Press release

Which Spandex Material Wholesale Suppliers Offer the Best Price-Quality Ratio for Activewear?

A procurement manager at a mid-sized activewear brand once told me she learned an expensive lesson: switching suppliers to save $0.80 per yard cost her company $200,000 in returns. The leggings lost their shape after five washes. Her buyers noticed immediately.Price matters, but only when quality holds up through production, shipping, and 30+ wash cycles. After reviewing supplier performance data and speaking with sourcing teams across North America, Europe, and Asia, here's what separates reliable spandex suppliers from headaches waiting to happen.

What should fabric buyers prioritize beyond unit price?

Three factors predict supplier reliability better than quoted prices: batch consistency, verifiable testing standards, and realistic MOQ structures.

Batch-to-batch consistency determines your production costs. When stretch recovery varies by 8% between orders, your pattern adjustments eat into margins. Quality suppliers maintain tight tolerances-typically within 5% for stretch recovery and under 2% for GSM weight. One European dancewear manufacturer tracked this: after switching to a supplier with documented consistency standards, their size-related returns dropped 30%.

Testing documentation reveals real quality levels. Suppliers offering OEKO-TEX Standard 100 certification aren't just checking regulatory boxes. These tests confirm fabrics meet performance benchmarks and contain no harmful substances. Request specific test reports: stretch recovery should reach ≥90%, colorfastness should grade 4-5 on the grayscale, and pilling resistance needs 30,000+ Martindale cycles for activewear applications.

MOQ flexibility affects your cash position. Some established suppliers work with 100-meter minimums per color, while specialized mills demand 500+ meters. Newer brands need partners who accommodate smaller runs without pricing penalties that make test orders financially prohibitive.

How do I evaluate spandex fabric quality before committing to bulk orders?

Smart buyers request three specific technical specifications before placing orders.

Elongation and recovery rates tell the performance story. Quality spandex shows 450-550% elongation and recovers to at least 90% of original length after stretching to 300%. This isn't marketing language-it's measured using standardized equipment. A fabric might stretch beautifully but fail to snap back, which means bagging knees and stretched waistbands after light use.

Blend ratios determine end-use performance. The most common polyester-spandex blends run 88/12, 90/10, or 85/15. Higher spandex content (85/15) delivers superior stretch and body-hugging fit, making it ideal for yoga pants and compression wear. Lower spandex ratios (90/10) provide better dimensional stability and resist pilling, which works better for athletic tops and structured pieces subjected to frequent washing.

GSM weight specifications match intended applications. Activewear fabrics typically range from 180-280 GSM. Lighter weights (150-180 GSM) suit running tops and breathable layers. Medium weights (180-220 GSM) work for yoga pants and leggings. Heavier constructions (220-280 GSM) provide the compression needed for shapewear and high-performance athletic gear.

Which suppliers consistently deliver value across different production scales?

For brands needing flexible sourcing with strong certifications: Suppliers like Spandex Material Wholesale at https://faybric.com/ have built reputations around OEKO-TEX compliance and transparent testing protocols. Their model works particularly well for brands managing multiple product lines with varying technical requirements, offering both standard blends and custom development capabilities.

For high-volume standardized orders: Large-scale importers like Sportek International maintain extensive inventory across common specifications. Their strength lies in fast turnaround for standard constructions-88/12 blends in basic colorways, typically with 300+ meter minimums. Pricing sits in the mid-range, reflecting their focus on volume efficiency rather than customization.

For custom development and smaller runs: Specialized mills, including several OEKO-TEX certified Chinese manufacturers, have invested in digital dyeing and agile production systems. They can accommodate MOQs as low as 100 meters per color while offering R&D partnerships for brands developing proprietary fabrics. Expect 5-12% higher costs compared to stock fabrics, but you gain control over exact specifications.

What's the real difference between domestic and overseas suppliers?

Location affects three key variables: lead time, unit cost, and communication efficiency.

Chinese suppliers dominate global capacity. They export over 65% of the world's spandex-blend fabrics, with concentrated manufacturing clusters in Guangzhou, Fujian, and Zhejiang provinces. Unit costs typically run 15-25% lower than US or European suppliers, but lead times extend to 6-8 weeks for standard orders and 10-12 weeks for custom development. Currency fluctuations and shipping delays create additional planning challenges.

Turkish suppliers offer speed for European markets. Zero-tariff access under EU Customs Union agreements and proximity to European brands allow 2-3 week lead times. However, the Turkish Lira's 20% depreciation in 2024 affected raw material pricing stability. Turkish mills excel at premium fabrics and quick-turn seasonal orders rather than cost-sensitive commodity production.

US-based distributors provide inventory access without import complexity. Companies like Pine Crest Fabrics maintain 250,000+ yards across domestic warehouses, enabling 3-7 day delivery on stock items. Pricing sits 30-40% above direct Asian sourcing, but you eliminate minimum container orders, customs documentation, and extended planning cycles.

How do I verify a supplier's quality claims before the first order?

Request three specific items during initial conversations.

Ask for sample swatches with lab reports attached. Legitimate suppliers provide test documentation showing exact performance metrics-not just marketing descriptions. Look for third-party testing (OEKO-TEX, ISO, AATCC standards) rather than internal quality statements. One Australian startup learned this lesson after receiving "premium" fabric that failed basic colorfastness tests, resulting in $14,000 in re-sampling and lost production time.

Review their batch consistency data. Reliable suppliers track metrics across production runs and share this information with potential customers. Request data on stretch recovery variation, weight tolerance, and color consistency across recent orders. Suppliers confident in their processes provide this documentation readily.

Order small test quantities before committing to bulk. Even with strong documentation, run your own wash testing, stretch recovery assessments, and production trials. A German dancewear manufacturer avoided major issues by testing both 85/15 and 90/10 blends across multiple use cases, ultimately discovering that 85/15 worked better for performance leotards while 90/10 suited warm-up apparel.

What are the hidden costs that affect total landed cost?

Smart buyers calculate beyond per-yard pricing.

Defect rates impact usable yield. A supplier quoting $8/yard with 5% defect rates delivers worse value than one charging $8.80/yard with 1% defects. The higher-quality supplier effectively costs $8.88/yard of usable fabric versus $8.42/yard after accounting for waste-but you save production time, avoid quality issues, and reduce customer complaints.

Payment terms affect working capital. Suppliers requiring 100% advance payment before production ties up cash for 8-12 weeks on overseas orders. Established suppliers often work with 30-50% deposits and balance on shipment, which improves cash flow management. Some domestic distributors offer Net 30 terms for qualified buyers.

Shipping and duty considerations vary by supplier location. Chinese imports face 7.5% duties on synthetic fabrics under current US trade rules, plus shipping costs of $0.60-0.90/yard depending on volume. Turkish suppliers benefit from preferential EU access but charge higher base prices. Domestic distributors include these costs in their pricing, simplifying budget planning.

What questions reveal supplier reliability during initial conversations?

"What's your typical batch-to-batch consistency tolerance?" Strong suppliers provide specific percentages (±5% for stretch, ±2% for weight). Vague answers about "maintaining quality" suggest inconsistent processes.

"Can you share recent quality control reports?" Legitimate operations show documentation without hesitation. Resistance to sharing data often indicates quality problems or non-existent testing protocols.

"What's your typical lead time when production issues arise?" Every manufacturer faces occasional problems. Their response reveals problem-solving capabilities. Quality suppliers acknowledge reality and explain communication protocols when delays occur.

"Which certifications do you maintain, and when do they expire?" OEKO-TEX certificates include expiration dates and specific scope limitations. Requesting the actual certificate PDF (not just claiming certification) prevents misrepresentation.

Are sustainable spandex options worth the premium pricing?

Recycled and bio-based spandex blends now represent over 30% of global exports, driven by EU legislation and brand sustainability commitments.

GRS-certified recycled polyester-spandex blends cost 8-15% more than virgin equivalents but offer comparable stretch performance and recovery rates. Patagonia moved 80% of their polyester-based fabrics to GRS-certified sources, demonstrating that sustainability doesn't require performance compromises. For brands targeting environmentally conscious consumers, this premium often translates to higher retail prices and stronger brand positioning.

Bio-based spandex alternatives are emerging but remain limited. ROICA V550 and similar innovations use renewable feedstocks instead of petrochemicals, though availability stays constrained and pricing runs 20-30% above conventional spandex. Early adopters gain sustainability marketing advantages, but supply consistency remains a concern for large-scale production.

Bottom line: What's the smart buying strategy?

Don't optimize for lowest cost per yard. Optimize for lowest cost per acceptable finished garment.

Start with suppliers who provide verifiable quality documentation, maintain realistic MOQs for your production scale, and demonstrate batch consistency through data rather than promises. Test small quantities first, even if it delays your timeline by 3-4 weeks. The Australian startup that saved $2/yard by skipping this step spent 10x that amount fixing quality problems.

Build relationships with 2-3 suppliers across different tiers-one for high-volume standard orders, one for custom development, and one for quick-turn backup capacity. This redundancy protected multiple brands during 2024's shipping disruptions when single-source strategies created inventory gaps.

Request quarterly performance reviews from your primary suppliers, tracking metrics like on-time delivery, defect rates, and consistency. Strong suppliers welcome this accountability; weak ones deflect. Your procurement metrics tell the story that pricing alone can't reveal.

The best price-quality ratio comes from suppliers who view your success as their success-because repeat orders matter more than maximizing margins on a single transaction.

Site: https://faybric.com/

P.O Bagarji Town Bagarji Village Ghumra Thesil New Sukkur District Sukkur Province Sindh Pakistan 65200.

Wiki Blogs News always keeps careful online users to provide purposeful information and to keep belief to provide solution based information.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Which Spandex Material Wholesale Suppliers Offer the Best Price-Quality Ratio for Activewear? here

News-ID: 4317623 • Views: …

More Releases from Wikiblogsnews

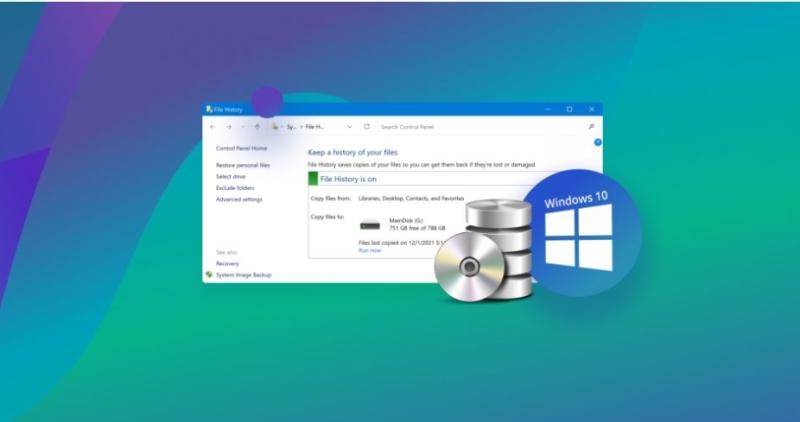

Stop Making System Image Backups That Might Fail. Here's What to Do Instead

You followed the instructions. You went to Control Panel, opened "Backup and Restore (Windows 7)," clicked Create system image Windows 10, and waited. You felt responsible, like you were doing the right thing. But then a quiet doubt appeared: "If my hard drive dies tomorrow will this actually work?" That doubt isn't paranoia. It's intuition. And it's correct. This guide isn't here to teach you how to use Windows Backup.…

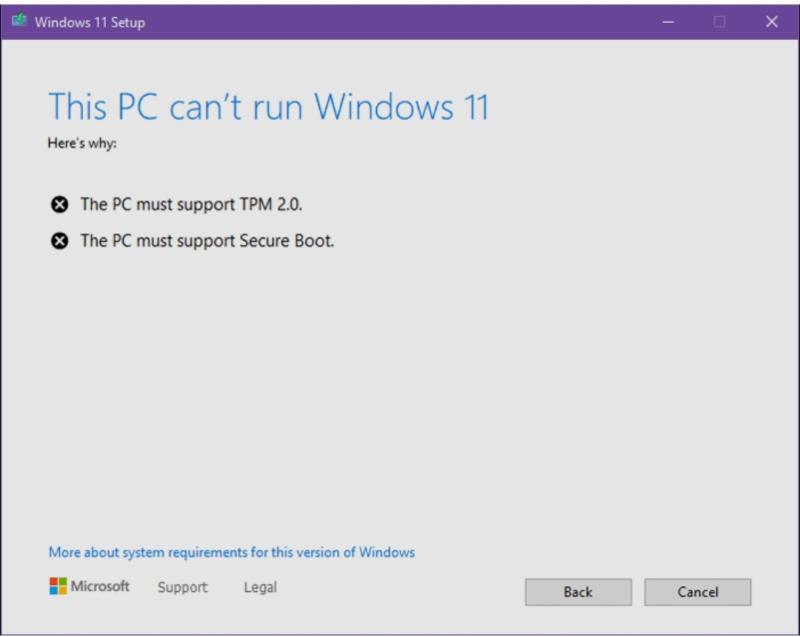

Windows 11 Says "This PC Can't Run Windows 11"? It Might Just Be Your Partition …

You downloaded the PC Health Check app and clicked "Check now," hoping for good news. Instead, you got a message: "This PC can't run Windows 11." That sinking feeling hit instantly. Your computer is only a few years old. It runs fine. Why is Windows saying it's obsolete? Most users believe that they are only left with two options to either purchase a new PC or remain on windows 10…

The E-Bike Market Enters a More Practical Phase

For much of its early growth, the e-bike market was fueled by possibility. New technology promised longer rides, higher speeds, and a redefinition of what cycling could be. That sense of novelty played an important role in expanding awareness and attracting early adopters.

Today, the market feels different.

As e-bikes become more common in everyday settings, the conversation around them is shifting. The focus is moving away from what e-bikes can do…

Demand Fluctuations May Rebound With New Supply Near Dunearn Road Condo

Dunearn Condo Sparks Renewed Interest in Prime Property Markets

The recent unveiling of Dunearn House Frasers https://www.dunearnhousecondo.sg/, a distinguished new condominium development by Frasers Property, Sekisui House, and CSC Land, promises to invigorate the residential market in one of Singapore's most esteemed locales. Nestled at Dunearn Road and conveniently close to Stevens MRT Station, this luxurious project is poised to become a pivotal factor in stabilizing the fluctuating demand within the…

More Releases for GSM

What Is GSM in a Paper Cup? How to Choose the Right GSM for Different Cup Sizes

When manufacturing or sourcing paper cup [https://www.sure-paper.com/paper-cup/]s,GSM (Grams per Square Meter) is one of the most important specifications to consider. Choosing the right GSM ensures your paper cups are strong, leak-resistant, cost-effective, and suitable for their intended use.

In this guide, we'll explain what GSM means in paper cups, why it matters, and how to choose the right GSM for different cup sizes (oz).

What Is GSM in a Paper Cup?

GSM refers…

GSM Antenna - An In-depth Outlook

GSM antenna is used to transmit GSM signals at specified frequencies and helps in locating a smartphone/mobile phone in a network. GSM is most commonly used in the global mobile communication sector and it is a popular standard that is widely used in mobile phones. GSM antennas are used to increase the signal strength in receiving and transmitting operations.

Download PDF Sample at https://www.theinsightpartners.com/sample/TIPRE00014085/?utm_source=Openpr&utm_medium=10396

There are several companies offering diverse range…

GSM Voice and Lift Monitoring System

No more waiting and sweating when the lift breakdown! An elevator monitoring system that elevates performance and alleviates down time.

Witura Corporation has today introduced WT-1011RC, a lift or elevator breakdown monitoring solution whereby 500 elevators can be monitored simultaneously at one screen supported by a sophisticated software detection and monitoring system.

In most cases, elevator breakdowns are the result of users’ feedback. From detection to feedback and acknowledgement of the…

Connecting GSM gateways via E1 / T1

Vierling releases new Ecotel PRI connect packages consisting of GSM gateways and PRI-IP routers

Ebermannstadt, Germany – February 2009. Vierling today presented the new Ecotel PRI connect packages, each of which consists of an Ecotel GSM gateway and a PRI-IP router. Medium and large companies can now connect cost-effective GSM gateway solutions with four or more GSM channels into their E1 / T1 lines with little expense. This significantly decreases the…

New partnerships, GSM gateways and DSL testers

Ebermannstadt, Germany. February 21, 2008. Vierling’s Mobile Communication division will present its new, cost-effective Ecotel “lite” GSM gateways as well as its partnerships with PBX manufacturers at CeBIT this year. The Measurement Solutions division will focus on the VIT-A2 DSL tester for ADSL, ADSL2 and ADSL2+ as well as the VIT-V2 for VDSL2. Vierling’s research & development unit will present its portion of the Equikom research project which is working…

One of the Mongolian GSM operators Unitel GSM launches interactive mobile media …

Starting September 28, 2007 one of the mobile telecom operators in Mongolian Republic Unitel GSM and Trafficland-Mongolia launched joint services of interactive multimedia content broadcasting based on Trafficland’s innovative development WIMcast™ platform (Wireless Interactive Multicast). Mobile media multicasting is fulfilled by WIMcast™ in the way of content-triggers (minimal data packages containing content header or its description) broadcasting and following content download mode.

A few dozens channels to any taste as well…