Press release

ARGOS Transforms Fab Operations with Data and Predictive Maintenance Service

ARGOS. Digital Semiconductor Services from Pfeiffer Vacuum+Fab Solutions. ( (C) Pfeiffer Vacuum+Fab Solutions.)

ARGOS addresses a core industry reality. Predictive maintenance delivers value only when two foundations are strong: data maturity (trustworthy, timely, well-governed data) and operational expertise to run a predictive maintenance strategy (vacuum pump and abatement know-how, reliability engineering practices, and disciplined PDCA (plan-do-check-act) routines). If either is weak, machine learning signals remain on dashboards instead of driving outcomes. ARGOS has been built to close that gap.

ARGOS combines production-grade machine learning with decades of vacuum pump and abatement expertise. Multivariate models feed a disciplined reliability engineering service so that fabs act on the right risks at the right time. Instead of raw analytics, ARGOS delivers machine-learning-driven, expert-validated recommendations that become planned work: Signals translate into work orders, parts are pre-staged, and unplanned tasks become scheduled activities.

How ARGOS works

Data capture gateway

Through a data capture plug-and-play gateway, ARGOS ingests subfab telemetry and service events without disrupting tools. Installation is easy and takes just minutes.

Domain-informed machine learning models

Multivariate health index, anomaly detection and classification, and survival/remaining useful life (RUL) estimators are tuned to asset families and process conditions. They have been calibrated with physics--of- failure patterns and process- to- pump interactions.

Operational expertise and playbooks

Domain libraries and methods turn signals into outcomes. These methods include failure-physics and symptom-to-cause trees, process- to- pump duty classification and risk tiers by production consequence, FMEA (failure mode and effects analysis) action playbooks with plan-do-check-act routines, parts readiness and overhaul/EOL (end of life) criteria aligned to RUL windows, and service evidence capture to feed model improvement.

Risk engine

A risk engine combines a machine-learning-estimated likelihood of a failure with the consequence it would have on production to produce a ranked risk list and next best actions.

Continuous learning

The ARGOS models are continuously learning and are retrained with service outcomes. RUL accuracy, false positive rates and alert precision are tracked for continuous improvement over time.

Decision packages

Weekly and monthly deliverables translate model outputs into scheduled work, EOL recommendations, and key performance indicator (KPI) updates aligned to availability targets.

Vendor-independent by design

ARGOS uses open, standards-based interfaces for data import and export, enabling no vendor lock-in and full portability of data and models. The service operates entirely on the premises, keeping sensitive fab data under customer control.

What fabs receive

o A weekly machine-learning driven risk report focused on high consequence assets.

o A next-best action queue with timing, parts, and prerequisites.

o KPI tracking to show availability, MTBF (mean time between failure)/MTTR (mean time to repair), planned-work ratio, downtime avoided, and RUL accuracy. In addition, false-positive rates and alert precision are continuously monitored as method KPIs.

o Periodic readiness checks and maturity lift actions across data and methods.

o A data-and-skills maturity assessment upon deployment to verify ROI conditions and tune model training to the local installed base.

Dr. Sandra Thirtle-H?ck

Head of Communications Busch Group

Pfeiffer Vacuum+Fab Solutions

Berliner Strasse 43

35614 Asslar, Germany

+49 (0)6441 802 - 1460

sandra.hoeck@pfeiffer-vacuum.com

www.pfeiffer-vacuum.com

www.buschgroup.com

About the Busch Group

The Busch Group is one of the world's largest manufacturers of vacuum pumps, vacuum systems, blowers, compressors and gas abatement systems. Under its umbrella, the group houses two well-known brands: Busch Vacuum Solutions and Pfeiffer Vacuum+Fab Solutions. The gas abatement systems previously offered by centrotherm clean solutions - a former Busch Group brand - are now part of the Pfeiffer portfolio.

The extensive product and service offer includes solutions for vacuum, overpressure and abatement applications in all industries, such as food, semiconductors, analytics, chemicals and plastics. This also includes the design and construction of tailor-made vacuum systems and a worldwide service network.

The Busch Group is a family business that is managed by the Busch family. More than 8,000 employees in 44 countries worldwide work for the group. Busch is headquartered in Maulburg, Baden-W?rttemberg, in the tri-country region of Germany, France and Switzerland. The Busch Group manufactures in its 23 own production plants in China, the Czech Republic, France, Germany, India, Romania, South Korea, Switzerland, the United Kingdom, the USA and Vietnam.

The Busch Group has an annual consolidated revenue of close to 2 billion Euro.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release ARGOS Transforms Fab Operations with Data and Predictive Maintenance Service here

News-ID: 4296547 • Views: …

More Releases from Pfeiffer Vacuum+Fab Solutions

Pfeiffer Vacuum+Fab Solutions presents the new ATH 4506 M Turbopump

With a pumping speed of 4,500 l/s for nitrogen, the new turbopump is suited for processes in semiconductor manufacturing, large-area coating, and other applications where high gas throughput is required, such as the evacuation of large vacuum chambers for space simulation.

Plug&play operation with integrated controller

The ATH 4506 M comes with an integrated controller. This eliminates the need for separate external control units, which simplifies installation and reduces the space required…

Pfeiffer Vacuum+Fab Solutions Introduces COMBI WVD Vacuum Booster Pump Unit

Pfeiffer Vacuum+Fab Solutions - a member of the global Busch Group - announces the launch of the COMBI WVD vacuum booster pump unit. This compact unit offers high performance and a small footprint. It is an expansion to the existing COMBI series and consists of a PANDA vacuum booster and a DuoVane two-stage oil-lubricated rotary vane vacuum pump.

The COMBI WVD vacuum booster pump unit features high pumping speed and low…

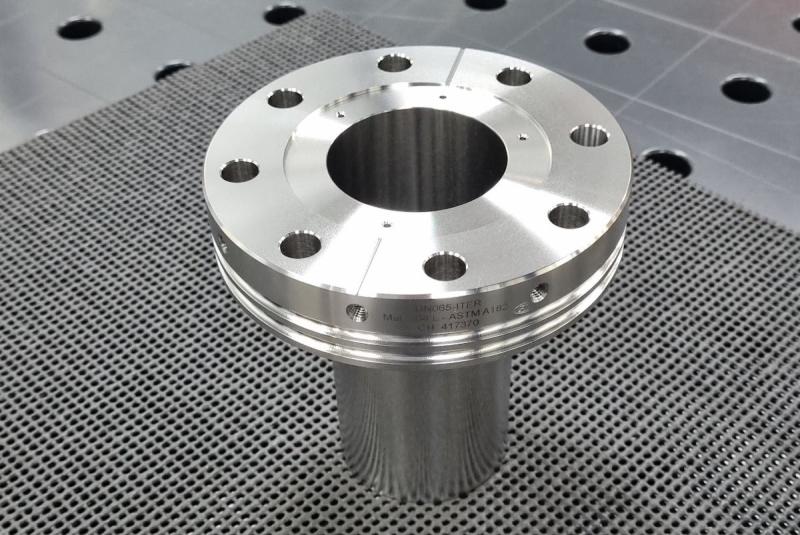

Pfeiffer Vacuum+Fab Solutions Becomes Official Global Supplier of ITER Flanges

Pfeiffer Vacuum+Fab Solutions, a member of the global Busch Group, announces its completion of the qualification process for the supply of ITER-specific flanges.

After a one-year evaluation period, Pfeiffer now offers ITER flanges to support the world's largest fusion energy research project. The ITER organization has officially qualified Pfeiffer as a recommended supplier of ConFlat, ISO, ITER, and many more flange styles for use in US ITER hardware procurements.

ITER:…

Pfeiffer Vacuum+Fab Solutions Presents Vacuum Technology and Gas Abatement Syste …

Pfeiffer - a member of the global Busch Group - will be showcasing its innovative technology from November 18 to 21, 2025, at the Semicon Europa 2025 trade show in Munich.

Visitors to Semicon Europa can look forward to innovative vacuum technology and gas abatement systems used in semiconductor fabs and at OEMs. They can talk to experts from Pfeiffer Vacuum+Fab Solutions about vacuum pumps, leak detectors, gas abatement systems…

More Releases for ARGOS

Online Age Verification Services in Real-Time | ARGOS Identity

ARGOS Identity offers fast and accurate online age verification services designed to help businesses ensure compliance with age-restricted regulations. This service is particularly valuable for industries such as online gaming, e-commerce, alcohol sales, and other sectors where age verification is essential.

With ARGOS's technology, companies can instantly verify users' ages, preventing underage access and maintaining legal compliance. The system is highly efficient and easy to integrate, providing businesses with a seamless…

Comprehensive Automated Online Identity Verification Services | ARGOS Identity

ARGOS Identity offers comprehensive automated online identity verification services that streamline and secure the customer onboarding process. These services are designed to enhance identity management in sectors requiring reliable verification, such as banking, finance, and government.

ARGOS's Identity Verification Solutions

- Global ID Verification:

ARGOS can analyze over 4,000 types of IDs from around the world, providing reliable verification across borders, regardless of the ID type or country of origin. This global reach…

Fast and Accurate Online Age Verification Services | ARGOS Identity

ARGOS Identity online age verification services ensure that users meet the minimum age requirements for accessing certain services. These services are particularly valuable in industries such as online gaming, online purchases, and other age-restricted platforms.

By accurately verifying users' ages, businesses can comply with legal regulations and provide a safer, more responsible user experience. This solution helps prevent unauthorized access by minors, enhancing both compliance and security for digital platforms.

Benefits…

Sophisticated and Accurate Identity Verification Platforms | ARGOS

ARGOS Identity sophisticated and accurate identity verification platforms provide advanced solutions for verifying customer identities with precision. These platforms are designed to meet the highest standards of security and reliability, making them ideal for sectors that demand robust identity checks, such as banking, finance, and government services.

With state-of-the-art technology, they ensure real-time, accurate verification, reducing fraud risks and enhancing user trust. These platforms streamline the verification process, delivering a…

Accurate Online OCR Recognition Technology | ARGOS Identity

ARGOS Identity online OCR recognition technology efficiently extracts text from images or scanned documents, improving document accessibility. This technology is highly useful for automating data entry, streamlining processes in various applications, and reducing manual effort. The ability to convert text into digital formats provides great value to industries that require accurate data extraction and fast processing.

Benefits of ARGOS's online OCR recognition technology:

Improved Efficiency: Automating data entry saves time and reduces…

Real-Time Facial Recognition for Quick Verification | ARGOS Identity

Real-time facial recognition verification ensures the security and privacy of personal information. Enhance information security with the ARGOS Face ID solution.

ARGOS Face ID Verification Technology

In the digital age, safeguarding personal information has never been more critical. Face ID leverages facial recognition technology to deliver a secure and efficient user onboarding process. This solution searches for matching faces within a collection of stored identifiers, ensuring that both individuals and organizations benefit…