Press release

Tannic Acid Production Plant Setup: Investment Planning & Expansion Strategy

Setting up a tannic acid production plant involves selecting a suitable manufacturing method such as hot water extraction from tannin-rich plant materials followed by purification, securing raw material supply of gallnuts, tara pods, or other botanical sources, installing extraction vessels, concentration equipment, spray drying or crystallization units, and filtration systems, and ensuring compliance with food safety regulations and pharmaceutical quality standards.IMARC Group's report, titled "Tannic Acid Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a tannic acid production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/tannic-acid-manufacturing-plant-project-report/requestsample

What is Tannic Acid?

Tannic acid is a naturally occurring polyphenolic compound found in various plant sources such as oak bark, gallnuts, sumac, and certain fruits like grapes and pomegranates. It belongs to the broader class of tannins and is known for its astringent taste, which is responsible for the dry sensation in tea and red wine. Tannic acid is widely used for its antioxidant, antimicrobial, and anti-inflammatory properties. In industrial applications, it plays an important role in leather tanning, ink manufacturing, dyeing, and water purification processes. Additionally, it is used in pharmaceuticals, food processing, and cosmetics due to its functional characteristics and health-related benefits.

What is driving Tannic Acid Production?

The growing production of tannic acid is primarily driven by its expanding application across multiple industries. In the food and beverage sector, tannic acid is valued as a natural additive, flavoring ingredient, and clarification agent, particularly in beverages like wine, beer, and tea. The pharmaceutical and healthcare industries are also fueling demand due to its availability as a natural antioxidant and antimicrobial agent used in wound care, anti-diarrheal treatments, and oral hygiene products. Additionally, the cosmetics and personal care industry increasingly uses tannic acid in skin care formulations for its anti-aging and anti-inflammatory properties. The leather and textile industries rely on tannic acid for tanning and dyeing processes. Moreover, sustainability trends and consumer preference for natural, plant-based chemicals over synthetic alternatives boost production. Technological advancements in extraction and processing methods further support cost-effective manufacturing and broader commercial adoption, contributing to continuous market growth.

Key Insights for setting up a Tannic Acid Production Plant

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Buy Now: https://www.imarcgroup.com/checkout?id=9805&method=2142

Key Cost Components

• Land and Site Development: Cost of land acquisition near botanical raw material sources or agricultural regions, site preparation, infrastructure development, and utility connections including water supply for extraction processes.

• Machinery and Equipment: Extraction vessels with heating systems, crushing and grinding equipment for raw material preparation, filtration systems (plate and frame filters, membrane filters), concentration equipment (evaporators, vacuum concentrators), spray dryers or crystallization tanks, storage tanks for extracts, pumps, heat exchangers, and quality control analytical instruments (HPLC, spectrophotometers).

• Raw Materials: Gallnuts (Quercus infectoria), tara pods (Caesalpinia spinosa), sumac leaves, chestnut wood, myrobalan fruits, or other tannin-rich botanical sources, extraction solvents (water, ethanol), processing aids, and packaging materials (food-grade containers, pharmaceutical-grade bottles).

• Construction and Civil Work: Food-grade or pharmaceutical-grade facility construction, stainless steel processing areas, temperature and humidity-controlled storage, wastewater treatment infrastructure, and utility connections.

• Environmental Compliance: Wastewater treatment for spent extraction liquor containing organic matter, solid waste management for spent botanical materials (composting or energy recovery), emission controls, and environmental permits.

• Technology Licensing or R&D: Cost of optimized extraction protocols, purification processes, standardization methods for polyphenol content, or in-house product development for specialized grades (pharmaceutical, food, technical).

Economic Trends Influencing Tannic Acid Plant Setup Costs 2025

• Botanical Raw Material Availability: Dependence on seasonal harvests of gallnuts, tara pods, and other plant sources creates supply variability and price fluctuations affecting production economics.

• Sustainable Sourcing Pressures: Growing emphasis on sustainable wild-harvesting practices and cultivated botanical sources increases raw material costs but improves supply reliability and certification potential.

• Natural Ingredients Demand: Increasing consumer preference for natural over synthetic additives in food, beverages, and pharmaceuticals drives market growth and supports premium pricing for high-purity grades.

• Regulatory Compliance Evolution: Stricter food contact regulations, pharmaceutical excipient standards (USP, EP, JP), and organic certification requirements necessitate enhanced quality control and traceability systems.

• Competition from Synthetic Alternatives: Pressure from synthetic tannins (particularly in leather processing) and alternative clarifying agents affects market positioning in certain applications.

• Value-Added Applications: Growing demand for standardized polyphenol extracts in nutraceuticals and functional foods creates opportunities for premium product development and diversification.

Request for Customized Report: https://www.imarcgroup.com/request?type=report&id=9805&flag=E

Challenges and Considerations for Investors

• High Capital Investment: Establishing a tannic acid plant requires substantial investment in extraction vessels, concentration equipment, spray drying facilities, and quality control laboratories meeting food or pharmaceutical standards.

• Raw Material Supply Variability: Seasonal availability, harvest fluctuations, and weather impacts on botanical sources create procurement challenges and inventory management requirements.

• Extraction Efficiency Optimization: Achieving maximum yield from botanical materials while maintaining polyphenol structure and activity requires optimized temperature, pH, extraction time, and solvent ratios.

• Quality Standardization: Natural botanical sources exhibit compositional variability requiring blending strategies and analytical controls to achieve consistent tannic acid content and performance characteristics.

• Market Segmentation Complexity: Different applications demand varying specifications-food-grade requires safety certifications, pharmaceutical needs USP compliance, technical grade for leather has different purity requirements.

• Wastewater Management: Large volumes of spent extraction liquor with high organic content require treatment before discharge, adding operational costs and environmental responsibilities.

• Regulatory Compliance: Food additive approvals, pharmaceutical excipient monographs, organic certifications, and kosher/halal compliance require ongoing documentation and audits across different markets.

• Competition and Pricing Pressure: Competition from established producers, particularly in China and South America, and from synthetic alternatives in industrial applications affects margin potential.

Browse More Related Report:

• Pressure Sensitive Adhesive Film Production Plant: https://www.imarcgroup.com/pressure-sensitive-adhesive-film-manufacturing-plant-project-report

• Ricinoleic Acid Production Plant: https://www.imarcgroup.com/ricinoleic-acid-manufacturing-plant-project-report

• Silicon Emulsion Production Plant: https://www.imarcgroup.com/silicon-emulsion-manufacturing-plant-project-report

• Sodium Ascorbate Production Plant: https://www.imarcgroup.com/sodium-ascorbate-manufacturing-plant-project-report

• Sodium Diacetate Production Plant: https://www.imarcgroup.com/sodium-diacetate-manufacturing-plant-project-report

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Tannic Acid Production Plant Setup: Investment Planning & Expansion Strategy here

News-ID: 4301802 • Views: …

More Releases from IMARC Group

India Smart Advertising Market Expected to Reach USD 275.30 Million by 2034, Ind …

IMARC Group's latest research publication "India Smart Advertising Market Size, Share, Trends and Forecast by Component, Product, End Use, and Region, 2026-2034" the India smart advertising market size was valued at USD 68.71 Million in 2025. The market is expected to reach USD 275.30 Million by 2034, exhibiting a growth rate (CAGR) of 16.68% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-smart-advertising-market/requestsample

What is Smart Advertising?

Smart advertising refers to digital, data-driven advertising solutions…

India Consumer IoT Market Expected to Reach USD 27,045.64 Million by 2034, Indus …

IMARC Group's latest research publication "India Consumer IoT Market Size, Share, Trends and Forecast by Component, Connectivity Technology, Application, and Region, 2026-2034" the India consumer IoT market size was valued at USD 9,678.01 Million in 2025. The market is projected to reach USD 27,045.64 Million by 2034, exhibiting a growth rate (CAGR) of 12.10% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-consumer-iot-market/requestsample

What is Consumer IoT?

Consumer IoT refers to interconnected smart devices used…

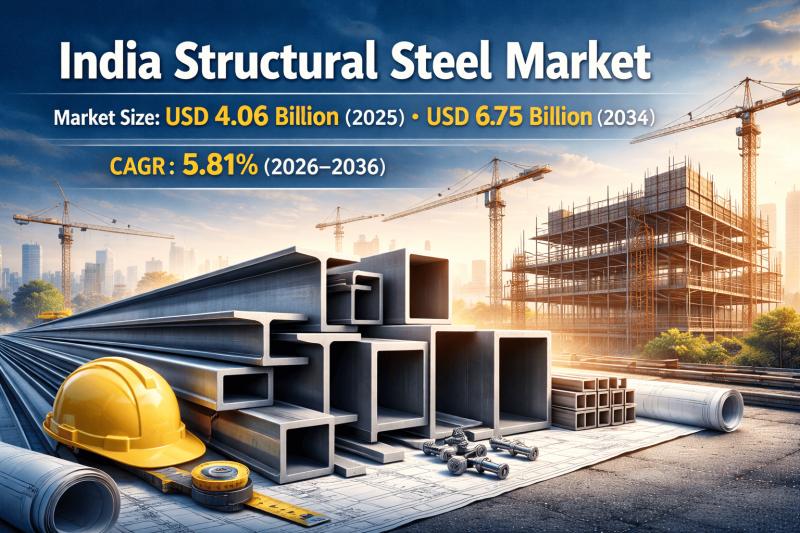

India Structural Steel Market Expected to Reach USD 6.75 Million by 2034, Indust …

IMARC Group's latest research publication "India Structural Steel Market Size, Share, Trends and Forecast by Product, Application, and Region, 2026-2034" the India structural steel market size reached USD 4.06 Million in 2025. The market is expected to reach USD 6.75 Million by 2034, exhibiting a growth rate (CAGR) of 5.81% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-structural-steel-market/requestsample

What is Structural Steel?

Structural steel refers to specially designed steel shapes like beams, columns, angles,…

India Fungicide Market Expected to Reach USD 976.70 Million by 2034, Industry Gr …

IMARC Group's latest research publication "India Fungicide Market Size, Share, Trends and Forecast by Type, Form, Crop Type, Mode of Action, Application, and Region, 2026-2034" the India fungicide market size was valued at USD 695.79 Million in 2025. The market is projected to reach USD 976.70 Million by 2034, growing at a compound annual growth rate of 3.84% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-fungicide-market/requestsample

What is Fungicide?

Fungicides are chemical or biological…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…