramic manufacturing, and industrial fillers continues to drive the talc market. Establishing a talc processing unit enables entrepreneurs and investors to enter a stable mineral-processing business with diversified end-use markets.

Request a Sample Report: https://www.imarcgroup.com/talc-manufacturing-plant-project-report/requestsample

IMARC Group's Report Overview

IMARC Group's report titled "Talc Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive roadmap for establishing a talc manufacturing facility. The report covers market analysis, raw material sourcing, processing technologies, plant layout, machinery selection, utilities, manpower planning, environmental compliance, packaging, transportation, and financial projections.

This detailed project report helps stakeholders evaluate talc manufacturing plant setup costs, machinery investment, operating expenses, production economics, and profitability benchmarks.

Talc Industry Outlook 2025

By 2025, the talc industry is expected to experience steady growth driven by expanding cosmetic and pharmaceutical sectors, increased use in plastics and automotive components, and rising demand for specialty fillers. Growth in construction materials, ceramics, and paints further supports market expansion. Technological advancements in micronization and surface-treated talc grades are enhancing product quality and widening application scope.

Key Insights for Talc Manufacturing Plant Setup

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Manufacturing Process Overview

Talc manufacturing generally involves the following steps:

• Talc ore mining or procurement

• Crushing and primary grinding

• Beneficiation (if required)

• Fine grinding and micronization

• Classification and particle size control

• Surface treatment (optional, application-specific)

• Quality inspection and testing

• Packaging and storage

Careful control of particle size, brightness, purity, and moisture content is essential to meet industry-specific requirements.

Project Details, Requirements and Costs Involved

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis

Project Economics

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Components of a Talc Manufacturing Plant

Raw Materials

• Talc ore

• Processing chemicals (if beneficiation is required)

• Packaging materials (bags, jumbo bags)

Machinery

• Crushers and feeders

• Grinding mills (raymond mill, ball mill, jet mill)

• Air classifiers

• Micronizers

• Dust collection systems

• Conveyors and material handling equipment

• Storage silos

• Packaging and bagging machines

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=18091&flag=C

Key Cost Components of Setting Up a Talc Manufacturing Plant

• Land & Site Development: Land acquisition/lease, leveling, infrastructure

• Plant Construction: Processing sheds, grinding units, warehouses, offices

• Machinery & Equipment: Crushers, mills, classifiers, dust collectors

• Raw Materials: Talc ore procurement and consumables

• Utilities & Power Systems: Electricity, compressed air, dust suppression

• Environmental & Safety Systems: Dust control, PPE, emission management

• Quality Control Setup: Particle size analysis, brightness and purity testing

• Packaging & Storage: Bags, pallets, storage silos

• Labor & Workforce: Operators, technicians, supervisors, QC staff

• Transportation & Logistics: Ore sourcing and finished product distribution

• Licensing & Regulatory Compliance: Mining, environmental, factory approvals

• Maintenance & Spares: Wear parts, servicing, and repairs

• Working Capital & Contingency: Inventory and operational buffer

Economic Trends Influencing Talc Plant Setup Costs 2025

• Fluctuations in talc ore prices

• Rising electricity and energy costs

• Increased investment in dust control systems

• Stricter occupational health and safety regulations

• Labor cost inflation

• Transportation and logistics cost volatility

• Growing demand for high-purity and micronized grades

• Export market dynamics and compliance costs

Challenges and Considerations for Investors

• Variability in talc ore quality

• Dust management and worker safety

• High energy consumption in fine grinding

• Regulatory scrutiny for mining and processing

• Competition from substitute fillers

• Need for consistent quality control

• Capital investment in micronization technology

• Market price competition in commodity grades

Buy Now: https://www.imarcgroup.com/checkout?id=18091&method=2142

Conclusion

Setting up a Talc Manufacturing Plant offers strong growth potential due to diversified industrial demand and expanding application areas. However, success depends on consistent raw material quality, efficient grinding and classification systems, strict dust control, and compliance with environmental and occupational safety regulations. Strategic location selection, adoption of advanced micronization technology, and targeted market positioning are essential for achieving operational efficiency and long-term profitability in the talc processing industry.

About Us

IMARC Group is a global management consulting firm that helps organizations identify opportunities, mitigate risks, and implement impactful growth strategies. Our services include market research, feasibility studies, company incorporation, factory setup support, regulatory approvals, branding, marketing strategies, competitive benchmarking, pricing analysis, and procurement research.

Contact Us

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Set Up a Talc Manufacturing Plant: Machinery Requirements, Production Cost & Revenue Potential here

News-ID: 4320009 • Views: …

More Releases from IMARC Group

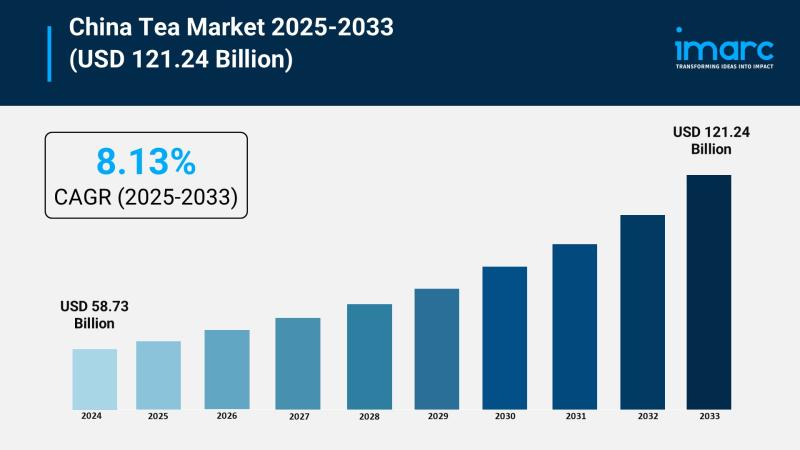

China Tea Market Forecast CAGR of 8.13%, Innovation Trends, and Strategic Insigh …

Market Overview

The China tea market was valued at USD 58.73 Billion in 2024 and is projected to reach USD 121.24 Billion by 2033, growing at a CAGR of 8.13% during 2025-2033. Growth is driven by rising health consciousness, premium product trends, government support, and expanding online retail. Innovation in flavors and packaging attracts younger consumers and global buyers, expanding the market.

Study Assumption Years

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period: 2025-2033

China Tea…

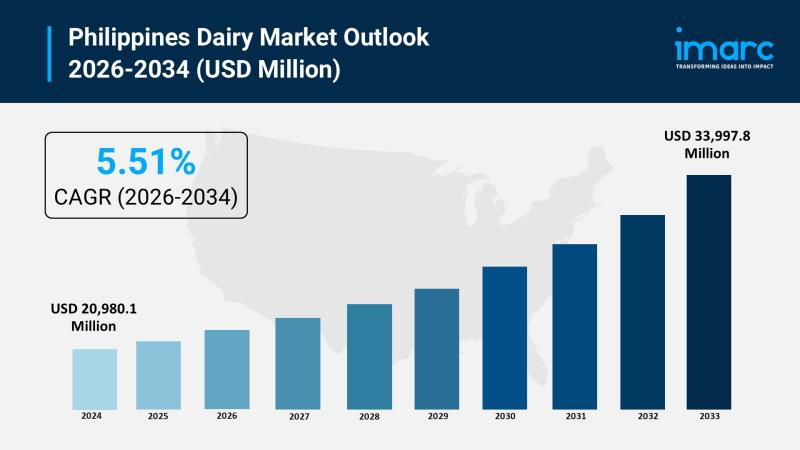

Philippines Dairy Market 2026: Expected to Reach USD 33,997.8 Million by 2034

Market Overview

The Philippines dairy market reached a size of USD 20,980.1 Million and is anticipated to grow to USD 33,997.8 Million by 2034 with a significant growth rate of 5.51%. This expansion is driven by rising demand for nutritious and diverse dairy products, rapid urbanization, increased disposable incomes, improved retail infrastructure, and strong government initiatives promoting local dairy production. Health-conscious consumers and expanding food service sectors further fuel this growth…

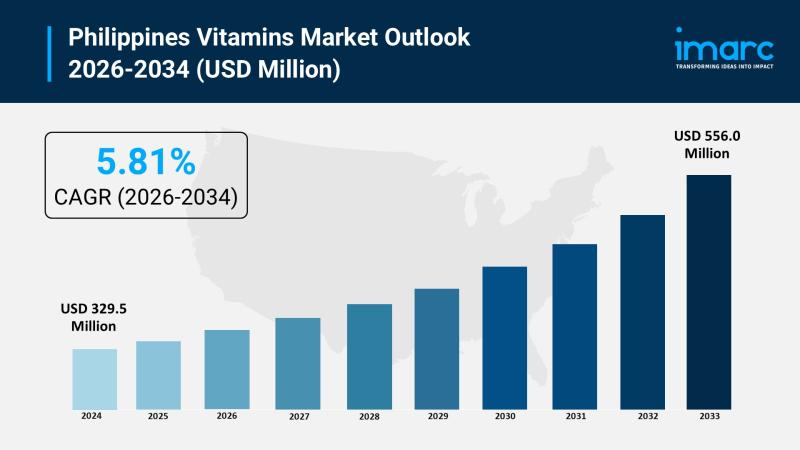

Philippines Vitamins Market 2026 | Projected to Reach USD 556.0 Million by 2034

Market Overview

The Philippines vitamins market was valued at USD 329.5 Million in 2025 and is projected to reach USD 556.0 Million by 2034, growing steadily over the forecast period. The market's growth is driven by increasing health consciousness, a rising geriatric population, and escalating demand for supplements that support immunity, energy, and overall wellness due to proactive health measures. The forecast period for this expansion is 2026-2034, with a CAGR…

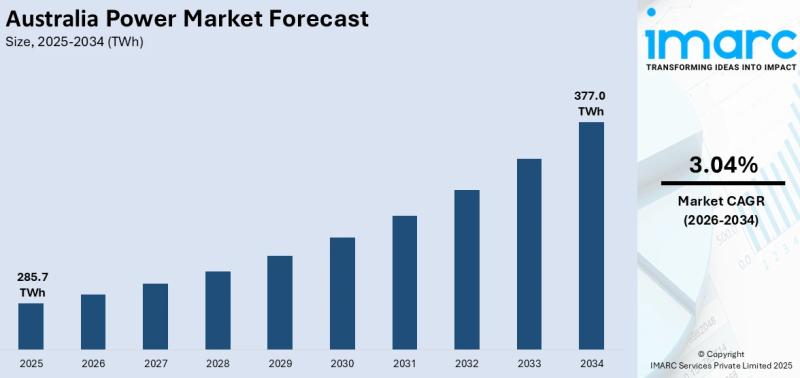

Australia Power Market Projected to Reach TWH 377 by 2034

Market Overview

The Australia power market size reached 285.7 TWh in 2025 and is projected to grow to 377.0 TWh by 2034, with a CAGR of 3.04% during the forecast period of 2026-2034. This growth is driven by rising renewable energy adoption, increased electricity demand, grid modernization, battery storage expansion, transition from coal plants, and government incentives for clean power. Key strategies such as virtual power plant integration and investments in…

More Releases for Talc

Talc Market Analysis By Top Keyplayers - Imerys, Nippon Talc, Liaoning Aihai Tal …

The "Talc Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Talc Market, 2024-2031

Verified Market Research's most recent report, "Talc Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," provides an in-depth examination of the…

Talc Market Size: Segmented By Application, Geography Trends, Growth & Forecasts …

Global "Talc Market" Research report is an in-depth study of the market Analysis. Along with the most recent patterns and figures that uncovers a wide examination of the market offer. This report provides exhaustive coverage on geographical segmentation, latest demand scope, growth rate analysis with industry revenue and CAGR status. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the…

Talc Market to Witness Growth Acceleration by: Imerys talc, Mondo Minerals, Golc …

Talc is a mineral composed of hydrated magnesium silicate and is an important industrial and commercial mineral. It has broad applications as an industrial mineral due to its resistance to heat, electricity and acids and oil and grease adsorption. Talc has extensive commercial use because of its luster, softness, purity, fragrance retention, softness and whiteness. It is the softest known mineral and has a rating of 1 on the Mohs…

Talc Market (Talc Carbonate, Talc Chlorite) - Global Forecast to 2023

The global talc market is projected to grow from an estimated USD 2.68 billion in 2018 to USD 3.35 billion by 2023, at a CAGR of 4.6% from 2018 to 2023. Growth of the market can be attributed to the rising demand for talc-reinforced polypropylene from the automotive industry, as automotive components made from talc-reinforced polypropylene reduce the weight of vehicles.

Get Free Market Updates Now at https://www.reportsnreports.com/contacts/requestsample.aspx?name=684714.

Lawsuits related…

Global Cosmetic Grade Talc Powder Market 201- Hayashi-Kasei, Beihai Group, Liaon …

The Cosmetic Grade Talc Powder Market 2017 examines the performance of the Cosmetic Grade Talc Powder market, enclosing an in-depth judgment of the Cosmetic Grade Talc Powder market state and the competitive landscape globally. This report analyzes the potential of Cosmetic Grade Talc Powder market in the present as well as the future prospects from various angles in detail.

The Global Cosmetic Grade Talc Powder Market 2017 report includes Cosmetic Grade…

Super Fine Talc Powder Sales Market - Magnesita, Beihai Group, Guangxi Longguang …

In depth analysis of Super Fine Talc Powder Sales Market is a professional research report.The review has been based on the report titled, " Super Fine Talc Powder Sales Market 2016 - 2020."

Read Complete Report @ http://www.marketresearchstore.com/report/global-super-fine-talc-powder-sales-market-report-89827

To begin with, the report elaborates the Super Fine Talc Powder Sales Market Various definitions and classification of the industry, applications of the industry and chain structure are given. Present day status…