Press release

Complete Guide to Monocalcium Phosphate Production Cost 2025 by IMARC Group

IntroductionMonocalcium phosphate (MCP) is a highly valuable inorganic compound widely used in animal feed, fertilizer formulations, and food-grade applications. It is produced by reacting phosphoric acid with calcium carbonate or limestone, resulting in a fine, free-flowing, and highly bioavailable phosphate source. MCP is known for its excellent solubility, high phosphorus content, and superior nutritional value, making it a key ingredient in poultry, livestock, and aquaculture feed. Its controlled chemical composition ensures optimal phosphorus absorption and enhances animal growth performance. In agriculture, MCP serves as an efficient fertilizer component, improving soil conditioning and plant nutrient uptake. Owing to its consistent quality, cost-effectiveness, and broad industrial use, demand for monocalcium phosphate continues to rise across global markets.

Request for a Sample Report: https://www.imarcgroup.com/monocalcium-phosphate-processing-plant-project-report/requestsample

Market Drivers and Outlook

The global monocalcium phosphate market is driven by the expanding animal feed industry, rising demand for high-performance nutritional additives, and the growing focus on enhancing livestock productivity. Increasing global population, rapid growth in poultry and aquaculture sectors, and the shift toward balanced, nutrient-rich feed formulations are fueling MCP consumption. Additionally, improvements in agricultural practices and the need for efficient phosphate fertilizers to support crop yields are boosting its usage in the fertilizer segment. The expansion of food processing industries, where MCP is used as a leavening agent, is further accelerating market growth. Rising adoption of cost-effective, high-purity mineral supplements, technological advancements in phosphate processing, and favorable government policies supporting livestock health and feed quality continue to strengthen the market outlook. Demand is particularly strong in Asia-Pacific, Latin America, and the Middle East due to large-scale animal husbandry expansion.

Monocalcium Phosphate Production Plant Report Overview

IMARC's new report titled "Monocalcium Phosphate Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a comprehensive guide for establishing a monocalcium phosphate production plant. The report offers detailed insights into capital requirements, plant layout design, production workflow, equipment selection, and operational planning. It also delivers an in-depth monocalcium phosphate production cost analysis, enabling investors and entrepreneurs to assess the financial viability of the venture. This report is essential for manufacturers, investors, consultants, business strategists, and industry stakeholders seeking clarity on production economics, market potential, and long-term profitability in the monocalcium phosphate sector.

Understanding of Monocalcium Phosphate

Monocalcium phosphate (MCP) is a highly soluble inorganic compound produced by reacting phosphoric acid with calcium carbonate. It is widely used in animal feed as a key source of phosphorus and calcium, helping improve growth, digestion, and bone development. MCP is also used in fertilizers and food processing. Its high purity, bioavailability, and cost-effectiveness make it essential across agriculture, livestock nutrition, and industrial applications.

Key Steps: Production Process and Technical Workflow

This section provides detailed insights into the process flow, chemical reactions, and unit operations involved in monocalcium phosphate production. It includes raw material specifications, mass balance analysis, and quality standards essential for producing high-grade MCP suitable for feed, fertilizer, or industrial use.

Aspects Covered

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Infrastructure and Setup Requirements

This section highlights critical considerations for establishing a monocalcium phosphate production plant, including land selection, proximity to utilities, transportation access, and environmental compliance. It outlines the plant design, equipment list, and operational expenditure, covering all key cost determinants such as utilities, packaging, logistics, raw materials, and labor.

Aspects Covered

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Financial Projections and Economic Viability

This section presents a complete financial evaluation for launching a monocalcium phosphate production plant. It includes CapEx, OpEx, depreciation, taxation, profit margins, and revenue forecasts. Additionally, it features NPV calculation, payback period estimation, sensitivity analysis, and profitability assessments under different market scenarios.

Aspects Covered

• Capital Investments

• Operating CostsExpenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Frequently Asked Questions

• What are the raw material requirements for monocalcium phosphate production?

• How much does it cost to set up a monocalcium phosphate production plant?

• What machinery is required for monocalcium phosphate production?

• Is monocalcium phosphate production a profitable business in 2025?

Financial Forecasts Overview

• CAPEX (Capital Expenditure): Covers the initial investment required for plant setup, including land development, machinery installation, utilities, and infrastructure. It represents all upfront costs needed to establish full production capability.

• OPEX (Operating Expenditure): Refers to ongoing expenses involved in day-to-day operations such as raw materials, labor, maintenance, utilities, packaging, and administrative functions. These costs determine the plant's operational efficiency and long-term sustainability.

• ROI (Return on Investment): Indicates the expected profitability of the project by comparing projected returns with the total investment. It helps assess whether the plant will generate attractive long-term value and meet investor expectations.

• Break-even Analysis: Identifies the point at which total revenue equals total costs, meaning the project begins generating profit. This analysis helps determine the required production output and timeframe to recover initial investments.

Key Considerations for Plant Design and Operations

• Production Capacity: Machinery selection and layout design should match the targeted production volume, ensuring efficient use of space and resources.

• Automation Levels: Automation can range from basic semi-automated systems to fully automated plants depending on budget, labor availability, and production goals.

• Location Adaptation: Selecting a site close to raw material sources (phosphoric acid and limestone) and target markets reduces logistics costs and ensures regulatory compliance.

• Product Flexibility: Equipment should support multiple grades of MCP (feed-grade, fertilizer-grade, food-grade) to meet diverse market demands.

• Sustainability Features: Energy-efficient machinery, proper waste treatment systems, and optimized resource utilization enhance sustainability and reduce operational costs.

• Raw Material Sourcing: A reliable and cost-effective supply chain for phosphoric acid and calcium carbonate is essential for maintaining consistent production quality and minimizing input costs.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new production plants globally.

Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Our expertise includes:

• Market Entry and Expansion Strategy

• Feasibility Studies and Business Planning

• Company Incorporation and Factory Setup Support

• Regulatory and Licensing Navigation

• Competitive Analysis and Benchmarking

• Procurement and Supply Chain Research

• Branding, Marketing, and Sales Strategy

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Complete Guide to Monocalcium Phosphate Production Cost 2025 by IMARC Group here

News-ID: 4304761 • Views: …

More Releases from IMARC Group

India B2B Events Market: Industry Trends & Growth Forecast by 2034

The India B2B events market size was valued at USD 1,688.72 Million in 2025 and is expected to reach USD 2,750.10 Million by 2034, growing at a compound annual growth rate (CAGR) of 5.57% from 2026 to 2034. The market growth is driven by increasing corporate spending on marketing, networking initiatives, and brand-building across industries, supported by government development of world-class MICE infrastructure and adoption of digital and hybrid event…

India Cold Chain Logistics Market to Reach USD 27.00 Bn by 2033 at 8.90% CAGR Am …

Source: IMARC Group | Category: Transportation and Logistics

Report Introduction

According to IMARC Group's latest report titled "India Cold Chain Logistics Market Size, Share, Trends and Forecast by Type, Application, and Region, 2025-2033", this study offers a granular analysis of the country's developing temperature-controlled supply chain. The study offers a profound analysis of the industry, encompassing market share, size, growth factors, key trends, and regional insights. The report covers critical market dynamics,…

India Plastic Packaging Market is set to reach USD 17.3 Billion by 2034 | Indust …

The India plastic packaging market size reached USD 13.2 Billion in 2025. The market is expected to reach USD 17.3 Billion by 2034, growing at a CAGR of 3.10% from 2026-2034. The market is majorly driven by the advancements in plastic materials and technologies, development of lightweight packaging solutions, creation of flexible packaging options, and innovation in barrier-enhanced packaging that extends shelf life and improves product performance.

Key Highlights in India…

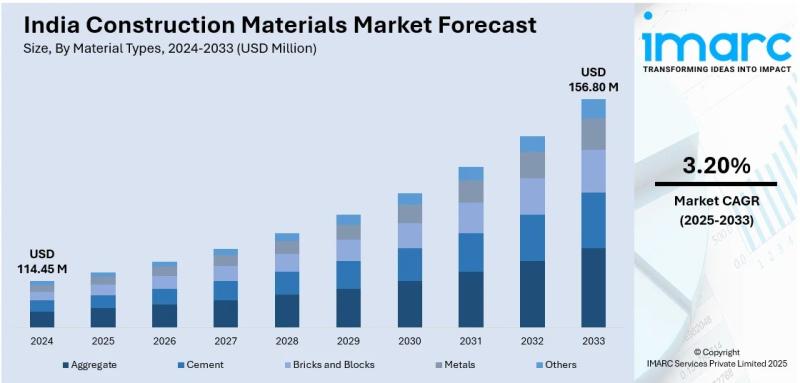

India Construction Materials Market to Hit USD 156.80 Mn by 2033 at 3.20% CAGR D …

Source: IMARC Group | Category: Chemical & Materials

Report Introduction

According to IMARC Group's latest report titled "India Construction Materials Market Size, Share, Trends and Forecast by Material Type, End User, and Region, 2025-2033", this study offers a granular analysis of the country's booming construction sector. The study offers a profound analysis of the industry, encompassing market share, size, growth factors, key trends, and regional insights. The report covers critical market…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…