Press release

Retort Food Technology: A Key Driver of Food Safety and Global Supply Expansion

Retort Food Technology has become a strategic pillar of modern food manufacturing. As global demand continues to rise for shelf-stable foods, export-ready packaging, and convenient nutrition, industrial food processors rely on retort sterilization systems to achieve reliable food safety, extended shelf-life, and efficient distribution without refrigeration. For B2B manufacturers, this technology is not merely a thermal process, but a crucial force supporting international competitiveness and scalable business growth.By investing in retort processing, food companies can expand globally while maintaining high standards in product quality, regulatory compliance, and consumer trust. This article introduces how Retort Food Technology works, its industrial benefits, equipment types, packaging innovations, and future technology trends.

What Is Retort Food Technology [https://www.mfirstpack.com/high-temperature-retortable-pouches-food-packaging-product/] and Why Is It Important?

Retort Food Technology refers to the high-temperature, high-pressure sterilization of packaged foods to eliminate harmful microorganisms and heat-resistant spores such as Clostridium botulinum.Once sterilized, products achieve ambient shelf stability without preservatives, reducing reliance on cold chain logistics and minimizing food waste.

Industries widely adopting Retort Technology include:

- Ready-to-eat (RTE) meals

- Meat and seafood canned foods

- Curries, sauces, and liquid foods

- Infant and elderly nutrition foods

- Plant-based protein meals

- Wet pet food

- Aviation, outdoor, and emergency rations

This technology ensures long-term food safety, supports global distribution performance, and protects brand integrity in environments with strict standards.

How Retort Processing Works in Industrial Production

Retort sterilization uses controlled heat lethality to achieve Commercial Sterility:

*

Pressurizing the retort vessel to ensure uniform heating

*

Raising the product core temperature to 115 degrees C-135 degrees C

*

Holding temperature to destroy harmful microorganisms

*

Cooling under controlled pressure to maintain structural integrity

Because sterilization happens within sealed packaging, there is no risk of re-contamination, enabling long-term safe storage.

Common Industrial Retort System Types

Food processors must select retort systems based on product characteristics and production capacity:

Static Retort

- Suitable for solid foods and texture-sensitive canned products

Rotary Retort

- Enhances heat penetration, ideal for high-viscosity foods like sauces or baby food

Water Spray Retort

- Greater packaging protection and improved energy efficiency

Full Water Immersion Retort

- Suitable for large or heavy packaging formats

Packaging Innovation Enhances Retort Success

Packaging is fundamental to the performance of Retort Food Technology, influencing:

- Flavor and appearance

- Supply chain cost efficiency

- Sustainability performance

- International consumer acceptance

Common retort-grade packaging includes:

- Retort pouches - lightweight, high-barrier, fast sterilization

- Metal cans - durable for global logistics

- CPET/PP trays - microwaveable, foodservice-friendly

- Glass jars - premium product positioning

- Aluminum-reinforced laminate - ideal for high-end products

Among these, retort pouches are rapidly becoming mainstream due to better efficiency and reduced carbon footprint.

Core Business Benefits for B2B Food Supply Chains

Retort Food Technology creates measurable commercial value:

- No cold chain required right lower logistics and energy cost

- Shelf-life of 12-24 months right reduced waste, higher inventory flexibility

- Regulatory compliance right FDA / CFIA / EU Commercial Sterility standards

- Export reliability right withstands climate extremes during shipping

- Sustainability right lower emissions than frozen or refrigerated supply chains

- Product innovation and differentiation right stronger buyer appeal

These advantages significantly improve profitability, market reach, and supply chain resilience.

Expanding Global Market Applications

Retort Food Technology is rapidly expanding into numerous B2B sectors:

- Government procurement for disaster relief and military meals

- Retail private label and OEM/ODM food programs

- Airline, cruise, and hotel food supplies

- Outdoor and camping food brands

- Pet food manufacturing requiring strict hygiene

- Health-oriented and allergen-controlled shelf-stable meals

With consumers emphasizing convenience, retort products are increasingly preferred over frozen alternatives.

Challenges and Future Innovation

Although mature, Retort Technology continues to evolve:

- Optimized heating for better flavor and texture retention

- AI-assisted automation to enhance process precision and energy efficiency

- Recyclable and bio-based retort packaging solutions

- Development of pressure-assisted and microwave-assisted retort systems

- Advanced nutrient retention for premium foods

Future development direction:Sustainability + Smart Automation + Premium Product Positioning

Conclusion

Retort Food Technology is a mission-critical industrial solution enabling:

- Food safety assurance

- Long-distance distribution

- Global food supply stability

For B2B food manufacturers, its adoption means:

- Stronger global competitiveness

- Higher production efficiency

- Broader export market access

- Reduced operational costs

- Greater consumer confidence through proven safety standards

With advanced sterilization systems and modern retort packaging, food processors can deliver safe, shelf-stable, high-quality products that meet global demand.Investing now ensures leadership in the next generation of shelf-stable food innovation.

FAQ

1. What foods are suitable for retort processing?

Ready meals, canned meat, sauces, baby food, plant-based products, and wet pet food.

2. Does retort food require preservatives?

No. Retort sterilization ensures microbial stability without preservatives.

3. How long can retort foods be shelf-stable?

Typically 12-24 months, depending on formulation and packaging structure.

4. What packaging is commonly used?

Retort pouches, metal cans, CPET/PP trays, aluminum-laminated films, and glass jars.

Media Contact

Company Name: YanTai MeiFeng Plastic Products Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=retort-food-technology-a-key-driver-of-food-safety-and-global-supply-expansion]

Phone: +86-18663827016

Address:#8 Baoan Road, YanTai Development Zone

City: Shandong

Country: China

Website: https://www.mfirstpack.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Retort Food Technology: A Key Driver of Food Safety and Global Supply Expansion here

News-ID: 4308031 • Views: …

More Releases from ABNewswire

Velvet vs Chenille: A Comprehensive Comparison

Choosing between velvet and chenille for your furniture can make or break your living space's comfort and style. These two popular upholstery fabrics might both feel soft, but they're completely different in terms of durability, maintenance, and overall vibe.

Chenille gives you that cozy, lived-in comfort that's perfect for Netflix marathons and family gatherings. Velvet delivers luxury and elegance but demands more careful treatment to keep looking its best.

Chenille

Chenille is a…

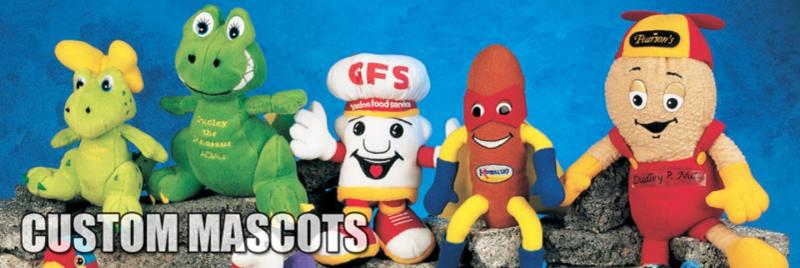

Why Custom Stuffed Animal Mascots? Industry Trends and Best Practices

Why Custom stuffed animal [https://www.yunlinplushtoys.com/stuffed-animal/] Mascots?

In a world where branding and personalization are key to standing out, custom stuffed animal mascots [https://www.yunlinplushtoys.com/manufacturer-forest-animal-tiger-plush-toys-children-birthday-gifts-product/] have emerged as a unique and effective marketing tool. At Yancheng Dafeng Yunlin Arts and Crafts Co. Ltd [https://www.yunlinplushtoys.com/], we specialize in creating high-quality custom plush toysthat not only capture the essence of your brand but also resonate with your audience. Let's explore why custom stuffed animal mascots…

How to Clean Stuffed Animals and Toys

How to Clean stuffed animal [https://www.yunlinplushtoys.com/stuffed-animal/]s and Toys

Cleaning well-loved stuffed animals and toys properly and regularly is essential. Not only is it important for maintaining basic cleanliness, but it also keeps toys in good condition to prolong their lifespan.

Cleaning methods depend on the particular toys-some are machine-washable, others should only be hand-washed, and some can't come into contact with water at all because of features such as musical mechanisms. If…

Introduction to National IV Diesel Generator Sets

MAMO Power Technology Co., Ltd. actively responds to national environmental protection policies by officially launching diesel generator sets [https://www.mamopower.com/products/] that comply with the "National IV" emission standards, driving industry green transformation through technological innovation.

I. Technical Background

With the continuous upgrade of national environmental protection requirements for non-road mobile machinery, the National IV emission standard has been fully implemented recently. This standard imposes stricter limits on pollutants such as nitrogen oxides (NOx)…

More Releases for Retort

Retort Charcoal Market Continues Rapid Growth, Study Reveals Size for Emerging S …

Report Description: -

The information made available in the Retort Charcoal report will definitely facilitate to increase the knowledge and decision-making skills of the business, thus providing an immense opportunity for growth. This will at last increase the return rate and drive the competitive edge within. Being a custom market report, it provides services tailored to the exact challenge. Whether it is survey work, in-depth interviewing, or a combination of multiple…

Retort Packaging Market Specifications, Analysis Forecast Upto 2024

Nearly half of the world’s population now lives in urban parts and their restless lifestyle is leading to radically changed eating habits, wherein packaged food products are preferred for their convenience. From the production facility to the table of consumers, food products need to be packaged in a way that their nutritious values are preserved and retort packaging provides for an adequate mode of increasing shelf-life of the products. With…

Retort Pouches share, Size & Research Report 2016-2021

The 'Global and Chinese Retort Pouches Industry, 2011-2021 Market Research Report' is a professional and in-depth study on the current state of the global Retort Pouches industry with a focus on the Chinese market.

The report provides key statistics on the market status of the Retort Pouches manufacturers and is a valuable source of guidance and direction for companies and individuals interested in the industry.Firstly, the report provides a basic…

Retort Packaging Market: Retort Pouches to Emerge Most Valued Product Variety

Transparency Market Research estimates that the global retort packaging market, which was valued at US$13,026.9 mn in 2015, will register a CAGR of 7.5% over the period between 2016 and 2024. If the prediction holds true, the market will surpass US$24,706 mn by 2024. In terms of product varieties, the segment of retort pouches accounted for a dominant share of over 45% in the global market and is expected to…

Global Retort Packaging Market reports, 2015 – 2021

A retort packet is a type of food packaging made from a layer of flexible plastic and metal foils. It allows the sterile packaging of a large range of food and drink handled by aseptic processing. Retort is a process that uses heat and pressure to cook food in a strong, sealed package. It is the most suitable form of food preservation in rigid, and flexible packaging system. Retort packets…

Global Retort Packaging Market 2014 – 2020

A retort packet is a type of food packaging made from a layer of flexible plastic and metal foils. It allows the sterile packaging of a large range of food and drink handled by aseptic processing. Retort is a process that uses heat and pressure to cook food in a strong, sealed package. It is the most suitable form of food preservation in rigid, and flexible packaging system. Retort packets…