Press release

EV Battery Manufacturing Business Plan: Cost, Profit and Market Potential

IMARC Group's report, "Electric Vehicle Battery Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The electric vehicle battery manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.What is Electric Vehicle Battery?

An electric vehicle battery is a rechargeable energy storage system that powers an electric vehicle's motor and supports its electrical components. It stores electricity in chemical form and releases it as needed to drive the vehicle. Most EV batteries are made using lithium-ion technology due to their high energy density, long lifespan, and fast charging capability. These batteries are essential for determining an EV's driving range, performance, and safety. As the world moves toward cleaner mobility, EV batteries play a critical role in the transition from traditional fuel-based vehicles to sustainable electric transportation.

Is Electric Vehicle Battery Manufacturing Profitable?

Yes, EV battery manufacturing is highly profitable because global demand for electric vehicles is growing rapidly. Governments are offering strong incentives, automakers are shifting to zero-emission fleets, and consumers prefer cleaner transportation options. EV batteries enjoy high market value, long-term contracts, and export potential. With rising investments in gigafactories and improved technology reducing production costs, the industry offers strong profit margins and long-term business stability.

Request for a Sample Report: https://www.imarcgroup.com/electric-vehicle-battery-manufacturing-plant-project-report/requestsample

What is Driving the Electric Vehicle Battery Market?

The electric vehicle battery market is expanding due to rising adoption of electric mobility worldwide, supported by government policies promoting clean energy and reducing carbon emissions. Major automakers are transitioning from internal combustion engines to fully electric models, boosting demand for high-performance batteries. Advancements in lithium-ion and solid-state technologies are making EVs more efficient, affordable, and safer. Growing consumer awareness of environmental sustainability and increasing fuel prices further encourage EV adoption. Additionally, rapid expansion of charging infrastructure and large-scale investments in battery manufacturing plants across Asia, Europe, and the US are accelerating market growth. Together, these factors create massive opportunities for EV battery production companies.

Key Insights Covered in the Electric Vehicle Battery Manufacturing Plant Report

Market Coverage:

• Market Trends: Analysis of current and emerging trends in the electric vehicle battery market.

• Market Segmentation: Breakdown of the market by different segments.

• Regional Analysis: Distribution and performance of the market across various regions.

• Price Analysis: Evaluation of pricing trends for electric vehicle battery.

• Impact of COVID-19: Examination of the effects of the COVID-19 pandemic on the electric vehicle battery market.

• Market Forecast: Outlook and projections for the electric vehicle battery industry.

Key Aspects Required for Setting Up an Electric Vehicle Battery Plant

Detailed Process Flow:

• Product Overview: Comprehensive description of the electric vehicle battery product and its characteristics.

• Unit Operations Involved: Step-by-step breakdown of the various operations in the production process.

• Mass Balance and Raw Material Requirements: Calculations for material inputs and outputs, along with required quantities of raw materials.

• Quality Assurance Criteria: Standards and procedures to ensure the quality of the final product.

• Technical Tests: Essential tests and evaluations to maintain product consistency and compliance.

Project Details, Requirements, and Costs Involved

• Land, Location, and Site Development: Assessment of land requirements, optimal location selection, and site development costs.

• Plant Layout: Design and layout planning for efficient plant operations.

• Machinery Requirements and Costs: Identification of machinery needed, along with the associated costs.

• Raw Material Requirements and Costs: Determination of the types and quantities of raw materials required and their costs.

• Packaging Requirements and Costs: Specifications for packaging materials and equipment, including associated expenses.

• Transportation Requirements and Costs: Logistics planning and cost estimation for the transportation of raw materials and finished products.

• Utility Requirements and Costs: Analysis of utility needs (such as water, electricity, and fuel) and their associated costs.

• Human Resource Requirements and Costs: Workforce planning, including staffing needs, roles, and costs for labor and management.

Project Economics

• Capital Investments: Initial costs required for setting up the electric vehicle battery manufacturing plant, including land, equipment, and infrastructure.

• Operating Costs: Ongoing expenses for running the plant, such as raw materials, labor, utilities, and maintenance.

• Expenditure Projections: Detailed forecasts of all costs over the short and long term.

• Revenue Projections: Expected income generated from the sale of electric vehicle battery and by-products.

• Taxation and Depreciation: Analysis of tax obligations, incentives, and asset depreciation over time.

• Profit Projections: Estimated profitability based on costs, revenues, and market conditions.

• Financial Analysis: Comprehensive evaluation of the plant's financial viability, including cash flow analysis, return on investment (ROI), and break-even point.

CAPEX/OPEX and ROI Analysis for Manufacturing Plant

Key Financial Insights for Investors

• Capital expenditure includes land acquisition, plant construction, advanced battery production machinery, automation systems, and quality-testing equipment.

• Operational expenses involve raw materials such as lithium, nickel, and cobalt, along with labor, power supply, maintenance, and logistics.

• Return on investment depends on production scale, technology efficiency, supply chain integration, and long-term contracts with EV manufacturers.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=22772&flag=C

Customization Options Available:

• Plant Location: Selection of optimal location for the plant.

• Plant Capacity: Customization based on desired production capacity.

• Machinery: Choice between automatic, semi-automatic, or manual machinery.

• List of Machinery Providers: Identification of suitable machinery suppliers.

Key Questions Addressed in This Report:

• What raw materials are needed for EV battery production?

The primary materials include lithium, nickel, cobalt, graphite, separators, electrolytes, and aluminum or copper components used in cell construction.

• How much space is required to set up a battery manufacturing plant?

A medium-scale unit generally needs large industrial space to install production lines, testing areas, storage zones, and safety-controlled environments.

• Which industries create the highest demand for EV batteries?

The automotive sector is the largest consumer, followed by energy storage systems, consumer electronics, and renewable power integration.

• What technology is most used for EV battery manufacturing?

Lithium-ion technology is widely used because it provides high energy density, long cycle life, and reliable performance for electric vehicles.

• What skills are required to operate an EV battery plant?

The workforce needs expertise in chemical engineering, automation, quality testing, safety management, and high-precision manufacturing operations.

Buy Full Report: https://www.imarcgroup.com/checkout?id=22772&method=2142

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

• Plant Setup

• Factory Audit Services

• Regulatory Approvals, and Licensing

• Company Incorporation

• Incubation Services

• Recruitment Services

• Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release EV Battery Manufacturing Business Plan: Cost, Profit and Market Potential here

News-ID: 4309431 • Views: …

More Releases from IMARC Group

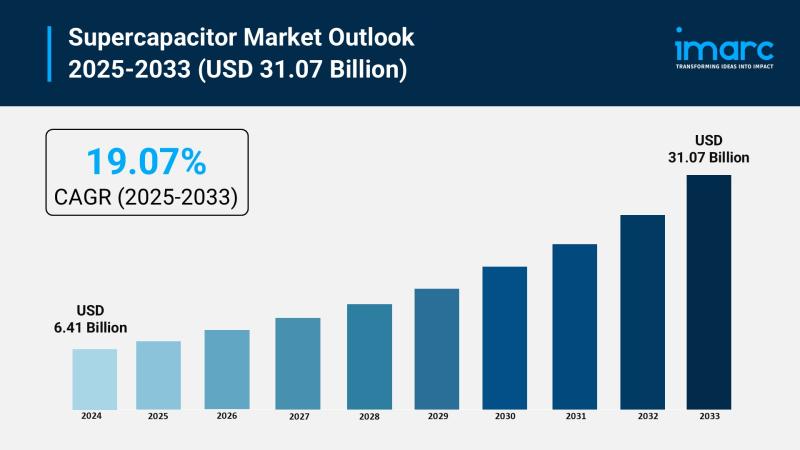

Supercapacitor Market Size to Reach $31.07B by 2033: Trends & Opportunities

Market Overview:

The supercapacitor market is experiencing rapid growth, driven by electrification of automotive systems, renewable energy and grid stabilization, and expansion of industrial automation and robotics. According to IMARC Group's latest research publication, "Supercapacitor Market Size, Share, Trends and Forecast by Product Type, Module Type, Material Type, End Use Industry, and Region, 2025-2033", the global supercapacitor market size was valued at USD 6.41 Billion in 2024. Looking forward, IMARC Group…

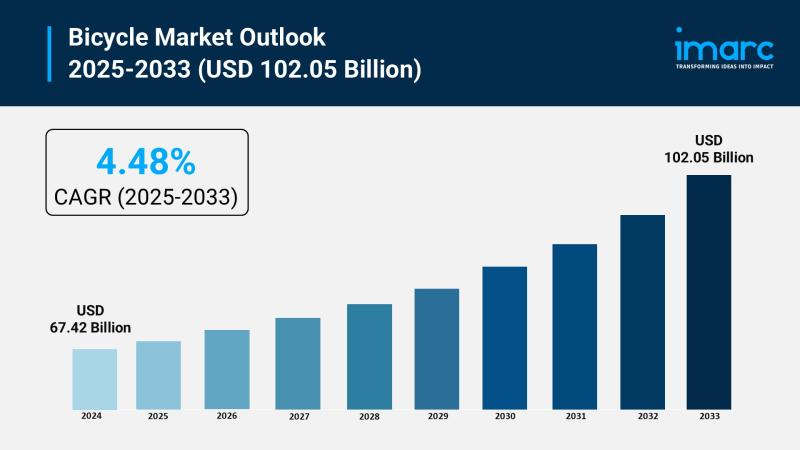

Bicycle Market Size to Surpass $102.05B by 2033: Growth & Insights

Market Overview:

The bicycle market is experiencing rapid growth, driven by global expansion of cycling infrastructure, rising health consciousness and preventative wellness, and technological advancements in e-bike propulsion. According to IMARC Group's latest research publication, "Bicycle Market Size, Share, Trends and Forecast by Type, Technology, Price, Distribution Channel, End User, and Region, 2025-2033", The global bicycle market size was valued at USD 67.42 Billion in 2024. Looking forward, IMARC Group estimates…

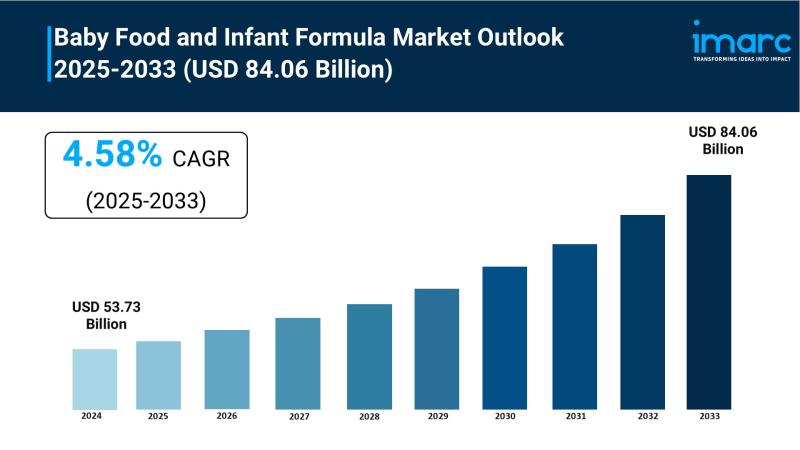

Baby Food and Infant Formula Market to Reach USD 84.06 Billion by 2033, Growing …

Market Overview:

The Baby Food and Infant Formula Market is experiencing steady expansion, driven by Increasing Awareness of Nutritional Needs for Infants, Rising Number of Working Women, and Technological Advancements and Product Innovation. According to IMARC Group's latest research publication, "Baby Food and Infant Formula Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global baby food and infant formula market size reached USD 53.73 Billion in 2024.…

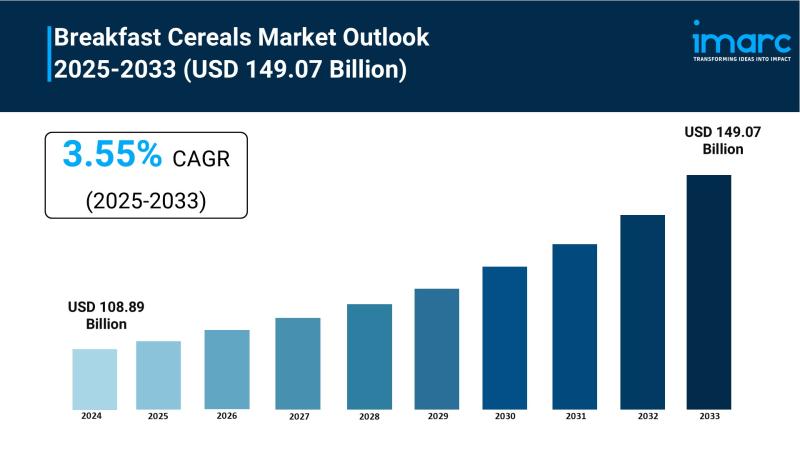

Breakfast Cereals Market to Reach USD 149.07 Billion by 2033, Growing at a CAGR …

Market Overview:

The Breakfast Cereals Market is experiencing rapid growth, driven by Health and Wellness Awareness, Busy Lifestyles and On-the-Go Demand and Rising Disposable Incomes and Global Market Expansion . According to IMARC Group's latest research publication, "Breakfast Cereals Market : Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global breakfast cereals market size was valued at USD 108.89 Billion in 2024. Looking forward, IMARC Group estimates…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…