Press release

Carrot Processing Plant Setup: Sensitivity Analysis, Payback Period & Project Economics

Introduction - Overview of a Carrot Processing Plant:Setting up a carrot processing plant is a promising agro-industrial venture driven by rising global demand for value-added vegetable products. Carrots can be processed into multiple forms such as juice, puree, dehydrated flakes, frozen cuts, pickles, baby carrots, and ready-to-cook packs. This enhances their shelf life, market value, and versatility across food, beverage, and nutraceutical industries.

A carrot processing plant helps reduce post-harvest losses, supports farmers, and provides profitable opportunities for food entrepreneurs. This article offers a project-report-style overview covering the processing steps, plant setup requirements, cost structure, and profitability considerations for launching a modern carrot processing facility.

Market Overview & Trends - Rising Demand for Value-Added Vegetable Products:

The carrot processing market is expanding due to increasing consumption of healthy foods, demand for ready-to-eat vegetables, growth in the juice industry, and the popularity of dehydrated and frozen vegetables. Trends include cold-pressed carrot juices, organic carrot products, carrot-based snacks, functional beverages, baby carrot production, and packaged salads.

The foodservice sector, retail supermarkets, and export markets are major growth drivers. Challenges include carrot spoilage, storage conditions, and quality consistency, but innovation and improved processing technologies create strong opportunities.

See the Data First: Download Your Sample Report: https://www.imarcgroup.com/carrot-processing-plant-project-report/requestsample

Report Coverage Highlights:

• Process Flow: Key operations, QA tests, mass balance, and raw material needs

• Land & Location: Site selection, development planning, environmental impact, and land costs

• Plant Layout: Core layout essentials and influencing factors

• Machinery: Equipment requirements, cost overview, and supplier options

• Raw Materials: Requirements, procurement details, and cost analysis

• Packaging: Material needs, procurement process, and cost breakdown

• Additional Needs: Transport, utilities, energy, water, and manpower costs

• Project Economics: Capital costs, revenue and expense forecasts, pricing, margins, taxes, depreciation

• Financial Analysis: Profitability, liquidity, NPV, IRR, payback, P&L, and risk assessment

• Market Insights: Trends, segmentation, pricing, competition, regulation, strategic recommendations, and case study

Technical Aspects / Manufacturing Process - How Carrots Are Processed:

The carrot processing workflow varies depending on the final product but typically includes sorting, washing, peeling, cutting, blanching, processing (juicing, drying, pureeing, freezing), and packaging.

Key steps include:

• Sorting & Washing: Removal of soil, stones, and damaged carrots.

• Peeling & Cutting: Peeled using mechanical peelers, followed by slicing, dicing, or shredding.

• Processing:

- For juice: mechanical pressing and filtration

- For puree: steam cooking and pulping

- For dehydration: hot-air drying or freeze drying

- For freezing: blanching followed by IQF freezing

• Packaging: Vacuum packs, cans, pouches, bottles, or bulk packaging.

Raw materials include fresh carrots, additives (if needed), preservatives (optional), and packaging materials. Quality control includes microbial testing, color measurement, moisture content, taste consistency, and shelf-life evaluation.

Plant Setup Requirements - Machinery, Layout & Infrastructure:

A carrot processing plant requires designated zones for raw material reception, washing & peeling, cutting & sorting, processing lines (drying, juicing, freezing), packaging, cold storage, and finished-goods warehousing.

Essential machinery includes washers, peelers, conveyors, slicers, blanchers, juicers, pulpers, dryers, freeze dryers, IQF freezers, pasteurizers, kettles, filling machines, sealing machines, and labeling systems.

Infrastructure needs include water supply, electricity, drainage, cold storage rooms, ventilation, waste management systems, hygienic floors, PPE equipment, and quality-control laboratories. Compliance with food safety standards (HACCP, FSSAI, ISO) is essential.

Project Economics - Capital Cost, Operating Cost & Profitability:

The setup cost of a carrot processing plant includes land development, machinery procurement, installation, utilities, building construction, and working capital. Operating expenses include raw carrot procurement, labor, utilities, packaging, cold storage, transport, and quality assurance.

Production cost varies depending on product type-juice production requires higher processing costs, whereas dehydration demands energy for dryers or freeze-dryers. Revenue is generated from selling carrot juice, puree, frozen cuts, dehydrated flakes, baby carrots, and pickled carrots to retailers, food processors, exporters, and restaurants.

Profitability is influenced by automation level, product mix, seasonal carrot prices, waste utilization, and distribution efficiency. By-products like carrot pulp can be used for animal feed or nutraceutical extraction to enhance profitability.

Risk Factors & Success Strategies - Ensuring Hygiene, Quality & Market Reach:

Key risks include raw material spoilage, microbial contamination, seasonal supply shortages, and machinery downtime. Ensuring strict hygiene protocols, cold-chain management, controlled processing temperatures, and regular equipment sanitation helps reduce production risks.

Success strategies include diversifying product lines, purchasing carrots directly from farmers, adopting energy-efficient equipment, ensuring strong branding, and targeting markets such as hotels, retailers, online grocery stores, and exporters. Innovation in packaging (vacuum-sealed, canned, frozen) also enhances product shelf life and market acceptance.

Get a Personalized Setup Cost & ROI Analysis: https://www.imarcgroup.com/request?type=report&id=8733&flag=C

Conclusion - Feasibility and Business Potential of Carrot Processing:

A carrot processing plant is a viable and profitable agribusiness opportunity with strong demand across food and beverage industries. With efficient processing methods, quality assurance, value-added product diversification, and a robust market strategy, investors can establish a sustainable and scalable carrot processing unit.

FAQs - Carrot Processing Plant Setup:

1. What products can be made in a carrot processing plant?

A. Carrot juice, puree, dehydrated flakes, frozen cuts, baby carrots, carrot powder, pickles, and ready-to-cook carrot blends.

2. What machinery is required for carrot processing?

A. Washers, peelers, slicers, blanchers, dryers, juicers, pulpers, IQF freezers, pasteurizers, filler machines, and packaging equipment.

3. What factors influence the production cost of carrot products?

A. Raw carrot prices, processing method, energy usage, labor costs, packaging materials, and quality testing requirements.

5. How can manufacturers maintain product quality?

A. By enforcing hygienic handling, controlled processing conditions, rapid cooling for fresh products, and regular microbial testing.

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Carrot Processing Plant Setup: Sensitivity Analysis, Payback Period & Project Economics here

News-ID: 4305022 • Views: …

More Releases from IMARC Group

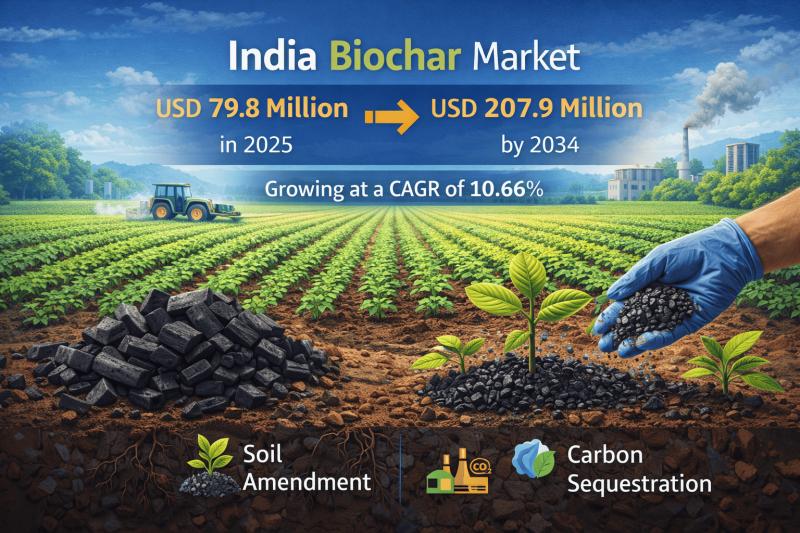

India Biochar Market Expected to Reach USD 207.9 Million by 2034, Industry Growi …

IMARC Group's latest research publication "India Biochar Market Size, Share, Trends and Forecast by Feedstock Type, Technology Type, Product Form, Application, and Region, 2026-2034" the India biochar market size reached USD 79.8 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 207.9 Million by 2034, exhibiting a growth rate (CAGR) of 10.66% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-biochar-market/requestsample

What is Biochar?

Biochar is a carbon-rich material produced through…

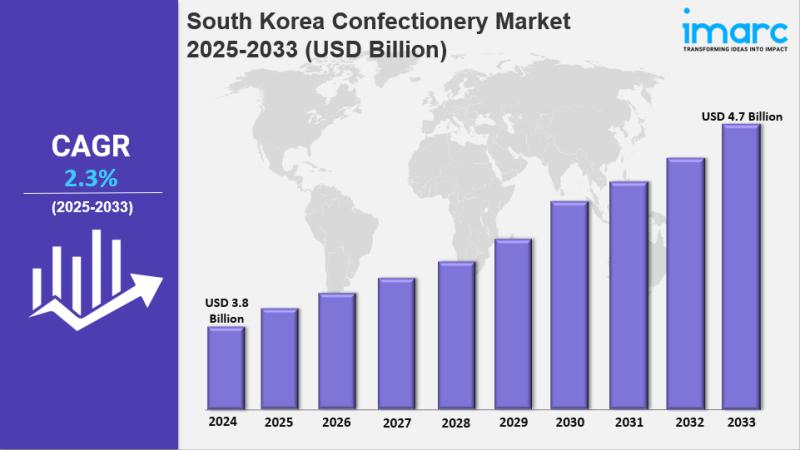

South Korea Confectionery Market Size, Growth, Latest Trends and Forecast To 203 …

IMARC Group has recently released a new research study titled "South Korea Confectionery Market Report by Product Type (Hard-Boiled Sweets, Mints, Gums and Jellies, Chocolate, Caramels and Toffees, Medicated Confectionery, Fine Bakery Wares, and Others), Age Group (Children, Adult, Geriatric), Price Point (Economy, Mid-Range, Luxury), Distribution Channel (Supermarkets and Hypermarkets, Convenience Stores, Pharmaceutical and Drug Stores, Online Stores, and Others), and Region 2025-2033", offers a detailed analysis of the market…

India Facility Management Market Expected to Reach USD 7.13 Billion by 2034, Ind …

IMARC Group's latest research publication "India Facility Management Market Size, Share, Trends and Forecast by Solution, Service, Deployment Type, Organization Size, Vertical, and Region, 2026-2034" The India facility management market size was valued at USD 2.86 Billion in 2025 and is projected to reach USD 7.13 Billion by 2034, growing at a compound annual growth rate of 10.66% from 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-facility-management-market/requestsample

What is Facility Management?

Facility management refers to…

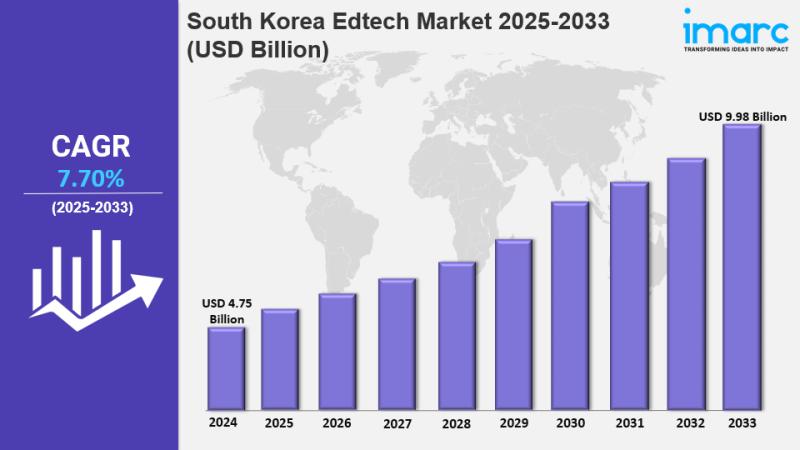

South Korea Edtech Market Share, Size, In-Depth Insights, Trends and Forecast To …

IMARC Group has recently released a new research study titled "South Korea Edtech Market Report by Sector (Preschool, K-12, Higher Education, and Others), Type (Hardware, Software, Content), Deployment Mode (Cloud-based, On-premises), End User (Individual Learners, Institutes, Enterprises), and Region 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview:

South Korea edtech market size reached USD…

More Releases for Process

Composites Market Registering a CAGR of 8.0%, by Manufacturing Process (Lay-Up P …

The composites market has witnessed increased usage of composites in the manufacturing of motorbikes, cycles, and cars. Additionally, with aerospace, automotive and transportation, construction, wind energy, marine, and electrical and electronics applications, the composites market is estimated to have accelerated expansion over the forecasted period.

Global Composites Market was valued at USD 88.00 billion in 2021 and is expected to reach USD 162.88 billion by 2029, registering a CAGR of 8.0%…

Process Automation and Instrumentation Market Process Automation and Instrumenta …

Growth of Process Automation and Instrumentation Market is Playing Key Role for Semiconductor Manufacturer and Software Vendors Process automation involves using software, hardware, and computing technology to allow end-use industries such as cement, oil & gas, chemical, paper, and others to operate more safely and efficiently.

The information is stored and analyzed on a computer with the help of sensors, which collect data on flows, pressures, and temperatures, among other devices.…

Chlor-Alkali Chemical Market: Information by Manufacturing Process (Diaphragm Ce …

Chlor-alkali is a set of scientific procedures followed for manufacturing caustic soda, chlorine, and sodium-based derivatives. Other derivatives from this process include hydrogen gas, sodium hypochlorite, bleaching powder, hydrochloric acid, and chlorinated paraffin. These products are used in a myriad of industries, further driving the market growth.

Manufacturers of chemicals such as chlorine have been upgrading their manufacturing facilities to cater to the growing demand for chlorine and other allied products.…

PASS Process Advanced Service System Market Rising Growth With Keyplayer: Schenc …

A new Profession Intelligence Report released by Stats and Reports with the title Global PASS Process Advanced Service System Market "can grow into the most important market in the world that has played an important role in making progressive impacts on the global economy. Global PASS Process Advanced Service System Market Report presents a dynamic vision to conclude and research market size, market hope and competitive environment. The study is…

1,4 Butanediol Market Report 2018: Segmentation by Technology (Reppe process, Da …

Global 1,4 Butanediol market research report provides company profile for BASF SE (Germany), Dairen Chemicals (Taiwan), LyondellBasell Chemicals (The Netherlands), Shanxi Sanwei Group (China), International Specialty Products (U.S.), Invista (U.S.), Mitsubishi Chemicals (Japan) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and…

Business Process Management Software – Process Control With Enhanced Productiv …

Awapal Solutions, an IT company, announced comprehensive BPM software services. These services will enable customers to automate business processes to improve efficiency and adapt to changing business environments. The company plans to extend BPM services to emerging industries. The use of big data, cloud, and mobile technologies have revolutionized businesses, and organizations are looking for new advancements that address growing business demands in a flexible manner. BPM software is relevant…