Press release

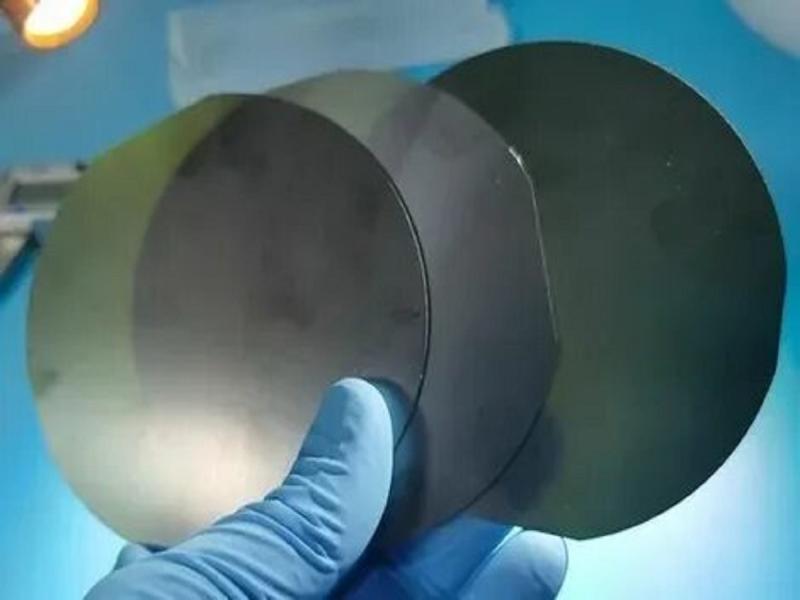

U.S. SiC Wafer Polishing Market to Expand at 34% CAGR, Driven by Key Players 3M, Entegris, and Kemet International

The U.S. SiC (Silicon Carbide) Wafer Polishing Market was valued at US$ 162.7 million in 2024 and is projected to expand at a CAGR of more than 34% through 2030. Growth is strongly driven by accelerating adoption of SiC-based power devices across electric vehicles, renewable energy systems, fast-charging infrastructure and high-efficiency industrial applications.The market holds a strengthening position within the U.S. semiconductor supply chain, supported by advancements in chemical-mechanical polishing technologies, improved slurry formulations and increasing domestic investments in wide-bandgap semiconductor manufacturing. As demand for high-performance SiC wafers rises, the U.S. continues to emerge as a critical hub for precision wafer finishing essential for next-generation power electronics.

Get a Free Sample PDF Of This Report (Get Higher Priority for Corporate Email ID):-https://www.datamintelligence.com/download-sample/sic-wafer-polishing-market?sai-v

The SiC Wafer Polishing Market covers advanced polishing materials, equipment, and processes used to achieve ultra-smooth, defect-free surfaces on silicon carbide wafers for high-performance power electronics and semiconductor applications.

Key Developments

United States

✅ June 2025: U.S. CMP consumable manufacturers announced a major capacity expansion for SiC-specific slurries and diamond abrasives, driven by accelerating power semiconductor demand from EV and renewable-energy markets.

✅ April 2025: Several U.S. semiconductor fabs began qualification runs for polished 200 mm SiC wafers, increasing orders for high-purity polishing pads and low-defect slurries.

✅ February 2025: U.S. polishing-tool suppliers introduced next-generation polishing modules with in-line metrology to provide real-time surface finish feedback during SiC wafer processing.

Japan

✅ May 2025: Japanese equipment manufacturers revealed new ECMP (electrochemical-mechanical polishing) systems tailored for SiC wafer finishing, highlighting reduced chemical consumption and improved surface flatness.

✅ March 2025: Domestic Japanese consumable producers launched updated diamond slurry formulations optimized for 200 mm SiC wafers to improve removal rate while minimizing subsurface damage.

✅ January 2025: Japanese R&D teams published early validation data on a newly developed polishing pad technology that supports faster throughput and consistent surface roughness on SiC wafers.

Mergers & Strategic Moves

✅ June 2025 (United States / Japan): A U.S. CMP consumable company formed a strategic joint development agreement with a leading Japanese semiconductor-equipment firm to co-create high-performance SiC polishing consumables and systems.

✅ April 2025 (Japan): A Japanese precision equipment maker entered into a technology licensing partnership with a U.S. diamond-abrasive supplier to accelerate development of next-generation SiC polishing platforms.

✅ February 2025 (United States): A major U.S.-based polishing tools vendor announced a minority equity investment in a Japanese startup specialized in AI-driven metrology for SiC wafer finishing, aiming to combine real-time monitoring with polishing hardware.

Key Players:

Kemnet International | Entegris | Ijin Diamond | Fujimi Corporation | Saint-Gobain | JSR Corporation | Engis Corporation | Ferro Corporation | 3M | DuPont Incorporated

Key Highlights :

• Kemnet International - A leading provider of high-precision polishing and surface-finishing materials, known for its strong product reliability and consistent supply capabilities across semiconductor and optical manufacturing sectors.

• Entegris - Reported strong annual growth driven by advanced materials, filtration, and contamination-control solutions supporting semiconductor device scaling and next-generation manufacturing technologies.

• Ijin Diamond - A major producer of high-performance diamond abrasives and polishing slurries with expanding global demand across electronics, optics, and hard-material processing industries.

• Fujimi Corporation - Demonstrated robust revenue performance supported by advanced CMP slurries, precision abrasives, and polishing technologies used widely in wafer fabrication and high-precision industrial applications.

• Saint-Gobain - Strengthened its position with diversified engineered materials and high-quality abrasive solutions, supported by continuous product innovation and expansion across global manufacturing markets.

• JSR Corporation - Maintained strong market presence driven by specialty chemicals, semiconductor materials, and advanced CMP formulations critical to cutting-edge chip production.

• Engis Corporation - Known for precision diamond-based polishing systems and lapping technologies, with increased global adoption in electronics, automotive, and defense manufacturing.

• Ferro Corporation - Delivered steady performance in engineered materials, polishing compounds, and specialty chemical solutions used across electronics, ceramics, and industrial applications.

• 3M - Continued to lead in advanced abrasive materials, micro-finishing technologies, and industrial process solutions with strong demand across global manufacturing and electronics markets.

• DuPont Incorporated - Recorded solid growth supported by advanced CMP pads, slurries, and semiconductor materials contributing to leading-edge node fabrication and high-performance electronics.

Buy Now & Unlock 360° Market Intelligence: https://www.datamintelligence.com/buy-now-page?report=sic-wafer-polishing-market?sai-v

Market Drivers & Growth

- Rising adoption of SiC power devices in electric vehicles, renewable energy systems, and industrial power electronics is increasing demand for high-quality polished wafers.

- Expansion of global semiconductor manufacturing and investments in next-generation power device production are supporting market growth.

- Strong material advantages of SiC, including high thermal conductivity and wide bandgap, are accelerating its use in EV fast chargers, solar inverters, and 5G infrastructure.

- Advancements in chemical mechanical polishing (CMP) technologies are improving wafer flatness, surface quality, and defect reduction.

- The transition toward large-diameter SiC wafers, including 6-inch and 8-inch formats, is driving demand for advanced polishing solutions.

Industrial Advances & Developments

- Introduction of low-defect CMP processes designed for high-performance SiC power device manufacturing.

- Development of next-generation polishing pads and slurries that enhance material removal rates and reduce subsurface damage.

- Increased automation and precision in wafer-polishing equipment to improve yield and throughput.

- Strategic collaborations between semiconductor manufacturers and equipment suppliers to strengthen 150 mm and 200 mm SiC wafer processing capabilities.

- Growing interest in wafer recycling and reclaim polishing to reduce production costs in high-volume manufacturing.

Regional Insights

- North America: Leading region driven by strong semiconductor manufacturing activity, growing EV production, and high adoption of SiC power electronics in automotive and industrial sectors.

- Europe: Supported by expanding EV manufacturing, renewable energy integration, and rising demand for advanced power semiconductor materials.

- Asia-Pacific: Fastest-growing region with major SiC wafer production hubs in Japan, China, Taiwan, and South Korea, supported by rapid semiconductor fab expansion.

- Latin America: Moderate growth driven by the development of industrial electronics and increasing interest in efficient power conversion technologies.

- Middle East and Africa: Emerging market with steady progress supported by industrial modernization and early-stage semiconductor initiatives.

Key Segments:

➥ By Process

Mechanical polishing is widely used for initial substrate leveling and cost-effective material removal. Chemical-mechanical polishing (CMP) dominates advanced semiconductor manufacturing due to its precision and ability to achieve ultra-flat surfaces. Electropolishing supports high-purity surface finishing for specialty materials. Chemical and plasma-assisted processes are increasingly adopted for advanced device fabrication requiring minimal surface damage.

➥ By Product

Abrasive powders serve as the base material for bulk surface removal. Polishing pads are essential consumables enabling consistent CMP performance. Diamond slurries lead in high-precision polishing due to superior hardness and effectiveness on wide bandgap materials. Colloidal silica suspensions are widely used for finishing steps that require nanoscale smoothness.

➥ By Application

Power electronics drive major demand as SiC and GaN devices require high-precision polishing for performance and reliability. LED manufacturing relies heavily on CMP for wafer planarization. Sensors and detectors utilize advanced polishing methods to achieve substrate uniformity. RF and microwave devices depend on ultra-flat surfaces to enhance signal efficiency and device integrity.

Speak to Our Analyst and Get Customization in the report as per your requirements: https://www.datamintelligence.com/customize/sic-wafer-polishing-market?sai-v

Unlock 360° Market Intelligence with DataM Subscription Services: https://www.datamintelligence.com/reports-subscription

Power your decisions with real-time competitor tracking, strategic forecasts, and global investment insights all in one place.

✅ Competitive Landscape

✅ Sustainability Impact Analysis

✅ KOL / Stakeholder Insights

✅ Unmet Needs & Positioning, Pricing & Market Access Snapshots

✅ Market Volatility & Emerging Risks Analysis

✅ Quarterly Industry Report Updated

✅ Live Market & Pricing Trends

✅ Import-Export Data Monitoring

Have a look at our Subscription Dashboard: https://www.youtube.com/watch?v=x5oEiqEqTWg

Contact Us -

Company Name: DataM Intelligence

Contact Person: Sai Kiran

Email: Sai.k@datamintelligence.com

Phone: +1 877 441 4866

Website: https://www.datamintelligence.com

About Us -

DataM Intelligence is a Market Research and Consulting firm that provides end-to-end business solutions to organizations from Research to Consulting. We, at DataM Intelligence, leverage our top trademark trends, insights and developments to emancipate swift and astute solutions to clients like you. We encompass a multitude of syndicate reports and customized reports with a robust methodology.

Our research database features countless statistics and in-depth analyses across a wide range of 6300+ reports in 40+ domains creating business solutions for more than 200+ companies across 50+ countries; catering to the key business research needs that influence the growth trajectory of our vast clientele.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release U.S. SiC Wafer Polishing Market to Expand at 34% CAGR, Driven by Key Players 3M, Entegris, and Kemet International here

News-ID: 4279769 • Views: …

More Releases from DataM intelligence 4 Market Research LLP

United States Direct Methanol Fuel Cell Market 2031 | North America's Led by 35% …

Direct Methanol Fuel Cell Market is expected to reach at a high CAGR during the forecast period (2024-2031).

DataM Intelligence unveils its latest report on the "Direct Methanol Fuel Cell Market Size 2025," offering an in-depth analysis of market trends, growth drivers, competitive landscape, and regional dynamics. The study covers market size in value and volume, CAGR forecasts, and emerging opportunities that can guide businesses in seizing growth potential and crafting…

United States High Temperature Sealant Market 2031 | North America's Led by 38% …

high-temperature sealant market size, shares, recent trends, competitive intelligence, and future market outlook 2024-2031

DataM Intelligence unveils its latest report on the "High Temperature Sealant Market Size 2025," offering an in-depth analysis of market trends, growth drivers, competitive landscape, and regional dynamics. The study covers market size in value and volume, CAGR forecasts, and emerging opportunities that can guide businesses in seizing growth potential and crafting winning strategies. Packed with data-driven…

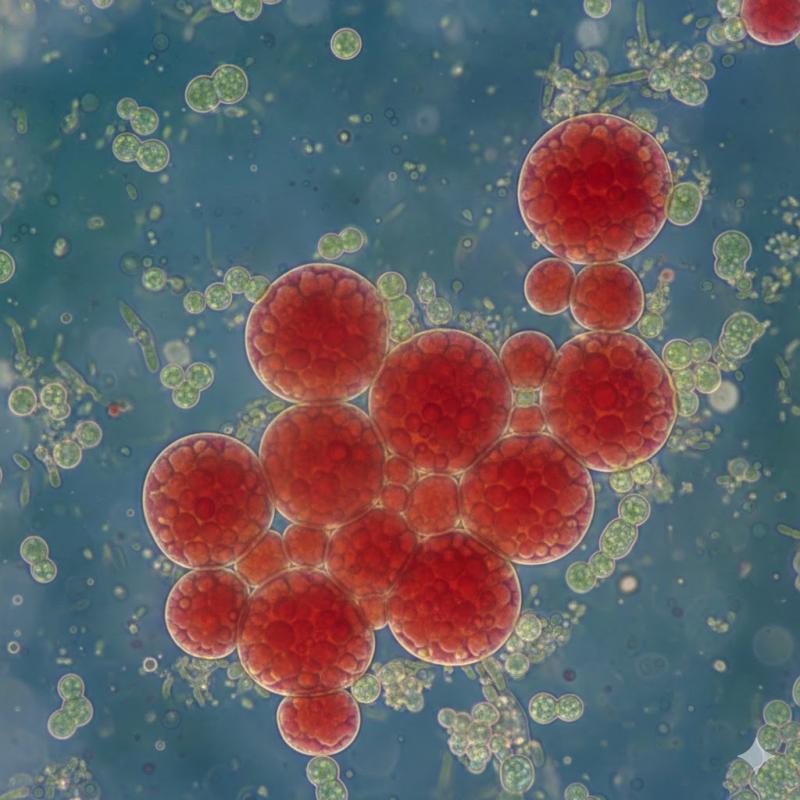

United States Haematococcus Pluvialis Market 2031 | Industry Developments, Futur …

Haematococcus Pluvialis Market is forecasted to reach at a CAGR of 10.23% during the forecast period (2024-2031)

DataM Intelligence unveils its latest report on the "Haematococcus Pluvialis Market Size 2025," offering an in-depth analysis of market trends, growth drivers, competitive landscape, and regional dynamics. The study covers market size in value and volume, CAGR forecasts, and emerging opportunities that can guide businesses in seizing growth potential and crafting winning strategies. Packed…

United States Point of Care Diagnostics Market 2033 | Industry Developments, Fut …

Point of Care Diagnostics Market reached US$ 44.72 Billion in 2024 and is expected to reach US$ 106.35 Billion by 2033, growing at a CAGR of 10.7% during the forecast period 2025-2033.

DataM Intelligence unveils its latest report on the "Point-of-Care Diagnostics Market Size 2025," offering an in-depth analysis of market trends, growth drivers, competitive landscape, and regional dynamics. The study covers market size in value and volume, CAGR forecasts, and…

More Releases for SiC

SiC Schottky Barrier Diodes (SiC SBD) Market Research Report

Global Info Research announces the release of the report "Global SiC Schottky Barrier Diodes (SiC SBD) Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands…

Global SiC MOSFETs Market

SiC MOSFETs Market Overview

Silicon carbide MOSFETs have the characteristics of low on-resistance and small switching losses, which can reduce device losses and improve system efficiency, and are more suitable for high-frequency circuits. It is widely used in the fields of new energy vehicle motor controller, vehicle power supply, solar inverter, charging pile, UPS, PFC power supply and other fields. This report provides a deep insight into the global SiC MOSFETs…

SIC Discrete Device Market

The "SIC Discrete Device Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global SIC Discrete Device Market, 2024-2031

Verified Market Research's most recent report, "SIC Discrete Device Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," provides…

SiC MOSFET and SiC SBD Market Analysis,Demand,Trends and Forecast 2029

Global Info Research announces the release of the report "Global SiC MOSFET and SiC SBD Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across…

Global High Purity SiC Powder for SiC Single Crystal Market Insights, Forecast …

Global Info Research announces the release of the report "Global High Purity SiC Powder for SiC Single Crystal Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company…

Latest Ceramic Matrix Composites Market by Matrix Type (C/C, C/Sic, Oxide/Oxide, …

The Ceramic Matrix Composites research report is valuable for every market enthusiast, stakeholder, policymaker, and market player. It offers vital information about the industry, including crucial facts, figures, expert opinions, and the latest developments across the globe. In addition, the Ceramic Matrix Composites research report provides data on the patterns and outcomes, target business sectors and materials, limits, and advancements.

Download FREE Sample Report @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=319907

The ceramic matrix composites market…