Press release

Planning a Calcium Perchlorate Manufacturing Plant? Explore Investment Cost, Process & ROI Outlook

Calcium Perchlorate Production Cost Analysis ReportCalcium perchlorate is a high-performance inorganic salt widely used as a strong oxidizer and desiccant across specialty chemical applications. It finds demand in areas such as chemical synthesis, laboratory reagents, pyrotechnic/ignition formulations (regulated), specialty oxidizing systems, and moisture control/desiccant applications where high hygroscopicity and stable perchlorate chemistry are required.

Setting up a calcium perchlorate production unit can be commercially attractive due to its niche, high-value end-use demand and recurring industrial consumption. However, the project requires careful planning around raw material sourcing, strict safety protocols, oxidation risk management, environmental compliance, and cost optimization. This Production Cost Analysis Report provides a structured view of cost drivers, process requirements, utilities, manpower, and feasibility considerations.

Request for Production Cost Analysis Report: https://www.imarcgroup.com/calcium-perchlorate-manufacturing-plant-project-report/requestsample

Understanding Calcium Perchlorate and Its Importance

Calcium perchlorate is typically supplied in anhydrous or hydrated forms and is known for:

• Strong oxidizing behavior (requires controlled handling and regulated storage)

• High hygroscopicity (effective drying/desiccant applications)

• Use as a specialty chemical intermediate in certain synthesis routes

• High purity requirements for research and electronics-grade applications (where relevant)

Because it is an oxidizer, production and storage require robust safety systems, segregation from combustible materials, and compliance with applicable hazardous chemical regulations.

Raw Material Requirements

Key raw materials depend on the chosen process route and grade (industrial/lab). Typical inputs include:

• Calcium source: calcium carbonate / calcium hydroxide / calcium oxide (process-dependent)

• Perchloric acid (where acid neutralization route is used)

• Process water (for solution preparation and crystallization)

• pH control agents / neutralizing agents (as required)

• Filtration aids (if required)

• Packaging materials: HDPE drums, fiber drums, liners, labels (hazard compliant)

Raw material purity significantly affects final product quality and downstream acceptance.

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=24010&flag=C

Production Process Overview

A typical calcium perchlorate production workflow may include:

1. Raw material preparation (calcium base and perchlorate source handling)

2. Reaction / neutralization under controlled temperature and concentration

3. Clarification / filtration to remove insolubles

4. Concentration (evaporation) to reach crystallization strength

5. Crystallization (controlled cooling/evaporation crystallization)

6. Solid-liquid separation (centrifuge/filtration)

7. Drying (as per required hydration level)

8. Milling / screening (if required)

9. Packaging & labeling under hazardous material protocols

Process selection impacts energy use (evaporation/drying), yield, and operating cost.

Machinery Requirements

A calcium perchlorate unit generally requires:

• Reaction vessels (corrosion-resistant materials as needed)

• Agitators and dosing systems (controlled addition)

• Heat exchangers / temperature control systems

• Filtration systems (filter press / cartridge filtration)

• Evaporators (for concentration)

• Crystallizers

• Centrifuges / solid-liquid separation units

• Dryers (vacuum/ tray/ rotary-depending on product spec)

• Storage tanks (raw materials, intermediates, finished product)

• Packing line (drum filling, sealing, labeling)

• Quality control instruments (purity, moisture, assay testing)

• Safety & pollution control systems (scrubbers, ventilation, spill containment)

Equipment selection must prioritize safety, corrosion compatibility, and product purity control.

Infrastructure Needs

Key infrastructure requirements include:

• Segregated hazardous chemical handling zones

• Ventilation and fume management systems

• Fire safety & explosion prevention infrastructure (as applicable)

• Utility block: power, steam, chilled water/cooling, compressed air

• Water treatment and effluent management

• Hazardous storage warehouse (oxidizer compliant, segregation, temperature control as needed)

• Quality control laboratory

• Loading/unloading area designed for safe chemical logistics

Proper plant layout and segregation are critical to regulatory compliance and risk reduction.

Buy Report Now: https://www.imarcgroup.com/checkout?id=24010&method=2142

Production Cost Breakdown

The overall cost of producing calcium perchlorate is influenced by both CapEx and OpEx. Major cost components include:

1) Raw Material Costs

• Calcium source (lime/limestone derivatives)

• Perchlorate source (e.g., perchloric acid route inputs)

• Water, filtration aids, consumables

• Packaging (hazard-compliant drums/liners)

2) Utilities

• Electricity for mixing, pumping, centrifugation

• Steam/thermal energy for evaporation and drying

• Cooling water/chilled utilities for crystallization control

• Water treatment and ETP operating costs

3) Labor & Plant Overheads

• Operators, shift supervisors, EHS personnel

• QC chemists and lab technicians

• Maintenance and engineering support

• Admin, security, plant services

4) Maintenance & Consumables

• Spare parts for pumps, seals, filters

• Corrosion-related replacements

• Calibration and QC consumables

5) Compliance, Safety & Environmental Costs

• Hazardous chemical licensing and inspections

• Safety audits, PPE, training, incident preparedness

• Emission control (scrubbers), effluent treatment

• Storage compliance (oxidizer segregation, labeling, MSDS systems)

This report framework helps estimate per-ton cost, margin sensitivity, and breakeven feasibility based on capacity and grade.

Challenges

Key challenges in calcium perchlorate production include:

• Stringent safety requirements due to oxidizer classification

• Corrosion and material compatibility issues (equipment selection is critical)

• Energy intensity for concentration and drying steps

• Regulatory approvals for hazardous chemical handling and transport

• Raw material price volatility (perchlorate source can be cost-sensitive)

• Quality consistency for high-purity or specialty-grade markets

Strong EHS systems and process control are essential for stable operations and market acceptance.

Growth Opportunities

Market opportunities are supported by:

• Rising demand for specialty oxidizers in regulated industrial segments

• Growth in laboratory, research, and specialty chemical consumption

• Need for high-performance desiccants in niche applications

• Premium pricing potential for high-purity grades and consistent supply contracts

Export opportunities may exist depending on compliance capability, documentation, and packaging standards.

Conclusion

The Calcium Perchlorate Production Cost Analysis Report enables investors and manufacturers to evaluate production economics, understand major cost drivers, and plan a compliant, safe, and efficient facility. While the product offers attractive value due to specialized demand, project success depends on robust safety systems, reliable raw material sourcing, energy optimization, and strict regulatory compliance. With the right technology and operational controls, calcium perchlorate production can be a scalable and profitable specialty chemical venture.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Planning a Calcium Perchlorate Manufacturing Plant? Explore Investment Cost, Process & ROI Outlook here

News-ID: 4319993 • Views: …

More Releases from IMARC Goup

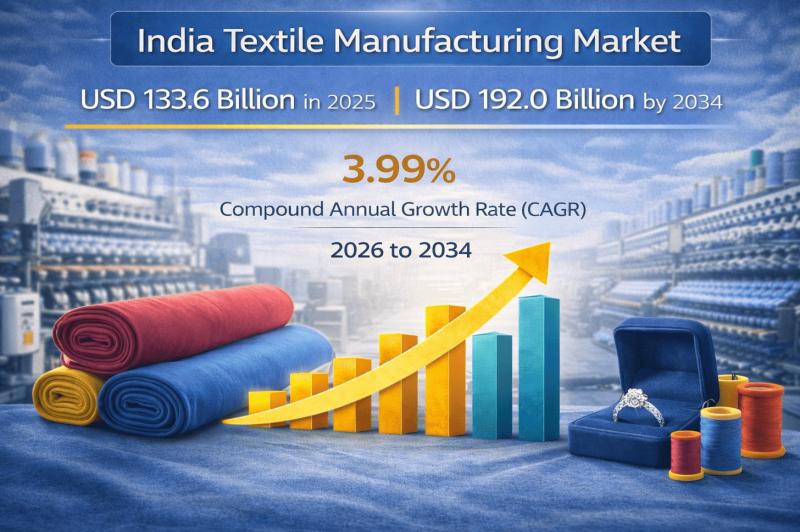

India Textile Manufacturing Market Report 2026-2034: Industry Size, Share, Growt …

According to IMARC Group's report titled "India Textile Manufacturing Market Size, Share, Trends and Forecast by Process Type, Textile Type, Equipment and Machinery, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Textile Manufacturing Market Outlook

The India textile manufacturing market size reached USD 133.6 Billion in 2025. The market is projected to grow at a compounded annual growth rate…

India Whey Protein Market Outlook 2026-2034: Size, Share, Growth, Trends and Ind …

According to IMARC Group's report titled "India Whey Protein Market Size, Share, Trends and Forecast by Product Type, Application, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Whey Protein Market Outlook

The India whey protein market size reached USD 185.9 Million in 2025. The market is projected to grow at a CAGR of 3.27% during the forecast period from…

India Cosmetics Market to Reach USD 25.39 Billion by 2034 Expanding at 5.7% CAGR …

According to IMARC Group's report titled "India Cosmetics Market Size, Share, Trends and Forecast by Product Type, Category, Gender, Distribution Channel, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Cosmetics Market Overview

The India cosmetics market size was valued at USD 15.46 Billion in 2025 and is projected to reach USD 25.39 Billion by 2034, growing at a compound…

India CDMO Market Size, Share, Trends, Growth, Insights and Industry Report 2025 …

According to IMARC Group's report titled "India CDMO Market Size, Share, Trends and Forecast by Service Type, Type, Scale of Operation, Therapeutic Area, and Region, 2025-2033" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Cdmo Market Overview

The India CDMO market size reached USD 7.9 Billion in 2024 and is projected to reach USD 15.4 Billion by 2033, exhibiting a CAGR of…

More Releases for Calcium

Calcium Phosphate Market - Latest Report on the Current Trends and Future Opport …

The New Market Research Report - Calcium Phosphate Market

The analysis tracks the impact of key market dynamics on the major challenges and the strategies adopted by key vendors and market players to overcome the challenges and expand their market presence. The study takes a closer look at the strategies and measures adopted by key stakeholders and investors to boost the development of product; the analysis will be useful in understanding…

Nano Calcium Carbonate Market Segment by Type: Standard Grade Nano Calcium Carbo …

Nano Calcium Carbonate market is segmented by region (country), players, by Type, and by Application. Players, stakeholders, and other participants in the global Nano Calcium Carbonate market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by region (country), by Type and by Application in terms of revenue and forecast for the period 2016-2027.

For…

Calcium Phosphate Market 2019 Analysis By Regional Outlook Competitive Landscape …

LOS ANGELES, United States: The report offers an industry-standard and a highly authentic research study on the global Calcium Phosphate market. With qualitative and quantitative analysis, it throws light on some of the crucial factors contributing to the growth of the global Calcium Phosphate market. As part of a study on market dynamics, it also explains factors affecting the global market growth. The authors of the report have provided a…

Calcium Phosphate Market Report 2018: Segmentation by Product (Mono Calcium Phos …

Global Calcium Phosphate market research report provides company profile for Sichuan Hongda, Jindi Chemical, Yunnan Xinlong, Mianzhu Panlong Mineral, J.R. Simplot Company, Lomon Group, Advance Inorganics, Nitta Gelatin Inc, Raymon Patel Gelatine Pvt. Ltd., Timab, Fosfitalia SpA, Gadot Biochemical Industries and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms…

Calcium Phosphate Market 2018 Size, Shares | Global Industry Revenue by Top Key …

Calcium phosphate is a family of materials and minerals containing calcium ions (Ca2+) together with inorganic phosphate anions. Some so-called calcium phosphates contain oxide and hydroxide as well.

The Asia-Pacific region dominated the market in the historic year 2017 and is expected to grow at the fastest rate among all areas across the world, followed by North America and then Europe.

Global Calcium Phosphate Market research report 2018 and forecast to 2023…

Calcium Supplements Market Report 2018: Segmentation by Type (Calcium Carbonate, …

Global Calcium Supplements market research report provides company profile for Osteoform, Integrative Therapeutics, NutraLab Canada, Caltrate, P. S. Health Care, Chambio, Holland & Barrett, Blackmores, Swisse and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to 2025,…