Press release

Process Piping Market to Grow at 4.33% CAGR by 2035 | Unlock Data-Driven Market Research Future Insights

As per Market Research Future analysis, the process piping market was valued at USD 139.9 billion in 2024 and is forecast to expand from USD 145.96 billion in 2025 to USD 223.06 billion by 2035, registering a CAGR of 4.33% during the forecast period.The process piping market plays a vital role in modern industrial infrastructure, enabling the safe and efficient transportation of liquids, gases, and slurries across complex production environments. Process piping systems are extensively used in industries such as oil and gas, chemicals, power generation, pharmaceuticals, food and beverages, water treatment, and mining. These systems are engineered to handle extreme temperatures, high pressures, corrosive materials, and stringent safety requirements, making them indispensable for continuous and reliable operations.

As global industrialization accelerates and manufacturing processes become more sophisticated, the demand for advanced process piping solutions continues to rise. From refineries and petrochemical plants to power stations and clean energy facilities, process piping ensures operational integrity, regulatory compliance, and long-term efficiency. Growing investments in infrastructure modernization, industrial automation, and energy transition projects are further reinforcing the importance of this market.

In addition, aging industrial assets across developed economies are driving replacement and upgrade activities, while emerging economies are investing heavily in new plants and facilities. This combination of new installations and retrofitting projects is creating sustained demand for high-quality process piping systems worldwide.

Get Free Sample PDF Brochure:

https://www.marketresearchfuture.com/sample_request/30781

Market Drivers

One of the primary drivers of the process piping market is the expansion of the oil and gas industry. Upstream, midstream, and downstream operations rely heavily on complex piping networks to transport hydrocarbons, chemicals, and by-products safely and efficiently. New exploration projects, refinery expansions, and pipeline upgrades are generating consistent demand for robust process piping solutions.

The rapid growth of the chemical and petrochemical industries is another significant driver. These sectors require specialized piping materials capable of handling corrosive and hazardous substances under high pressure and temperature conditions. Increasing production of specialty chemicals, polymers, and industrial gases is directly contributing to market growth.

Power generation is also a key demand contributor. Thermal power plants, nuclear facilities, and renewable energy projects such as biomass and geothermal plants depend on process piping for steam, water, and fuel handling. As countries invest in energy security and cleaner power generation, piping systems designed for efficiency and durability are becoming increasingly important.

Industrial water and wastewater treatment projects are further accelerating market demand. Growing urbanization, stricter environmental regulations, and water scarcity concerns are prompting governments and industries to invest in advanced treatment facilities, all of which require extensive piping networks.

Additionally, the pharmaceutical and food and beverage industries are driving demand for hygienic and precision-engineered piping systems. Compliance with strict quality, safety, and sanitation standards has increased the adoption of stainless steel and high-purity piping solutions, supporting overall market expansion.

Buy Now Premium Research Report:

https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=30781

Technology Advancement

Technological advancements are transforming the process piping market by improving performance, safety, and lifecycle efficiency. One of the most notable developments is the increasing use of advanced materials. High-performance alloys, composite materials, and corrosion-resistant coatings are being widely adopted to enhance durability and reduce maintenance costs in harsh operating environments.

Prefabrication and modular piping systems are gaining traction across industries. By manufacturing piping components off-site under controlled conditions, companies can significantly reduce installation time, labor costs, and on-site safety risks. Modular construction also improves quality control and project predictability, making it an attractive option for large-scale industrial projects.

Digitalization is another key area of advancement. The integration of smart sensors, monitoring systems, and industrial Internet of Things (IIoT) technologies allows real-time tracking of pressure, temperature, flow rates, and potential leak points. Predictive maintenance enabled by data analytics helps prevent failures, minimize downtime, and extend the service life of piping systems.

Advanced welding and joining technologies are also enhancing system reliability. Automated welding, laser welding, and improved inspection techniques such as ultrasonic and radiographic testing ensure higher joint integrity and compliance with international standards. These technologies are particularly critical in high-pressure and safety-sensitive applications.

Sustainability-focused innovation is increasingly shaping the market. Manufacturers are developing piping solutions that support energy efficiency, reduced material usage, and recyclability. Compliance with environmental regulations and corporate sustainability goals is encouraging the adoption of eco-friendly materials and optimized system designs.

Browse In-depth Market Research Report:

https://www.marketresearchfuture.com/reports/process-piping-market-30781

Regional Analysis

Regionally, the process piping market shows diverse growth patterns influenced by industrial activity, infrastructure investment, and regulatory frameworks. North America holds a significant share of the market due to its well-established oil and gas sector, chemical manufacturing base, and ongoing investments in industrial modernization. Aging infrastructure replacement and the adoption of advanced piping technologies continue to support steady demand in the region.

Europe represents another major market, driven by strong chemical, pharmaceutical, and power generation industries. Stringent environmental and safety regulations in the region are encouraging the use of high-quality, compliant piping systems. Additionally, investments in energy transition projects, including hydrogen and renewable energy infrastructure, are creating new opportunities for process piping solutions.

Asia-Pacific is expected to witness the fastest growth in the process piping market. Rapid industrialization, urban expansion, and large-scale infrastructure development in countries such as China, India, and Southeast Asian nations are fueling demand. The region's expanding manufacturing base, coupled with increasing investments in power generation, water treatment, and petrochemicals, is driving significant market expansion.

The Middle East and Africa region is strongly influenced by oil and gas investments. Large refinery projects, petrochemical complexes, and energy infrastructure developments are sustaining high demand for process piping systems designed to operate under extreme conditions. Water desalination and treatment projects also contribute to market growth in this region.

Latin America is gradually emerging as a growth market, supported by mining, oil and gas, and power sector developments. While economic fluctuations can impact investment cycles, long-term infrastructure needs continue to create opportunities for process piping suppliers.

Overall, the process piping market remains a fundamental component of global industrial development. Supported by industrial expansion, technological innovation, and infrastructure modernization, the market is set to experience sustained growth. As industries prioritize efficiency, safety, and sustainability, advanced process piping solutions will continue to play a crucial role in supporting complex and demanding industrial operations worldwide.

More Trending Reports on Drilling Intervention and Completion by Market Research Future

Drill Pipe Market https://www.marketresearchfuture.com/reports/drill-pipe-market-3154

Pipeline Integrity Market https://www.marketresearchfuture.com/reports/pipeline-integrity-market-8067

Pipeline Monitoring System Market https://www.marketresearchfuture.com/reports/pipeline-monitoring-system-market-4141

Oil and Gas Pipeline Market https://www.marketresearchfuture.com/reports/oil-gas-pipeline-market-7681

Pipe Laying Vessels Market https://www.marketresearchfuture.com/reports/pipe-laying-vessel-market-8096

Virtual Pipelines Market https://www.marketresearchfuture.com/reports/virtual-pipelines-market-6178

Cutting Pipe and Perforating Pipe Drilling Tools Market https://www.marketresearchfuture.com/reports/cutting-pipe-perforating-pipe-drilling-tools-market-9542

About Market Research Future:

Market Research Future® (Part of WantStats Research and Media Pvt. Ltd.) has specialized research analysts in the areas of Aerospace & Defense, Automotive, C&M, Energy & Power, F&B, Healthcare & Pharmaceutical, ICT, Industrial Equipment, Packaging Construction & Mining and Semiconductor. Market Research Future (MRFR) is a global market research company that takes pride in its services, offering a complete and accurate analysis with regard to diverse markets and consumers worldwide. MRFR's approach combines the proprietary information with various data sources to give an extensive understanding to the client about the latest key developments, expected events and about what action to take based on these aspects.

Contact

Market Research Future (Part of Wantstats Research and Media Private Limited)

99 Hudson Street, 5Th Floor

New York, NY 10013

United States of America

+1 628 258 0071 (US)

+44 2035 002 764 (UK)

Email: sales@marketresearchfuture

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Process Piping Market to Grow at 4.33% CAGR by 2035 | Unlock Data-Driven Market Research Future Insights here

News-ID: 4319077 • Views: …

More Releases from MRFR

Thorium Industry Projected to Achieve 7.3% CAGR Amid Nuclear Energy Advancements

The global thorium market is gaining renewed attention as countries explore alternative nuclear fuel cycles to support long-term clean energy goals. According to insights from Market Research Future, the thorium market was valued at approximately USD 0.9147 billion in 2024 and is expected to increase to around USD 0.9817 billion in 2025. Over the forecast horizon, the industry is projected to reach nearly USD 1.99 billion by 2035, reflecting a…

Behind-the-Meter (BTM) Industry to Expand at a Robust 44.5% CAGR by 2035

The global behind-the-meter (BTM) market is witnessing transformative growth as energy consumers increasingly seek greater control, resilience, and cost efficiency in electricity usage. According to insights from Market Research Future, the BTM market was valued at approximately USD 375.45 billion in 2024 and is expected to expand to around USD 542.79 billion in 2025. Over the long term, the industry outlook is extraordinary, with the market projected to reach nearly…

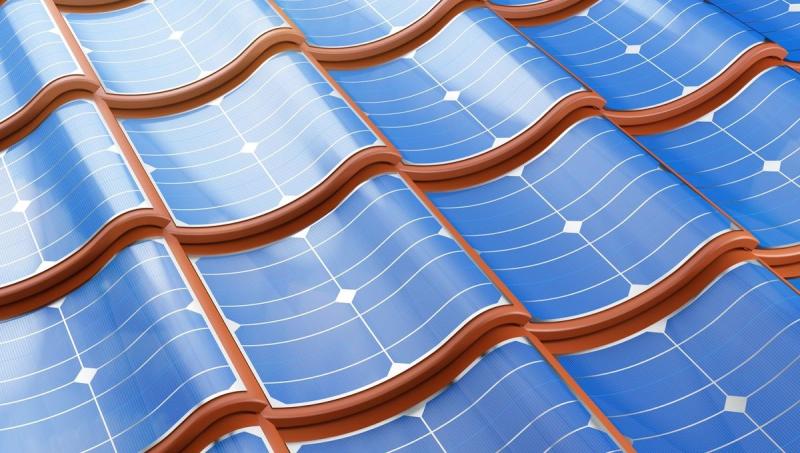

Flexible Solar Panel Industry to Witness Rapid 25.65% CAGR Growth Through 2035

The global flexible solar panel market is entering a phase of rapid expansion as demand rises for lightweight, adaptable, and efficient renewable energy solutions. According to insights from Market Research Future, the market was valued at approximately USD 9.443 billion in 2024 and is expected to increase to around USD 11.87 billion in 2025. Over the long term, the industry outlook is highly optimistic, with the market projected to surge…

Hot Briquetted Iron Industry Set to Grow at 8.3% CAGR Driven by Low-Carbon Steel …

The global Hot Briquetted Iron (HBI) market is witnessing strong expansion as steel producers increasingly shift toward cleaner and more efficient raw materials. According to Market Research Future insights, the market was valued at approximately USD 94.06 billion in 2024 and is expected to reach around USD 101.95 billion in 2025. Over the longer term, the industry is projected to grow substantially, reaching nearly USD 228.23 billion by 2035. This…

More Releases for Pipe

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Comparison of ERW Welded Pipe and Seamless Steel Pipe (tested by PetroChina Pipe …

1. Outer diameter tolerance

ERW steel pipe: It is cold-formed and sizing is completed by reducing the diameter by 0.6%. The process temperature is basically constant at room temperature. Therefore, the outer diameter is controlled accurately and the fluctuation range is small, which is helpful to eliminate black leather buckles.

Seamless steel tube: The hot-rolling forming process is used, and its sizing is completed at about 8000C. The raw material composition, cooling…

HDPE Pipes Market Current Trends and Detailed Study with Forecast to 2028 | Oil …

Global HDPE Pipes Market: Overview

The application of high density polyethylene (HDPE) pipes has increased in industry like chemical, electronics, and gas distribution. As a result of this extensive application, the global HDPE pipes market is witnessing a substantial growth in the forecast period of 2018 to 2028. Moreover, the growing demand for HDPE pipes in drainage and sewerage industry is another factor that is responsible for the growth of…

Global HDPE 100 Pipe Market 2017 LESSO, Cangzhou Mingzhu, Junxing Pipe, Ginde Pi …

In this report, the global HDPE 100 Pipe market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Global Market Report HDPE 100 Pipe Market Size, Status and Forecast 2022 provides Market information about Manufacturers, Countries, Type and Application.This HDPE 100 Pipe Industry report also states Company Profile, sales,…

Anti-corrosion Steel Pipe and Coating Steel Pipe

Anti-corrosion steel pipe refers to do anti-corruption treatment for the ordinary steel pipe with special technology, making the steel pipe equipped certain corrosion resistance.Generally used in waterproof, anti-rust, acid and alkali proof, anti-oxidation and so on.Different needs, different inside and outside wall corresponding anti-corrosion measures.Common are: epoxy coal tar anti-corrosion, anti-corrosion epoxy coatings, urethane paint anti-corrosion, IPN8710 water pipeline corrosion protection, non-toxic paint anti corrosion,anti-corrosion polymer coating, steel pipe lining…

Stainless Steel Pipe and Industrial Stainless Steel Pipe

Stainless steel pipe is divided into two series: decorative stainless steel pipe(stainless steel pipe) and industrial stainless steel pipe.

Decorative stainless steel pipe(stainless steel pipe(SS)): usually outside the wall will be bright tube, hence the name of thinking, stainless steel pipe(SS) is used for decorative purposes. Stainless steel pipe(SS) mainly used to decorate, such as railings, staircase handrails, windows, etc., the wall thickness is very thin. As with the industrial stainless…